sensor LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 324 of 873

Mpi

1

REPAIR KNOCK SENSOR

Service repair no - 18.30.18

Remove

1.Disconnect multiplug from knock sensor.

2.Remove knock sensor.

Refit

3.Clean mating face of cylinder block.

4.Fit knock sensor. Tighten to

15 Nm

5.Connect multiplug.IGNITION COILS

Service repair no - 18.20.40 - 1 & 4 Cylinders

Service repair no - 18.20.41 - 2 & 3 Cylinders

Remove

1.Disconnect battery negative lead.

2.Disconnect 4 h.t. leads from coils.

NOTE: Mark the position of the h.t. leads

to ensure correct refitment.

3.Disconnect 2 multiplugs from coils.

4.Disconnect crankshaft sensor multiplug.

5.Remove screw securing crankshaft sensor

multiplug to coil bracket.

6.Remove 3 bolts securing coil bracket to bell

housing.

NOTE: Access to the rear bolts is from

under the vehicle.

7.Remove coil assembly.

Refit

8.Position coil assembly to bell housing.

9.Fit 3 bolts and tighten to the correct torque.

10.Secure crankshaft sensor multiplug to coil

bracket with screw.

11.Connect crankshaft sensor multiplug.

12.Connect multiplugs and h.t. leads to coils.

13.Reconnect battery negative lead.

Page 325 of 873

19FUEL SYSTEM

2

REPAIR COOLANT TEMPERATURE SENSOR

Service repair no - 18.30.10

Remove

1.Position drain tin below coolant pump hose.

2.Disconnect sensor multiplug.

3.Release harness clip and harness.

4.Remove sensor.

Refit

5.Clean sensor.

6.Fit sensor and tighten to the correct torque.

7.Position harness and secure with clip.

8.Connect multiplug.

9.Top-up cooling system.CRANKSHAFT SENSOR

Service repair no - 18.30.12

Remove

1.Position vehicle on ramp [hoist].

2.Disconnect multiplug from crankshaft sensor

flylead.

3.Remove screw, release lead from bracket.

4.Raise ramp [hoist].

5.Remove 2 bolts securing crankshaft sensor.

6.Remove crankshaft sensor.

Refit

7.Clean crankshaft sensor and mating surface of

backplate.

8.Fit crankshaft sensor, fit bolts. Tighten to

7Nm

9.Lower vehicle.

10.Position lead to bracket, fit and tighten screw.

