oil LAND ROVER DISCOVERY 1995 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 114 of 873

V8i

1

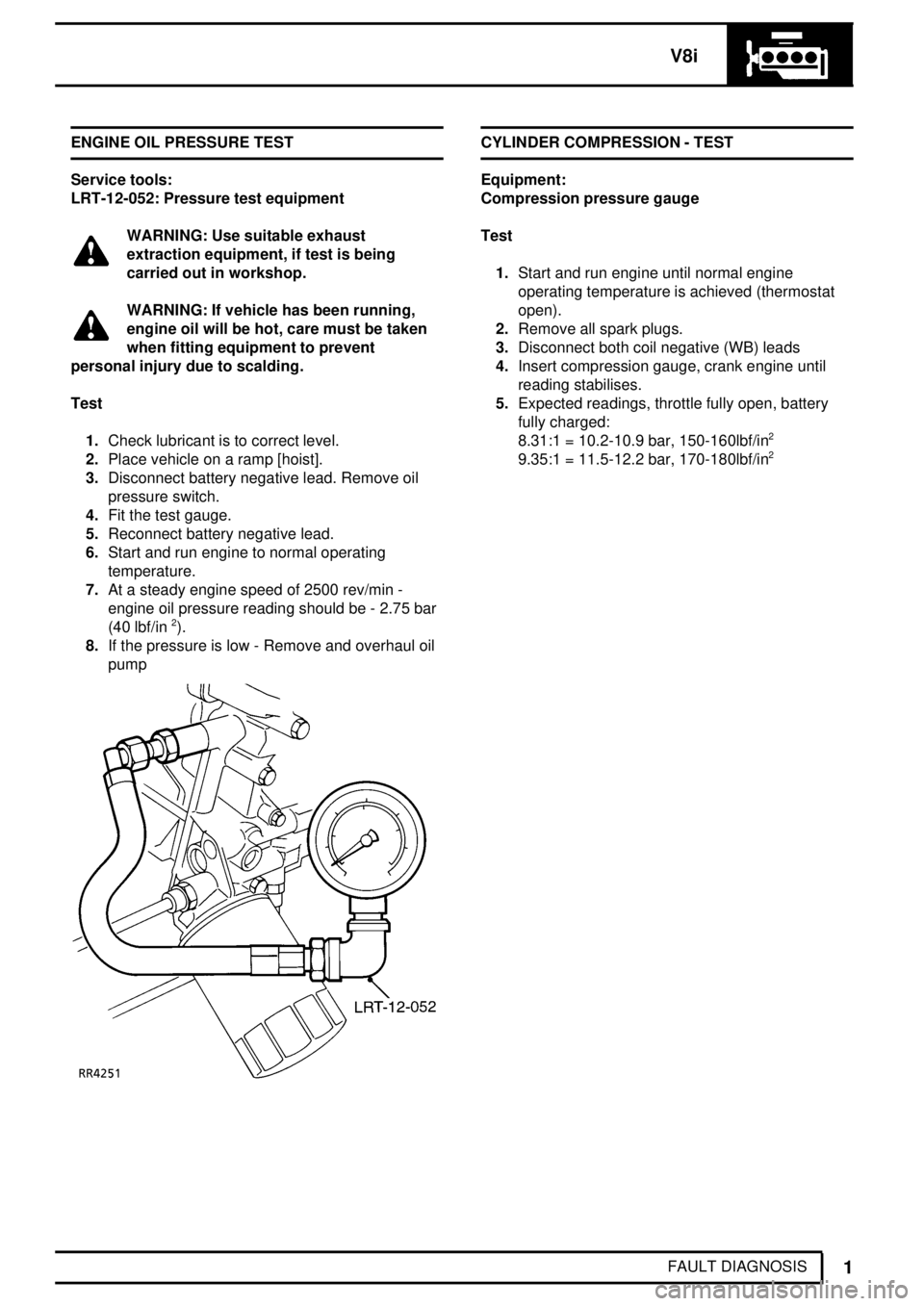

FAULT DIAGNOSIS ENGINE OIL PRESSURE TEST

Service tools:

LRT-12-052: Pressure test equipment

WARNING: Use suitable exhaust

extraction equipment, if test is being

carried out in workshop.

WARNING: If vehicle has been running,

engine oil will be hot, care must be taken

when fitting equipment to prevent

personal injury due to scalding.

Test

1.Check lubricant is to correct level.

2.Place vehicle on a ramp [hoist].

3.Disconnect battery negative lead. Remove oil

pressure switch.

4.Fit the test gauge.

5.Reconnect battery negative lead.

6.Start and run engine to normal operating

temperature.

7.At a steady engine speed of 2500 rev/min -

engine oil pressure reading should be - 2.75 bar

(40 lbf/in

2).

8.If the pressure is low - Remove and overhaul oil

pump

CYLINDER COMPRESSION - TEST

Equipment:

Compression pressure gauge

Test

1.Start and run engine until normal engine

operating temperature is achieved (thermostat

open).

