oil LAND ROVER DISCOVERY 1995 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 181 of 873

Mpi

23

REPAIR CHECK CAMSHAFT DRIVE BELT

Service repair no - 12.65.17

CAUTION: This check must be carried out

at the service intervals specified and

whenever carrying out any repair which

requires the timing belt to be disturbed. Pay

particular attention for signs of belt splitting at

base of teeth.

1.Remove 5 bolts securing timing belt upper cover

2.Remove upper cover.

3.Using a socket and extension bar on the

crankshaft pulley bolt, rotate engine to allow the

timing belt to be inspected.

CAUTION: Do not use camshaft gears or

retaining bolts to rotate engine.

4.Check timing belt condition, renew any belt that

shows signs of oil contamination, cracking,

fraying or splitting at base of teeth.

CAUTION: Cause of oil contamination, if

present, must be rectified.

5.Clean timing belt upper cover.

6.Position upper cover.

7.Fit upper cover securing bolts.

Page 182 of 873

Mpi

1

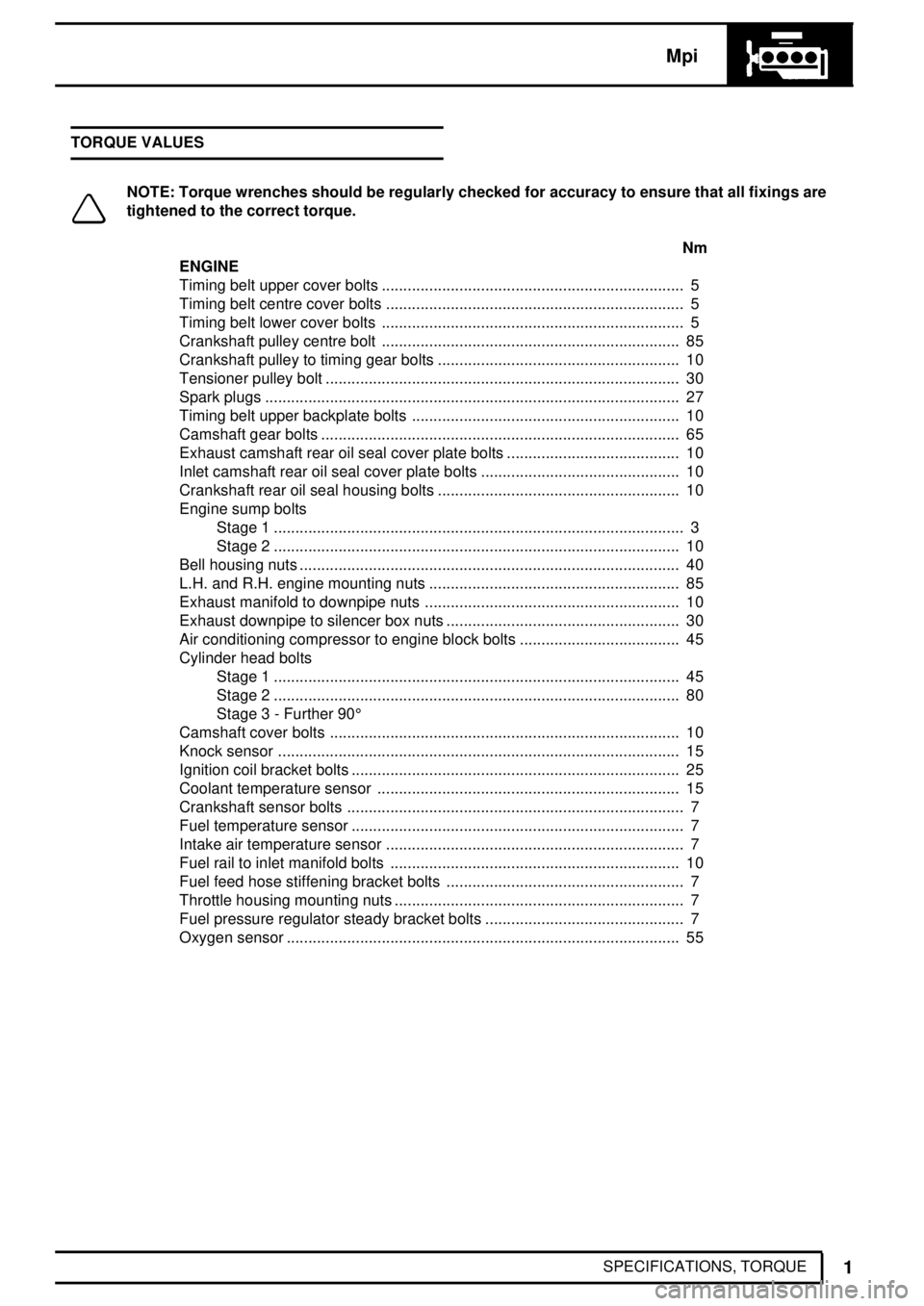

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

ENGINE

Timing belt upper cover bolts 5......................................................................

