LAND ROVER DISCOVERY 1995 Service Repair Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 976, PDF Size: 14.57 MB

Page 951 of 976

ENGINE

56

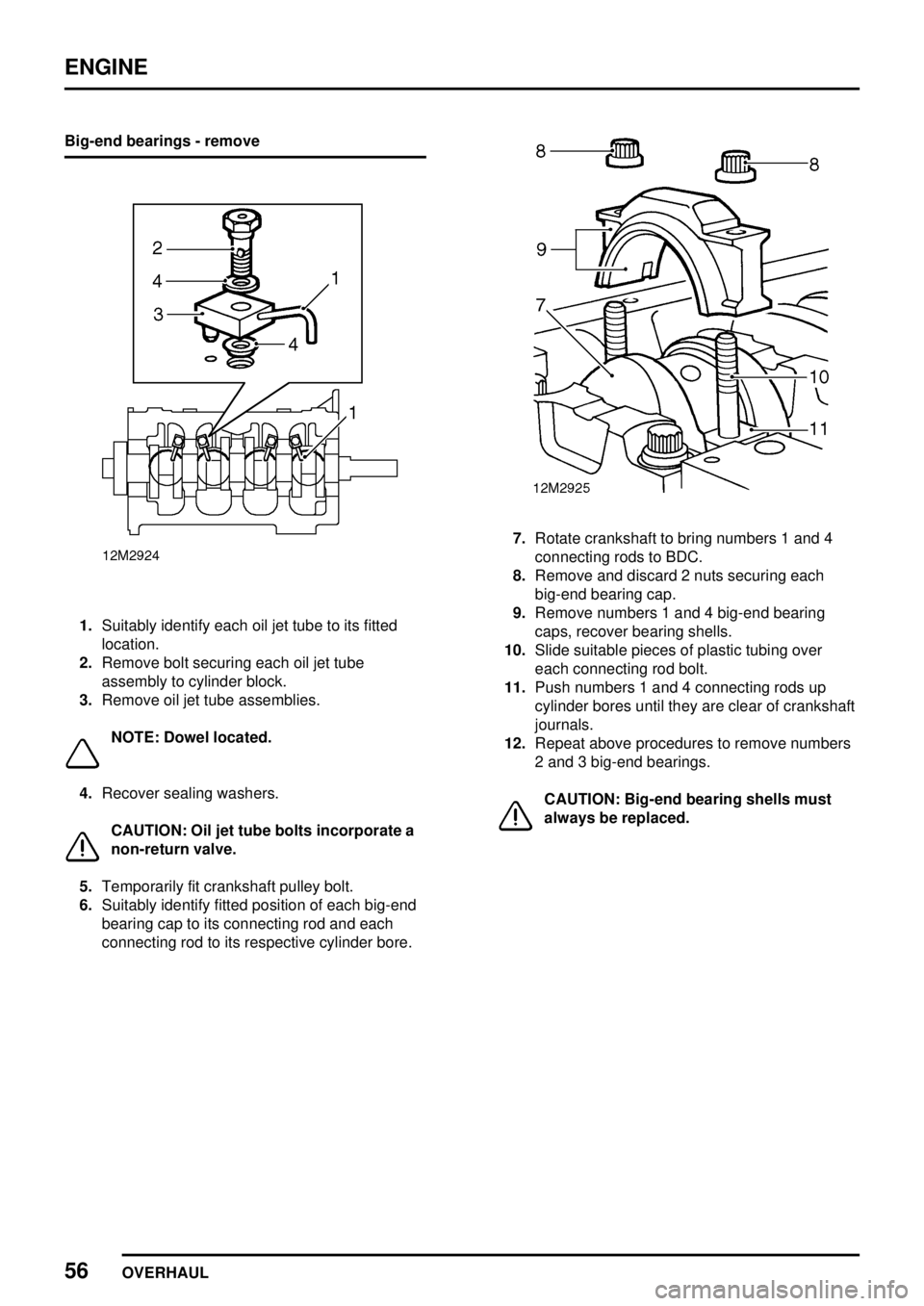

OVERHAUL Big-end bearings - remove

1.Suitably identify each oil jet tube to its fitted

location.

2.Remove bolt securing each oil jet tube

assembly to cylinder block.

3.Remove oil jet tube assemblies.

NOTE: Dowel located.

4.Recover sealing washers.

CAUTION: Oil jet tube bolts incorporate a

non-return valve.

5.Temporarily fit crankshaft pulley bolt.

6.Suitably identify fitted position of each big-end

bearing cap to its connecting rod and each

connecting rod to its respective cylinder bore.

7.Rotate crankshaft to bring numbers 1 and 4

connecting rods to BDC.

8.Remove and discard 2 nuts securing each

big-end bearing cap.

9.Remove numbers 1 and 4 big-end bearing

caps, recover bearing shells.

10.Slide suitable pieces of plastic tubing over

each connecting rod bolt.

11.Push numbers 1 and 4 connecting rods up

cylinder bores until they are clear of crankshaft

journals.

12.Repeat above procedures to remove numbers

2 and 3 big-end bearings.

CAUTION: Big-end bearing shells must

always be replaced.

