differential LAND ROVER DISCOVERY 1995 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 486 of 873

51REAR AXLE AND FINAL DRIVE

8

OVERHAUL CROWN WHEEL/PINION BACKLASH

ADJUSTMENT

63.Place differential housing in pinion housing.

64.Fit bearing caps and partly tighten bolts.

65.Fit bearing adjusting nuts.

66.Mesh crown wheel to pinion. Using service tool

LRT-54-508 loosen left bearing adjuster nut.

67.Tighten right nut until crown wheel/pinion

backlash is just removed.68.Tighten left nut until it contacts bearing. Continue

turning until a backlash of 0,10 to 0,17 mm is

met.DO NOTloosen right nut otherwise bearing

preload will be affected.

69.Fit locking fingers and roll pins. Align locking

finger with a slot.

70.Evenly tighten bearing cap bolts to

90 Nm.

71.Recheck crown wheel/pinion backlash.

72.Lubricate bearings and gears.

Page 490 of 873

REAR AXLE AND FINAL DRIVE

1

SPECIFICATIONS, TORQUE AXLE DIFFERENTIAL DATA

Pinion bearing pre-load:

(new bearings) 3 Nm........................................................

(bearings bedded in) 1,5 Nm...............................................

Crown wheel run-out 0,10 mm........................................................

Crown wheel/pinion backlash 0,10 to 0,17 mm...........................................

REAR HUB

Rear hub end float 0,010 mm............................................................

TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

REAR AXLE

Pinion housing to axle case 41.......................................................................

Crown wheel to differential case 58................................................................

Differential bearing cap to pinion housing 90..................................................

Differential drive flange to drive shaft 47.........................................................

Bevel pinion nut 129........................................................................................

Lower link to axle 176......................................................................................

Pivot bracket ball joint to axle 176...................................................................

REAR HUB ABS VEHICLES

Hub driving member to hub 65 *.......................................................................

Brake disc to hub 73 *......................................................................................

Stub axle rear to axle case 65........................................................................

Brake caliper to axle case 82..........................................................................

Disc shield to axle case 11.............................................................................

Sensor ring to brake disc ABS 9....................................................................

* Apply loctite 270 prior to assembly.