2.Remove all spark plugs.

3.Disconnect both coil negative (WB) leads

4.Insert compression gauge, crank engine until

reading stabilises.

5.Expected readings, throttle fully open, battery

fully charged:

8.31:1 = 10.2-10.9 bar, 150-160lbf/in

2

9.35:1 = 11.5-12.2 bar, 170-180lbf/in2

Page 115 of 873

12ENGINE

2

FAULT DIAGNOSIS ENGINE NOISES

Excessive or obtrusive noise from the engine

compartment originates from three main sources:

A. The exhaust system, which makes an

unmistakable and easy to diagnose noise.

B. External components emit the greatest variety of

noises, but are also easy to diagnose by simply

removing the drive belt.

C. Engine internal mechanical noises which can

vary in volume and pitch and may be a

combination of, tapping - knocking or rumbling,

are the most difficult to diagnose. The following

is therefore a guide to diagnosis of engine

internal mechanical noises only.

Engine internal mechanical noises.

Single or multiple, light tapping noise, particularly

when engine is cold.

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Suspect valve operating mechanism.

3.To confirm diagnosis, remove the rocker covers

and with the engine idling, insert a feeler gauge

of 0,015mm between each rocker and valve

stem. A faulty valve operating mechanism will

emit a different noise when the feeler gauge is

inserted.

See Repair, Rocker Shaft Renew

Heavy knocking noise (particularly on load and

when engine is hot).

See Description and

operation, Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty big end bearings. To

confirm diagnosis, short out the ignition to

each spark plug in turn. The noise will

disappear or be reduced when the

cylinder with the faulty big end is shorted

out.

4.If noise is not conclusively diagnosed, check the

security of the flywheel and crankshaft front

pulley. Temporarily release the drive belt to

reduce general noise level and use a

stethoscope to locate source of noise.

Heavy rumbling noise (particularly during hard

acceleration).

See Description and operation,

Description

1.Is engine oil level correct?

NO - Top up to correct level.

See

LUBRICANTS, FLUIDS AND

CAPACITIES, Information,

Recommended Lubricants and Fluids

YES - Continue.

2.Is the lubricating pressure correct?

NO -

See Engine Oil Pressure Test

YES - Drain engine oil and filter, and examine

for metallic contamination.

3.Is the oil contaminated with metal particles?

YES - Suspect faulty main bearings. If noise is

not conclusively diagnosed, check the

security of the flywheel and crankshaft

front pulley. Temporarily release the drive

belt to reduce general noise level and use

a stethoscope to locate source of noise.

Page 117 of 873

12ENGINE

4

FAULT DIAGNOSIS 3.Are fuel supply, tank, pump, ventilation and

emission control systems in correct working

order or the fuel contaminated?

NO -

See FUEL SYSTEM, Repair, Fuel

Filter See FUEL SYSTEM, Repair,

Fuel Tank See FUEL SYSTEM, Repair,

Fuel Pump and Sender Unit

YES - Suspect valves held open by hydraulic

tappets due to high oil pressure.

See

Engine Oil Pressure Test

4.Is oil pressure high?

YES - Remove oil filter and cooler adaptor and

check pressure relief valve strainer gauze

for blockage and that the relief valve is

not stuck closed.

See Description and

operation, Description

NO - Carry out cylinder compression tests to

determine condition of head gaskets and

valves.

See Cylinder Compression -

Test

5.Are cylinder compressions satisfactory?

NO -

See Repair, Cylinder Heads - Renew

YES - Check brake vacuum connections.See

BRAKES, Description and operation,

Brake Servo Unit

Check heater/ventilation unit vacuum connections.

See HEATING AND VENTILATION, Description and

operation, Heating and Ventilation Unit

If problem is not diagnosed: Continue.

6.Are the brakes binding?

YES - Investigate cause of binding.

NO - Continue.

7.Automatic Transmission only. Is the Torque

Converter and Transmission operating correctly?

Carry out Road test, Static tests and Stall tests

to determine condition of Automatic

transmission.

If problem is not diagnosed: repeat tests starting at 1.Engine backfires into exhaust system

1.Are there any leaking joints/connections or holes

in the exhaust system?

YES -

See MANIFOLD AND EXHAUST

SYSTEM, Repair, Exhaust System

Complete

NO - Continue.

2.Is distributor fitted correctly, HT leads in correct

firing order and routed correctly?

NO -

See ELECTRICAL, Repair, Distributor

- V8i

YES - Continue.

3.Is air fuel ratio correct?

NO - Check multiport fuel injection.

See

Electrical Trouble Shooting Manual.

Check brake vacuum connections.See

BRAKES, Description and operation, Brake

Servo Unit

Check heater/ventilation unit vacuum

connections.

See HEATING AND

VENTILATION, Description and operation,

Heating and Ventilation Unit

Check the crank case and fuel tank ventilation

system.

See EMISSION CONTROL,

Description and operation, Emission Control

YES - Continue.

4.Are cylinder compressions satisfactory?