Timing belt centre cover bolts 5.....................................................................

Timing belt lower cover bolts 5......................................................................

Crankshaft pulley centre bolt 85.....................................................................

Crankshaft pulley to timing gear bolts 10........................................................

Tensioner pulley bolt 30..................................................................................

Spark plugs 27................................................................................................

Timing belt upper backplate bolts 10..............................................................

Camshaft gear bolts 65...................................................................................

Exhaust camshaft rear oil seal cover plate bolts 10........................................

Inlet camshaft rear oil seal cover plate bolts 10..............................................

Crankshaft rear oil seal housing bolts 10........................................................

Engine sump bolts

Stage 1 3...............................................................................................

Stage 2 10..............................................................................................

Bell housing nuts 40........................................................................................

L.H. and R.H. engine mounting nuts 85..........................................................

Exhaust manifold to downpipe nuts 10...........................................................

Exhaust downpipe to silencer box nuts 30......................................................

Air conditioning compressor to engine block bolts 45.....................................

Cylinder head bolts

Stage 1 45..............................................................................................

Stage 2 80..............................................................................................

Stage 3 - Further 90°

Camshaft cover bolts 10.................................................................................

Knock sensor 15.............................................................................................

Ignition coil bracket bolts 25............................................................................

Coolant temperature sensor 15......................................................................

Crankshaft sensor bolts 7..............................................................................

Fuel temperature sensor 7.............................................................................

Intake air temperature sensor 7.....................................................................

Fuel rail to inlet manifold bolts 10...................................................................

Fuel feed hose stiffening bracket bolts 7.......................................................

Throttle housing mounting nuts 7...................................................................

Fuel pressure regulator steady bracket bolts 7..............................................

Oxygen sensor 55...........................................................................................

Page 184 of 873

12ENGINE

2

SERVICE TOOLS

LRT-12-061 Protection sleeve crankshaft rear oil

18G 1108 seal

LRT-12-063 Remover camshaft oil seals

18G 1476

LRT-12-064 Replacer pilot camshaft front

18G 1475

LRT-12-069 Replacer crankshaft front oil seal

18G 1509

Page 185 of 873

Mpi

3

SERVICE TOOLS

LRT-12-070 Sleeve crankshaft front oil seal

18G 1510

LRT-12-072 Replacer drift camshaft front oil seals

LRT-12-073 Remover crankshaft front oil seal

LRT-12-074 Remover adapter bit

Page 187 of 873

EMISSION CONTROL

1

DESCRIPTION AND OPERATION REV: 09/95 EMISSION CONTROL

Three systems are used to control the vehicle

atmospheric emissions these are:

Engine crankcase fume emissions.

Fuel tank Evaporative emissions

Engine exhaust gas emissions.

Crankcase ventilation system - 3.9 MFi models

only

The crankcase ventilation system which is an integral

part of the air supply to the engine combustion

chambers, is often overlooked when diagnosing

problems associated with engine performance. A

blocked ventilation pipe or filter or excessive air leak

into the inlet system through a damaged pipe or

leaking gasket can effect the mixture, performance

and economy of the engine.

1. Three way connector

2. Air filter

3. Oil separatorThe purpose of the crankcase ventilation system is to

ensure that any noxious gas generated in the engine

crankcase is rendered harmless by burning in the

combustion chambers as follows:

Oil laden noxious gas in the engine crankcase is

drawn through an oil separator 3 located on the right

cylinder head rocker cover, where the oil is separated

and returned to the sump. The gas flows through a

restrictor in the three way connection 1 and into the

inlet plenum chamber where it is drawn into the

combustion chambers and burned. The volume of

fresh air which is drawn from the atmospheric side of

the throttle butterfly to mix with the gas, depends on

the position of the throttle and the engine speed.