11.Connect multiplug

Page 326 of 873

Mpi

3

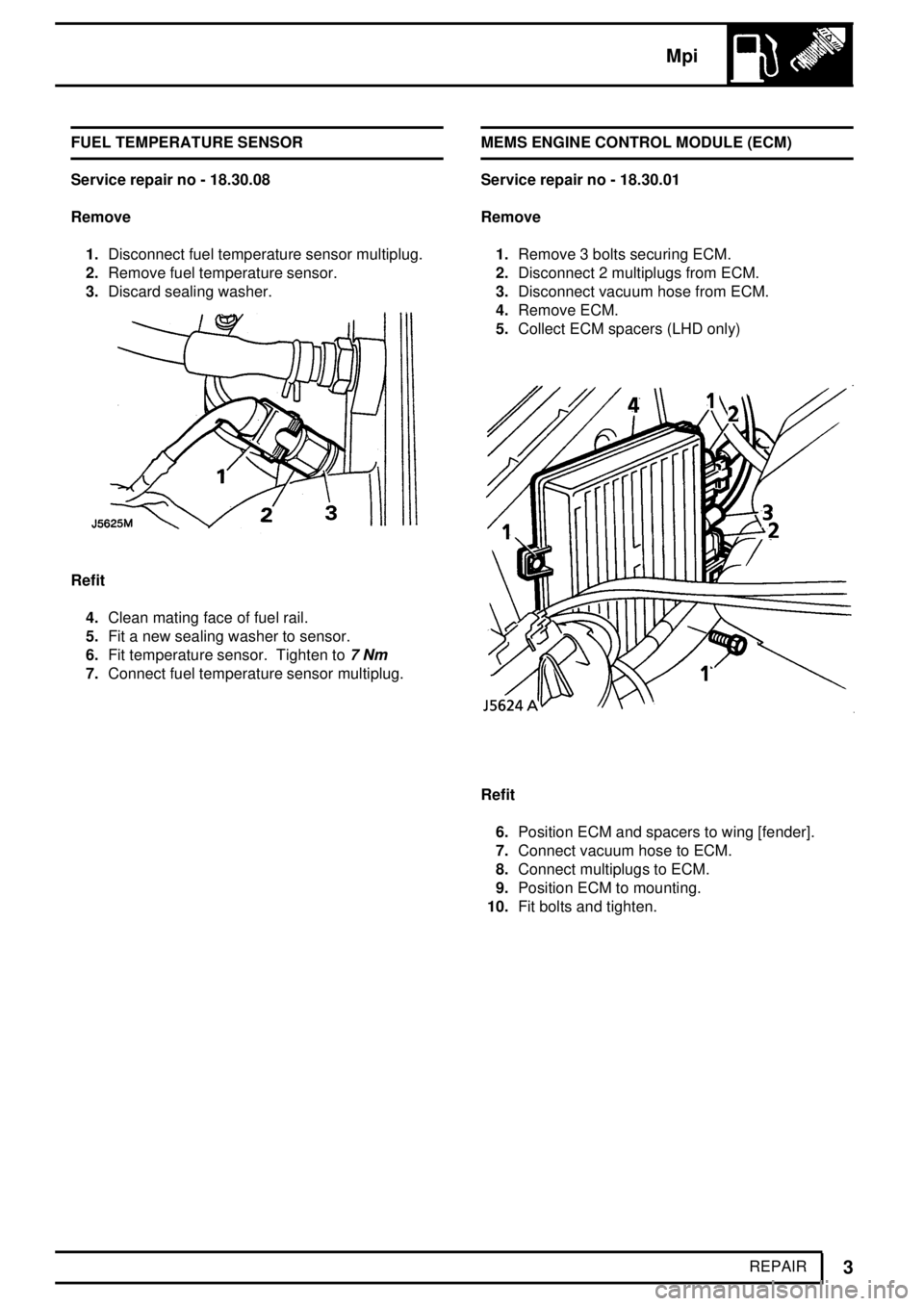

REPAIR FUEL TEMPERATURE SENSOR

Service repair no - 18.30.08

Remove

1.Disconnect fuel temperature sensor multiplug.

2.Remove fuel temperature sensor.

3.Discard sealing washer.

Refit

4.Clean mating face of fuel rail.

5.Fit a new sealing washer to sensor.

6.Fit temperature sensor. Tighten to

7Nm

7.Connect fuel temperature sensor multiplug.MEMS ENGINE CONTROL MODULE (ECM)

Service repair no - 18.30.01

Remove

1.Remove 3 bolts securing ECM.

2.Disconnect 2 multiplugs from ECM.

3.Disconnect vacuum hose from ECM.

4.Remove ECM.

5.Collect ECM spacers (LHD only)

Refit

6.Position ECM and spacers to wing [fender].

7.Connect vacuum hose to ECM.

8.Connect multiplugs to ECM.

9.Position ECM to mounting.

10.Fit bolts and tighten.

Page 329 of 873

19FUEL SYSTEM

6

REPAIR INTAKE AIR TEMPERATURE SENSOR

Service repair no - 18.30.09

Remove

1.Disconnect multiplug from temperature sensor.

2.Remove sensor from inlet manifold.

Refit

3.Clean sensor threads and mating face.

4.Fit sensor to inlet manifold. Tighten to

7Nm

5.Connect multiplug to sensor.PURGE CONTROL VALVE

Service repair no - 17.15.39

Remove

1.Disconnect multiplug from purge control valve.

2.Release clip and disconnect hose from valve.

3.Release valve from charcoal canister.

4.Remove valve.

5.Discard 'O' ring.

Refit

6.Clean valve and valve location.

