wheel bolts LAND ROVER DISCOVERY 1995 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 154 of 873

12ENGINE

4

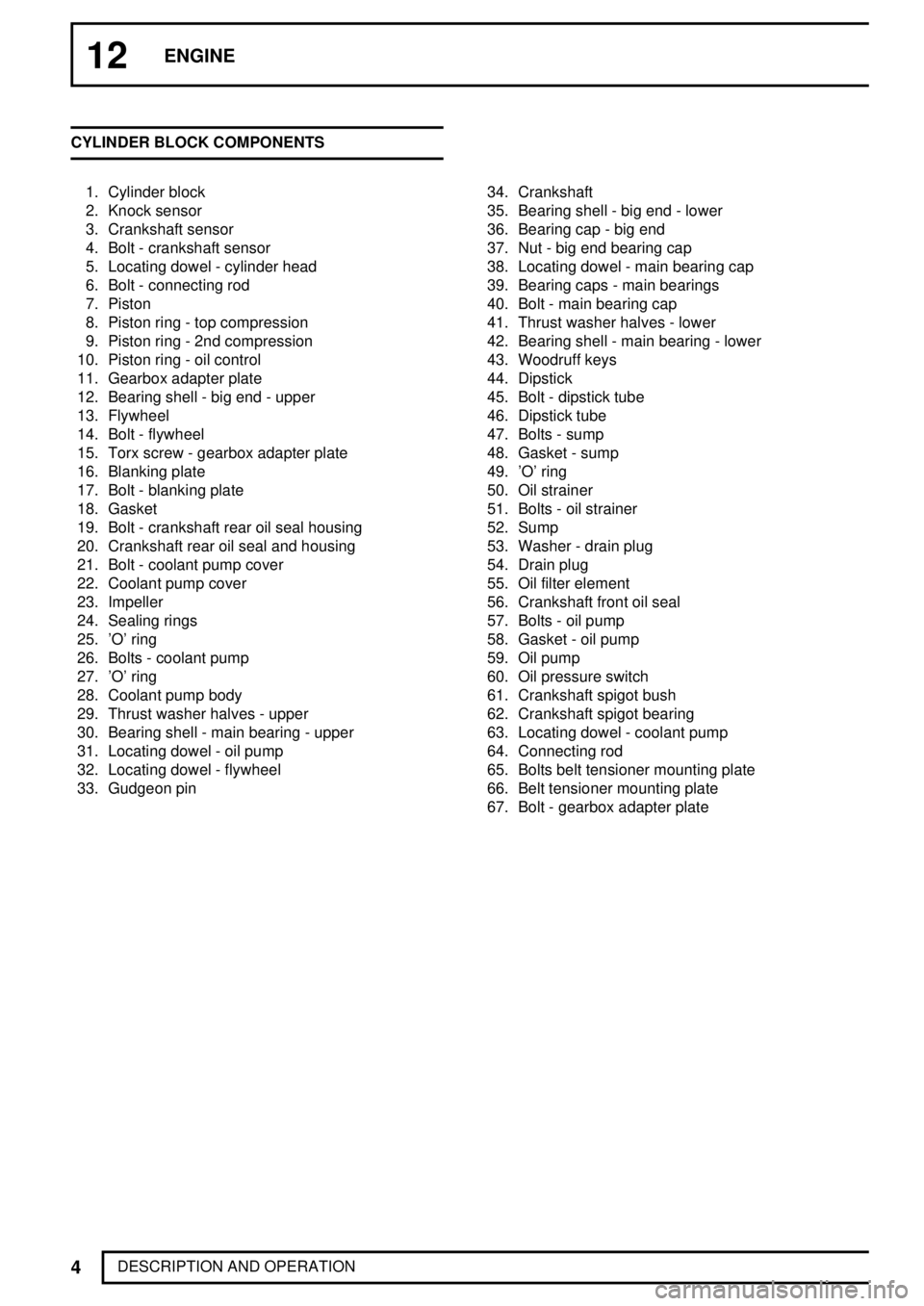

DESCRIPTION AND OPERATION CYLINDER BLOCK COMPONENTS

1. Cylinder block

2. Knock sensor

3. Crankshaft sensor

4. Bolt - crankshaft sensor

5. Locating dowel - cylinder head

6. Bolt - connecting rod

7. Piston

8. Piston ring - top compression

9. Piston ring - 2nd compression

10. Piston ring - oil control

11. Gearbox adapter plate

12. Bearing shell - big end - upper

13. Flywheel

14. Bolt - flywheel

15. Torx screw - gearbox adapter plate

16. Blanking plate

17. Bolt - blanking plate

18. Gasket

19. Bolt - crankshaft rear oil seal housing

20. Crankshaft rear oil seal and housing

21. Bolt - coolant pump cover

22. Coolant pump cover

23. Impeller

24. Sealing rings

25. 'O' ring

26. Bolts - coolant pump

27. 'O' ring

28. Coolant pump body

29. Thrust washer halves - upper

30. Bearing shell - main bearing - upper

31. Locating dowel - oil pump

32. Locating dowel - flywheel

33. Gudgeon pin34. Crankshaft

35. Bearing shell - big end - lower

36. Bearing cap - big end

37. Nut - big end bearing cap

38. Locating dowel - main bearing cap

39. Bearing caps - main bearings

40. Bolt - main bearing cap

41. Thrust washer halves - lower

42. Bearing shell - main bearing - lower

43. Woodruff keys

44. Dipstick

45. Bolt - dipstick tube

46. Dipstick tube

47. Bolts - sump

48. Gasket - sump

49. 'O' ring

50. Oil strainer

51. Bolts - oil strainer

52. Sump

53. Washer - drain plug

54. Drain plug

55. Oil filter element

56. Crankshaft front oil seal

57. Bolts - oil pump

58. Gasket - oil pump

59. Oil pump

60. Oil pressure switch

61. Crankshaft spigot bush

62. Crankshaft spigot bearing

63. Locating dowel - coolant pump

64. Connecting rod

65. Bolts belt tensioner mounting plate

66. Belt tensioner mounting plate

67. Bolt - gearbox adapter plate

Page 159 of 873

Mpi

1

REPAIR CAMSHAFT FRONT OIL SEAL

Service repair no - 12.13.07 - Exhaust

Service repair no - 12.13.09 - Inlet

Remove

1.Disconnect battery negative lead.

2.Remove drive belt.

See SECTION 10,

Maintenance, Under Bonnet [Hood]

Maintenance

3.Remove 5 bolts, timing belt upper cover.

4.Remove timing belt upper cover.

5.Remove 5 bolts, timing belt centre cover.

6.Remove timing belt centre cover.

7.Rotate crankshaft to align camshaft gear timing

marks - 90°B.T.D.C.

8.Fit tool LRT-12-058 to lock flywheel.

9.Fit tool LRT-12-060 to lock camshaft gears.

10.Loosen camshaft belt tensioner bolt.

11.Move tensioner away from belt and tighten

tensioner bolt.

12.Remove belt from camshaft gears.

Page 161 of 873

Mpi

3

REPAIR

For torque values.See Specifications, torque,

Torque Values

3.Fit timing belt upper backplate and tighten bolts

to the correct torque.

4.Fit camshaft gears noting the 'IN' and

'EXHAUST' identifying marks.

5.Fit, but do not tighten, camshaft gear centre

bolts.

6.Ensure timing marks are aligned.

7.Fit camshaft locking tool LRT-12-060.

8.Tighten camshaft gear bolts to the correct

torque.

9.Fit timing belt.

See Camshaft Drive Belt

10.Adjust timing belt tension.

11.Remove tool LRT-12-058 from flywheel.

12.Fit timing belt centre cover and tighten bolts to

correct torque.

13.Fit timing belt upper cover and tighten bolts to

correct torque.

14.Fit drive belt.