The air filter 2 fitted to the left cylinder head rocker

cover, must be maintained in clean condition to

ensure sufficient air enters the crankcase under

varying throttle openings and manifold depression, to

prevent excessive crankcase pressure or depression

developing.

Page 200 of 873

17EMISSION CONTROL

4

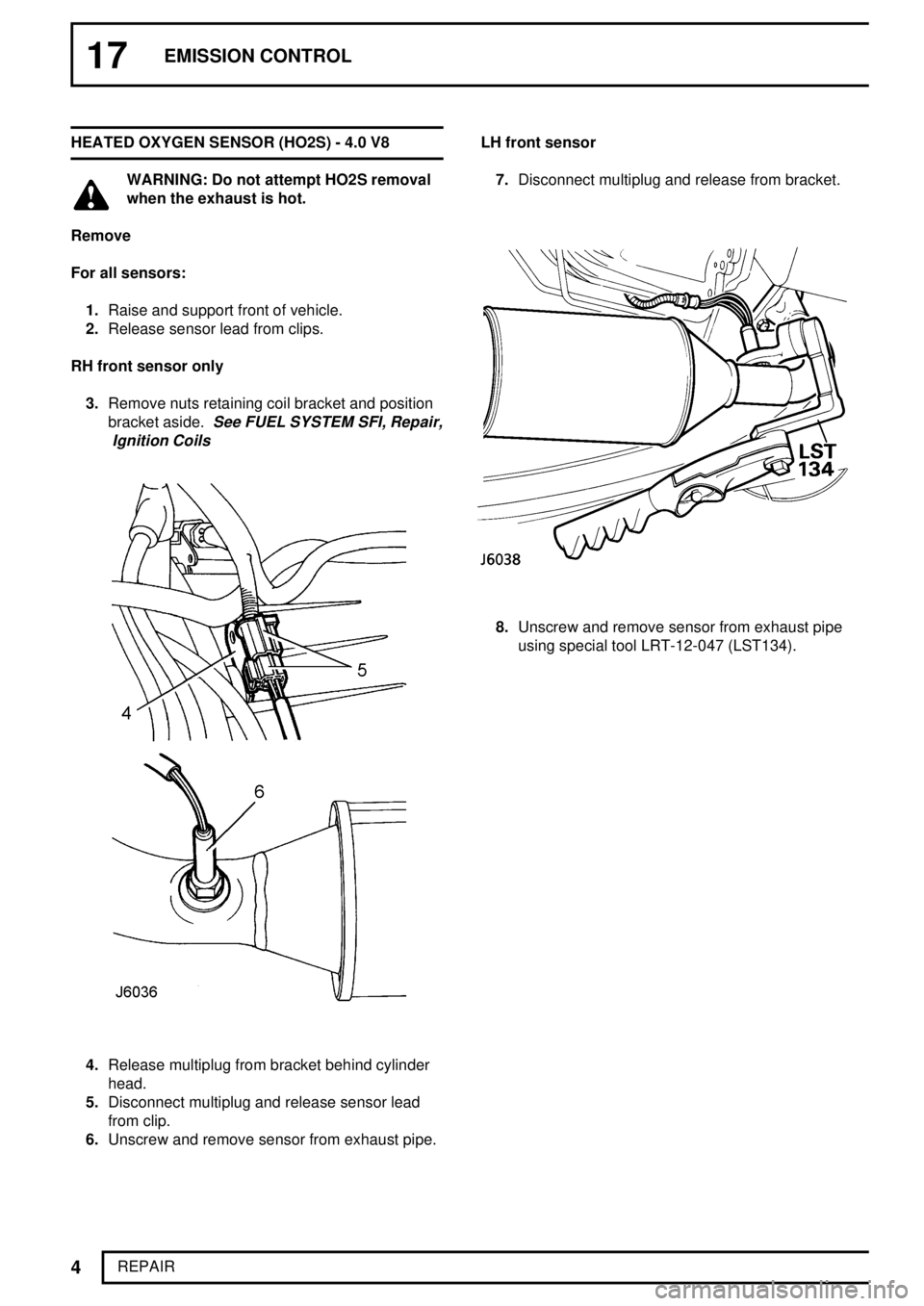

REPAIR HEATED OXYGEN SENSOR (HO2S) - 4.0 V8

WARNING: Do not attempt HO2S removal

when the exhaust is hot.

Remove

For all sensors:

1.Raise and support front of vehicle.

2.Release sensor lead from clips.