7.Position and secure valve to charcoal canister.

8.Connect hose to purge valve and secure with

clip.

9.Connect multiplug to valve.

Page 330 of 873

Mpi

7

REPAIR FUEL RAIL AND INJECTORS

Service repair no - 19.60.04 - Rail

Service repair no - 19.60.10 - Injectors

Remove

1.Remove inlet manifold chamber gasket.

See

MANIFOLD AND EXHAUST SYSTEM, Repair,

Manifold Chamber Gasket - Mpi

2.Remove pressure regulator.

3.Remove 4 bolts securing fuel feed hose flange

stiffening bracket, remove stiffening bracket.

4.Release fuel feed hose from fuel rail.

5.Discard 'O' ring.

6.Disconnect 4 injector multiplugs.

7.Move injector harness aside.

8.Remove 2 bolts securing fuel rail to inlet

manifold.

9.Release 4 injectors from inlet manifold.

10.Remove fuel rail complete with injectors.

11.Discard outlet 'O' rings from injectors.

12.Fix protective cap to each injector.

Do not carry out further dismantling if component

is removed for access only.

13.Remove clip(s) securing injector(s) to fuel rail.

14.Remove injector(s).

15.Discard inlet 'O' ring(s) from injector(s).

16.Remove fuel temperature sensor.

Page 331 of 873

19FUEL SYSTEM

8

REPAIR Refit

17.Clean fuel rail, temperature sensor and pressure

regulator mating surfaces.

18.Fit fuel temperature sensor. Tighten to

7Nm

19.Clean injectors and injector recesses in fuel rail

and inlet manifold.

20.Fit new 'O' ring(s) to inlet end of injector(s).

21.Fit injector(s) to fuel rail, fit and secure clip(s).

22.Fit new 'O' rings to outlet ends of injectors.

23.Align injectors to inlet manifold and push fuel rail

into position.

24.Fit fuel rail securing bolts. Tighten to

10 Nm

25.Connect injector multiplugs.

26.Remove plugs from fuel feed hose and fuel rail.

27.Fit new 'O' ring to fuel feed hose.

28.Connect fuel feed hose to fuel rail.

29.Fit stiffening bracket.

30.Tighten stiffening bracket and feed hose bolts.

31.Fit pressure regulator.

32.Fit inlet manifold chamber.THROTTLE HOUSING

Service repair no - 19.22.45

Remove

1.Loosen clip, disconnect hose from throttle

housing.

2.Disconnect multiplug from stepper motor.

3.Disconnect multiplug from throttle potentiometer.

4.Disconnect breather hose from throttle housing.

5.Loosen 2 nuts securing throttle cable to

abutment bracket and release cable.

6.Release throttle cable from cam.

7.Remove 4 nuts securing throttle housing to

flexible mounting.

8.Release throttle housing from studs.

Page 332 of 873

Mpi

9

REPAIR

Refit

9.Examine flexible mounting for splits or damage;

renew as necessary.

10.Thoroughly clean throttle housing and mating

face of flexible mounting.

11.Connect breather hose to throttle housing.

12.Position throttle housing to mounting studs, fit

nuts. Tighten to

7 Nm.

13.Connect throttle cable to cam.

14.Adjust throttle cable.

15.Connect multiplug to stepper motor.

16.Connect multiplug to throttle potentiometer.

17.Connect hose to throttle housing, tighten clip.FUEL PRESSURE REGULATOR

Service repair no - 19.45.06

Remove

1.Disconnect battery negative lead.

2.Position absorbant cloth around fuel pipe to fuel

rail union. Loosen bolt to relieve pressure.

Re-tighten bolt.

3.Release clip and disconnect fuel hose from

pressure regulator.

CAUTION: Plug the connectors.

4.Disconnect intake air temperature sensor

multiplug.

5.Remove 4 bolts securing pressure regulator

steady bracket to fuel rail and manifold, remove

steady bracket.

6.Disconnect vacuum hose from pressure

regulator.

7.Manoeuvre pressure regulator from fuel rail.