See SECTION 10, Maintenance,

Under Bonnet [Hood] Maintenance

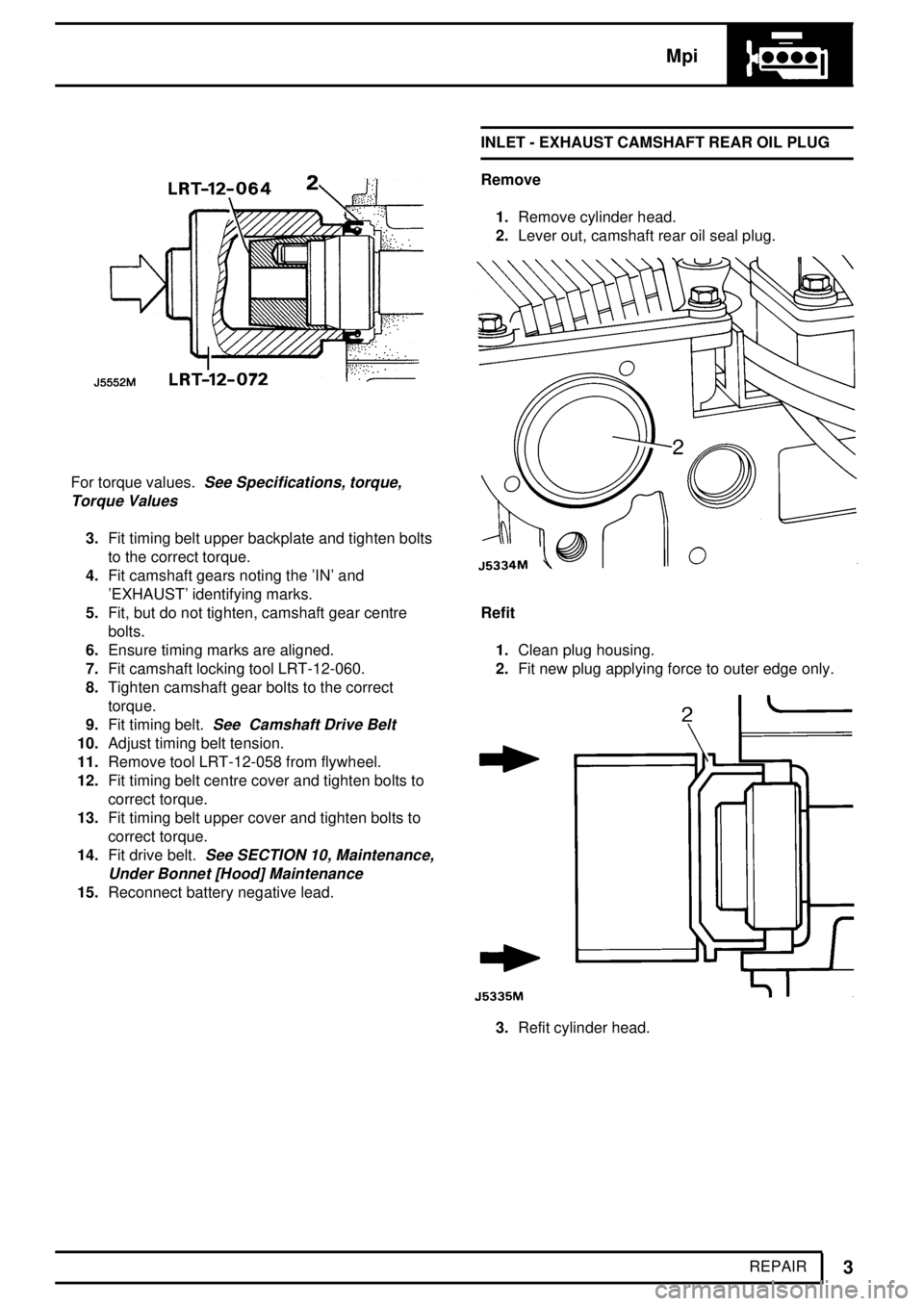

15.Reconnect battery negative lead.INLET - EXHAUST CAMSHAFT REAR OIL PLUG

Remove

1.Remove cylinder head.

2.Lever out, camshaft rear oil seal plug.

