differential LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 410 of 873

TRANSFER GEARBOX

3

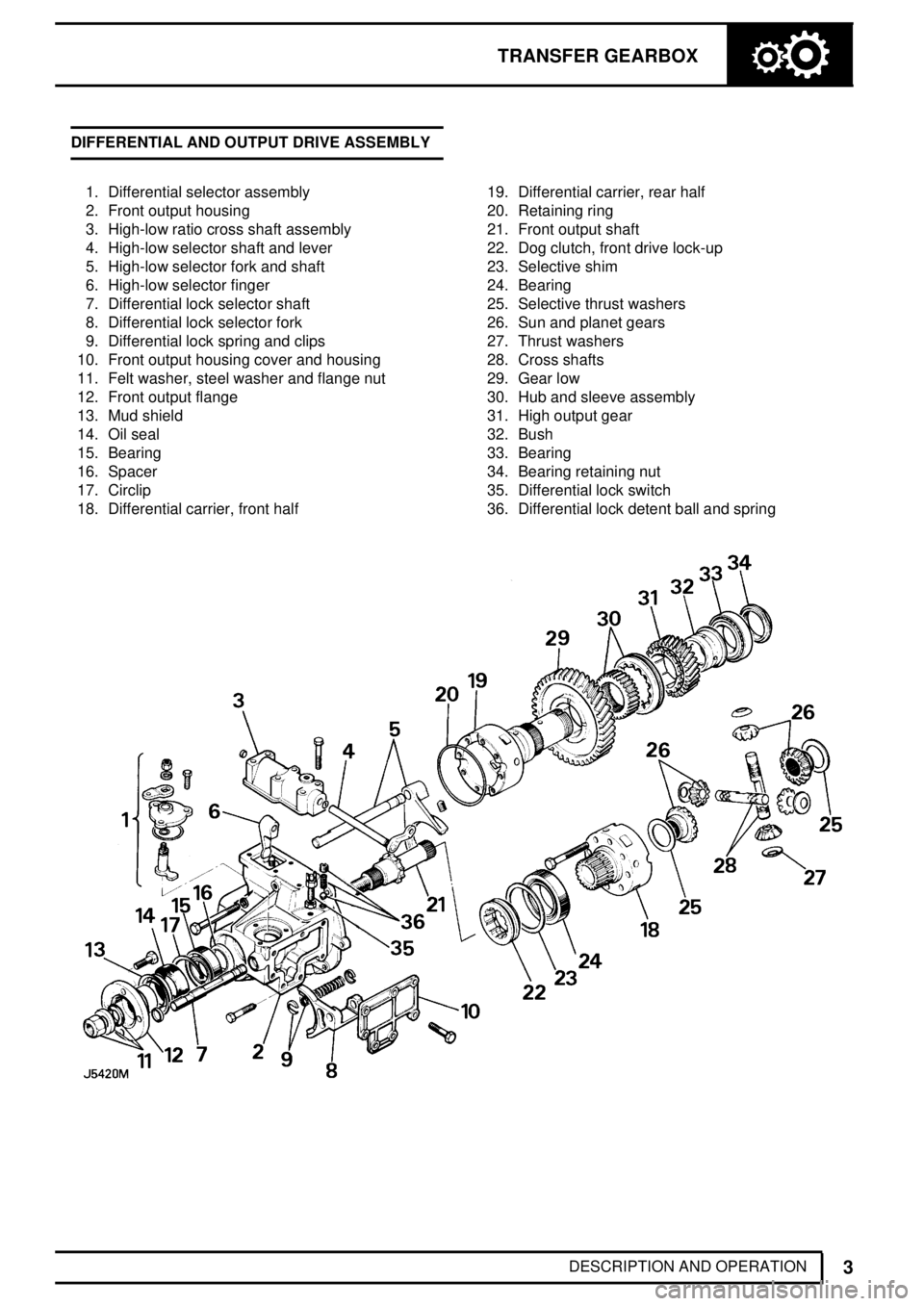

DESCRIPTION AND OPERATION DIFFERENTIAL AND OUTPUT DRIVE ASSEMBLY

1. Differential selector assembly

2. Front output housing

3. High-low ratio cross shaft assembly

4. High-low selector shaft and lever

5. High-low selector fork and shaft

6. High-low selector finger

7. Differential lock selector shaft

8. Differential lock selector fork

9. Differential lock spring and clips

10. Front output housing cover and housing

11. Felt washer, steel washer and flange nut

12. Front output flange

13. Mud shield

14. Oil seal

15. Bearing

16. Spacer

17. Circlip

18. Differential carrier, front half19. Differential carrier, rear half

20. Retaining ring

21. Front output shaft

22. Dog clutch, front drive lock-up

23. Selective shim

24. Bearing

25. Selective thrust washers

26. Sun and planet gears

27. Thrust washers

28. Cross shafts

29. Gear low

30. Hub and sleeve assembly

31. High output gear

32. Bush

33. Bearing

34. Bearing retaining nut

35. Differential lock switch

36. Differential lock detent ball and spring

Page 416 of 873

![LAND ROVER DISCOVERY 1995 User Guide 41TRANSFER GEARBOX

2

REPAIR Remove

1.Site vehicle on a ramp [hoist].

2.Disconnect battery negative lead.

3.Remove fan cowl from radiator.

4.Remove transfer gear lever knob and gaiter.

5.Raise vehicle LAND ROVER DISCOVERY 1995 User Guide 41TRANSFER GEARBOX

2

REPAIR Remove

1.Site vehicle on a ramp [hoist].

2.Disconnect battery negative lead.

3.Remove fan cowl from radiator.

4.Remove transfer gear lever knob and gaiter.

5.Raise vehicle](/img/64/57248/w960_57248-415.png)

41TRANSFER GEARBOX

2

REPAIR Remove

1.Site vehicle on a ramp [hoist].

2.Disconnect battery negative lead.

3.Remove fan cowl from radiator.

4.Remove transfer gear lever knob and gaiter.

5.Raise vehicle on ramp [hoist].

6.Drain oil and refit plug.

7.Detach heat shield at front exhaust pipe to

manifold.

8.Disconnect electrics to Lambda sensors.

9.Remove catalytic converter assembly.

10.Remove chassis crossmember from under

gearbox.

11.Remove heat shield from speedometer cable at

transfer gearbox.

12.Remove clamp and disconnect speedometer

cable from transfer gearbox. Tie cable to one