Page 492 of 873

REAR AXLE AND FINAL DRIVE

1

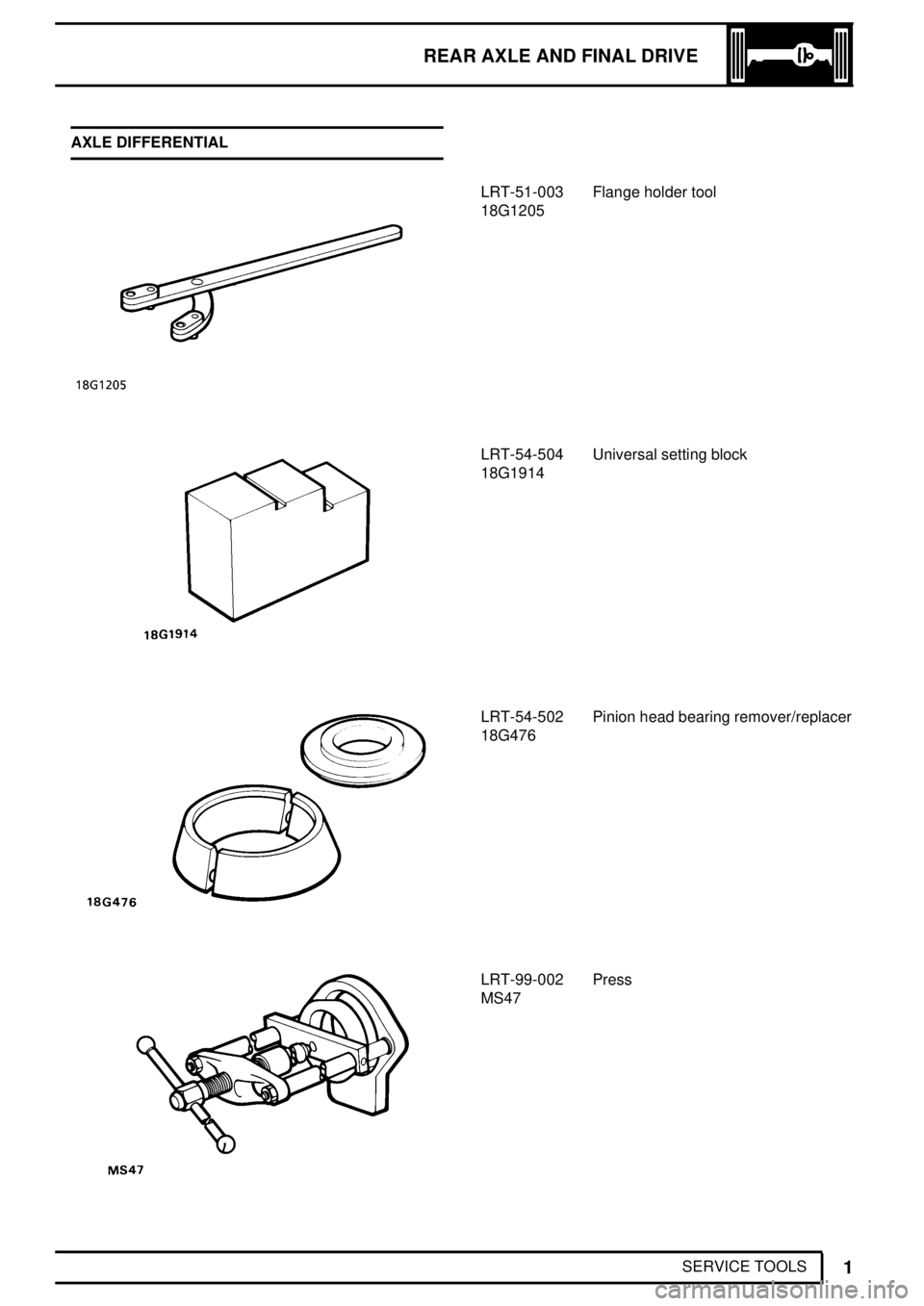

SERVICE TOOLS AXLE DIFFERENTIAL

LRT-51-003 Flange holder tool

18G1205

LRT-54-504 Universal setting block

18G1914

LRT-54-502 Pinion head bearing remover/replacer

18G476

LRT-99-002 Press

MS47

Page 496 of 873

FRONT AXLE AND FINAL DRIVE

1

DESCRIPTION AND OPERATION DESCRIPTION

The welded steel front axle casing houses a separate

spiral bevel type differential unit, which is off set to the

right of the vehicle centre line. The differential unit

drives the front wheels via the axle shafts and

constant velocity joints which are totally enclosed in

the spherical and swivel housings.

The front axles fitted with ABS brakes or non ABS

brakes are of the same construction except for

different top swivel pins in the swivel housing and a

sensor on the constant velocity joint.

Front axle - ABS

The front wheels are pivoted on taper roller bearings

19 at the bottom of the swivel housing and a 'Rialco

bush' 25 at the top. The top swivel pin also houses the

ABS pickup (electrical connection) as shown in the

main illustration, J5367.

Front axle - non ABS

The front wheels are pivoted on tape roller bearings at

the top (see insert) and bottom of the swivel housing.

The wheel hubs on all axles are supported by two

taper bearings and driven by drive flanges which are

splined to the one piece, stub shaft/constant velocity

joint.

Lubrication

The differential, swivel pin housing and wheel hubs

are indiviudally lubricated and separated by oil seals 7

and 8 to prevent oil transfer across the axle when the

vehicle is traversing steep inclines. The wheel

bearings are lubricated with grease and the swivel

housing and differential with oil.

Ventilation

Ventilation of the differential is through a plastic pipe 2

which terminates at a high level in the vehicle on both

ABS and non ABS axles. The swivel housings

ventilate through axle shaft oil seals 8 into the

differential and the hub bearings vent via the oil seals

into swivel housing.

Page 498 of 873

FRONT AXLE AND FINAL DRIVE

1

FAULT DIAGNOSIS FAULT DIAGNOSIS

Complaint - Oil leaks

An external leak of lubrication can be caused by a

faulty internal seal. For example, if the seals which

separate the differential from the swivel housings are

faulty and the vehicle is operating or parked on an

embankment, oil may leak across the axle leaving one

swivel with a high level and the other swivel and

differential lacking lubrication.

