wiring LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 33 of 873

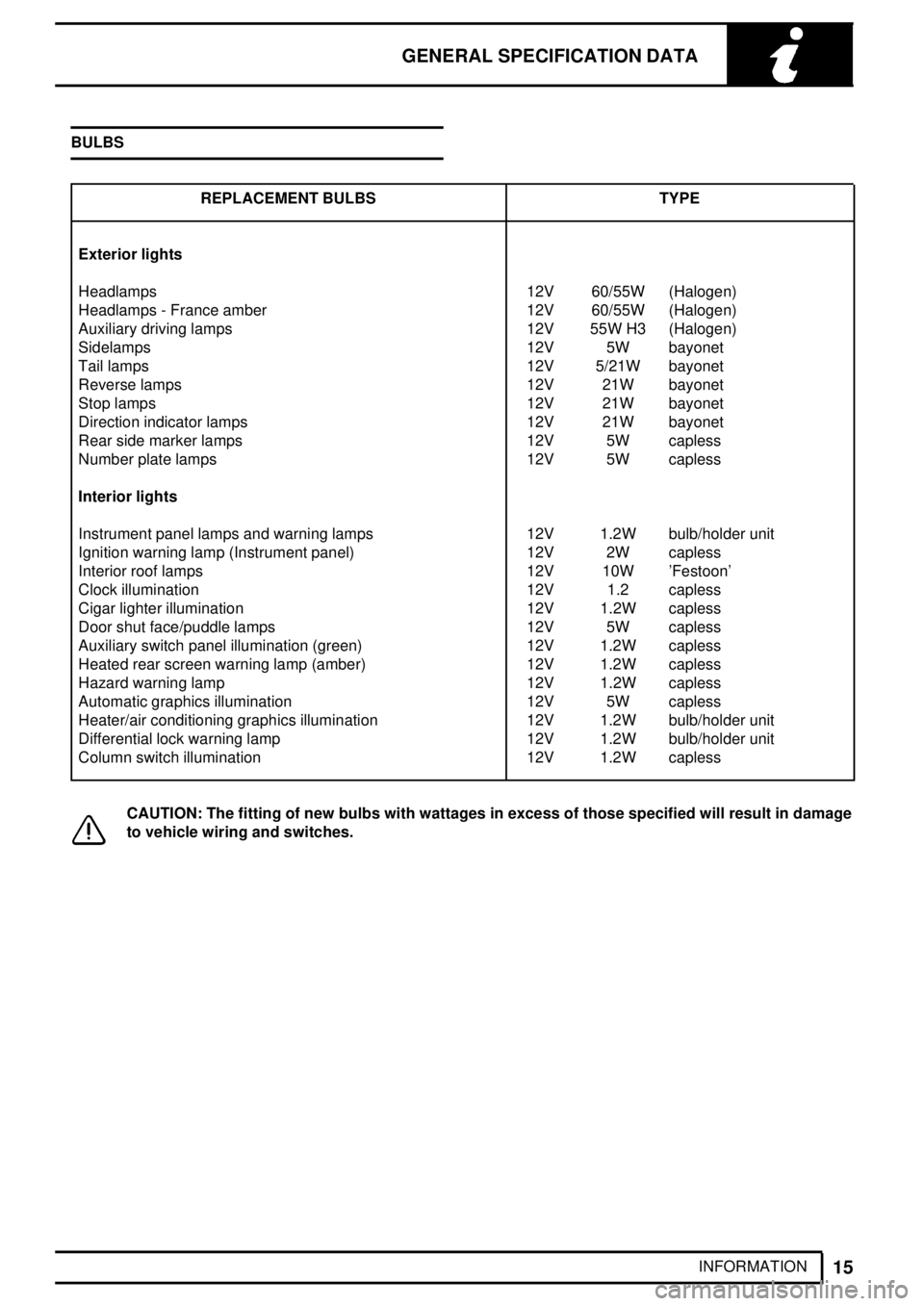

GENERAL SPECIFICATION DATA

15

INFORMATION BULBS

REPLACEMENT BULBS TYPE

Exterior lights

Headlamps 12V 60/55W (Halogen)

Headlamps - France amber 12V 60/55W (Halogen)

Auxiliary driving lamps 12V 55W H3 (Halogen)

Sidelamps 12V 5W bayonet

Tail lamps 12V 5/21W bayonet

Reverse lamps 12V 21W bayonet

Stop lamps 12V 21W bayonet

Direction indicator lamps 12V 21W bayonet

Rear side marker lamps 12V 5W capless

Number plate lamps 12V 5W capless

Interior lights

Instrument panel lamps and warning lamps 12V 1.2W bulb/holder unit

Ignition warning lamp (Instrument panel) 12V 2W capless

Interior roof lamps 12V 10W 'Festoon'

Clock illumination 12V 1.2 capless

Cigar lighter illumination 12V 1.2W capless

Door shut face/puddle lamps 12V 5W capless

Auxiliary switch panel illumination (green) 12V 1.2W capless

Heated rear screen warning lamp (amber) 12V 1.2W capless

Hazard warning lamp 12V 1.2W capless

Automatic graphics illumination 12V 5W capless

Heater/air conditioning graphics illumination 12V 1.2W bulb/holder unit

Differential lock warning lamp 12V 1.2W bulb/holder unit

Column switch illumination 12V 1.2W capless

CAUTION: The fitting of new bulbs with wattages in excess of those specified will result in damage

to vehicle wiring and switches.