side.

13.Mark for reassembly then disconnect propeller

shaft to output flange, tie to one side.

14.Repeat on front propeller shaft to output flange.

15.Remove bolts retaining silencer front and rear

securing brackets and tie silencer to one side.

16.Place four 30mm long spacers between top of

hoist and adaptor plate, at securing points, and

secure adaptor plate to hoist.17.Remove four central bolts from transfer gearbox

bottom cover, move hoist into position and

secure adaptor plate to transfer gearbox.

18.Adjust hoist to take weight of transfer gearbox.

19.Remove tie bar, transfer gearbox to main

gearbox.

20.Remove nuts and bolts securing right transfer

gearbox mounting bracket to chassis.

21.Repeat for left mounting bracket. Removal of

these fixings will also free speedometer

transducer bracket.

22.Remove right side mounting bracket to flexible

mounting rubber.

23.Lower hoist until rear brake drum clears

passenger footwell. Check engine does not

crush any components while lowering.

24.Loosen park brake adjustment nut.

25.Remove park brake drum.

26.Remove park brake assembly complete from

rear output flange.

27.Disconnect leads from transfer gearbox

temperature sensor and differential lock warning

light switch.

28.Remove banjo bolt from breather pipe, retrieve

sealing washers and lay pipe aside.

29.Remove split [cotter] pin and washers securing

differential lock to connecting rod and disconnect

rod from lever.

30.Select low range transfer gearbox position.

31.Remove high/low rod lower lock nut and remove

rod from yoke.

32.Position hoist jack channel under bell housing.

33.Using wooden block support the main gearbox

and bell housing.

34.Remove upper and lower bolts securing transfer

gearbox to main gearbox.

35.Fit guide studs 18G 1425 to main gearbox and

move transfer gearbox rearwards to detach.

Page 417 of 873

TRANSFER GEARBOX

3

REPAIR Refit

36.Select 'P' in main gearbox, with low range and

differential lock selected in transfer gearbox.

37.Secure transfer gearbox to adaptor plate on

lifting hoist.

38.Ensure joint faces of transfer and main

gearboxes are clean and guide studs 18G 1425

are fitted.

39.Raise hoist until transfer gearbox can be located

over guide studs to main gearbox. At the same

time locate high/low lower link to yoke.

