light LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 821 of 873

ELECTRICAL

1

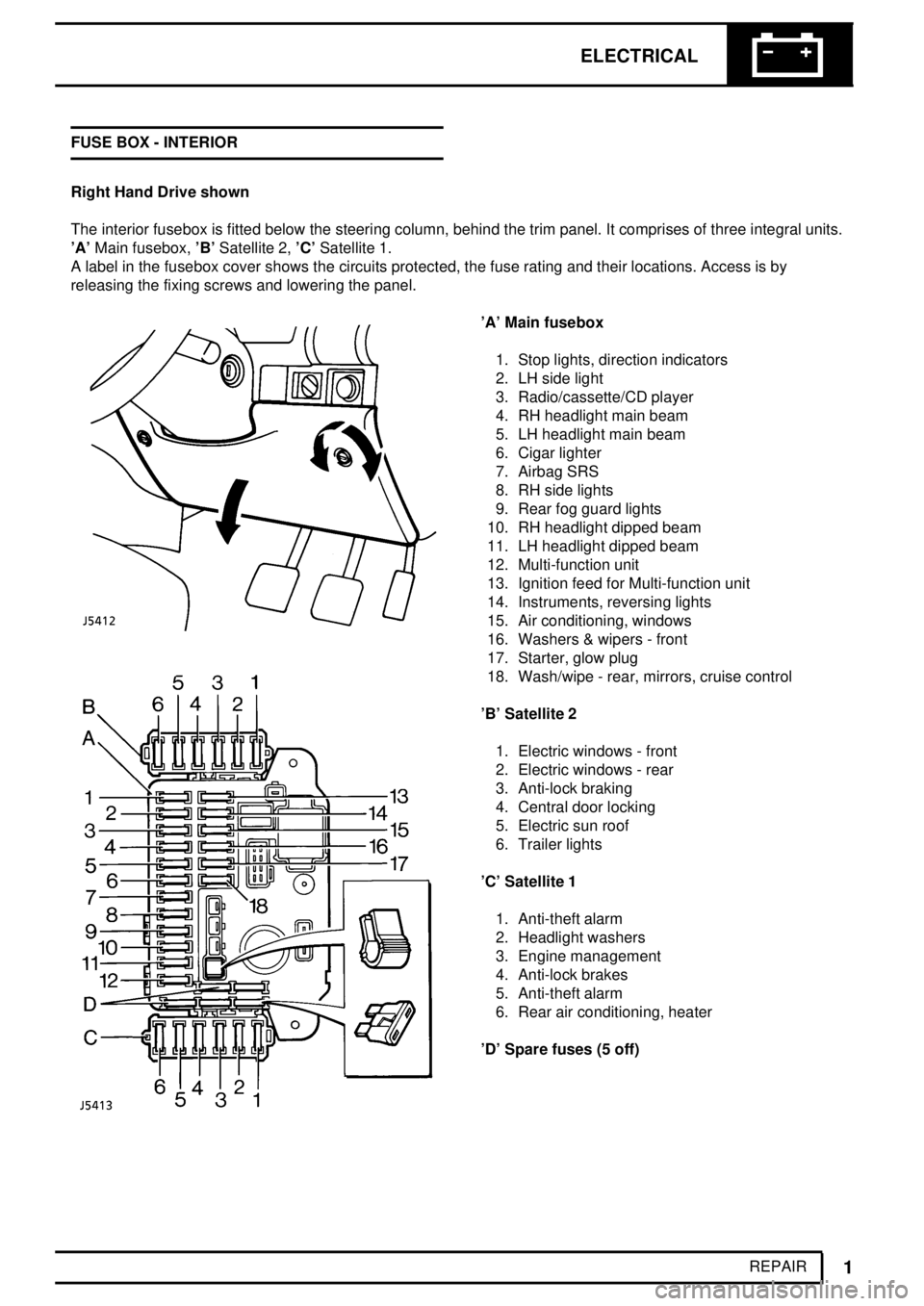

REPAIR FUSE BOX - INTERIOR

Right Hand Drive shown

The interior fusebox is fitted below the steering column, behind the trim panel. It comprises of three integral units.