Refit

1.Clean plug housing.

2.Fit new plug applying force to outer edge only.

3.Refit cylinder head.

Page 163 of 873

Mpi

5

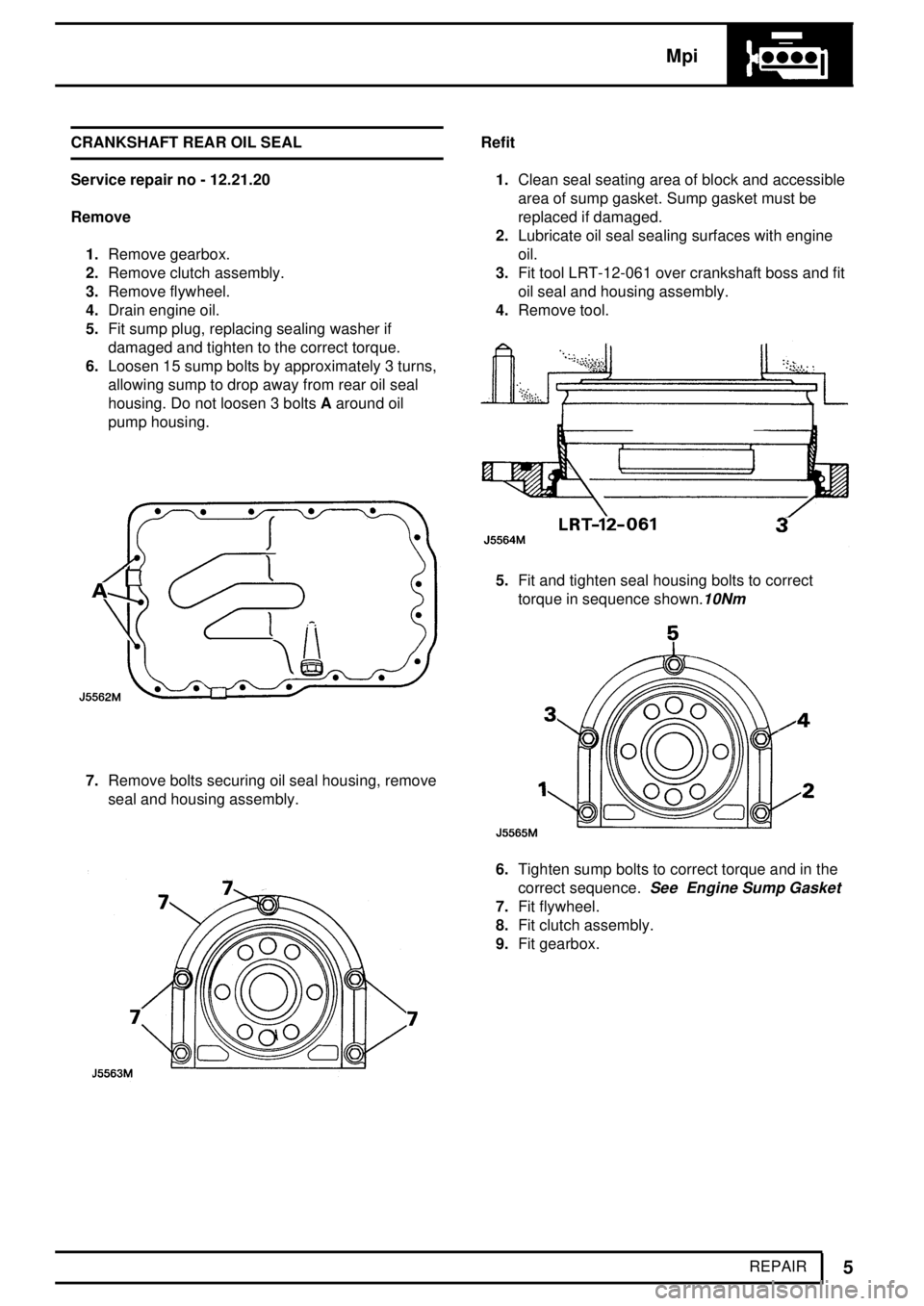

REPAIR CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

Remove

1.Remove gearbox.