40.Remove guide studs and secure transfer

gearbox to main gearbox.41.Complete refitting by reversing removal

procedure, noting the following important points.

42.After removal of adaptor plate from transfer

gearbox, clean threads of four bottom cover

bolts, coat threads with Loctite 290 and fit

together with spring washers. Tighten to

25Nm

43.Add correct grade of oil to transfer gearbox to oil

level plug hole.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

44.Check main gearbox oil level.

45.Check operation of parking brake and adjust as

necessary.

See SECTION 10, Maintenance,

Vehicle Interior

Page 419 of 873

TRANSFER GEARBOX

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

LT230T Transfer gearbox

Pinch bolt - operating arm to crank arm 9......................................................

End cover gear change housing 9.................................................................

Bottom cover to transfer case 25....................................................................

Front output housing to transfer case 25........................................................

Cross shaft housing to front output housing 25...............................................

Gear change housing 25.................................................................................

Pivot shaft to link arm 25.................................................................................

Connecting rod to adjustable clevis 25...........................................................

Anti-rotation plate intermediate shaft 25.........................................................

Front output housing cover 25........................................................................

Pivot bracket to extension housing 25............................................................

Finger housing to front output housing 25......................................................

Bearing housing to transfer case 25...............................................................

Brake drum to coupling flange 25...................................................................

Bearing housing cover to transfer gearbox 45................................................

Rear output speedometer housing to transfer gearbox 45..............................

Selector finger to cross shaft high/low 25.......................................................

Selector fork, high/low to shaft 25...................................................................

Transmission brake to speedometer housing 72............................................

Gate plate to grommet plate 9.......................................................................

Gearbox to transfer case 45...........................................................................

Oil drain plug 30..............................................................................................

Oil filler/level plug 30.......................................................................................

Differential case (front to rear) 60...................................................................

Output flanges 162...........................................................................................

Differential case rear stake nut 72..................................................................

Transfer breather 15.......................................................................................

Transfer box front drive flange to drive shaft 45..............................................

Transfer box rear drive flange to drive shaft 45..............................................

Transfer gearbox mounting brackets to chassis 30........................................

Mounting brackets to transfer gearbox 55......................................................

Mounting rubbers to mounting brackets 21.....................................................

Shiftlock

Shiftlock screws 9..........................................................................................

Neutral switch 25............................................................................................

Page 420 of 873

41TRANSFER GEARBOX

2

SPECIFICATIONS, TORQUE LT230T TRANSFER GEARBOX DATA

High range gear end - float 0,05 to 0,15 mm..............................................

Front differential bearing pre - load 0.56 to 1.69 Nm..................................

Input gear bearing pre - load 0.56 to 2.25 Nm............................................

Intermediate shaft bearing pre - load 0.56 to 1.69 Nm...............................

JOINT SEALANT

Joint faces use BLS. 22SE03 TYPE 2.................................................................

Shiftlock solenoid cover HYLOSIL RTV...................................................

Neutral switch HYLOMAR...................................................................

Page 440 of 873

ZF

3

REPAIR 19.Disconnect rear propeller shaft to output flange,

and tie to one side.

20.Repeat instructions 18 and 19 on front propeller

shaft to main gearbox.

21.Remove bolts retaining silencer front and rear

securing brackets and tie silencer to one side.

22.Disconnect oil cooler feed and return pipes from

bottom and side of main gearbox.

23.Release cooler pipes from clamp at engine sump

and remove distance piece.

24.Blank pipe ends and unions.

25.Move oil cooler pipes clear of transmission and

tie aside.

26.Disconnect selector cable from operating lever.

27.Disconnect inhibitor switch at multiplug.

28.Attach adaptor plate to hoist.