8.Discard 'O' ring.

Page 333 of 873

19FUEL SYSTEM

10

REPAIR

Refit

9.Clean pressure regulator and mating surfaces.

10.Fit new 'O' ring to pressure regulator.

11.Fit vacuum hose to pressure regulator.

12.Position pressure regulator.

13.Fit steady bracket.

14.Fit bolts and tighten.

15.Connect multiplug to air temperature sensor.

16.Remove plugs, fit fuel hose to regulator and

secure with clip.

17.Reconnect battery negative lead.OXYGEN SENSOR

Service repair no - 18.30.41 - L.H

Service repair no - 18.30.42 - R.H

Remove

1.Disconnect oxygen sensor multiplug.

2.Release multiplug from bracket.

3.Release harness lead from cable tie.

4.Remove oxygen sensor; recover sealing washer.

Refit

5.Fit sealing washer to oxygen sensor.

6.Fit oxygen sensor. Tighten to

55 Nm.

7.Secure multiplug to bracket, connect multiplug.

8.Secure harness lead with cable tie.

Page 335 of 873

CRUISE CONTROL

1

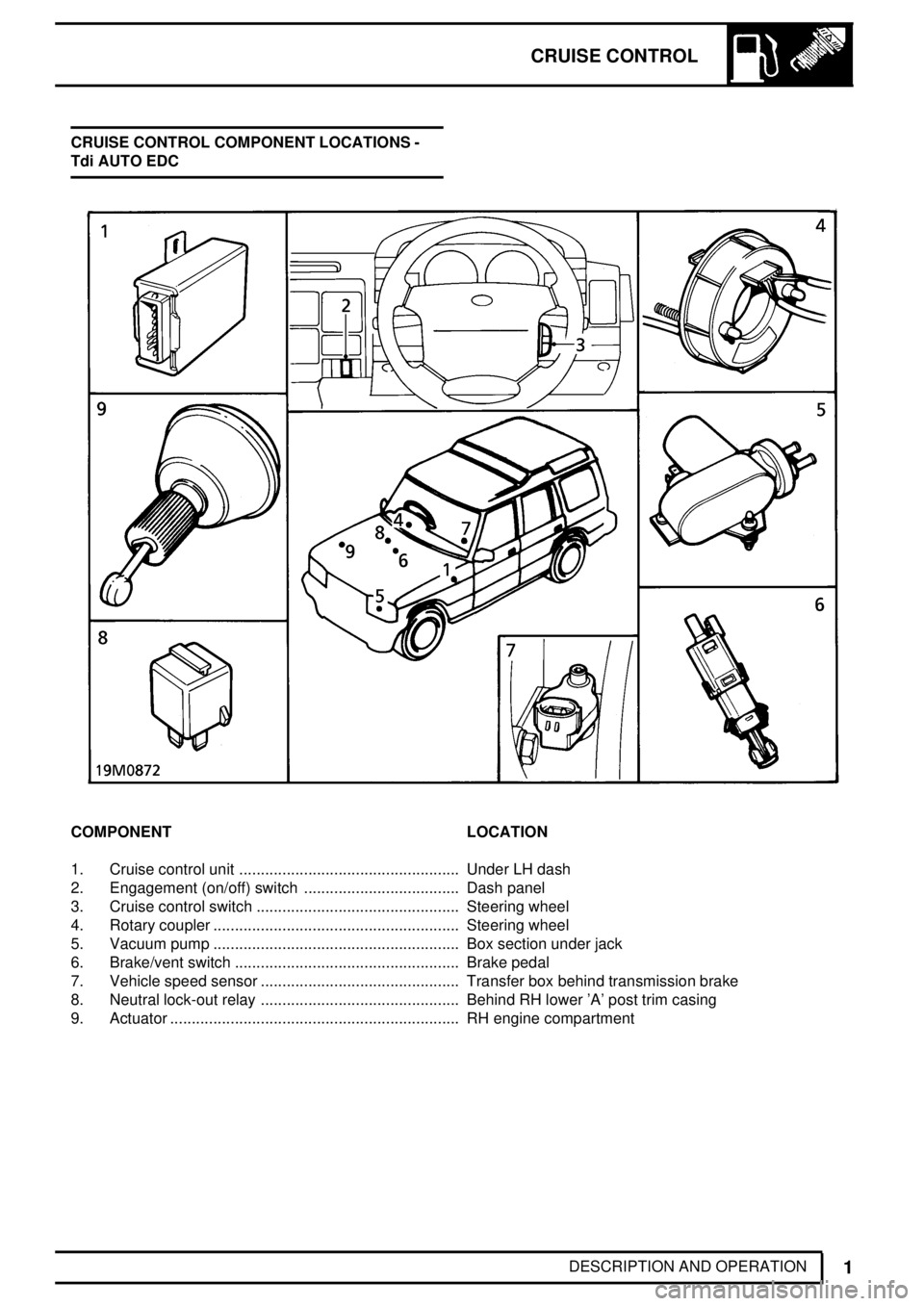

DESCRIPTION AND OPERATION CRUISE CONTROL COMPONENT LOCATIONS -

Tdi AUTO EDC

COMPONENT LOCATION

1. Cruise control unit Under LH dash...................................................

2. Engagement (on/off) switch Dash panel....................................

3. Cruise control switch Steering wheel...............................................

4. Rotary coupler Steering wheel.........................................................

5. Vacuum pump Box section under jack.........................................................

6. Brake/vent switch Brake pedal....................................................