2.Remove clutch assembly.

3.Remove flywheel.

4.Drain engine oil.

5.Fit sump plug, replacing sealing washer if

damaged and tighten to the correct torque.

6.Loosen 15 sump bolts by approximately 3 turns,

allowing sump to drop away from rear oil seal

housing. Do not loosen 3 boltsAaround oil

pump housing.

7.Remove bolts securing oil seal housing, remove

seal and housing assembly.

Refit

1.Clean seal seating area of block and accessible

area of sump gasket. Sump gasket must be

replaced if damaged.

2.Lubricate oil seal sealing surfaces with engine

oil.

3.Fit tool LRT-12-061 over crankshaft boss and fit

oil seal and housing assembly.

4.Remove tool.

5.Fit and tighten seal housing bolts to correct

torque in sequence shown.

10Nm

6.Tighten sump bolts to correct torque and in the

correct sequence.

See Engine Sump Gasket

7.Fit flywheel.

8.Fit clutch assembly.

9.Fit gearbox.

Page 179 of 873

Mpi

21

REPAIR

CAUTION: Never use the camshaft gears,

gear retaining bolts or timing belt to rotate

crankshaft.

7.Fit tool LRT-12-058 to lock flywheel.

8.Position tool LRT-12-060 to lock camshaft gears.

9.Loosen camshaft belt tensioner pulley bolt.

10.Move tensioner to release timing belt tension.

11.Retighten tensioner pulley bolt.

12.Remove 4 bolts securing crankshaft pulley to

crankshaft timing gear.13.Fit tool LRT-12-059 to crankshaft pulley, fit 2

pulley bolts to retain tool.

14.Restrain crankshaft pulley using tool LRT-12-059

and remove crankshaft pulley bolt.

15.Remove bolts securing tool LRT-12-059, remove

crankshaft pulley.

16.Remove timing belt lower cover.

17.If timing belt is to be refitted, mark direction of

rotation of belt.

18.Remove timing belt.

Page 180 of 873

12ENGINE

22

REPAIR

CAUTION: Ease timing belt off gears using

fingers only. Metal levers may damage the

belt and gears. Do not rotate engine with

timing belt removed and cylinder head fitted.

Timing belts must be stored and handled with

care. Always store a timing belt on its edge with a

bend radius greater than 50 mm. Do not use a

timing belt which has been twisted or bent double

as this can fracture reinforcing fibres. Do not use

an oil contaminated timing belt. Although the belt

has a service life of 96,000 miles, 160,000 km, an

existing belt should only be refitted if it has

completed less than 48,000 miles, 80,000 km.

Refit

NOTE: For torque values.See

Specifications, torque, Torque values

1.Clean timing belt gears and pulleys.

2.Clean crankshaft pulley.

CAUTION: If original belt is to be refitted,

ensure direction of rotation mark is facing

correct way.

3.Fit timing belt to gears, starting at the crankshaft

gear and working in an anti-clockwise direction.

CAUTION: Ensure the belt run between the

crankshaft and exhaust camshaft gear is

kept taut during the fitting procedure.

4.Fit timing belt lower cover, tighten 3 bolts to the

correct torque.

5.Fit crankshaft pulley to crankshaft timing gear.

6.Fit tool LRT-12-059 to crankshaft pulley, fit 2

bolts to retain tool.

7.Fit crankshaft pulley centre bolt, and using tool

LRT-12-059 to restrain pulley, tighten bolt to the

correct torque.

8.Remove tool LRT-12-059

9.Fit bolts securing crankshaft pulley to timing

gear, tighten bolts to the correct torque.

10.Remove tool LRT-12-060.Tension belt

1.Loosen timing belt tensioner pulley bolt.

2.Apply

40Nmanti-clockwise torque to inlet cam

pulley bolt and release.

3.Tighten tensioner pulley bolt to the correct

torque.

4.Remove tool LRT-12-058 from flywheel.

5.Fit timing belt centre cover, tighten 5 bolts to the

correct torque.

6.Fit timing belt upper cover, tighten 5 bolts to the

correct torque.

7.Fit drive belt.