See 'Description and Operation' for illustrations of oil

seal locations.

When investigating leaks or checking oil levels, it is

essential that all the lubrication is drained from any

housing with a high level and that the other levels are

checked.

Swivel oil should be checked for signs of grease

leaking from the hub bearings and the hub grease

should not contain oil.

Check that the axle ventilation system is clear, as a

blockage can cause internal pressure to force oil past

the seals.

If the vehicle is driven in deep water with defective oil

seals, water may contaminate the lubricants and when

checked, give a false impression that the housing has

been overfilled with oil.

Do not assume that a high oil level is due to over

filling or, that a low level is because of an external

leak.

Page 503 of 873

FRONT AXLE AND FINAL DRIVE

1

OVERHAUL FRONT DIFFERENTIAL

Service repair no - 54.10.07.

Overhaul

The front and rear differentials are the same. When

overhauling front differential.

See REAR AXLE AND

FINAL DRIVE, Overhaul, Axle Differential

Assembly

FRONT HUB

Service repair no - 60.26.14.

Overhaul

1.Remove front hub assembly.

See Repair,

Front Hub Assembly

2.Remove outer bearing.

3.Mark, for reassembly, relationship between hub

and brake disc, if original hub is to be refitted.

4.Remove five bolts and separate hub from brake

disc.5.Drift out grease seal and inner bearing from hub

and discard seal.

6.Drift out inner and outer bearing tracks.

7.Clean hub and drift in inner and outer bearing

tracks.

8.Pack hub inner bearing with recommended

grease and fit to hub.

HUB COMPONENTS

1. Dust cap.

2. Drive shaft circlip.

3. Drive shaft shim.

4. Drive member.

5. Drive member joint

washer.

6. Drive member

retaining bolt.

7. Lock nut.8. Lock washer.

9. Hub adjusting nut.

10. Spacing washer.

11. Outer bearing.

12. Hub.

13. Inner bearing.

14. Grease seal.

15. Brake disc.

16. Disc retaining bolt.

Page 509 of 873

FRONT AXLE AND FINAL DRIVE

7

OVERHAUL Fit driveshaft and stub axle

59.Insert axle shaft, and when differential splines

are engaged, push assembly in fully.

CAUTION: Take care not to damage axle

shaft oil seals.

60.Place a new joint washer in position on swivelpin

housing to stub axle mating face. Coat threads

of stub axle bolts with Loctite 270.

61.Fit stub axle with flat at 12 o'clock position.

CAUTION: Ensure that constant velocity

joint bearing journal is butted against

thrust ring on stub axle. Before stub axle

is secured.

62.Place mud shield in position and secure stub

axle to swivel pin housing with six bolts and

tighten evenly to

65 Nm.

63.Fit brake jump hoses to brake jump hose

bracket.

64.Fit front hub complete assembly.

See Repair,

Front Hub Assembly

65.Check swivel pin housing oil drain plug is fitted.

66.Fill swivel assembly to correct level, with new oil.

See SECTION 10, Maintenance, Under

Vehicle Maintenance

67.Set steering lock stop bolts to provide a

clearance of 20mm.