RH front sensor only

3.Remove nuts retaining coil bracket and position

bracket aside.

See FUEL SYSTEM SFI, Repair,

Ignition Coils

4.Release multiplug from bracket behind cylinder

head.

5.Disconnect multiplug and release sensor lead

from clip.

6.Unscrew and remove sensor from exhaust pipe.LH front sensor

7.Disconnect multiplug and release from bracket.

8.Unscrew and remove sensor from exhaust pipe

using special tool LRT-12-047 (LST134).

Page 201 of 873

EMISSION CONTROL

5

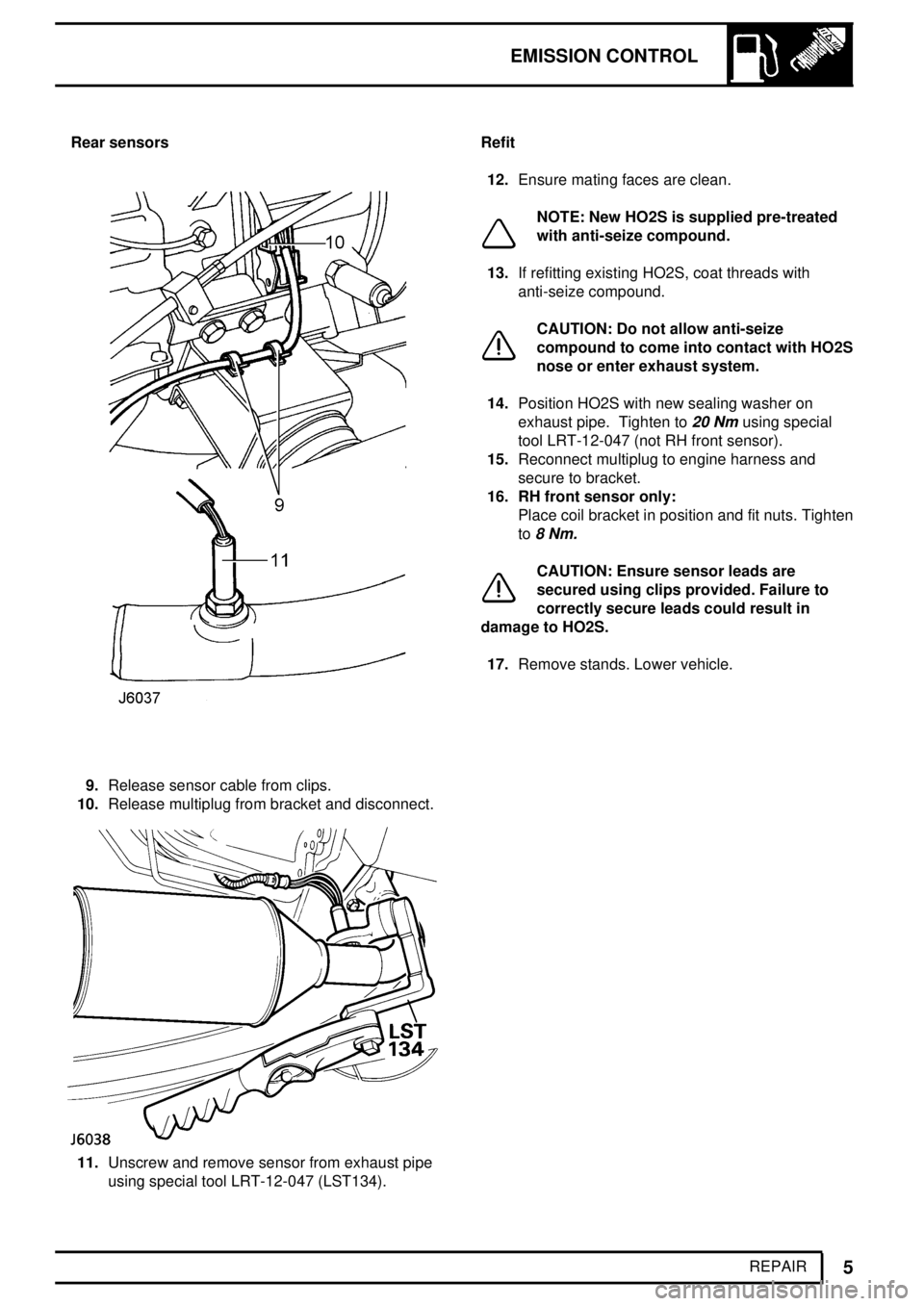

REPAIR Rear sensors

9.Release sensor cable from clips.