Page 952 of 976

ENGINE

OVERHAUL57

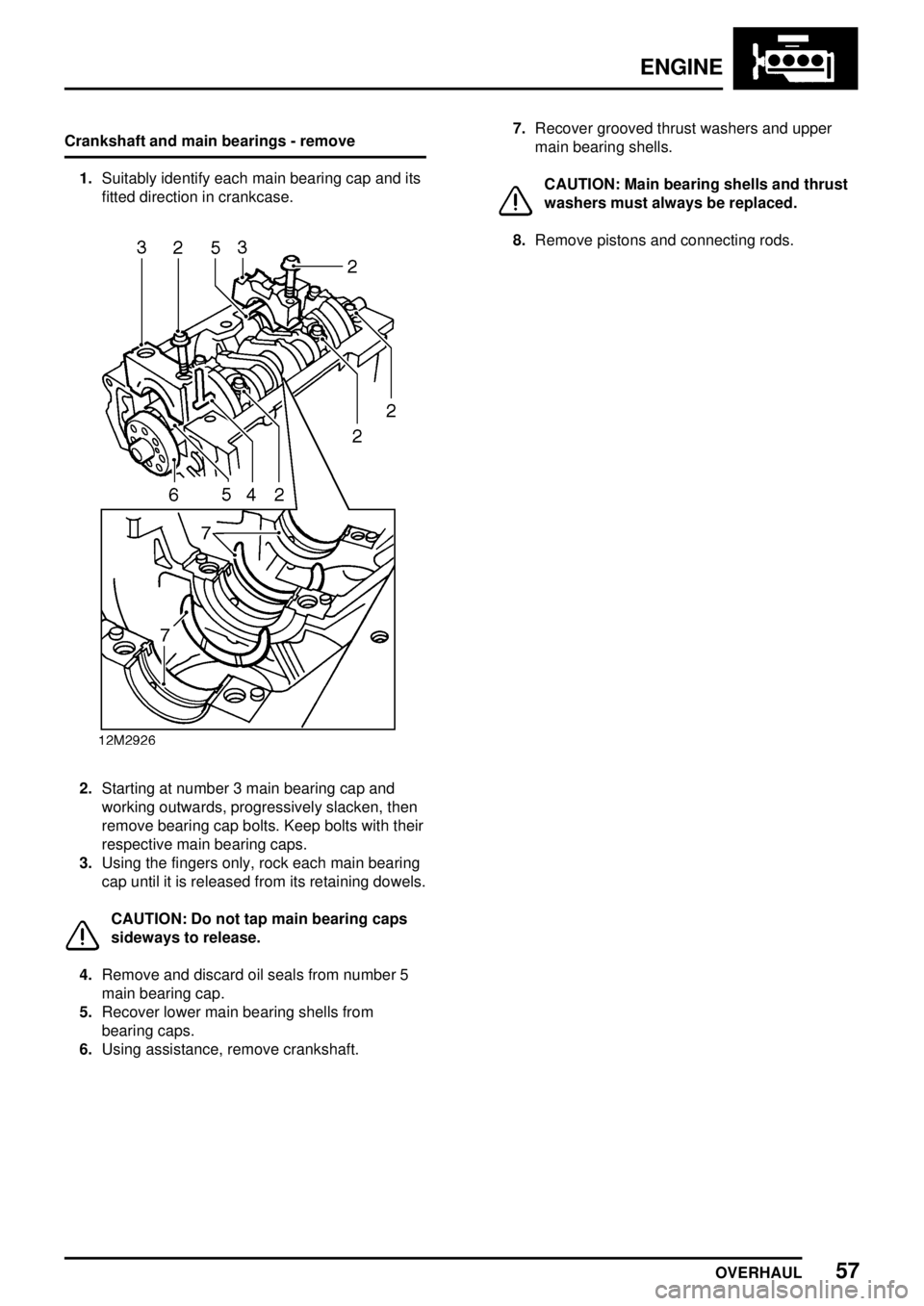

Crankshaft and main bearings - remove

1.Suitably identify each main bearing cap and its

fitted direction in crankcase.

2.Starting at number 3 main bearing cap and

working outwards, progressively slacken, then

remove bearing cap bolts. Keep bolts with their

respective main bearing caps.

3.Using the fingers only, rock each main bearing

cap until it is released from its retaining dowels.

CAUTION: Do not tap main bearing caps

sideways to release.

4.Remove and discard oil seals from number 5

main bearing cap.

5.Recover lower main bearing shells from

bearing caps.

6.Using assistance, remove crankshaft.7.Recover grooved thrust washers and upper

main bearing shells.

CAUTION: Main bearing shells and thrust

washers must always be replaced.

8.Remove pistons and connecting rods.

Page 953 of 976

ENGINE

58

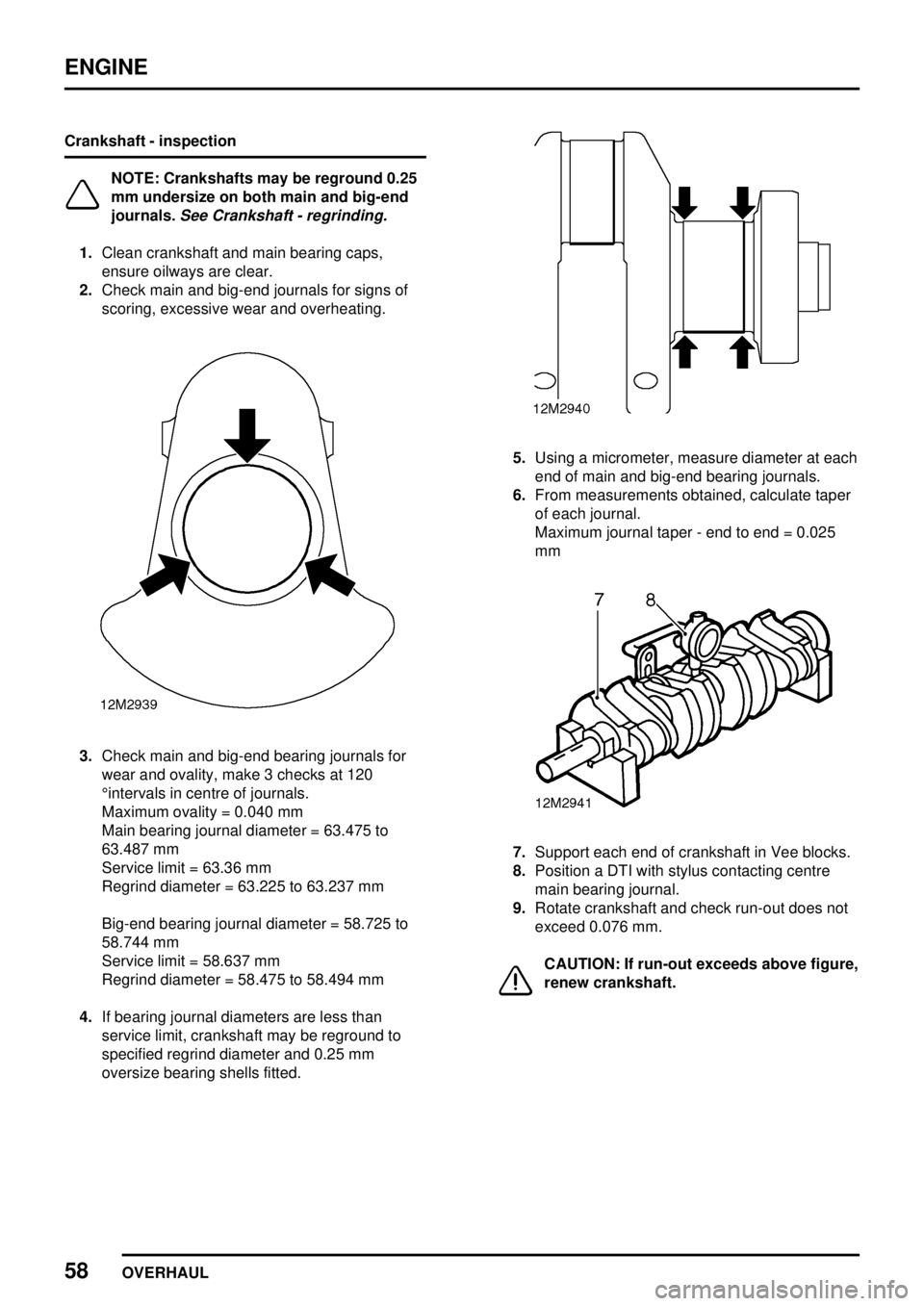

OVERHAUL Crankshaft - inspection

NOTE: Crankshafts may be reground 0.25

mm undersize on both main and big-end

journals.