NO - Carry out compression test to check for

leaking gaskets valves etc.

See

Cylinder Compression - Test

See Repair, Cylinder Heads - Renew

If problem is not diagnosed: repeat tests starting

at 1.

Page 119 of 873

V8i

1

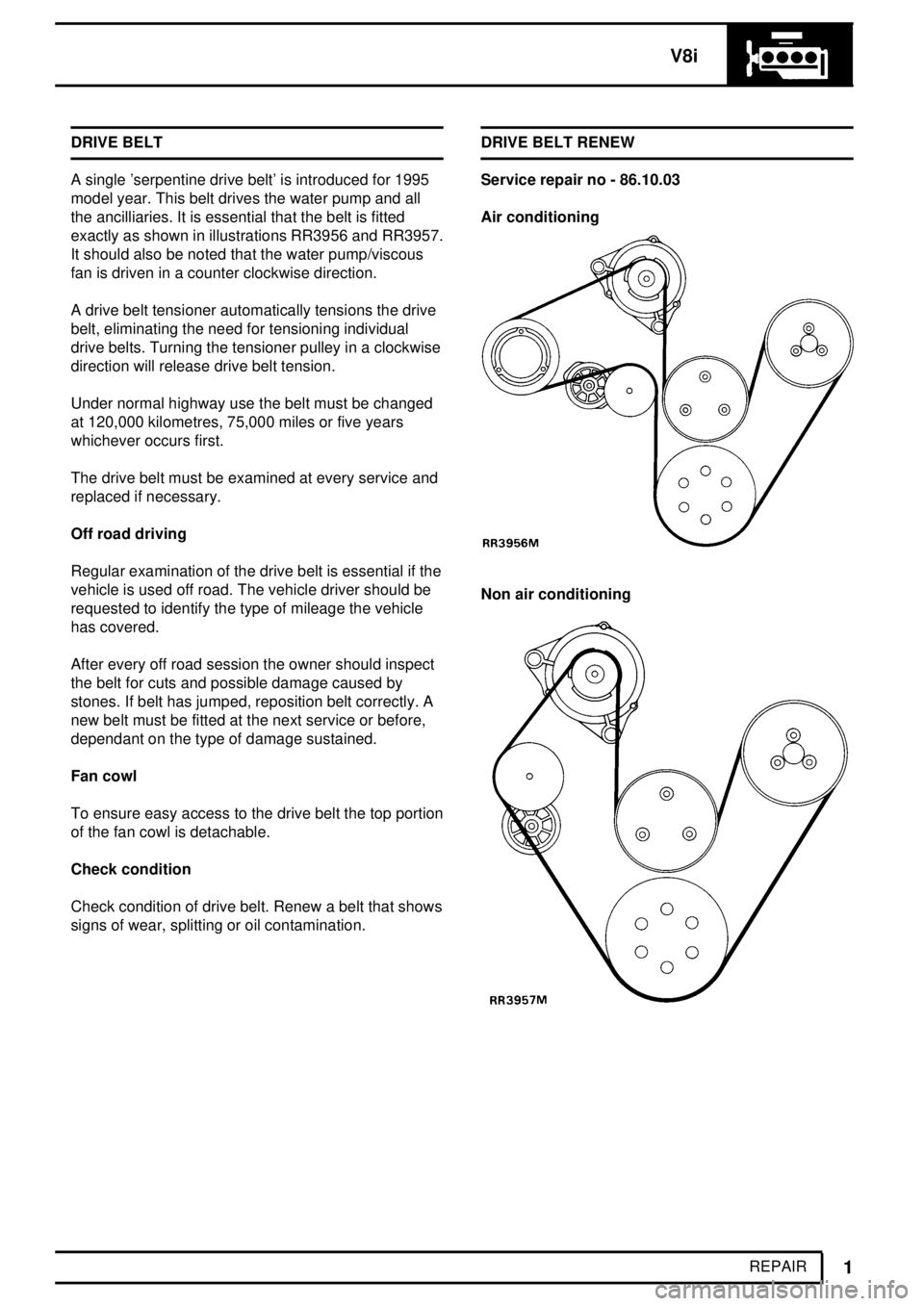

REPAIR DRIVE BELT

A single 'serpentine drive belt' is introduced for 1995

model year. This belt drives the water pump and all

the ancilliaries. It is essential that the belt is fitted

exactly as shown in illustrations RR3956 and RR3957.

It should also be noted that the water pump/viscous

fan is driven in a counter clockwise direction.

A drive belt tensioner automatically tensions the drive

belt, eliminating the need for tensioning individual

drive belts. Turning the tensioner pulley in a clockwise

direction will release drive belt tension.

Under normal highway use the belt must be changed

at 120,000 kilometres, 75,000 miles or five years

whichever occurs first.

The drive belt must be examined at every service and

replaced if necessary.

Off road driving

Regular examination of the drive belt is essential if the

vehicle is used off road. The vehicle driver should be

requested to identify the type of mileage the vehicle

has covered.