10.Release multiplug from bracket and disconnect.

11.Unscrew and remove sensor from exhaust pipe

using special tool LRT-12-047 (LST134).Refit

12.Ensure mating faces are clean.

NOTE: New HO2S is supplied pre-treated

with anti-seize compound.

13.If refitting existing HO2S, coat threads with

anti-seize compound.

CAUTION: Do not allow anti-seize

compound to come into contact with HO2S

nose or enter exhaust system.

14.Position HO2S with new sealing washer on

exhaust pipe. Tighten to

20 Nmusing special

tool LRT-12-047 (not RH front sensor).

15.Reconnect multiplug to engine harness and

secure to bracket.

16. RH front sensor only:

Place coil bracket in position and fit nuts. Tighten

to

8 Nm.

CAUTION: Ensure sensor leads are

secured using clips provided. Failure to

correctly secure leads could result in

damage to HO2S.

17.Remove stands. Lower vehicle.

Page 220 of 873

Tdi

3

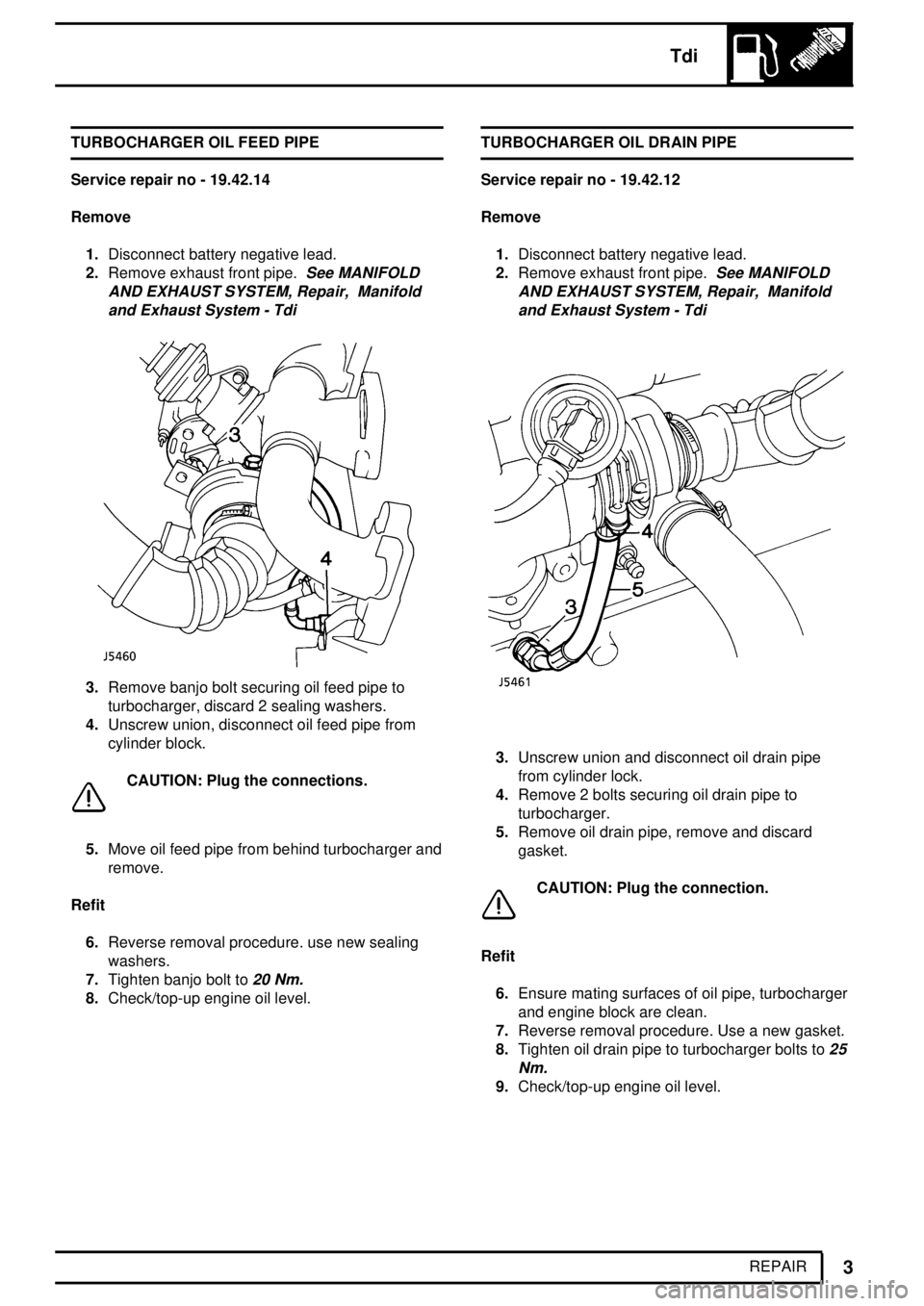

REPAIR TURBOCHARGER OIL FEED PIPE

Service repair no - 19.42.14

Remove

1.Disconnect battery negative lead.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Manifold

and Exhaust System - Tdi

3.Remove banjo bolt securing oil feed pipe to

turbocharger, discard 2 sealing washers.

4.Unscrew union, disconnect oil feed pipe from

cylinder block.

CAUTION: Plug the connections.

5.Move oil feed pipe from behind turbocharger and

remove.

Refit

6.Reverse removal procedure. use new sealing

washers.

7.Tighten banjo bolt to

20 Nm.

8.Check/top-up engine oil level.TURBOCHARGER OIL DRAIN PIPE

Service repair no - 19.42.12

Remove

1.Disconnect battery negative lead.

2.Remove exhaust front pipe.

See MANIFOLD

AND EXHAUST SYSTEM, Repair, Manifold

and Exhaust System - Tdi

3.Unscrew union and disconnect oil drain pipe

from cylinder lock.

4.Remove 2 bolts securing oil drain pipe to

turbocharger.

5.Remove oil drain pipe, remove and discard

gasket.

CAUTION: Plug the connection.

Refit

6.Ensure mating surfaces of oil pipe, turbocharger

and engine block are clean.

7.Reverse removal procedure. Use a new gasket.

8.Tighten oil drain pipe to turbocharger bolts to

25

Nm.

9.Check/top-up engine oil level.