See Crankshaft - regrinding.

1.Clean crankshaft and main bearing caps,

ensure oilways are clear.

2.Check main and big-end journals for signs of

scoring, excessive wear and overheating.

3.Check main and big-end bearing journals for

wear and ovality, make 3 checks at 120

°intervals in centre of journals.

Maximum ovality = 0.040 mm

Main bearing journal diameter = 63.475 to

63.487 mm

Service limit = 63.36 mm

Regrind diameter = 63.225 to 63.237 mm

Big-end bearing journal diameter = 58.725 to

58.744 mm

Service limit = 58.637 mm

Regrind diameter = 58.475 to 58.494 mm

4.If bearing journal diameters are less than

service limit, crankshaft may be reground to

specified regrind diameter and 0.25 mm

oversize bearing shells fitted.

5.Using a micrometer, measure diameter at each

end of main and big-end bearing journals.

6.From measurements obtained, calculate taper

of each journal.

Maximum journal taper - end to end = 0.025

mm

7.Support each end of crankshaft in Vee blocks.

8.Position a DTI with stylus contacting centre

main bearing journal.

9.Rotate crankshaft and check run-out does not

exceed 0.076 mm.

CAUTION: If run-out exceeds above figure,

renew crankshaft.

Page 954 of 976

ENGINE

OVERHAUL59

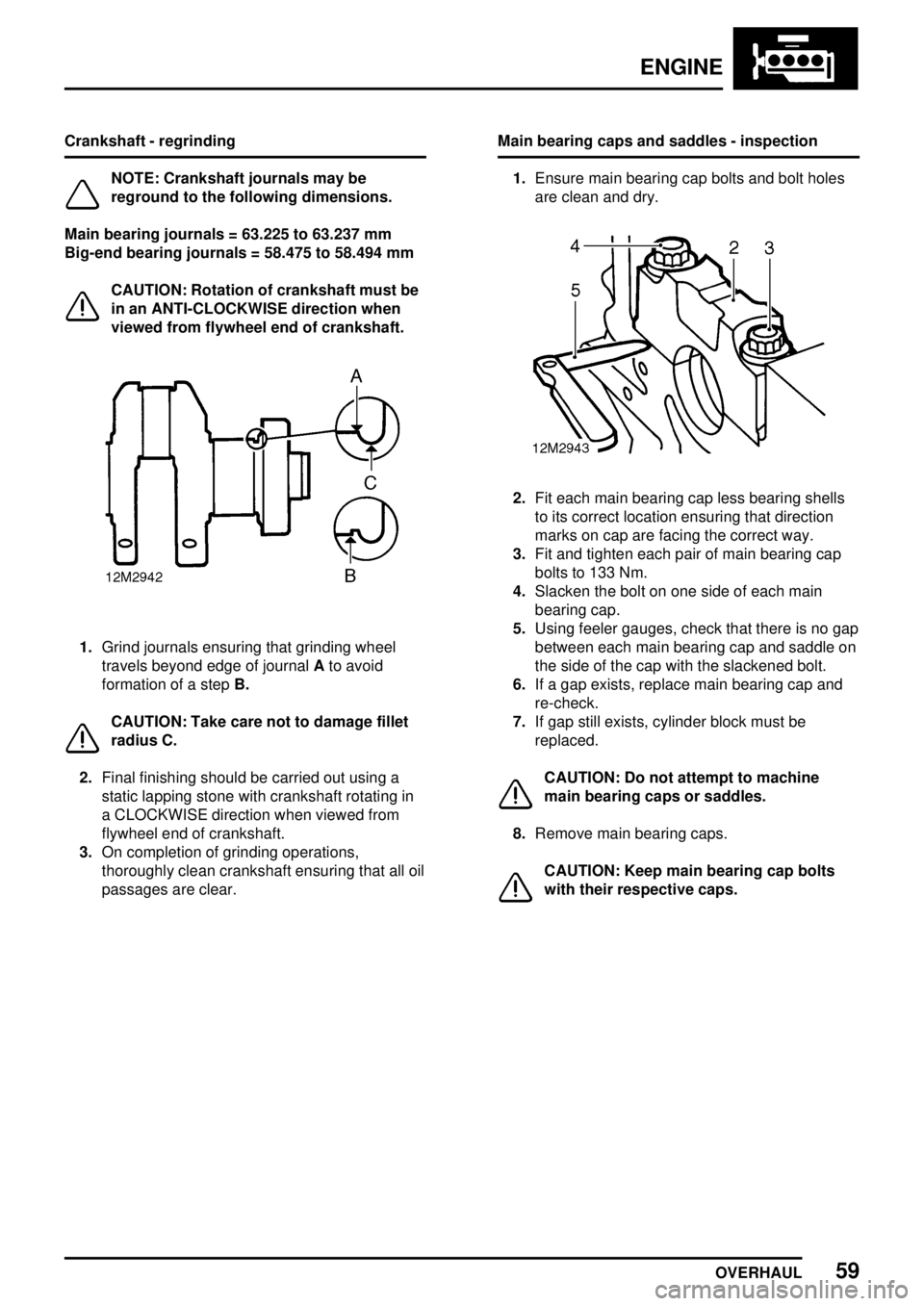

Crankshaft - regrinding

NOTE: Crankshaft journals may be

reground to the following dimensions.

Main bearing journals = 63.225 to 63.237 mm

Big-end bearing journals = 58.475 to 58.494 mm

CAUTION: Rotation of crankshaft must be

in an ANTI-CLOCKWISE direction when

viewed from flywheel end of crankshaft.