After every off road session the owner should inspect

the belt for cuts and possible damage caused by

stones. If belt has jumped, reposition belt correctly. A

new belt must be fitted at the next service or before,

dependant on the type of damage sustained.

Fan cowl

To ensure easy access to the drive belt the top portion

of the fan cowl is detachable.

Check condition

Check condition of drive belt. Renew a belt that shows

signs of wear, splitting or oil contamination.DRIVE BELT RENEW

Service repair no - 86.10.03

Air conditioning

Non air conditioning

Page 122 of 873

12ENGINE

4

REPAIR CYLINDER HEAD GASKETS - RENEW

Service repair no - 12.29.01

1.Drain cooling system.

See COOLING SYSTEM,

Adjustment, Coolant

2.Remove inlet manifold.See FUEL SYSTEM,

Repair, Intake Manifold

3.Remove generator.

4.If fitted, remove compressor.

See AIR

CONDITIONING, Repair, Compressor

5.Remove rocker shafts.See Rocker Shaft

Renew

6.Remove push rods.

7.Remove both exhaust manifolds.

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Exhaust Manifold - V8i

8.Remove air cleaner assembly.See FUEL

SYSTEM, Repair, Air Cleaner Assembly

9.Remove air flow sensor.See FUEL SYSTEM,

Repair, Air Flow Sensor

10.Remove ground leads from rear of left hand

cylinder head

11.Right hand cylinder head - remove breather pipe

from lifting bracket.

12.Loosen cylinder head bolts, reversing tightening

sequence.

13.Remove cylinder heads.

14.Remove cylinder head gaskets.

15.Clean exhaust mating faces.

16.Clean head and block faces.

17.Fit new cylinder head gaskets, word TOP

uppermost. DO NOT use sealant.

18.Oil cylinder bores.

19.Clean threads of head bolts and lightly oil.

20.Locate cylinder heads on block.

21.Locate cylinder head bolts in position illustrated.

96 mm long bolts - 2, 4, 6, 7, 8, 9, 10

66 mm long bolts - 1, 3, 5

NOTE: There are no bolts fitted in the four

lower holes in each cylinder head.

NOTE: Left hand cylinder head illustrated,

arrow points to front of vehicle.

22.Tighten bolts progressively in sequence, shown

to

20 Nmthen a further 180°±5°

23.Reverse removal procedure. 1 to 11.