Page 221 of 873

19FUEL SYSTEM

4

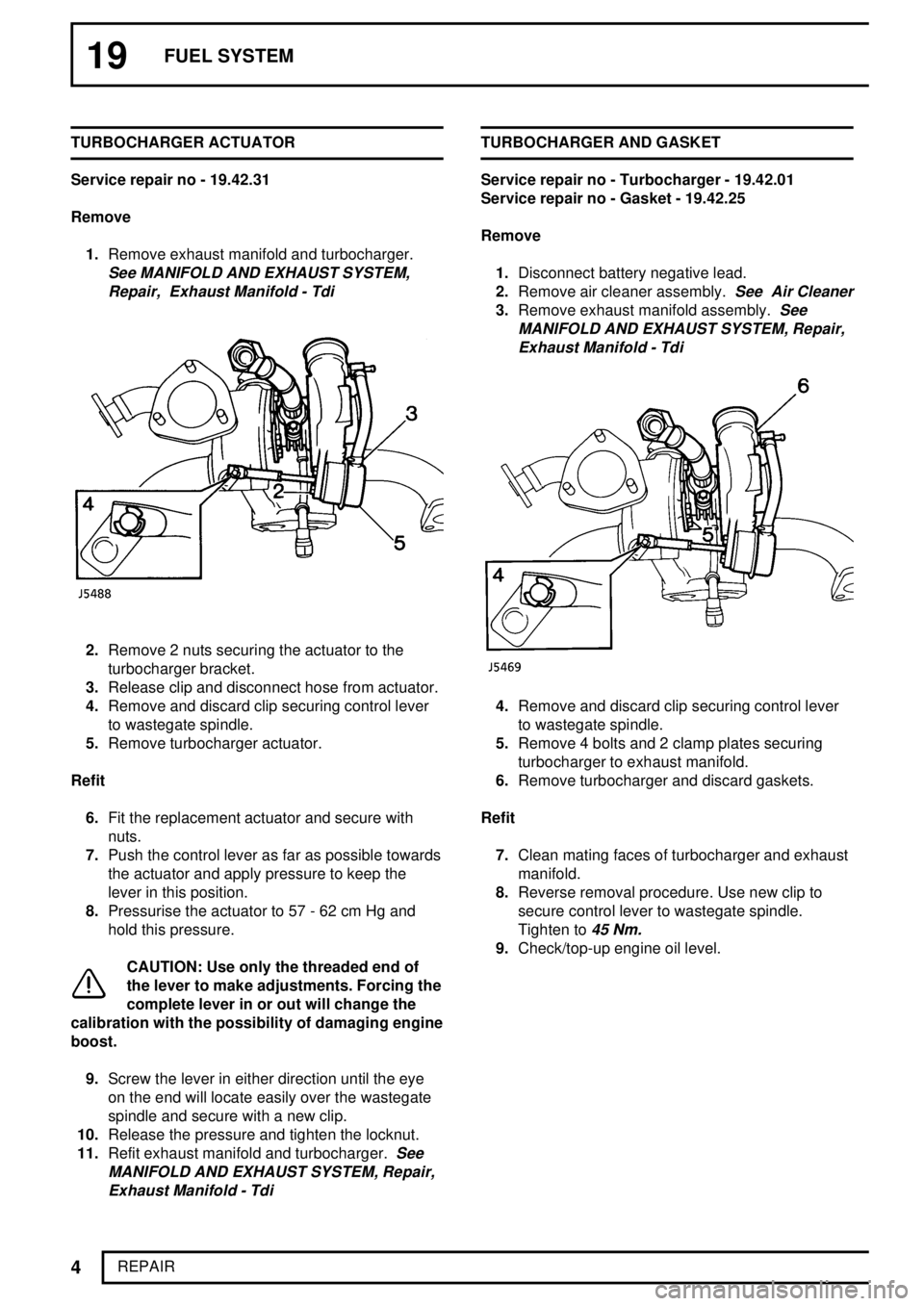

REPAIR TURBOCHARGER ACTUATOR

Service repair no - 19.42.31

Remove

1.Remove exhaust manifold and turbocharger.

See MANIFOLD AND EXHAUST SYSTEM,

Repair, Exhaust Manifold - Tdi

2.Remove 2 nuts securing the actuator to the

turbocharger bracket.

3.Release clip and disconnect hose from actuator.

4.Remove and discard clip securing control lever

to wastegate spindle.

5.Remove turbocharger actuator.

Refit

6.Fit the replacement actuator and secure with

nuts.

7.Push the control lever as far as possible towards

the actuator and apply pressure to keep the

lever in this position.

8.Pressurise the actuator to 57 - 62 cm Hg and

hold this pressure.

CAUTION: Use only the threaded end of

the lever to make adjustments. Forcing the

complete lever in or out will change the

calibration with the possibility of damaging engine

boost.

9.Screw the lever in either direction until the eye

on the end will locate easily over the wastegate

spindle and secure with a new clip.

10.Release the pressure and tighten the locknut.

11.Refit exhaust manifold and turbocharger.

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust Manifold - Tdi

TURBOCHARGER AND GASKET

Service repair no - Turbocharger - 19.42.01

Service repair no - Gasket - 19.42.25

Remove

1.Disconnect battery negative lead.