See STEERING,

Adjustment, Steering Lock Stops

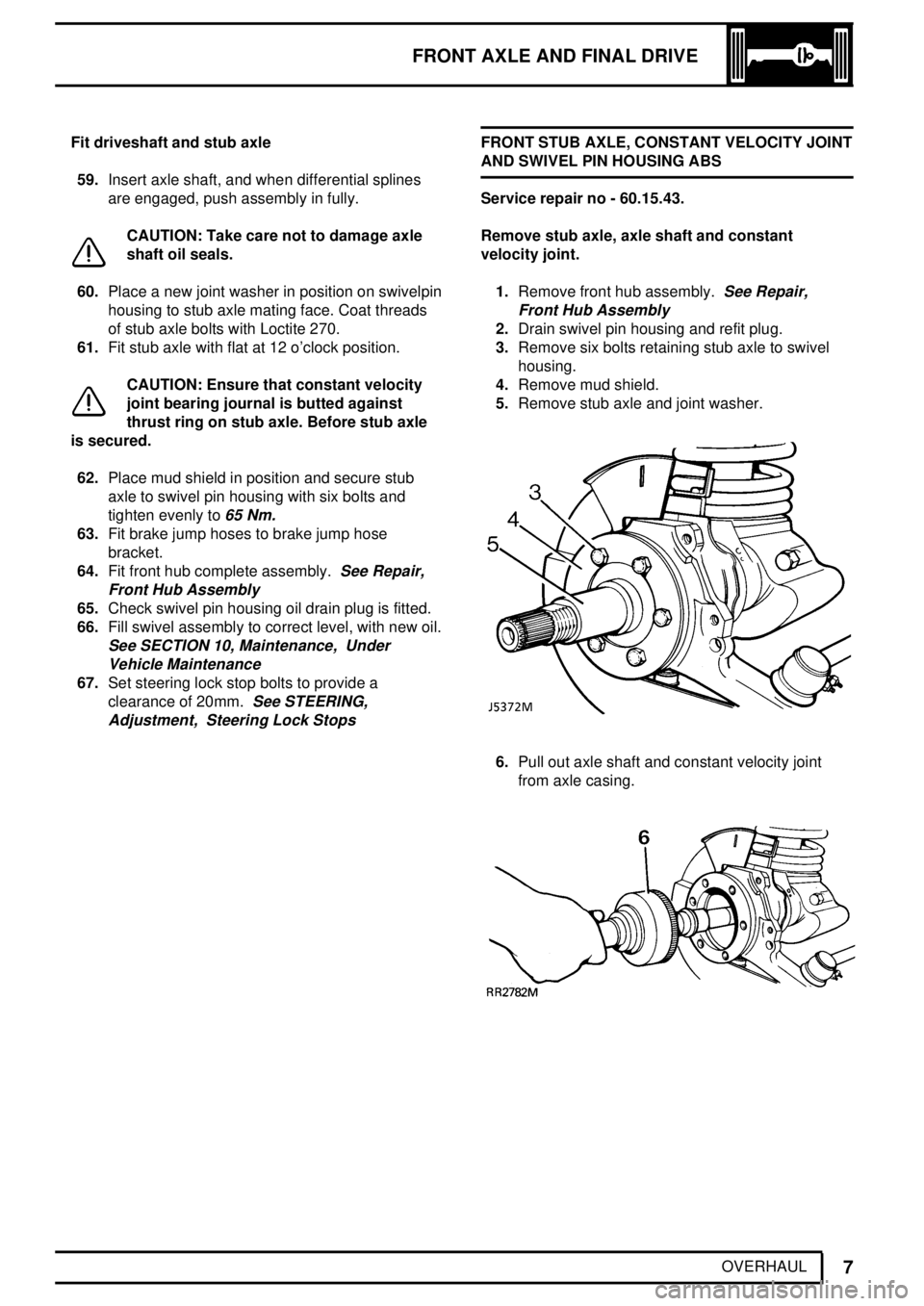

FRONT STUB AXLE, CONSTANT VELOCITY JOINT

AND SWIVEL PIN HOUSING ABS

Service repair no - 60.15.43.

Remove stub axle, axle shaft and constant

velocity joint.

1.Remove front hub assembly.

See Repair,

Front Hub Assembly

2.Drain swivel pin housing and refit plug.

3.Remove six bolts retaining stub axle to swivel

housing.

4.Remove mud shield.

5.Remove stub axle and joint washer.

6.Pull out axle shaft and constant velocity joint

from axle casing.

Page 513 of 873

FRONT AXLE AND FINAL DRIVE

11

OVERHAUL Fit driveshaft and stub axle

59.Insert axle shaft, and when differential splines

are engaged, push assembly in fully.

CAUTION: Take care not to damage axle

shaft oil seals.

60.Place a new joint washer in position on swivelpin

housing to stub axle mating face. Coat threads

of stub axle bolts with Loctite 270.

61.Fit stub axle with flat at 12 o'clock position.

CAUTION: Ensure that constant velocity

joint bearing journal is butted against

thrust ring on stub axle. Before stub axle

is secured.