29.Remove two bolts from transfer gearbox rear

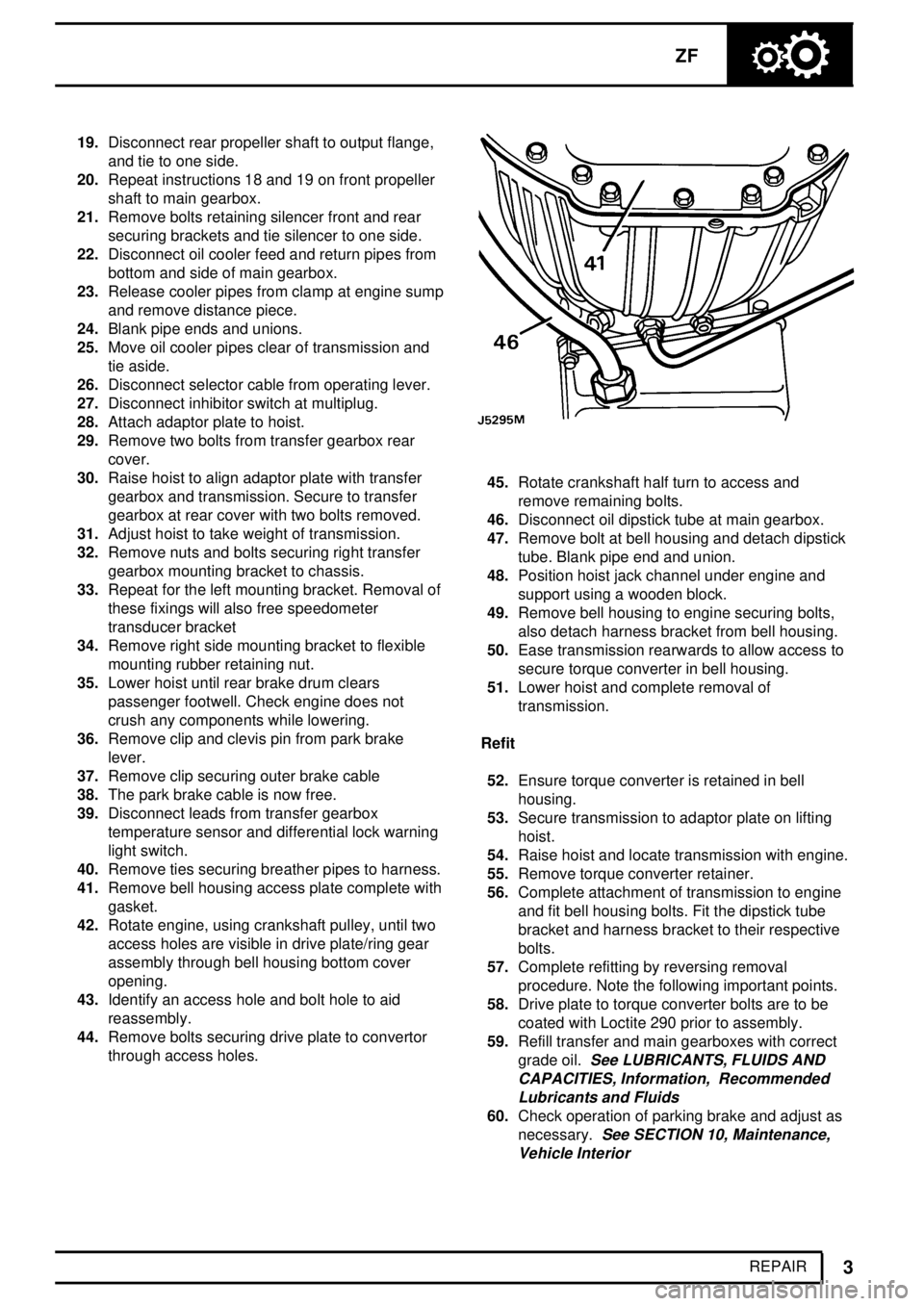

cover.

30.Raise hoist to align adaptor plate with transfer

gearbox and transmission. Secure to transfer

gearbox at rear cover with two bolts removed.

31.Adjust hoist to take weight of transmission.

32.Remove nuts and bolts securing right transfer

gearbox mounting bracket to chassis.

33.Repeat for the left mounting bracket. Removal of

these fixings will also free speedometer

transducer bracket

34.Remove right side mounting bracket to flexible

mounting rubber retaining nut.

35.Lower hoist until rear brake drum clears

passenger footwell. Check engine does not

crush any components while lowering.

36.Remove clip and clevis pin from park brake

lever.

37.Remove clip securing outer brake cable

38.The park brake cable is now free.

39.Disconnect leads from transfer gearbox

temperature sensor and differential lock warning

light switch.

40.Remove ties securing breather pipes to harness.

41.Remove bell housing access plate complete with

gasket.

42.Rotate engine, using crankshaft pulley, until two

access holes are visible in drive plate/ring gear

assembly through bell housing bottom cover

opening.