Page 228 of 873

Tdi

11

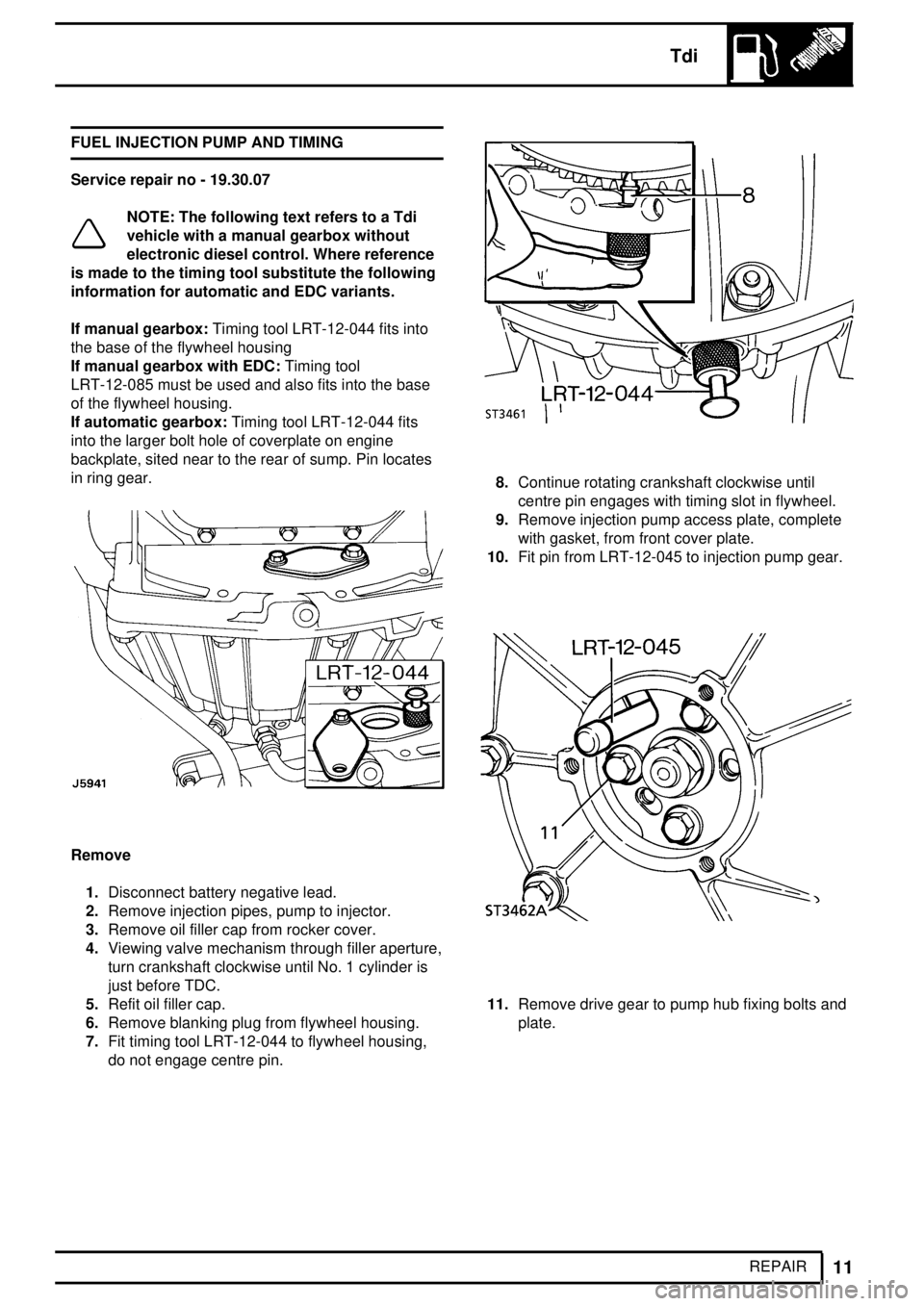

REPAIR FUEL INJECTION PUMP AND TIMING

Service repair no - 19.30.07

NOTE: The following text refers to a Tdi

vehicle with a manual gearbox without

electronic diesel control. Where reference

is made to the timing tool substitute the following

information for automatic and EDC variants.

If manual gearbox:Timing tool LRT-12-044 fits into

the base of the flywheel housing

If manual gearbox with EDC:Timing tool

LRT-12-085 must be used and also fits into the base

of the flywheel housing.

If automatic gearbox:Timing tool LRT-12-044 fits

into the larger bolt hole of coverplate on engine

backplate, sited near to the rear of sump. Pin locates

in ring gear.

Remove

1.Disconnect battery negative lead.

2.Remove injection pipes, pump to injector.

3.Remove oil filler cap from rocker cover.

4.Viewing valve mechanism through filler aperture,

turn crankshaft clockwise until No. 1 cylinder is

just before TDC.

5.Refit oil filler cap.

6.Remove blanking plug from flywheel housing.

7.Fit timing tool LRT-12-044 to flywheel housing,

do not engage centre pin.

8.Continue rotating crankshaft clockwise until

centre pin engages with timing slot in flywheel.

9.Remove injection pump access plate, complete

with gasket, from front cover plate.

10.Fit pin from LRT-12-045 to injection pump gear.

11.Remove drive gear to pump hub fixing bolts and

plate.