1.Grind journals ensuring that grinding wheel

travels beyond edge of journalAto avoid

formation of a stepB.

CAUTION: Take care not to damage fillet

radius C.

2.Final finishing should be carried out using a

static lapping stone with crankshaft rotating in

a CLOCKWISE direction when viewed from

flywheel end of crankshaft.

3.On completion of grinding operations,

thoroughly clean crankshaft ensuring that all oil

passages are clear.Main bearing caps and saddles - inspection

1.Ensure main bearing cap bolts and bolt holes

are clean and dry.

2.Fit each main bearing cap less bearing shells

to its correct location ensuring that direction

marks on cap are facing the correct way.

3.Fit and tighten each pair of main bearing cap

bolts to 133 Nm.

4.Slacken the bolt on one side of each main

bearing cap.

5.Using feeler gauges, check that there is no gap

between each main bearing cap and saddle on

the side of the cap with the slackened bolt.

6.If a gap exists, replace main bearing cap and

re-check.

7.If gap still exists, cylinder block must be

replaced.

CAUTION: Do not attempt to machine

main bearing caps or saddles.

8.Remove main bearing caps.

CAUTION: Keep main bearing cap bolts

with their respective caps.

Page 955 of 976

ENGINE

60

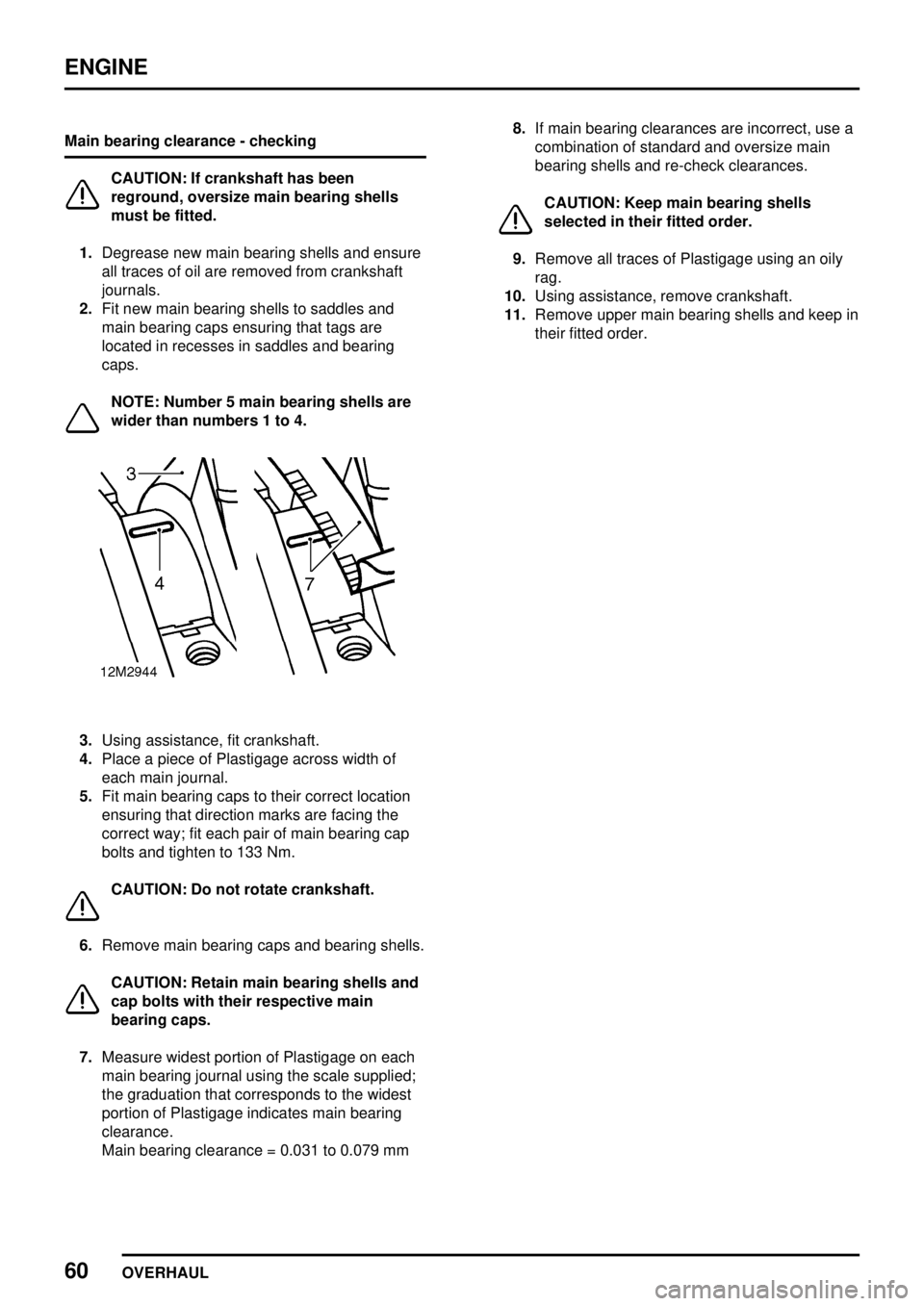

OVERHAUL Main bearing clearance - checking

CAUTION: If crankshaft has been

reground, oversize main bearing shells

must be fitted.

1.Degrease new main bearing shells and ensure

all traces of oil are removed from crankshaft

journals.

2.Fit new main bearing shells to saddles and

main bearing caps ensuring that tags are

located in recesses in saddles and bearing

caps.

NOTE: Number 5 main bearing shells are

wider than numbers 1 to 4.

3.Using assistance, fit crankshaft.

4.Place a piece of Plastigage across width of

each main journal.

5.Fit main bearing caps to their correct location

ensuring that direction marks are facing the

correct way; fit each pair of main bearing cap

bolts and tighten to 133 Nm.

CAUTION: Do not rotate crankshaft.

6.Remove main bearing caps and bearing shells.

CAUTION: Retain main bearing shells and

cap bolts with their respective main

bearing caps.

7.Measure widest portion of Plastigage on each

main bearing journal using the scale supplied;

the graduation that corresponds to the widest

portion of Plastigage indicates main bearing

clearance.

Main bearing clearance = 0.031 to 0.079 mm8.If main bearing clearances are incorrect, use a

combination of standard and oversize main

bearing shells and re-check clearances.

CAUTION: Keep main bearing shells

selected in their fitted order.