43.Identify an access hole and bolt hole to aid

reassembly.

44.Remove bolts securing drive plate to convertor

through access holes.

45.Rotate crankshaft half turn to access and

remove remaining bolts.

46.Disconnect oil dipstick tube at main gearbox.

47.Remove bolt at bell housing and detach dipstick

tube. Blank pipe end and union.

48.Position hoist jack channel under engine and

support using a wooden block.

49.Remove bell housing to engine securing bolts,

also detach harness bracket from bell housing.

50.Ease transmission rearwards to allow access to

secure torque converter in bell housing.

51.Lower hoist and complete removal of

transmission.

Refit

52.Ensure torque converter is retained in bell

housing.

53.Secure transmission to adaptor plate on lifting

hoist.

54.Raise hoist and locate transmission with engine.

55.Remove torque converter retainer.

56.Complete attachment of transmission to engine

and fit bell housing bolts. Fit the dipstick tube

bracket and harness bracket to their respective

bolts.

57.Complete refitting by reversing removal

procedure. Note the following important points.

58.Drive plate to torque converter bolts are to be

coated with Loctite 290 prior to assembly.

59.Refill transfer and main gearboxes with correct

grade oil.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

60.Check operation of parking brake and adjust as

necessary.

See SECTION 10, Maintenance,

Vehicle Interior

Page 443 of 873

44AUTOMATIC GEARBOX

6

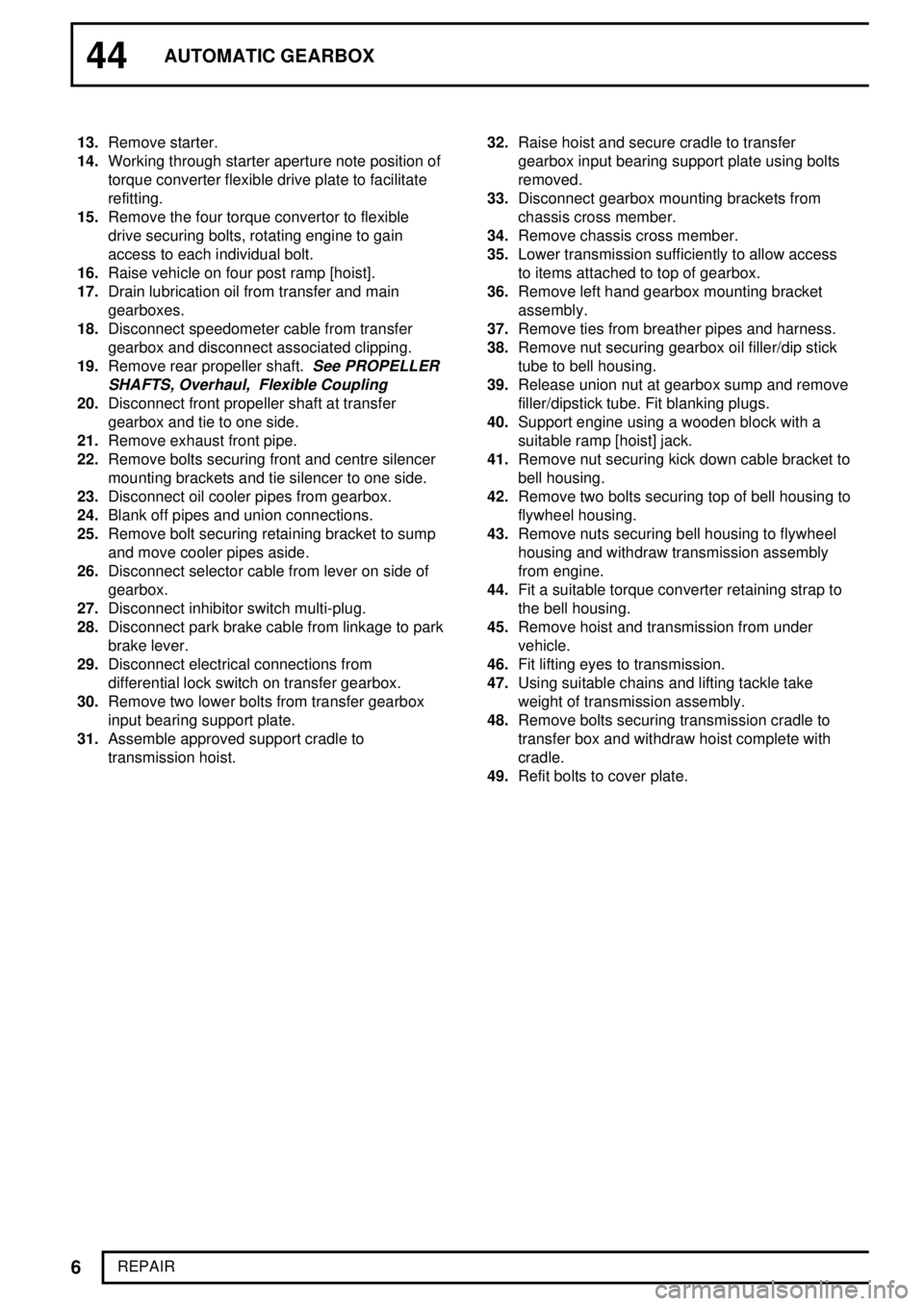

REPAIR 13.Remove starter.

14.Working through starter aperture note position of

torque converter flexible drive plate to facilitate

refitting.

15.Remove the four torque convertor to flexible

drive securing bolts, rotating engine to gain

access to each individual bolt.

16.Raise vehicle on four post ramp [hoist].

17.Drain lubrication oil from transfer and main

gearboxes.

18.Disconnect speedometer cable from transfer

gearbox and disconnect associated clipping.

19.Remove rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