Page 124 of 873

12ENGINE

6

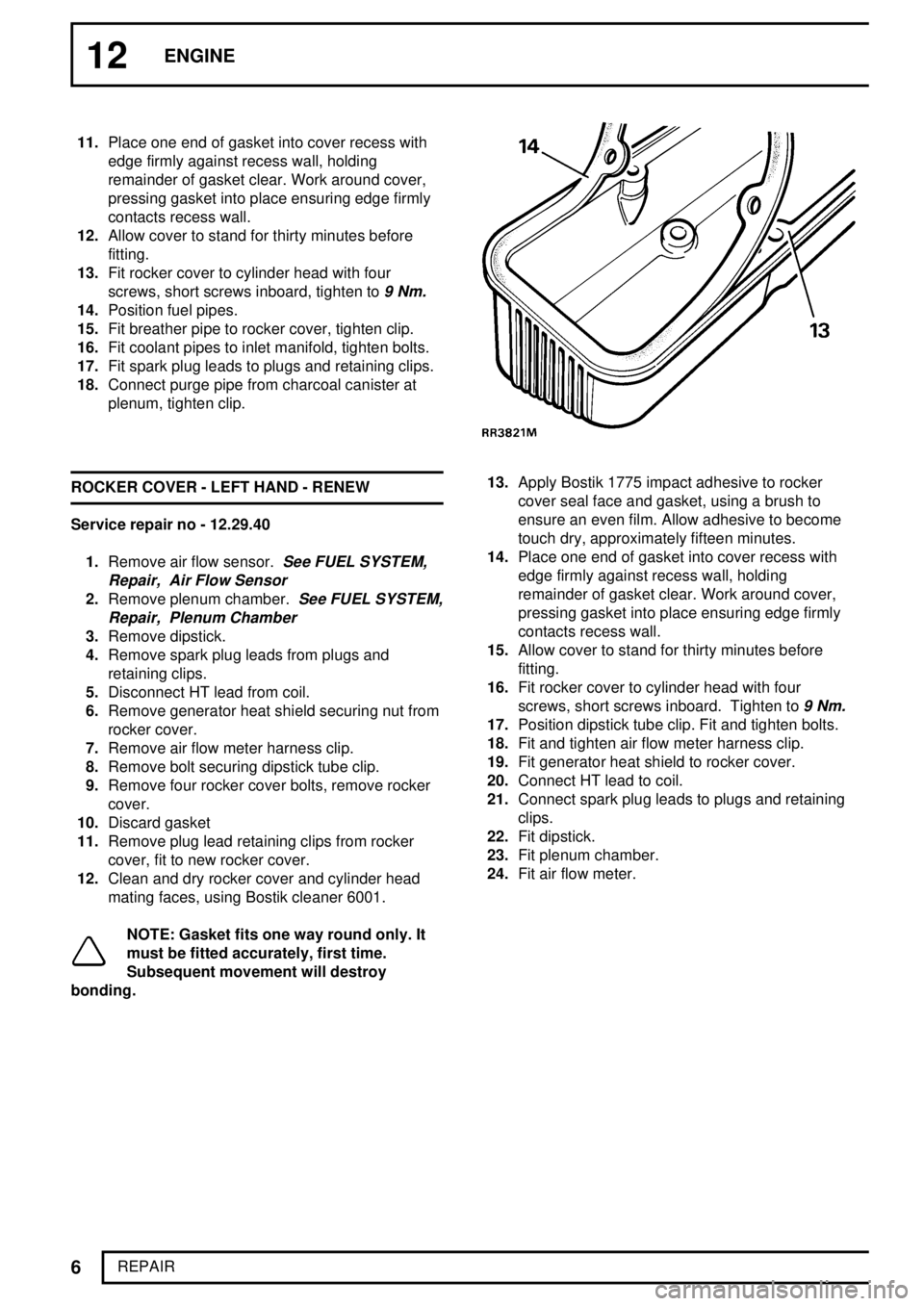

REPAIR 11.Place one end of gasket into cover recess with

edge firmly against recess wall, holding

remainder of gasket clear. Work around cover,

pressing gasket into place ensuring edge firmly

contacts recess wall.

12.Allow cover to stand for thirty minutes before

fitting.

13.Fit rocker cover to cylinder head with four

screws, short screws inboard, tighten to

9 Nm.

14.Position fuel pipes.

15.Fit breather pipe to rocker cover, tighten clip.

16.Fit coolant pipes to inlet manifold, tighten bolts.

17.Fit spark plug leads to plugs and retaining clips.

18.Connect purge pipe from charcoal canister at

plenum, tighten clip.

ROCKER COVER - LEFT HAND - RENEW

Service repair no - 12.29.40

1.Remove air flow sensor.

See FUEL SYSTEM,

Repair, Air Flow Sensor

2.Remove plenum chamber.See FUEL SYSTEM,

Repair, Plenum Chamber

3.Remove dipstick.

4.Remove spark plug leads from plugs and

retaining clips.

5.Disconnect HT lead from coil.

6.Remove generator heat shield securing nut from

rocker cover.

7.Remove air flow meter harness clip.

8.Remove bolt securing dipstick tube clip.

9.Remove four rocker cover bolts, remove rocker

cover.

10.Discard gasket

11.Remove plug lead retaining clips from rocker

cover, fit to new rocker cover.

12.Clean and dry rocker cover and cylinder head

mating faces, using Bostik cleaner 6001.

NOTE: Gasket fits one way round only. It

must be fitted accurately, first time.

Subsequent movement will destroy

bonding.

13.Apply Bostik 1775 impact adhesive to rocker

cover seal face and gasket, using a brush to

ensure an even film. Allow adhesive to become

touch dry, approximately fifteen minutes.

14.Place one end of gasket into cover recess with

edge firmly against recess wall, holding

remainder of gasket clear. Work around cover,

pressing gasket into place ensuring edge firmly

contacts recess wall.

15.Allow cover to stand for thirty minutes before

fitting.

16.Fit rocker cover to cylinder head with four

screws, short screws inboard. Tighten to

9 Nm.

17.Position dipstick tube clip. Fit and tighten bolts.

18.Fit and tighten air flow meter harness clip.

19.Fit generator heat shield to rocker cover.

20.Connect HT lead to coil.

21.Connect spark plug leads to plugs and retaining

clips.

22.Fit dipstick.

23.Fit plenum chamber.

24.Fit air flow meter.

Page 126 of 873

12ENGINE

8

REPAIR CRANKSHAFT PULLEY ASSEMBLY

Service repair no - 12.21.01

1.Remove viscous coupling.

See COOLING

SYSTEM, Repair, Viscous Coupling, Fan

Blades, Pulley and Fan Cowl

2.Remove drive belt.See Drive Belt

3.Raise vehicle on ramp [hoist].

4.Remove bell housing bottom cover.

5.Remove engine undertray.

6.With assistance to stop flywheel rotation, remove

crankshaft pulley assembly retaining bolt.

7.Remove crankshaft pulley assembly.

8.If required: Place assembly in vice and remove

pulley.

9.Fit pulley to torsional vibration damper.

10.Lubricate seal face of assembly.

11.Fit pulley assembly.

12.With assistance to stop flywheel rotation, fit

retaining bolt. Tighten to

280 Nm.

13.Reverse removal procedure. 1 to 5.FRONT COVER OIL SEAL - RENEW

Service repair no - 12.21.14

1.Remove crankshaft pulley.

See Crankshaft

Pulley Assembly. Do not remove pulleys.

2.Remove eight screws and remove mud

excluder.

3.Fit button of 18G1328 to crankshaft, fit extractor

to seal.