2.Remove air cleaner assembly.

See Air Cleaner

3.Remove exhaust manifold assembly.See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust Manifold - Tdi

4.Remove and discard clip securing control lever

to wastegate spindle.

5.Remove 4 bolts and 2 clamp plates securing

turbocharger to exhaust manifold.

6.Remove turbocharger and discard gaskets.

Refit

7.Clean mating faces of turbocharger and exhaust

manifold.

8.Reverse removal procedure. Use new clip to

secure control lever to wastegate spindle.

Tighten to

45 Nm.

9.Check/top-up engine oil level.

Page 225 of 873

19FUEL SYSTEM

8

REPAIR

All glow plugs

5.Remove terminal nut from glow plug, disconnect

wire from glow plug terminal.

6.Remove glow plug.

Refit

7.Clean glow plug and seating.

8.Coat threads of glow plug with suitable anti-seize

compound operational to a temperature of

1000°C.

9.Fit glow plug. Tighten to

23 Nm.

10.Connect wire to glow plug terminal and secure

with nut.

NOTE: Feed wire must be connected to

No. 4 glow plug terminal.

11.

No. 3 glow plug:Lubricate new 'O' ring with

engine oil and fit to Hummel valve. Fit valve and

secure with bolt. Tighten to

15 Nm.

No. 1 glow plug - air conditioning models

12.Position compressor to front cover, fit bolts.

Tighten to

25 Nm.

13.Fit drive belt to compressor pulley and adjust

tension.