Page 230 of 873

Tdi

13

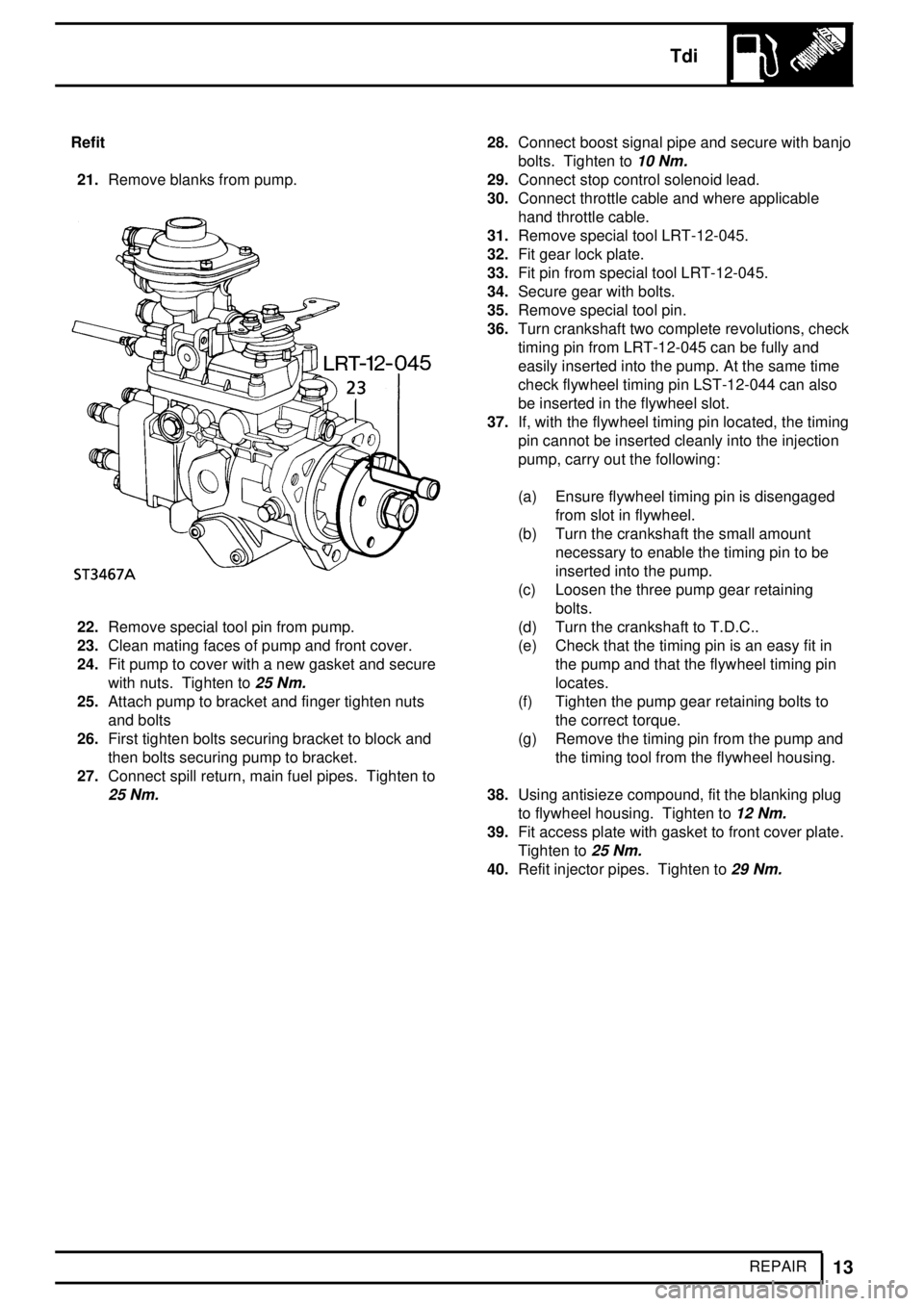

REPAIR Refit

21.Remove blanks from pump.

22.Remove special tool pin from pump.

23.Clean mating faces of pump and front cover.

24.Fit pump to cover with a new gasket and secure

with nuts. Tighten to

25 Nm.

25.Attach pump to bracket and finger tighten nuts

and bolts

26.First tighten bolts securing bracket to block and

then bolts securing pump to bracket.

27.Connect spill return, main fuel pipes. Tighten to

25 Nm.

28.Connect boost signal pipe and secure with banjo

bolts. Tighten to

10 Nm.

29.Connect stop control solenoid lead.

30.Connect throttle cable and where applicable

hand throttle cable.

31.Remove special tool LRT-12-045.

32.Fit gear lock plate.

33.Fit pin from special tool LRT-12-045.

34.Secure gear with bolts.

35.Remove special tool pin.

36.Turn crankshaft two complete revolutions, check

timing pin from LRT-12-045 can be fully and

easily inserted into the pump. At the same time

check flywheel timing pin LST-12-044 can also

be inserted in the flywheel slot.

37.If, with the flywheel timing pin located, the timing

pin cannot be inserted cleanly into the injection

pump, carry out the following:

(a) Ensure flywheel timing pin is disengaged

from slot in flywheel.

(b) Turn the crankshaft the small amount

necessary to enable the timing pin to be

inserted into the pump.

(c) Loosen the three pump gear retaining

bolts.

(d) Turn the crankshaft to T.D.C..

(e) Check that the timing pin is an easy fit in

the pump and that the flywheel timing pin

locates.

(f) Tighten the pump gear retaining bolts to

the correct torque.

(g) Remove the timing pin from the pump and

the timing tool from the flywheel housing.

38.Using antisieze compound, fit the blanking plug

to flywheel housing. Tighten to

12 Nm.

39.Fit access plate with gasket to front cover plate.

Tighten to

25 Nm.

40.Refit injector pipes. Tighten to29 Nm.

Page 254 of 873

19FUEL SYSTEM

8

REPAIR 10.Remove fuel rail and injectors.

11.Remove injector retaining clips, ease injectors

from rail. Remove and discard 'O' rings from

injectors.

12.Remove fuel pressure regulator if required.