62.Place mud shield in position and secure stub

axle to swivel pin housing with six bolts and

tighten evenly to

65 Nm.

63.Fit brake jump hoses to brake jump hose

bracket.

64.Fit front hub complete assembly.

See Repair,

Front Hub Assembly

65.Check swivel pin housing oil drain plug is fitted.

66.Fill swivel assembly to correct level, with new oil.

See SECTION 10, Maintenance, Under

Vehicle Maintenance

67.Set steering lock stop bolts to provide a

clearance of 20mm.

See STEERING,

Adjustment, Steering Lock Stops

68.Fit ABS brake sensor.See BRAKES, Repair,

Sensors - Front

Page 515 of 873

FRONT AXLE AND FINAL DRIVE

1

SPECIFICATIONS, TORQUE TORQUE VALUES

NOTE: Torque wrenches should be regularly checked for accuracy to ensure that all fixings are

tightened to the correct torque.

Nm

FRONT AXLE

Hub driving member to hub 65........................................................................ *

Brake disc to hub 73.......................................................................................

Stub axle to swivel pin housing 65.................................................................. *

Brake caliper to swivel pin housing 82............................................................

Upper swivel pin to swivel pin housing 78...................................................... *

Upper swivel pin to swivel pin housing ABS 65..............................................

Lower swivel pin to swivel pin housing 78...................................................... *

Lower swivel pin to swivel pin housing ABS 25.............................................. *

Oil seal retainer to swivel pin housing 11........................................................

Swivel bearing housing to axle case 73.......................................................... *

Pinion housing to axle case 41.......................................................................

Crown wheel to differential housing 58...........................................................

Differential bearing cap to pinion housing 90..................................................

Differential drive flange to drive shaft 47.........................................................

Mudshield to bracket lower swivel pin 11........................................................

Disc shield to bracket lower ABS 9................................................................

Bevel pinion nut 130........................................................................................

Draglink to hub arm 40....................................................................................

Panhard rod to axle bracket 88.......................................................................

Radius arm to axle 190....................................................................................

Radius arm to chassis side member 190.........................................................

NOTE: * These bolts to be coated with Loctite 270 prior to assembly.

Page 529 of 873

STEERING

3

FAULT DIAGNOSIS STEERING DAMPER

The power steering system, as well as reducing the

effort required to manoeuvre the vehicle when

parking, also helps to dampen any deflections of the

road wheels, being transmitted back to the steering

wheel.

When operating the vehicle off road, the road wheels

are often deflected by ruts and boulders causing the

steering wheel to turn left and right. This phenomenon

is known as 'steering kickback'. To subdue the effects

of 'steering kickback', a hydraulic damper is fitted in

the steering linkage between the track rod and the

differential casing. The damper, which offers the same

resistance in extension and compression, is sealed for

life.

Steering damper check

Check the condition operation of the hydraulic

steering damper as follows:

Check procedure

1.Inspect damper for casing damage or leaks.

2.Clamp one end of the damper horizontally in a

vice using soft jaws. Compress and extend the

unit by hand. Resistance should be equal in both

directions.

3.If it is felt that the unit is outside acceptable

limits, fit a new steering damperSTEERING FAULTS

Symptom:-

Excessive kickback through steering wheel - when

driven on rough terrain.

1.Is the steering damper in good working order?

See Steering Damper

NO - Renew unit.See Repair, Steering

Damper

YES - Continue.

2.Is there any looseness or free play in the

steering ball joints and linkage?

YES -

See Steering Linkage Inspect

NO - Continue.

3.Is there any looseness or worn bushes in front

suspension?

YES -

See FRONT SUSPENSION, Repair,

Radius Arm

NOTE: When replacing suspension bushes

ALL bushes and fixings must be replaced.

NO - Continue.

4.Is the steering exceptionally light/sensitive when

driven on good road surface?

YES - See fault symptom -Steering

excessively light/sensitive and

freeplay at steering wheel.

NO - Suspect axle swivel resistance.

5.Check the resistance of the axle swivels.

See

FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing Non ABS See FRONT

AXLE AND FINAL DRIVE, Overhaul, Front

Stub Axle, Constant Velocity Joint and

Swivel Pin Housing ABS