See ENGINE, Repair, Drive Belt

Renew

All models

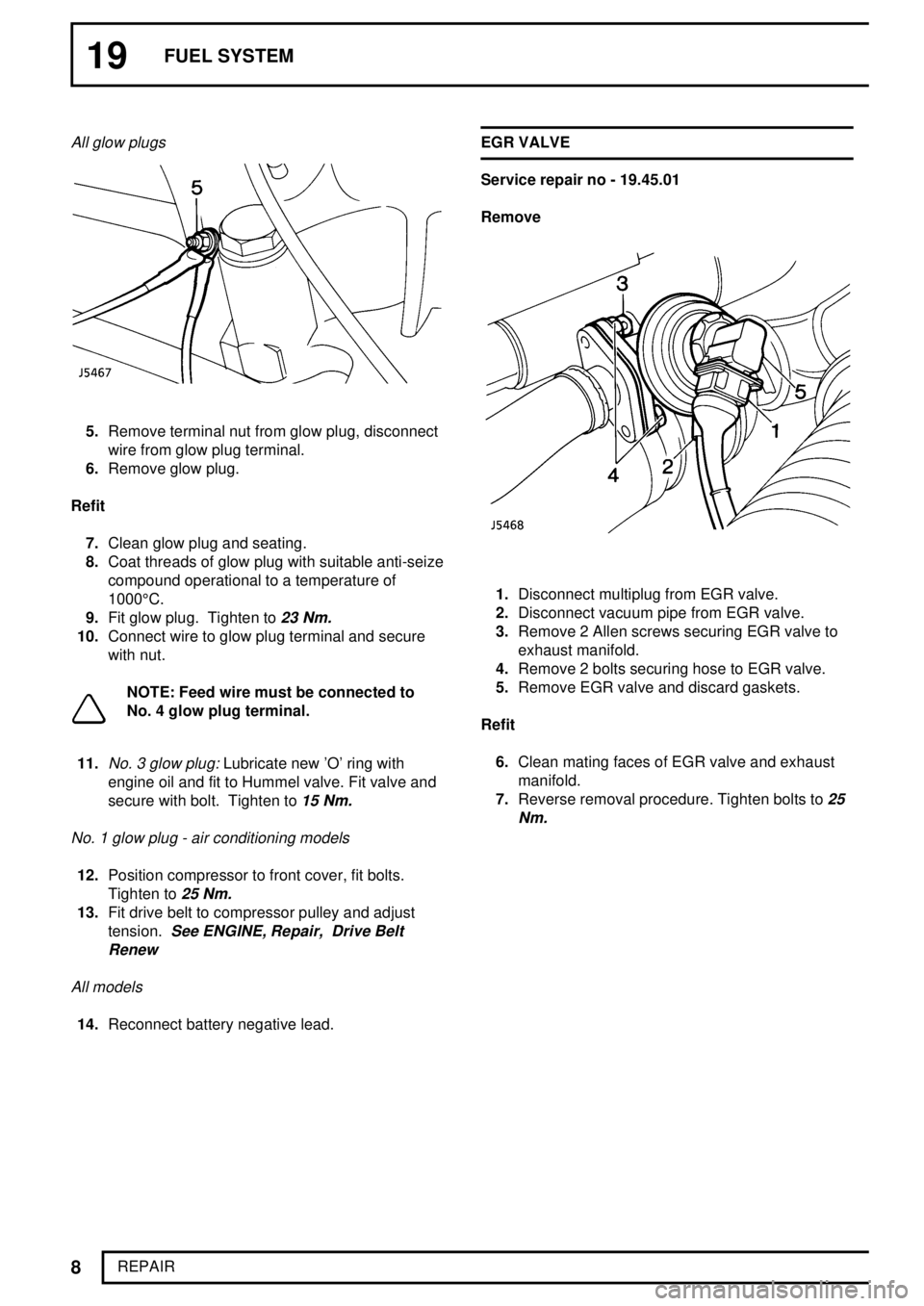

14.Reconnect battery negative lead.EGR VALVE

Service repair no - 19.45.01

Remove

1.Disconnect multiplug from EGR valve.

2.Disconnect vacuum pipe from EGR valve.

3.Remove 2 Allen screws securing EGR valve to

exhaust manifold.

4.Remove 2 bolts securing hose to EGR valve.

5.Remove EGR valve and discard gaskets.

Refit

6.Clean mating faces of EGR valve and exhaust

manifold.

7.Reverse removal procedure. Tighten bolts to

25

Nm.