'A'Main fusebox,'B'Satellite 2,'C'Satellite 1.

A label in the fusebox cover shows the circuits protected, the fuse rating and their locations. Access is by

releasing the fixing screws and lowering the panel.

'A' Main fusebox

1. Stop lights, direction indicators

2. LH side light

3. Radio/cassette/CD player

4. RH headlight main beam

5. LH headlight main beam

6. Cigar lighter

7. Airbag SRS

8. RH side lights

9. Rear fog guard lights

10. RH headlight dipped beam

11. LH headlight dipped beam

12. Multi-function unit

13. Ignition feed for Multi-function unit

14. Instruments, reversing lights

15. Air conditioning, windows

16. Washers & wipers - front

17. Starter, glow plug

18. Wash/wipe - rear, mirrors, cruise control

'B' Satellite 2

1. Electric windows - front

2. Electric windows - rear

3. Anti-lock braking

4. Central door locking

5. Electric sun roof

6. Trailer lights

'C' Satellite 1

1. Anti-theft alarm

2. Headlight washers

3. Engine management

4. Anti-lock brakes

5. Anti-theft alarm

6. Rear air conditioning, heater

'D' Spare fuses (5 off)

Page 822 of 873

86ELECTRICAL

2

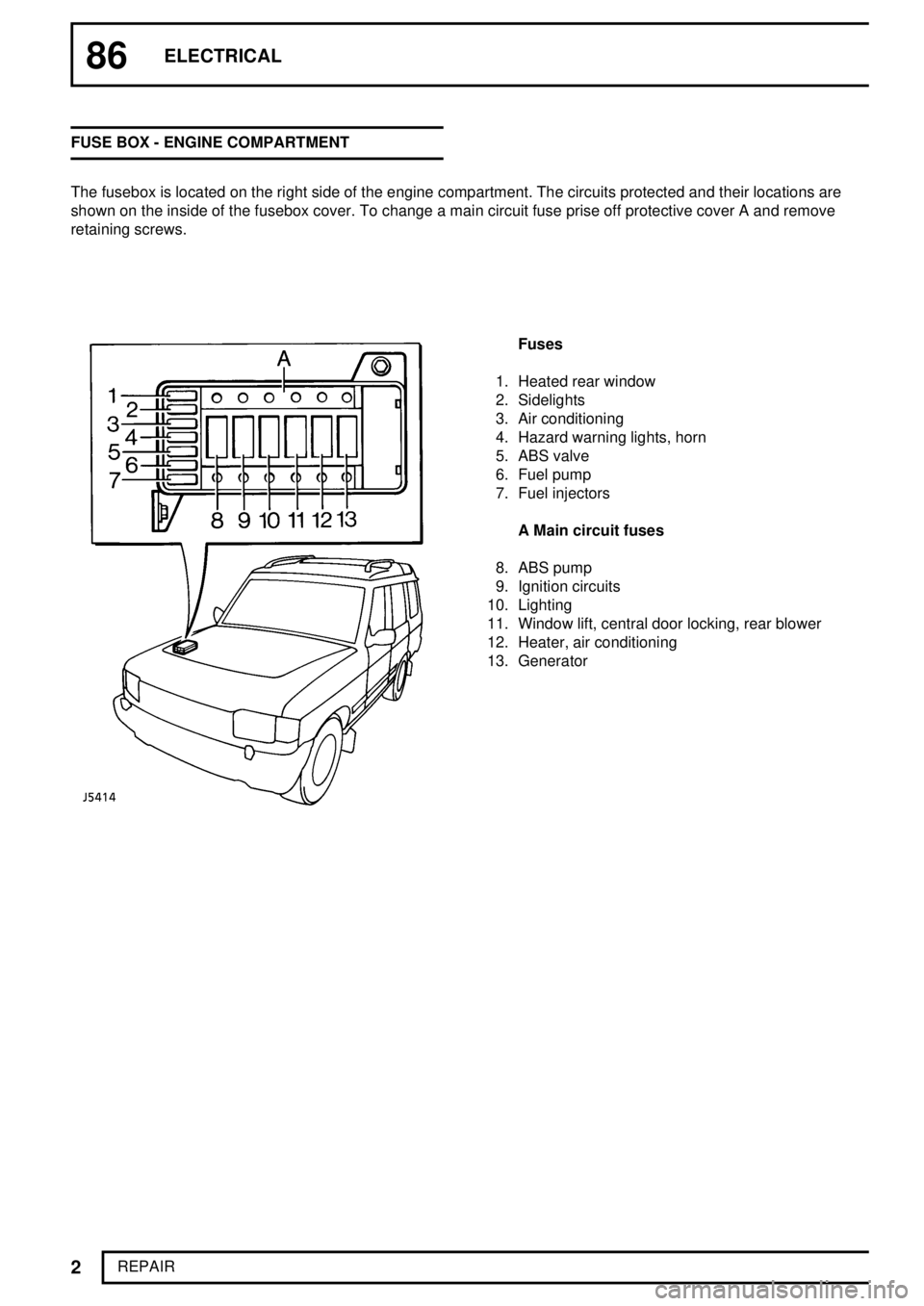

REPAIR FUSE BOX - ENGINE COMPARTMENT

The fusebox is located on the right side of the engine compartment. The circuits protected and their locations are

shown on the inside of the fusebox cover. To change a main circuit fuse prise off protective cover A and remove

retaining screws.

Fuses

1. Heated rear window

2. Sidelights

3. Air conditioning

4. Hazard warning lights, horn

5. ABS valve

6. Fuel pump

7. Fuel injectors

A Main circuit fuses

8. ABS pump

9. Ignition circuits

10. Lighting

11. Window lift, central door locking, rear blower

12. Heater, air conditioning

13. Generator

Page 826 of 873

86ELECTRICAL

6

REPAIR Refit