9.Remove all traces of Plastigage using an oily

rag.

10.Using assistance, remove crankshaft.

11.Remove upper main bearing shells and keep in

their fitted order.

Page 956 of 976

ENGINE

OVERHAUL61

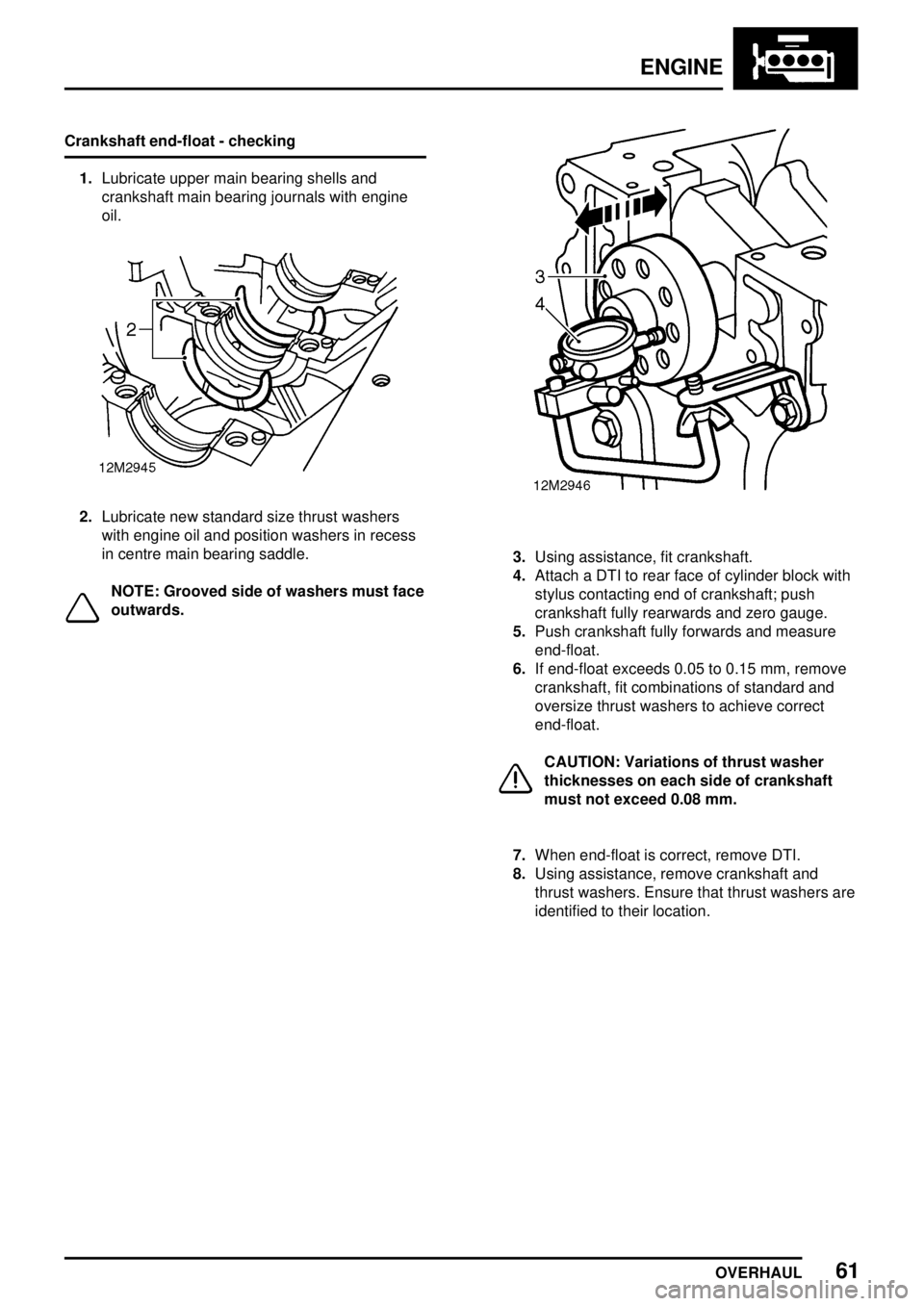

Crankshaft end-float - checking

1.Lubricate upper main bearing shells and

crankshaft main bearing journals with engine

oil.

2.Lubricate new standard size thrust washers

with engine oil and position washers in recess

in centre main bearing saddle.

NOTE: Grooved side of washers must face

outwards.

3.Using assistance, fit crankshaft.

4.Attach a DTI to rear face of cylinder block with

stylus contacting end of crankshaft; push

crankshaft fully rearwards and zero gauge.

5.Push crankshaft fully forwards and measure

end-float.

6.If end-float exceeds 0.05 to 0.15 mm, remove

crankshaft, fit combinations of standard and

oversize thrust washers to achieve correct

end-float.

CAUTION: Variations of thrust washer

thicknesses on each side of crankshaft

must not exceed 0.08 mm.

7.When end-float is correct, remove DTI.

8.Using assistance, remove crankshaft and

thrust washers. Ensure that thrust washers are

identified to their location.