4.Turn centre bolt of extractor to remove seal.

5.Remove seal from extractor.

6.Clean seal seating.

7.Lubricate outside diameter of seal.

8.Locate seal in front cover.

9.Fit adaptor 18G1291/5 to 18G1291/4.

10.Fit tool to seal.

11.Fit and tighten centre bolt to crankshaft, tighten

centre locknut to seat seal.

12.Slacken locknut and remove tool.

13.Lubricate seal lip.

14.Fit mud excluder and tighten screws.

15.Fit crankshaft pulley assembly.

Page 127 of 873

V8i

9

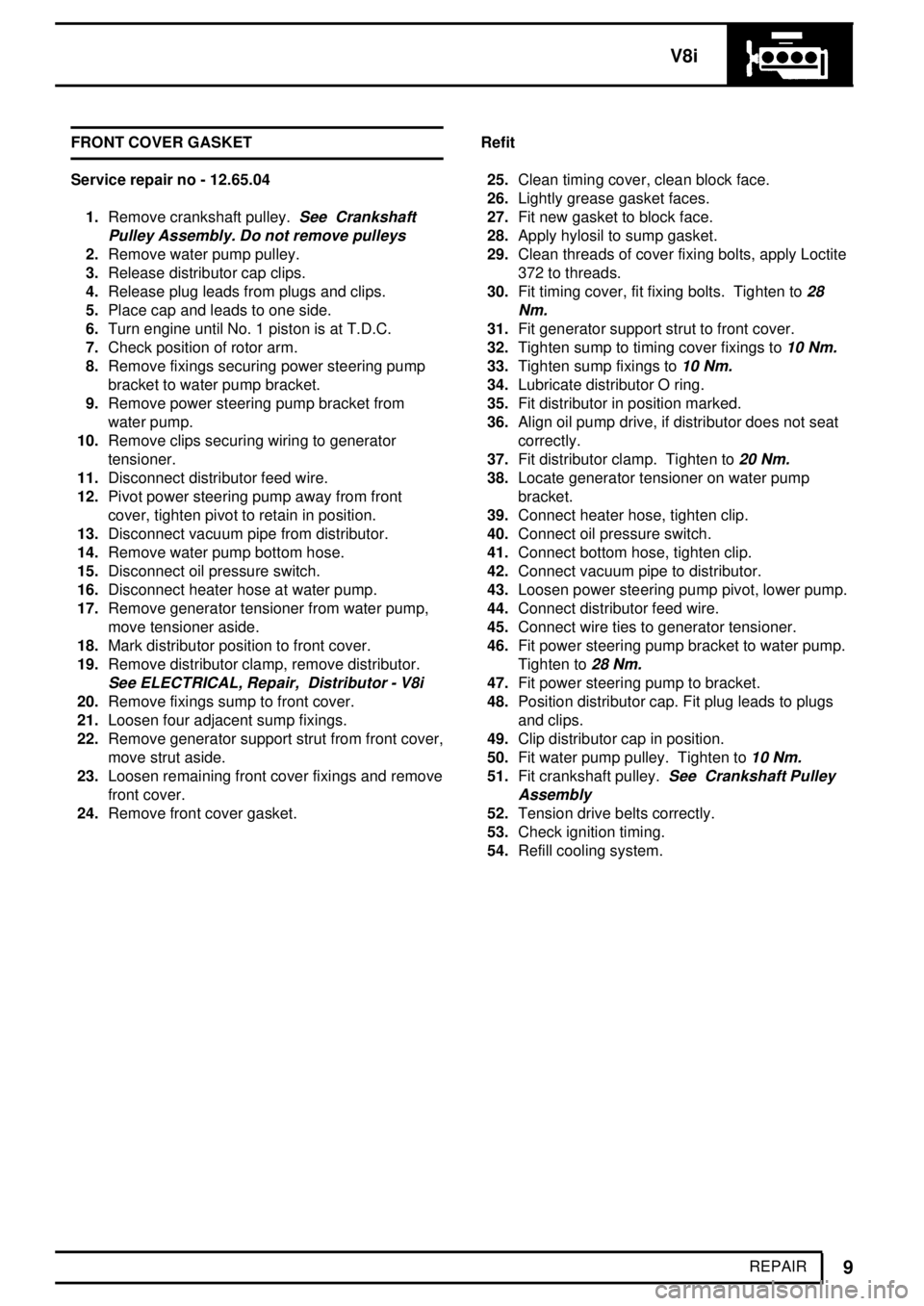

REPAIR FRONT COVER GASKET

Service repair no - 12.65.04

1.Remove crankshaft pulley.

See Crankshaft

Pulley Assembly. Do not remove pulleys

2.Remove water pump pulley.

3.Release distributor cap clips.

4.Release plug leads from plugs and clips.

5.Place cap and leads to one side.

6.Turn engine until No. 1 piston is at T.D.C.

7.Check position of rotor arm.

8.Remove fixings securing power steering pump

bracket to water pump bracket.