20.Disconnect front propeller shaft at transfer

gearbox and tie to one side.

21.Remove exhaust front pipe.

22.Remove bolts securing front and centre silencer

mounting brackets and tie silencer to one side.

23.Disconnect oil cooler pipes from gearbox.

24.Blank off pipes and union connections.

25.Remove bolt securing retaining bracket to sump

and move cooler pipes aside.

26.Disconnect selector cable from lever on side of

gearbox.

27.Disconnect inhibitor switch multi-plug.

28.Disconnect park brake cable from linkage to park

brake lever.

29.Disconnect electrical connections from

differential lock switch on transfer gearbox.

30.Remove two lower bolts from transfer gearbox

input bearing support plate.

31.Assemble approved support cradle to

transmission hoist.32.Raise hoist and secure cradle to transfer

gearbox input bearing support plate using bolts

removed.

33.Disconnect gearbox mounting brackets from

chassis cross member.

34.Remove chassis cross member.

35.Lower transmission sufficiently to allow access

to items attached to top of gearbox.

36.Remove left hand gearbox mounting bracket

assembly.

37.Remove ties from breather pipes and harness.

38.Remove nut securing gearbox oil filler/dip stick

tube to bell housing.

39.Release union nut at gearbox sump and remove

filler/dipstick tube. Fit blanking plugs.

40.Support engine using a wooden block with a

suitable ramp [hoist] jack.

41.Remove nut securing kick down cable bracket to

bell housing.

42.Remove two bolts securing top of bell housing to

flywheel housing.

43.Remove nuts securing bell housing to flywheel

housing and withdraw transmission assembly

from engine.

44.Fit a suitable torque converter retaining strap to

the bell housing.

45.Remove hoist and transmission from under

vehicle.

46.Fit lifting eyes to transmission.

47.Using suitable chains and lifting tackle take

weight of transmission assembly.

48.Remove bolts securing transmission cradle to

transfer box and withdraw hoist complete with

cradle.

49.Refit bolts to cover plate.