Page 957 of 976

ENGINE

62

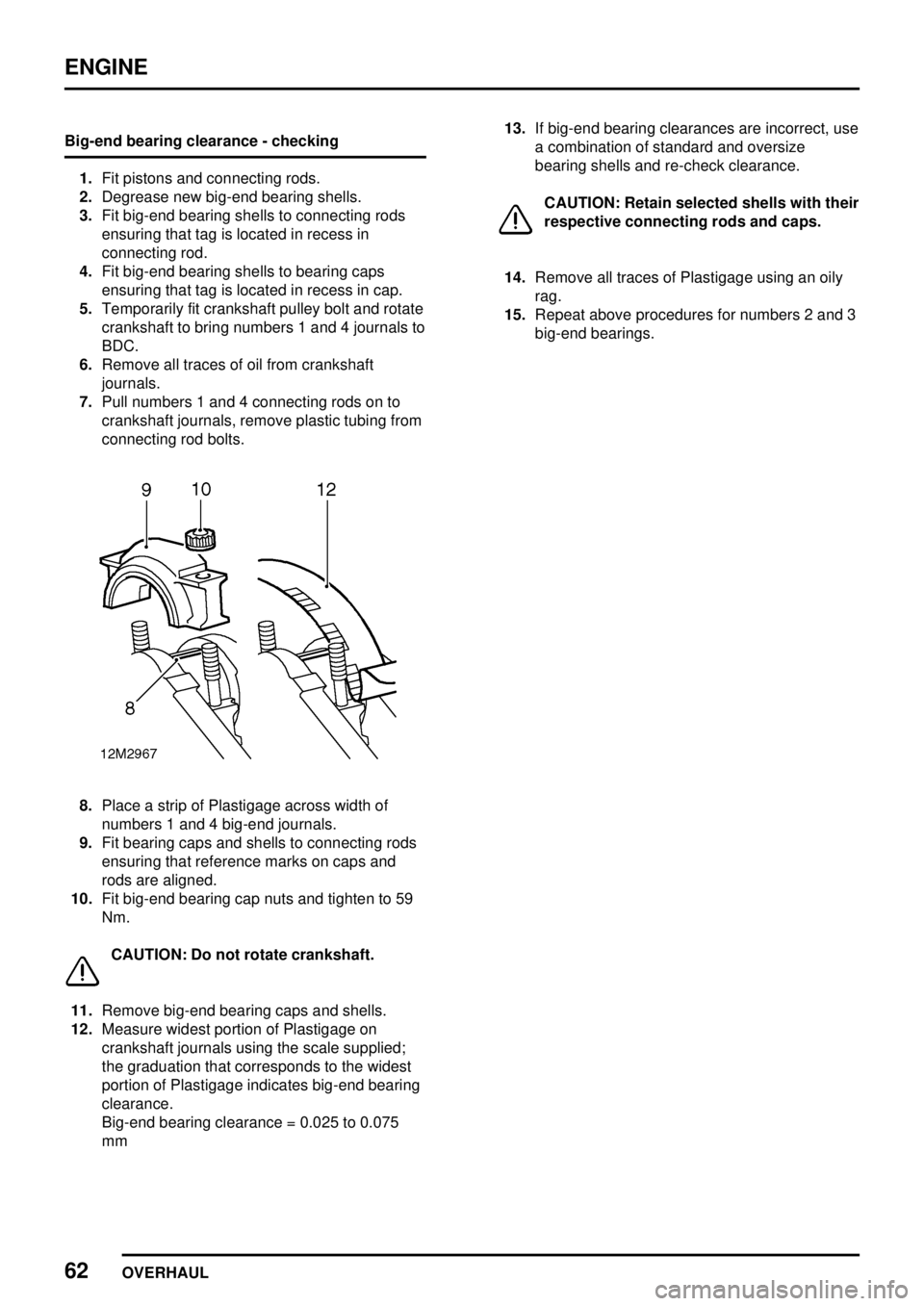

OVERHAUL Big-end bearing clearance - checking

1.Fit pistons and connecting rods.

2.Degrease new big-end bearing shells.

3.Fit big-end bearing shells to connecting rods

ensuring that tag is located in recess in

connecting rod.

4.Fit big-end bearing shells to bearing caps

ensuring that tag is located in recess in cap.

5.Temporarily fit crankshaft pulley bolt and rotate

crankshaft to bring numbers 1 and 4 journals to

BDC.

6.Remove all traces of oil from crankshaft

journals.

7.Pull numbers 1 and 4 connecting rods on to

crankshaft journals, remove plastic tubing from

connecting rod bolts.

8.Place a strip of Plastigage across width of

numbers 1 and 4 big-end journals.

9.Fit bearing caps and shells to connecting rods

ensuring that reference marks on caps and

rods are aligned.

10.Fit big-end bearing cap nuts and tighten to 59

Nm.

CAUTION: Do not rotate crankshaft.

11.Remove big-end bearing caps and shells.

12.Measure widest portion of Plastigage on

crankshaft journals using the scale supplied;

the graduation that corresponds to the widest

portion of Plastigage indicates big-end bearing

clearance.

Big-end bearing clearance = 0.025 to 0.075

mm13.If big-end bearing clearances are incorrect, use

a combination of standard and oversize

bearing shells and re-check clearance.

CAUTION: Retain selected shells with their

respective connecting rods and caps.

14.Remove all traces of Plastigage using an oily

rag.

15.Repeat above procedures for numbers 2 and 3

big-end bearings.