9.Remove power steering pump bracket from

water pump.

10.Remove clips securing wiring to generator

tensioner.

11.Disconnect distributor feed wire.

12.Pivot power steering pump away from front

cover, tighten pivot to retain in position.

13.Disconnect vacuum pipe from distributor.

14.Remove water pump bottom hose.

15.Disconnect oil pressure switch.

16.Disconnect heater hose at water pump.

17.Remove generator tensioner from water pump,

move tensioner aside.

18.Mark distributor position to front cover.

19.Remove distributor clamp, remove distributor.

See ELECTRICAL, Repair, Distributor - V8i

20.Remove fixings sump to front cover.

21.Loosen four adjacent sump fixings.

22.Remove generator support strut from front cover,

move strut aside.

23.Loosen remaining front cover fixings and remove

front cover.

24.Remove front cover gasket.Refit

25.Clean timing cover, clean block face.

26.Lightly grease gasket faces.

27.Fit new gasket to block face.

28.Apply hylosil to sump gasket.

29.Clean threads of cover fixing bolts, apply Loctite

372 to threads.

30.Fit timing cover, fit fixing bolts. Tighten to

28

Nm.

31.Fit generator support strut to front cover.

32.Tighten sump to timing cover fixings to

10 Nm.

33.Tighten sump fixings to10 Nm.

34.Lubricate distributor O ring.

35.Fit distributor in position marked.

36.Align oil pump drive, if distributor does not seat

correctly.

37.Fit distributor clamp. Tighten to

20 Nm.

38.Locate generator tensioner on water pump

bracket.

39.Connect heater hose, tighten clip.

40.Connect oil pressure switch.

41.Connect bottom hose, tighten clip.

42.Connect vacuum pipe to distributor.

43.Loosen power steering pump pivot, lower pump.

44.Connect distributor feed wire.

45.Connect wire ties to generator tensioner.

46.Fit power steering pump bracket to water pump.

Tighten to

28 Nm.

47.Fit power steering pump to bracket.

48.Position distributor cap. Fit plug leads to plugs

and clips.

49.Clip distributor cap in position.

50.Fit water pump pulley. Tighten to

10 Nm.

51.Fit crankshaft pulley.See Crankshaft Pulley

Assembly

52.Tension drive belts correctly.

53.Check ignition timing.

54.Refill cooling system.

Page 129 of 873

V8i

11

REPAIR FLEXIBLE DRIVE PLATE AND RING GEAR

Service repair no - 12.53.13

Remove

1.Remove transmission.

See AUTOMATIC

GEARBOX, Repair, LT230T Transfer Gearbox

with Automatic Gearbox Assembly - V8i

2.Remove flexible drive plate and ring gear

assembly.

See V8i Overhaul Manual.

Refit

3.Clean all components for reassembly.

4.Fit ring gear and flexible drive plate assembly.

See V8i Overhaul Manual.

5.Fit transmission.CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

1.Automatic transmission, remove drive plate.

See Flexible Drive Plate and Ring Gear

OR manual transmission, remove flywheel.See

Flywheel

2.Remove sump.See Oil Sump

3.Remove rear main bearing cap.

4.Remove cross seals from cap.

5.Remove crankshaft rear oil seal.

6.Clean main bearing cap and oil seal area of

block.

7.Fit new cross seals to bearing cap.

8.Apply Hylomar SQ32M to block as illustrated.

9.Lubricate bearing shell and cross seals using

clean engine oil.

10.Fit bearing cap, do not tighten bolts.

11.Ensure cap is fully home and seated squarely on

the block.