NOTE: If a new distributor is being fitted,

mark body in same relative position as

distributor removed.

8.Leads for distributor cap should be connected as

illustrated.

Figures 1 to 8 inclusive indicate plug lead

numbers.

RH-Right hand side of engine, when viewed

from rear.

LH-Left hand side of engine, when viewed from

rear.

9.If engine has not been turned while distributor

has been removed, carry out instructions 10. to

17. Alternatively proceed to instruction 18.

10.Fit new 'O' ring seal to distributor housing.

11.Turn distributor drive until centre line of rotor arm

is 30Ê anti-clockwise from mark made on top

edge of distributor body.

12.Fit distributor in accordance with alignment

markings.

NOTE: It may be necessary to align oil

pump drive shaft to enable distributor

drive shaft to engage in slot.

13.Fit clamp and bolt. Secure distributor in exact

original position.

14.Connect vacuum hose to distributor and low

tension lead to coil.

15.Fit distributor cap.

16.Reconnect battery.

17.Using suitable electronic equipment, set ignition

timing.

See Adjustment, Ignition timing

18.If engine has been turned with distributor

removed, carry out instructions 19 to 30.

19.Set engine-No. 1 piston to static ignition timing

figure

See ENGINE TUNING DATA,

Information, Engine 3.9 V8i

20.Turn distributor drive until rotor arm is

approximately 30Ê anti-clockwise from number

one sparking plug lead position on cap.

21.Fit distributor to engine.

22.Check that centre line of rotor arm is now in line

with number one sparking plug lead on cap.

Reposition distributor if necessary.

23.If distributor does not seat correctly in front

cover, oil pump drive is not engaged. Engage by

lightly pressing down distributor while turning

engine.

24.Fit clamp and bolt, do not tighten.