Page 958 of 976

ENGINE

OVERHAUL63

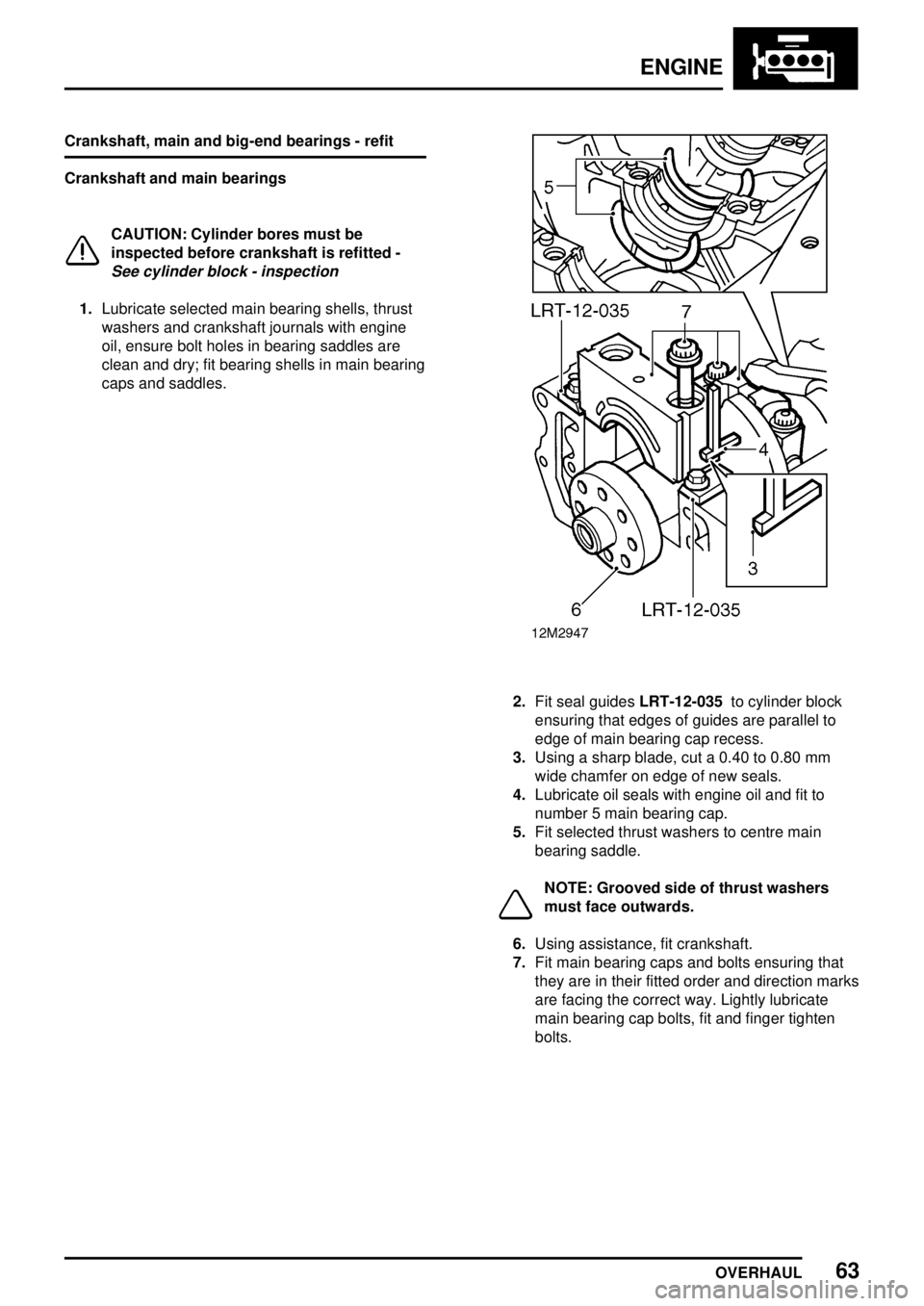

Crankshaft, main and big-end bearings - refit

Crankshaft and main bearings

CAUTION: Cylinder bores must be

inspected before crankshaft is refitted -

See cylinder block - inspection

1.Lubricate selected main bearing shells, thrust

washers and crankshaft journals with engine

oil, ensure bolt holes in bearing saddles are

clean and dry; fit bearing shells in main bearing

caps and saddles.

2.Fit seal guidesLRT-12-035to cylinder block

ensuring that edges of guides are parallel to

edge of main bearing cap recess.

3.Using a sharp blade, cut a 0.40 to 0.80 mm

wide chamfer on edge of new seals.

4.Lubricate oil seals with engine oil and fit to

number 5 main bearing cap.

5.Fit selected thrust washers to centre main

bearing saddle.

NOTE: Grooved side of thrust washers

must face outwards.

6.Using assistance, fit crankshaft.

7.Fit main bearing caps and bolts ensuring that

they are in their fitted order and direction marks

are facing the correct way. Lightly lubricate

main bearing cap bolts, fit and finger tighten

bolts.

Page 959 of 976

ENGINE

64

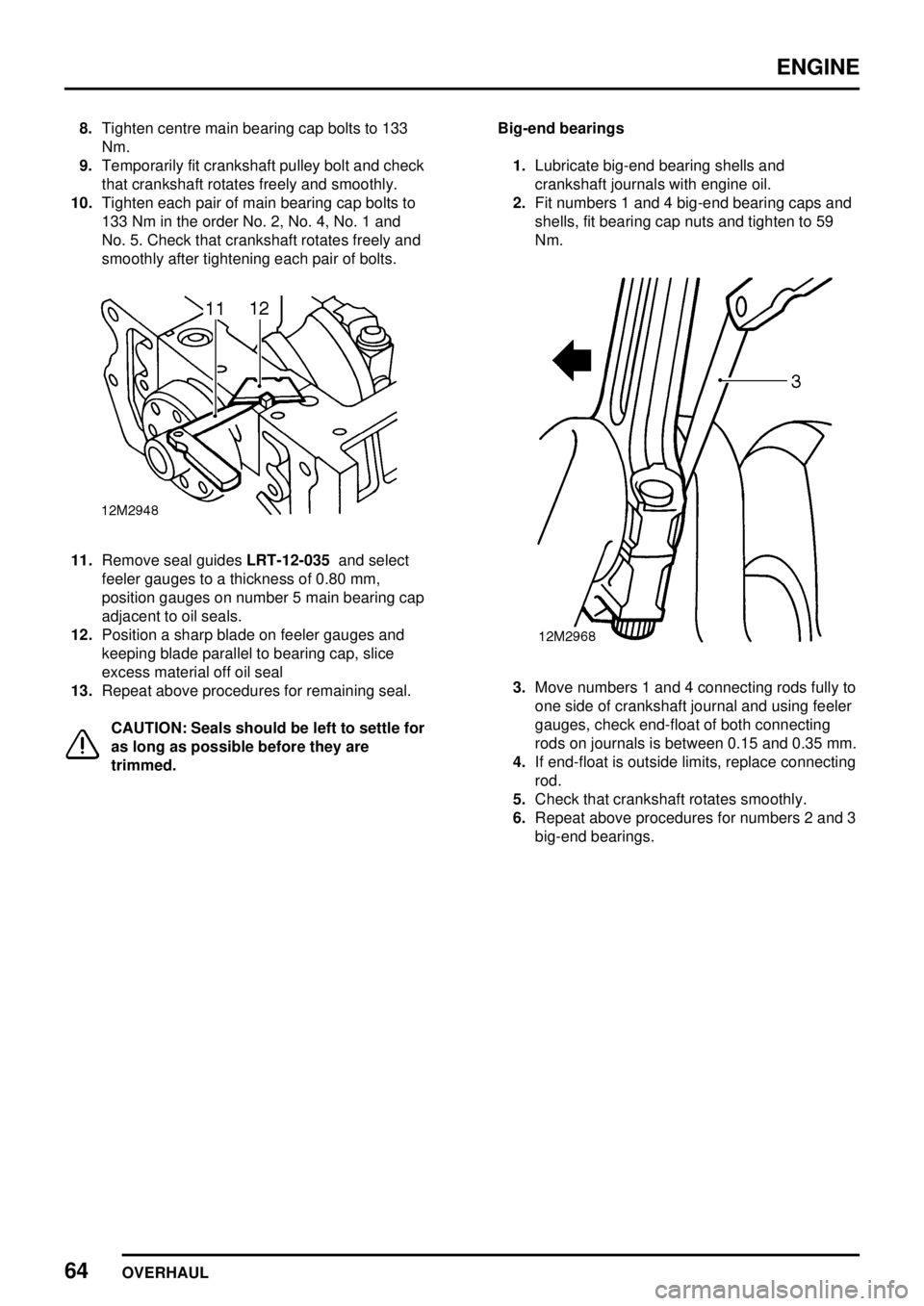

OVERHAUL 8.Tighten centre main bearing cap bolts to 133

Nm.