Page 444 of 873

ZF

7

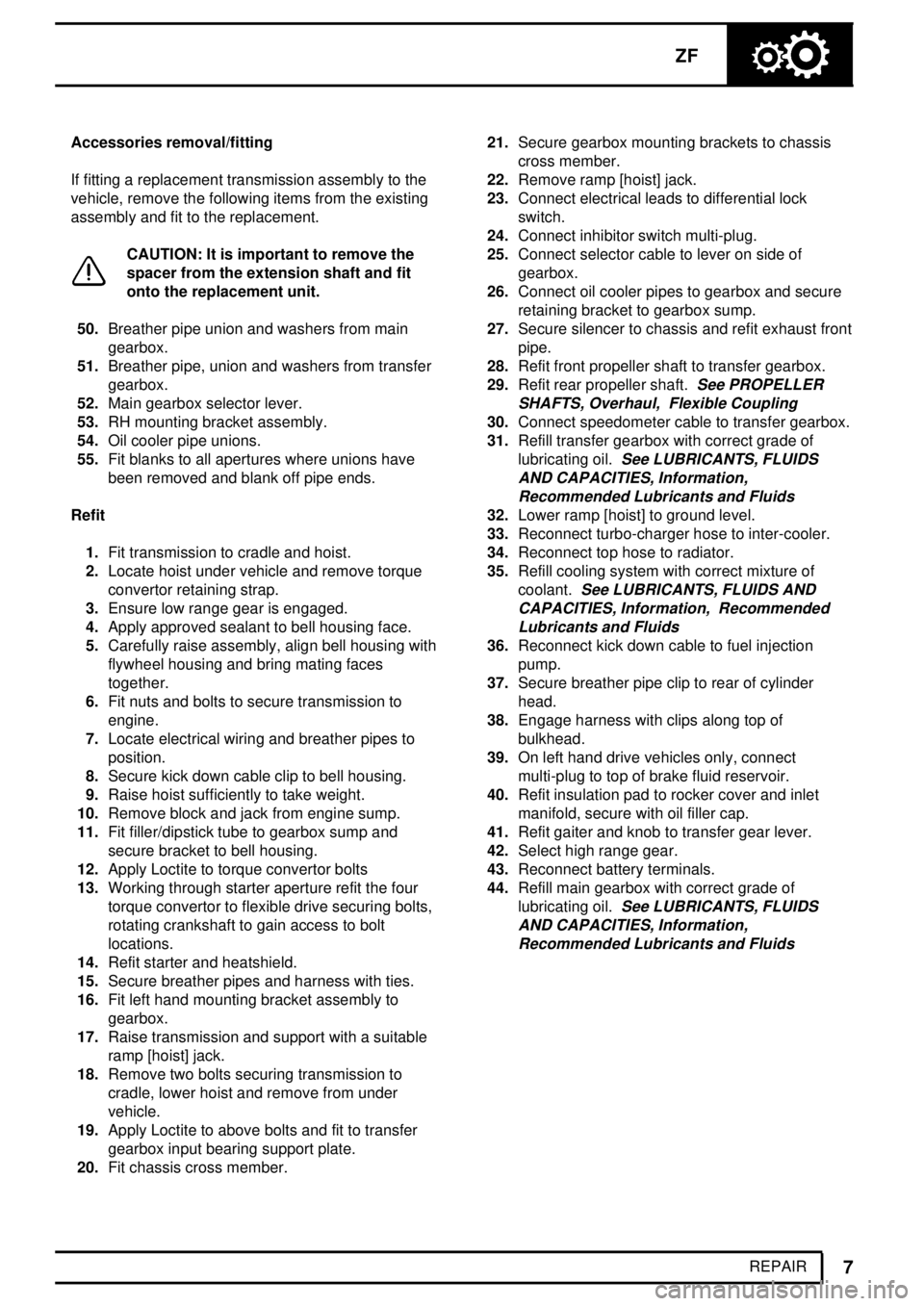

REPAIR Accessories removal/fitting

If fitting a replacement transmission assembly to the

vehicle, remove the following items from the existing

assembly and fit to the replacement.

CAUTION: It is important to remove the

spacer from the extension shaft and fit

onto the replacement unit.

50.Breather pipe union and washers from main

gearbox.

51.Breather pipe, union and washers from transfer

gearbox.

52.Main gearbox selector lever.

53.RH mounting bracket assembly.

54.Oil cooler pipe unions.

55.Fit blanks to all apertures where unions have

been removed and blank off pipe ends.

Refit

1.Fit transmission to cradle and hoist.

2.Locate hoist under vehicle and remove torque

convertor retaining strap.

3.Ensure low range gear is engaged.

4.Apply approved sealant to bell housing face.

5.Carefully raise assembly, align bell housing with

flywheel housing and bring mating faces

together.

6.Fit nuts and bolts to secure transmission to

engine.

7.Locate electrical wiring and breather pipes to

position.

8.Secure kick down cable clip to bell housing.

9.Raise hoist sufficiently to take weight.

10.Remove block and jack from engine sump.

11.Fit filler/dipstick tube to gearbox sump and

secure bracket to bell housing.

12.Apply Loctite to torque convertor bolts

13.Working through starter aperture refit the four

torque convertor to flexible drive securing bolts,

rotating crankshaft to gain access to bolt

locations.