25.Set ignition timing statically to 6Ê B.T.D.C.

26.Connect vacuum hose to distributor.

27.Fit low tension lead to coil.

28.Fit distributor cap.

29.Reconnect battery.

30.Using suitable electronic equipment set the

ignition timing.

See Adjustment, Ignition

timing

Page 827 of 873

ELECTRICAL

7

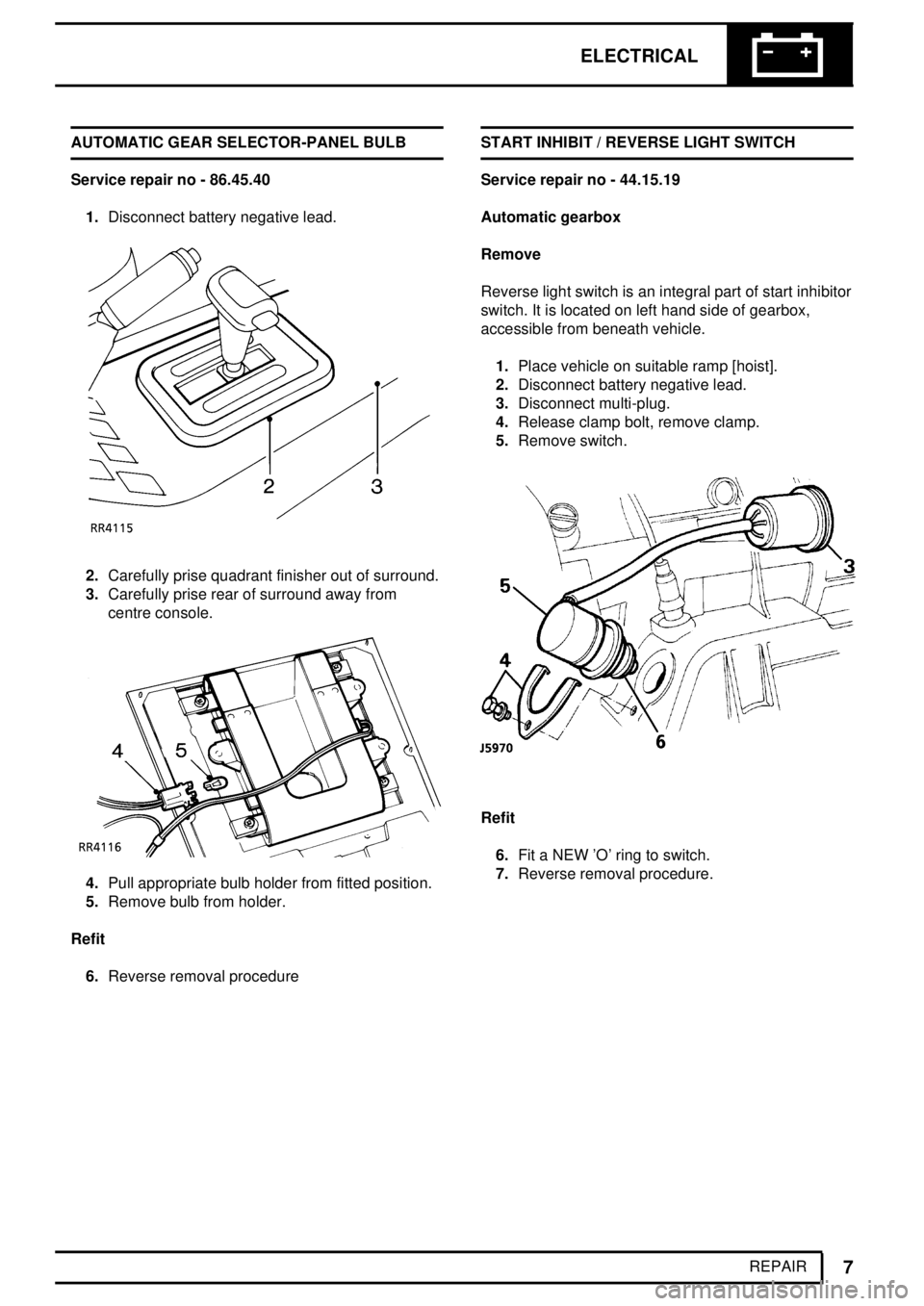

REPAIR AUTOMATIC GEAR SELECTOR-PANEL BULB

Service repair no - 86.45.40

1.Disconnect battery negative lead.