9.Temporarily fit crankshaft pulley bolt and check

that crankshaft rotates freely and smoothly.

10.Tighten each pair of main bearing cap bolts to

133 Nm in the order No. 2, No. 4, No. 1 and

No. 5. Check that crankshaft rotates freely and

smoothly after tightening each pair of bolts.

11.Remove seal guidesLRT-12-035and select

feeler gauges to a thickness of 0.80 mm,

position gauges on number 5 main bearing cap

adjacent to oil seals.

12.Position a sharp blade on feeler gauges and

keeping blade parallel to bearing cap, slice

excess material off oil seal

13.Repeat above procedures for remaining seal.

CAUTION: Seals should be left to settle for

as long as possible before they are

trimmed.Big-end bearings

1.Lubricate big-end bearing shells and

crankshaft journals with engine oil.

2.Fit numbers 1 and 4 big-end bearing caps and

shells, fit bearing cap nuts and tighten to 59

Nm.

3.Move numbers 1 and 4 connecting rods fully to

one side of crankshaft journal and using feeler

gauges, check end-float of both connecting

rods on journals is between 0.15 and 0.35 mm.

4.If end-float is outside limits, replace connecting

rod.

5.Check that crankshaft rotates smoothly.

6.Repeat above procedures for numbers 2 and 3

big-end bearings.

Page 960 of 976

ENGINE

OVERHAUL65

Crankshaft rear oil seal - refit

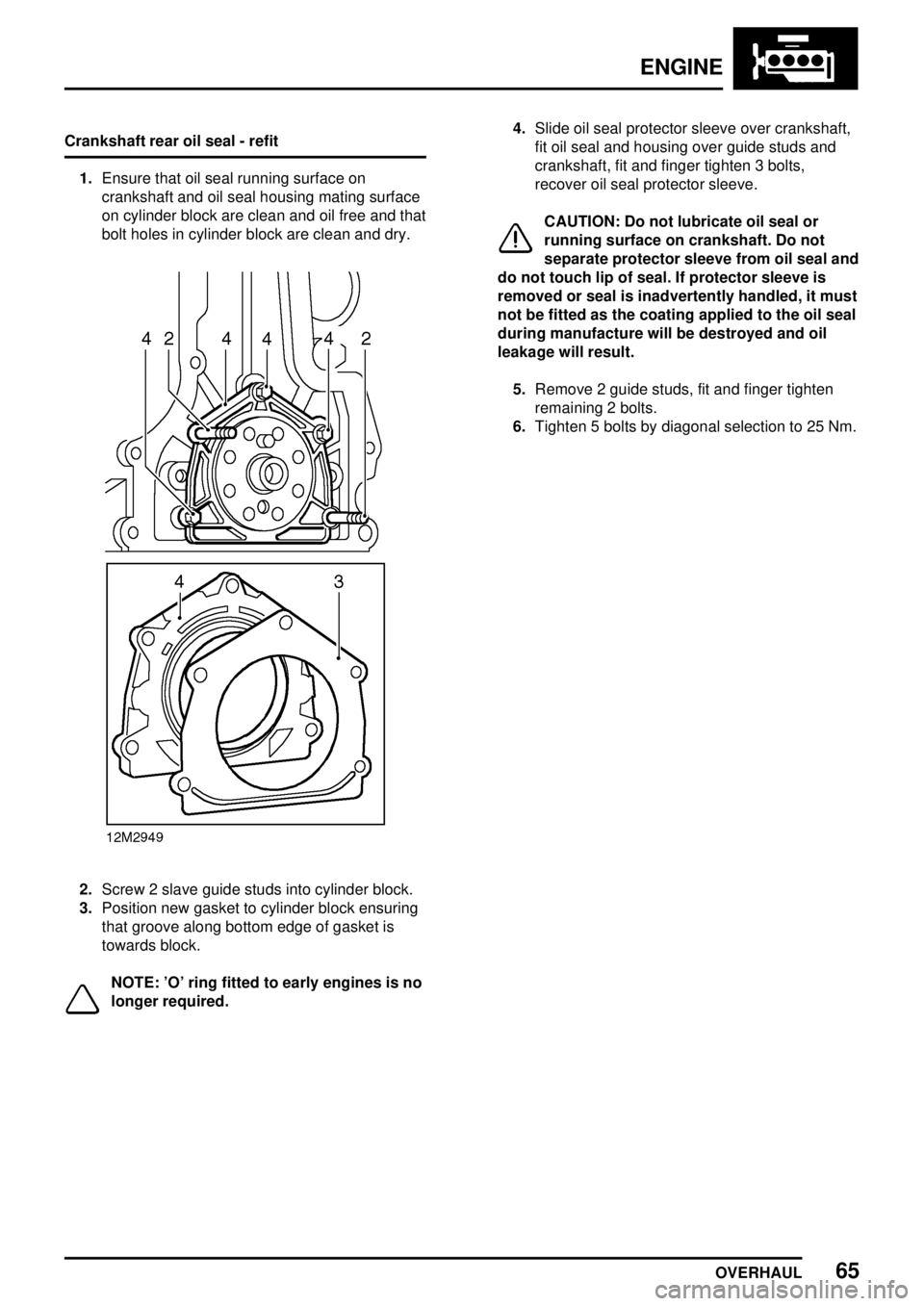

1.Ensure that oil seal running surface on

crankshaft and oil seal housing mating surface

on cylinder block are clean and oil free and that

bolt holes in cylinder block are clean and dry.

2.Screw 2 slave guide studs into cylinder block.

3.Position new gasket to cylinder block ensuring

that groove along bottom edge of gasket is

towards block.

NOTE: 'O' ring fitted to early engines is no

longer required.4.Slide oil seal protector sleeve over crankshaft,

fit oil seal and housing over guide studs and

crankshaft, fit and finger tighten 3 bolts,

recover oil seal protector sleeve.

CAUTION: Do not lubricate oil seal or

running surface on crankshaft. Do not

separate protector sleeve from oil seal and

do not touch lip of seal. If protector sleeve is

removed or seal is inadvertently handled, it must

not be fitted as the coating applied to the oil seal

during manufacture will be destroyed and oil

leakage will result.

5.Remove 2 guide studs, fit and finger tighten

remaining 2 bolts.

6.Tighten 5 bolts by diagonal selection to 25 Nm.