Refit

13.FitNEW'O' rings, to injectors. Lightly coat 'O'

rings with silicon grease 300. Insert injectors into

fuel rail, multi-plug connections facing outwards.

14.Refit retaining clips.

CAUTION: Care must be taken when

refitting the fuel rail and injectors to intake

manifold to prevent damage to 'O' rings.

15.Fit aNEW'O' ring to pressure regulator lightly

coat 'O' ring with silicon grease 300 and secure

regulator to the fuel rail.

16.Fit fuel rail and heater pipe assemblies to intake

manifold. Secure rail and pipes in position with

five bolts.

17.Reverse removal procedure. 2 to 7.

18.Pressurise fuel system and check for fuel leaks

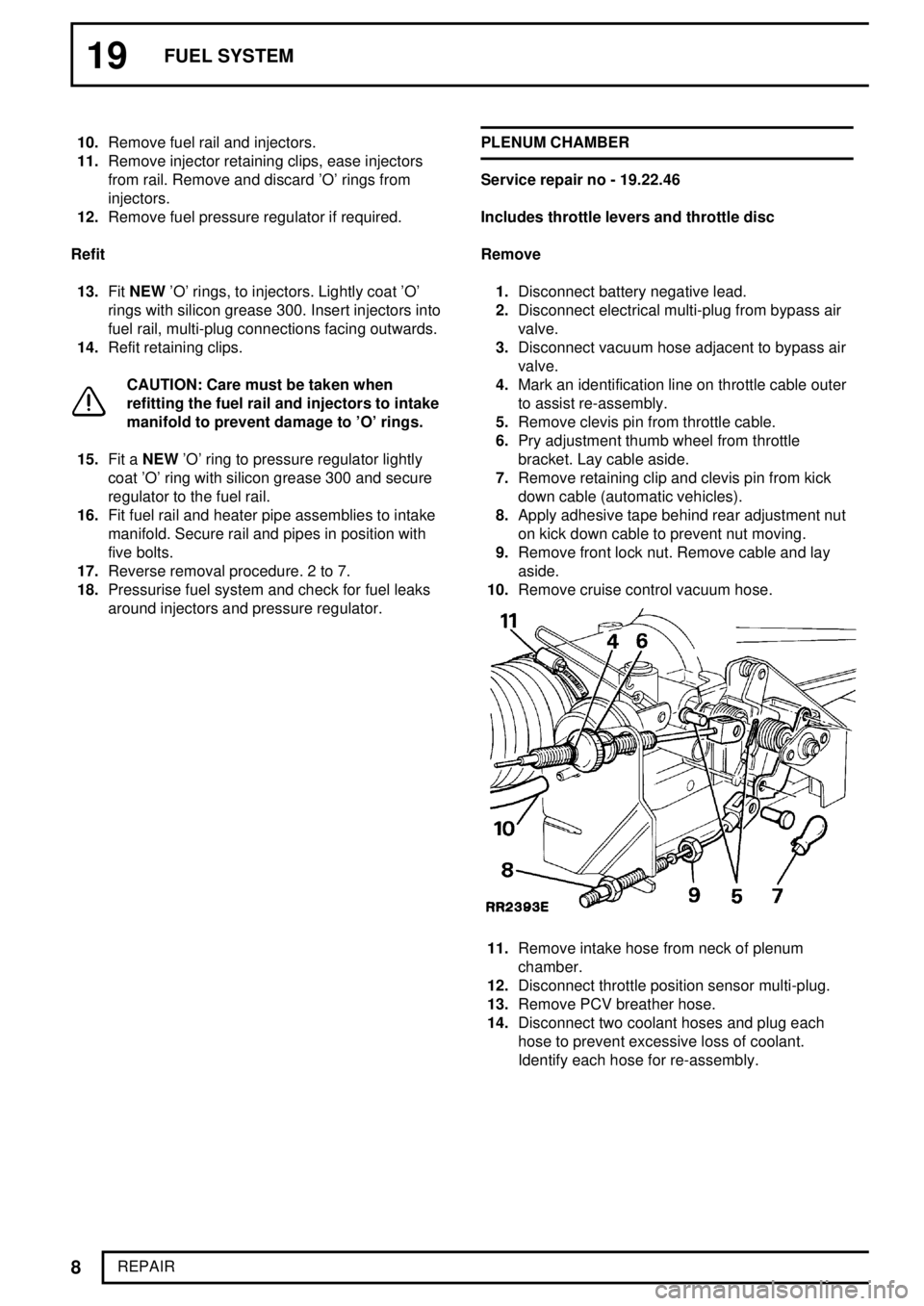

around injectors and pressure regulator.PLENUM CHAMBER

Service repair no - 19.22.46

Includes throttle levers and throttle disc

Remove

1.Disconnect battery negative lead.

2.Disconnect electrical multi-plug from bypass air

valve.

3.Disconnect vacuum hose adjacent to bypass air

valve.

4.Mark an identification line on throttle cable outer

to assist re-assembly.

5.Remove clevis pin from throttle cable.

6.Pry adjustment thumb wheel from throttle

bracket. Lay cable aside.

7.Remove retaining clip and clevis pin from kick

down cable (automatic vehicles).

8.Apply adhesive tape behind rear adjustment nut

on kick down cable to prevent nut moving.

9.Remove front lock nut. Remove cable and lay

aside.