Page 130 of 873

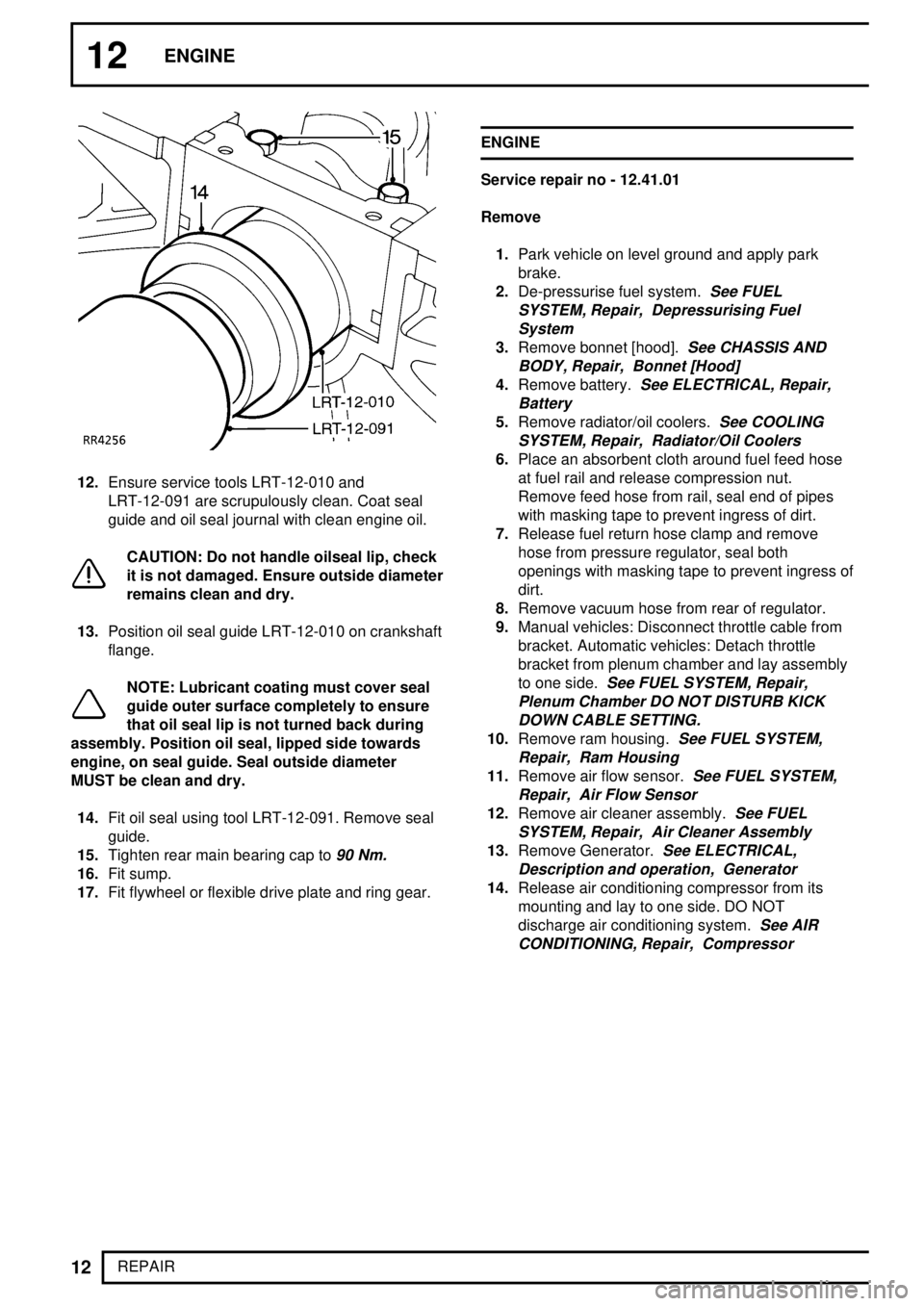

12ENGINE

12

REPAIR

12.Ensure service tools LRT-12-010 and

LRT-12-091 are scrupulously clean. Coat seal

guide and oil seal journal with clean engine oil.

CAUTION: Do not handle oilseal lip, check

it is not damaged. Ensure outside diameter

remains clean and dry.

13.Position oil seal guide LRT-12-010 on crankshaft

flange.

NOTE: Lubricant coating must cover seal

guide outer surface completely to ensure

that oil seal lip is not turned back during

assembly. Position oil seal, lipped side towards

engine, on seal guide. Seal outside diameter

MUST be clean and dry.

14.Fit oil seal using tool LRT-12-091. Remove seal

guide.

15.Tighten rear main bearing cap to

90 Nm.

16.Fit sump.

17.Fit flywheel or flexible drive plate and ring gear.ENGINE

Service repair no - 12.41.01

Remove

1.Park vehicle on level ground and apply park

brake.

2.De-pressurise fuel system.

See FUEL

SYSTEM, Repair, Depressurising Fuel

System

3.Remove bonnet [hood].See CHASSIS AND

BODY, Repair, Bonnet [Hood]

4.Remove battery.See ELECTRICAL, Repair,

Battery

5.Remove radiator/oil coolers.See COOLING

SYSTEM, Repair, Radiator/Oil Coolers

6.Place an absorbent cloth around fuel feed hose

at fuel rail and release compression nut.

Remove feed hose from rail, seal end of pipes

with masking tape to prevent ingress of dirt.

7.Release fuel return hose clamp and remove

hose from pressure regulator, seal both

openings with masking tape to prevent ingress of

dirt.

8.Remove vacuum hose from rear of regulator.

9.Manual vehicles: Disconnect throttle cable from

bracket. Automatic vehicles: Detach throttle

bracket from plenum chamber and lay assembly

to one side.

See FUEL SYSTEM, Repair,

Plenum Chamber DO NOT DISTURB KICK

DOWN CABLE SETTING.

10.Remove ram housing.See FUEL SYSTEM,

Repair, Ram Housing

11.Remove air flow sensor.See FUEL SYSTEM,

Repair, Air Flow Sensor

12.Remove air cleaner assembly.See FUEL

SYSTEM, Repair, Air Cleaner Assembly

13.Remove Generator.See ELECTRICAL,

Description and operation, Generator

14.Release air conditioning compressor from its

mounting and lay to one side. DO NOT

discharge air conditioning system.

See AIR

CONDITIONING, Repair, Compressor