2.Carefully prise quadrant finisher out of surround.

3.Carefully prise rear of surround away from

centre console.

4.Pull appropriate bulb holder from fitted position.

5.Remove bulb from holder.

Refit

6.Reverse removal procedureSTART INHIBIT / REVERSE LIGHT SWITCH

Service repair no - 44.15.19

Automatic gearbox

Remove

Reverse light switch is an integral part of start inhibitor

switch. It is located on left hand side of gearbox,

accessible from beneath vehicle.

1.Place vehicle on suitable ramp [hoist].

2.Disconnect battery negative lead.

3.Disconnect multi-plug.

4.Release clamp bolt, remove clamp.

5.Remove switch.

Refit

6.Fit a NEW 'O' ring to switch.

7.Reverse removal procedure.

Page 831 of 873

ELECTRICAL

11

REPAIR HANDSET INITIALISATION

NOTE: New handsets are supplied in pairs.

If a new handset is required, it will require

initialisation to the ECU using the

following procedure:

1.Starting conditions: ignition off, doors unlocked,

bonnet switch depressed.

2.Carry out instructions 3. to 9. within 8 seconds.

3.Switch ignition ON.

4.Switch ignition OFF.

5.Lock doors.

6.Unlock doors.

7.Release bonnet switch.

8.Switch ignition ON.

9.Switch ignition OFF.

If alarm is correctly accessed, horn will sound and

LED will light. It is now possible to programme two

handsets of correct frequency to vehicle alarm ECU.

This must be carried out within two minutes.

10.Press and hold down button on first handset until

dash LED flashes.

11.Repeat instruction 10. for second handset.

12.The LED will extinguish if both handsets have

been initialised correctly.CENTRAL DOOR LOCKING

Where electrically operated central door locking is

fitted, locking or unlocking the drivers door from

outside by key operation, or from the inside with the

sill knob automatically locks or unlocks the passenger

and rear doors.

Front and rear passenger doors can be independently

locked or unlocked from inside the vehicle by sill knob

operation but can be overidden by further operation of

the driver's door locking control.

On rear doors, where side facing fold down seats are

fitted, a child safety lock is provided which can be

mechanically pre-set to render the interior door

handles inoperative.

Failure of a door actuator will not affect the operation

of the remaining doors and the door with the

inoperative actuator can still be locked or unlocked

manually.

The actuator unit fitted to the driver's door is the

master actuator and is identified from the actuators

fitted to the passenger and rear doors by having a

white connecting link, whereas the passenger and

rear door actuators have grey coloured connecting

links.

NOTE: Actuator units are non-servicable, if

a fault should occur replace the unit with a

new one.

Page 835 of 873

ELECTRICAL

15

REPAIR Refit

9.If removed fit the mounting plate to the actuator.

10.Engage the actuator operating rod with hooked

end of the actuator link.

11.Fit the actuator and mounting plate to the door

and loosely secure with the four screws.

12.Set the mounting plate with the screws in the

centre of the slotted holes, then tighten the

screws.

13.Connect the actuator lead to the door harness.

14.Reconnect battery negative lead.

15.With the sill locking button held in position, set

the bellcrank to approximately the position it

would be in if the sill button was depressed to

half of its total movement.

16.At this setting check the electrical operation of

the door lock. Adjust the mounting plate as

necessary to achieve the correct setting. Fully

tighten the securing screws on completion.

17.Refit the vapour barrier.