10.Remove cruise control vacuum hose.

11.Remove intake hose from neck of plenum

chamber.

12.Disconnect throttle position sensor multi-plug.

13.Remove PCV breather hose.

14.Disconnect two coolant hoses and plug each

hose to prevent excessive loss of coolant.

Identify each hose for re-assembly.

Page 340 of 873

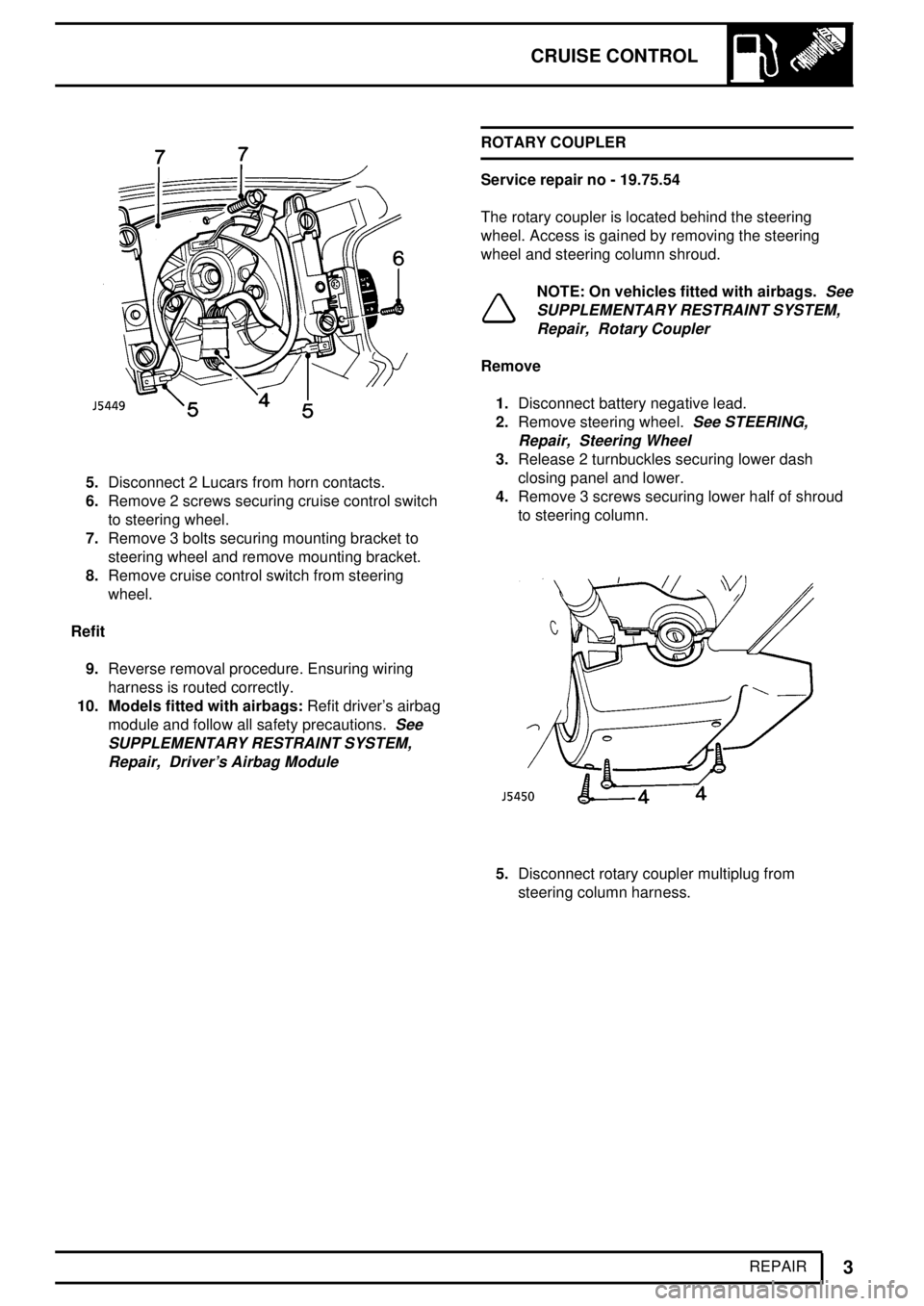

CRUISE CONTROL

3

REPAIR

5.Disconnect 2 Lucars from horn contacts.

6.Remove 2 screws securing cruise control switch

to steering wheel.

7.Remove 3 bolts securing mounting bracket to

steering wheel and remove mounting bracket.

8.Remove cruise control switch from steering

wheel.

Refit

9.Reverse removal procedure. Ensuring wiring

harness is routed correctly.

10. Models fitted with airbags:Refit driver's airbag

module and follow all safety precautions.

See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Driver's Airbag Module

ROTARY COUPLER

Service repair no - 19.75.54

The rotary coupler is located behind the steering

wheel. Access is gained by removing the steering

wheel and steering column shroud.

NOTE: On vehicles fitted with airbags.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Rotary Coupler

Remove

1.Disconnect battery negative lead.

2.Remove steering wheel.

See STEERING,

Repair, Steering Wheel

3.Release 2 turnbuckles securing lower dash

closing panel and lower.

4.Remove 3 screws securing lower half of shroud

to steering column.

5.Disconnect rotary coupler multiplug from

steering column harness.