7. Vehicle speed sensor Transfer box behind transmission brake..............................................

8. Neutral lock-out relay Behind RH lower 'A' post trim casing..............................................

9. Actuator RH engine compartment...................................................................

Page 336 of 873

19FUEL SYSTEM

2

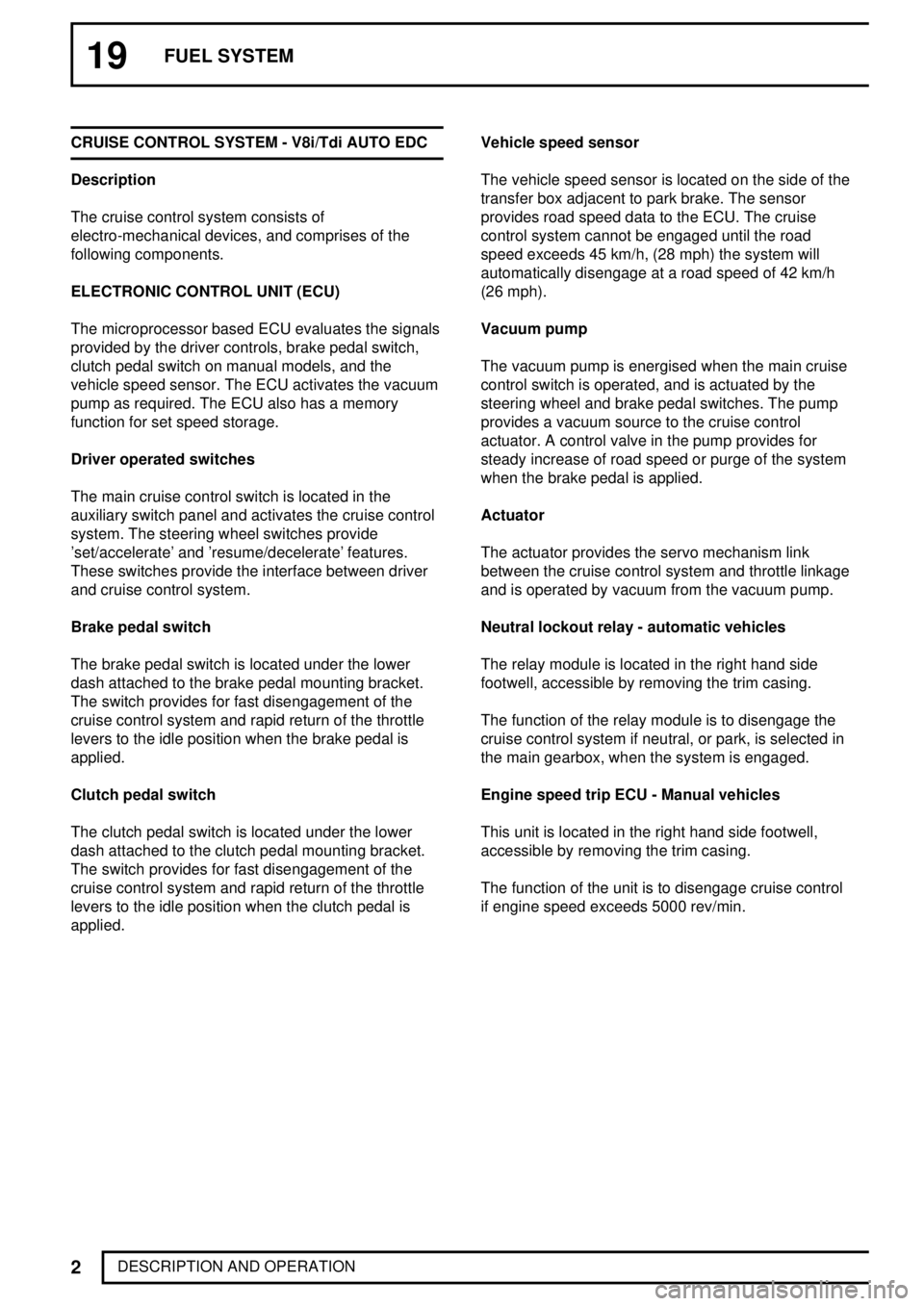

DESCRIPTION AND OPERATION CRUISE CONTROL SYSTEM - V8i/Tdi AUTO EDC

Description

The cruise control system consists of

electro-mechanical devices, and comprises of the

following components.

ELECTRONIC CONTROL UNIT (ECU)

The microprocessor based ECU evaluates the signals

provided by the driver controls, brake pedal switch,

clutch pedal switch on manual models, and the

vehicle speed sensor. The ECU activates the vacuum

pump as required. The ECU also has a memory

function for set speed storage.

Driver operated switches

The main cruise control switch is located in the

auxiliary switch panel and activates the cruise control

system. The steering wheel switches provide

'set/accelerate' and 'resume/decelerate' features.

These switches provide the interface between driver

and cruise control system.

Brake pedal switch

The brake pedal switch is located under the lower

dash attached to the brake pedal mounting bracket.

The switch provides for fast disengagement of the

cruise control system and rapid return of the throttle

levers to the idle position when the brake pedal is

applied.

Clutch pedal switch

The clutch pedal switch is located under the lower