14.Refit starter and heatshield.

15.Secure breather pipes and harness with ties.

16.Fit left hand mounting bracket assembly to

gearbox.

17.Raise transmission and support with a suitable

ramp [hoist] jack.

18.Remove two bolts securing transmission to

cradle, lower hoist and remove from under

vehicle.

19.Apply Loctite to above bolts and fit to transfer

gearbox input bearing support plate.

20.Fit chassis cross member.21.Secure gearbox mounting brackets to chassis

cross member.

22.Remove ramp [hoist] jack.

23.Connect electrical leads to differential lock

switch.

24.Connect inhibitor switch multi-plug.

25.Connect selector cable to lever on side of

gearbox.

26.Connect oil cooler pipes to gearbox and secure

retaining bracket to gearbox sump.

27.Secure silencer to chassis and refit exhaust front

pipe.

28.Refit front propeller shaft to transfer gearbox.

29.Refit rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

30.Connect speedometer cable to transfer gearbox.

31.Refill transfer gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

32.Lower ramp [hoist] to ground level.

33.Reconnect turbo-charger hose to inter-cooler.

34.Reconnect top hose to radiator.

35.Refill cooling system with correct mixture of

coolant.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

36.Reconnect kick down cable to fuel injection

pump.

37.Secure breather pipe clip to rear of cylinder

head.

38.Engage harness with clips along top of

bulkhead.

39.On left hand drive vehicles only, connect

multi-plug to top of brake fluid reservoir.

40.Refit insulation pad to rocker cover and inlet

manifold, secure with oil filler cap.

41.Refit gaiter and knob to transfer gear lever.

42.Select high range gear.

43.Reconnect battery terminals.

44.Refill main gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 467 of 873

PROPELLER SHAFTS

1

DESCRIPTION AND OPERATION PROPELLER SHAFT ALIGNMENT

Description

The front and rear propeller shafts have non-constant

velocity 'Hooks' type universal joints, with needle roller

bearings. The bearing cups are pre-packed with

lubricant on assembly and a grease nipple is fitted for

servicing as specified, in maintenance section.

Both shafts have Rilsan coated sliding splines to

accommodate the variation in distance between the

axles and transmission. The splines are pre-packed

with lubricant and sealed.

The rear shaft is fitted with a conventional joint at

gearbox end and the sliding joint sealed with a rubber

gaiter. An SGF rubber coupling is fitted at the

differential end of the shaft.

The front shaft which is shorter than the rear is

'Phased', with the joints at each end, A and B

mis-aligned as shown in RR4199.

The phasing is necessary on the front shaft only to

allow for greater variation in angular changes.

Catalyst vehicles

The front shaft is 'phased' as above but is of solid bar

construction.

Page 472 of 873

47PROPELLER SHAFTS

4

REPAIR REAR PROPELLER SHAFT

Service repair no - 47.15.03

NOTE: SGF rubber coupling should be left

attached to propeller shaft. Only remove

coupling from propeller shaft if

replacement is required.

Remove

1.Scribe alignment marks on flanges at both ends

of propeller shaft to ensure correct refitting.

2.Remove three nuts and bolts securing flexible

coupling to axle flange.

3.Remove nuts securing propeller shaft flange to

transfer gearbox.

4.Raise propeller shaft at gearbox end detach

coupling from spigot at differential and withdraw

shaft.

NOTE: For replacement of spigot (pinion

flange centralising peg).

See REAR AXLE

AND FINAL DRIVE, Overhaul, Axle

Differential Assembly

Overhaul

Service repair no - 47.15.12

NOTE: Refer to front propeller shaft

overhaul procedure for gearbox end of

shaft. The SGF rubber coupling is a

non-serviceable item.

Refit

5.Locate flexible coupling over spigot, align

scribed marks and secure at transfer gearbox.

Tighten to

47 Nm.

6.Secure flexible coupling to axle flange with three

nuts and bolts and Tighten to

78 Nm.

FLEXIBLE COUPLING

NOTE: Flexible coupling should only be

removed if a new coupling is to be fitted.

Remove

1.Remove rear propeller shaft.

See Rear

Propeller Shaft.

2.Remove nuts and bolts securing flexible

coupling to propeller shaft.

Refit

3.Reverse removal procedure. Fit nuts and bolts.

Tighten to

78 Nm.