18.Connect the sill button operating rod to the

bellcrank, hold in position, fit the door trim panel

and the door pull.

BULB REPLACEMENT

For bulb type and rating refer to rating shown on the

bulb or bulb replacement list.

See GENERAL

SPECIFICATION DATA, Information, Bulbs

HEADLIGHT

Service repair no - 86.40.02/13

Remove

1.Rotate three retaining clips 10 degrees, to align

with slots in headlight mounting plate.

2.Withdraw light unit

NOTE: Detach adjustment operating rod

on vehicles fitted with headlight levelling.3.Disconnect electrical multiplugs and remove

headlight unit.

4.Release spring clips and withdraw headlight

bulb.

Key

1. Headlight

2. Retaining clips

3. Bulb

4. Spring clip

5. Cover

6. Bulb sidelight

7. Plug

8. Plug sidelight

Refit

5.Reverse removal procedure.

Page 836 of 873

86ELECTRICAL

16

REPAIR SIDELIGHT BULB

Service repair no - 86.40.33

Remove

1.Remove headlight,

See Headlight

2.Disengage bulb holder by twisting a quarter turn

anti-clockwise.

3.Withdraw bulb from holder.

Refit

4.Reverse removal procedure.FRONT DIRECTION INDICATORS

Service repair no - 86.40.41

Remove

1.Pull spring clips, release from location and lift out

direction indicator unit.

2.Turn bulb holder anti-clockwise to release from

indicator unit.

3.Push and twist the bulb to remove.

Refit

4.Reverse removal procedure. When replacing

light unit, locate the two lugs at the bottom of the

lens before re-engaging spring clips.

Page 837 of 873

ELECTRICAL

17

REPAIR REAR LIGHT UNIT

Service repair no - 86.40.74

Remove

1.Pull out side facing seat or pocket cover.

2.Unscrew fastener and remove access panel.

3.Disconnect wiring harness multi-plug from light

unit.

4.Remove retaining nuts and withdraw light unit

from rear of vehicle.

Key

1. Access panel

2. Multiplug

3. Retaining nut

4. Bulb holder

5. Bulb

Refit

5.Reverse removal procedure. Ensure that the

rubber seal is seated correctly.STOP, REVERSING, FOG GUARD BULBS

Service repair no - 86.40.74

Remove

1.Pull out side facing seat or pocket cover.

2.Unscrew fastener and remove access panel.

3.Turn bulb holder anti-clockwise to release.

4.Remove bulb.

NOTE: On vehicles fitted with rear air

conditioning remove access panel

housing rear loadspace light to gain

access.

Key

1. Access panel

2. Multiplug

3. Retaining nut

4. Bulb holder

5. Bulb

Refit

5.Reverse removal procedure.

Page 838 of 873

86ELECTRICAL

18

REPAIR REAR LIGHTS, BUMPER MOUNTED

Service repair no - 86.41.42

Remove

1.From behind bumper disconnect light plugs.

2.Unscrew two retaining nuts and remove light unit

from bumper.

Refit

3.Reverse removal procedure.

NOTE: The black lead plug fits into the

direction indication light, the white lead

plugs into the tail light, the bulb holder

being colour coded red.DIRECTION INDICATOR, TAIL LIGHT BULBS

Service repair no - 86.41.43

Remove

1.Turn bulb holder anti-clockwise to release from

light unit.

2.Push and twist the bulb to remove.

Refit

3.Reverse removal procedure.

Page 839 of 873

ELECTRICAL

19

REPAIR NUMBER PLATE LIGHTS

Service repair no - 86.40.86

Remove

1.Remove two screws and withdraw light unit.

2.Disconnect wiring leads and remove light unit.

3.Remove bulb.

Refit

4.Reverse removal procedure.DOOR EDGE LIGHT

Service repair no - 86.40.35

Remove

1.Pry lens from housing.

2.Disconnect wiring leads and remove light unit.

3.Remove bulb.

Refit

4.Reverse removal procedure.