dash attached to the clutch pedal mounting bracket.

The switch provides for fast disengagement of the

cruise control system and rapid return of the throttle

levers to the idle position when the clutch pedal is

applied.Vehicle speed sensor

The vehicle speed sensor is located on the side of the

transfer box adjacent to park brake. The sensor

provides road speed data to the ECU. The cruise

control system cannot be engaged until the road

speed exceeds 45 km/h, (28 mph) the system will

automatically disengage at a road speed of 42 km/h

(26 mph).

Vacuum pump

The vacuum pump is energised when the main cruise

control switch is operated, and is actuated by the

steering wheel and brake pedal switches. The pump

provides a vacuum source to the cruise control

actuator. A control valve in the pump provides for

steady increase of road speed or purge of the system

when the brake pedal is applied.

Actuator

The actuator provides the servo mechanism link

between the cruise control system and throttle linkage

and is operated by vacuum from the vacuum pump.

Neutral lockout relay - automatic vehicles

The relay module is located in the right hand side

footwell, accessible by removing the trim casing.

The function of the relay module is to disengage the

cruise control system if neutral, or park, is selected in

the main gearbox, when the system is engaged.

Engine speed trip ECU - Manual vehicles

This unit is located in the right hand side footwell,

accessible by removing the trim casing.

The function of the unit is to disengage cruise control

if engine speed exceeds 5000 rev/min.