Page 66 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 10MAINTENANCE

4

MAINTENANCE UNDER BONNET [HOOD] MAINTENANCE

CHECK COOLING/HEATER SYSTEMS

Check cooling/heater systems for leaks and hoses for

security and condition.

Cooling system hoses should be cha LAND ROVER DISCOVERY 1995 Workshop Manual 10MAINTENANCE

4

MAINTENANCE UNDER BONNET [HOOD] MAINTENANCE

CHECK COOLING/HEATER SYSTEMS

Check cooling/heater systems for leaks and hoses for

security and condition.

Cooling system hoses should be cha](/img/64/57248/w960_57248-65.png)

10MAINTENANCE

4

MAINTENANCE UNDER BONNET [HOOD] MAINTENANCE

CHECK COOLING/HEATER SYSTEMS

Check cooling/heater systems for leaks and hoses for

security and condition.

Cooling system hoses should be changed at first

signs of deterioration.

CHECK CONDITION OF ENGINE MOUNTING

RUBBERS

CHECK BRAKE SERVO HOSE FOR SECURITY

AND CONDITION

CHECK FUEL EVAPORATIVE LOSS CONTROL

SYSTEM FOR LEAKS - V8i CATALYST, Mpi

CHECK FUEL FILLER CAP SEAL FOR LEAKS - V8i

- CATALYST, Mpi

CHECK CONDITION OF HEATER PLUG WIRING

FOR FRAYING, CHAFING AND DETERIORATION -

Tdi

CHECK IGNITION WIRING

Check ignition wiring and high tension leads for

fraying, chafing and deterioration.

CLEAN DISTRIBUTOR CAP - V8i

The electronic ignition employs a Lucas 35DLM8

distributor.

Internal operating parts of distributor are pre-set at

factory and do not normally require resetting.

Adjustments should only be made if unit is known to

be faulty or damaged. Distributor maintenance

consists of following items.

1.Clean outer surfaces of distributor cap to remove

dirt, grease etc.

2.Unclip cap, check cap for cracks.

3.Wipe inside cap with lint free cloth.

4.Check rotor arm, cap and flash shield tracking.

DO NOT DISTURB clear plastic insulating

cover (flash shield) which protects magnetic

pick-up module.

LUBRICATE DISTRIBUTOR ROTOR SPINDLE - V8i

Apply a spot of clean engine oil into rotor spindle after

rotor arm has been removed.

CLEAN/ADJUST SPARK PLUGS - V8i CATALYST

RENEW SPARK PLUGS V8i - V8i CATALYST

Clean, adjust and renew

1.Take great care when fitting spark plugs not to

cross-thread plug, otherwise costly damage to

cylinder head will result.

Page 127 of 873

V8i

9

REPAIR FRONT COVER GASKET

Service repair no - 12.65.04

1.Remove crankshaft pulley.

See Crankshaft

Pulley Assembly. Do not remove pulleys

2.Remove water pump pulley.

3.Release distributor cap clips.

4.Release plug leads from plugs and clips.

5.Place cap and leads to one side.

6.Turn engine until No. 1 piston is at T.D.C.

7.Check position of rotor arm.

8.Remove fixings securing power steering pump

bracket to water pump bracket.

9.Remove power steering pump bracket from

water pump.

10.Remove clips securing wiring to generator

tensioner.

11.Disconnect distributor feed wire.

12.Pivot power steering pump away from front

cover, tighten pivot to retain in position.

13.Disconnect vacuum pipe from distributor.

14.Remove water pump bottom hose.

15.Disconnect oil pressure switch.

16.Disconnect heater hose at water pump.

17.Remove generator tensioner from water pump,

move tensioner aside.

18.Mark distributor position to front cover.

19.Remove distributor clamp, remove distributor.

See ELECTRICAL, Repair, Distributor - V8i

20.Remove fixings sump to front cover.

21.Loosen four adjacent sump fixings.

22.Remove generator support strut from front cover,

move strut aside.

23.Loosen remaining front cover fixings and remove

front cover.

24.Remove front cover gasket.Refit

25.Clean timing cover, clean block face.

26.Lightly grease gasket faces.

27.Fit new gasket to block face.

28.Apply hylosil to sump gasket.

29.Clean threads of cover fixing bolts, apply Loctite

372 to threads.

30.Fit timing cover, fit fixing bolts. Tighten to

28

Nm.

31.Fit generator support strut to front cover.

32.Tighten sump to timing cover fixings to

10 Nm.

33.Tighten sump fixings to10 Nm.

34.Lubricate distributor O ring.

35.Fit distributor in position marked.

36.Align oil pump drive, if distributor does not seat

correctly.

37.Fit distributor clamp. Tighten to

20 Nm.

38.Locate generator tensioner on water pump

bracket.

39.Connect heater hose, tighten clip.

40.Connect oil pressure switch.

41.Connect bottom hose, tighten clip.

42.Connect vacuum pipe to distributor.

43.Loosen power steering pump pivot, lower pump.

44.Connect distributor feed wire.

45.Connect wire ties to generator tensioner.

46.Fit power steering pump bracket to water pump.

Tighten to

28 Nm.

47.Fit power steering pump to bracket.

48.Position distributor cap. Fit plug leads to plugs

and clips.

49.Clip distributor cap in position.

50.Fit water pump pulley. Tighten to

10 Nm.

51.Fit crankshaft pulley.See Crankshaft Pulley

Assembly

52.Tension drive belts correctly.

53.Check ignition timing.

54.Refill cooling system.

Page 234 of 873

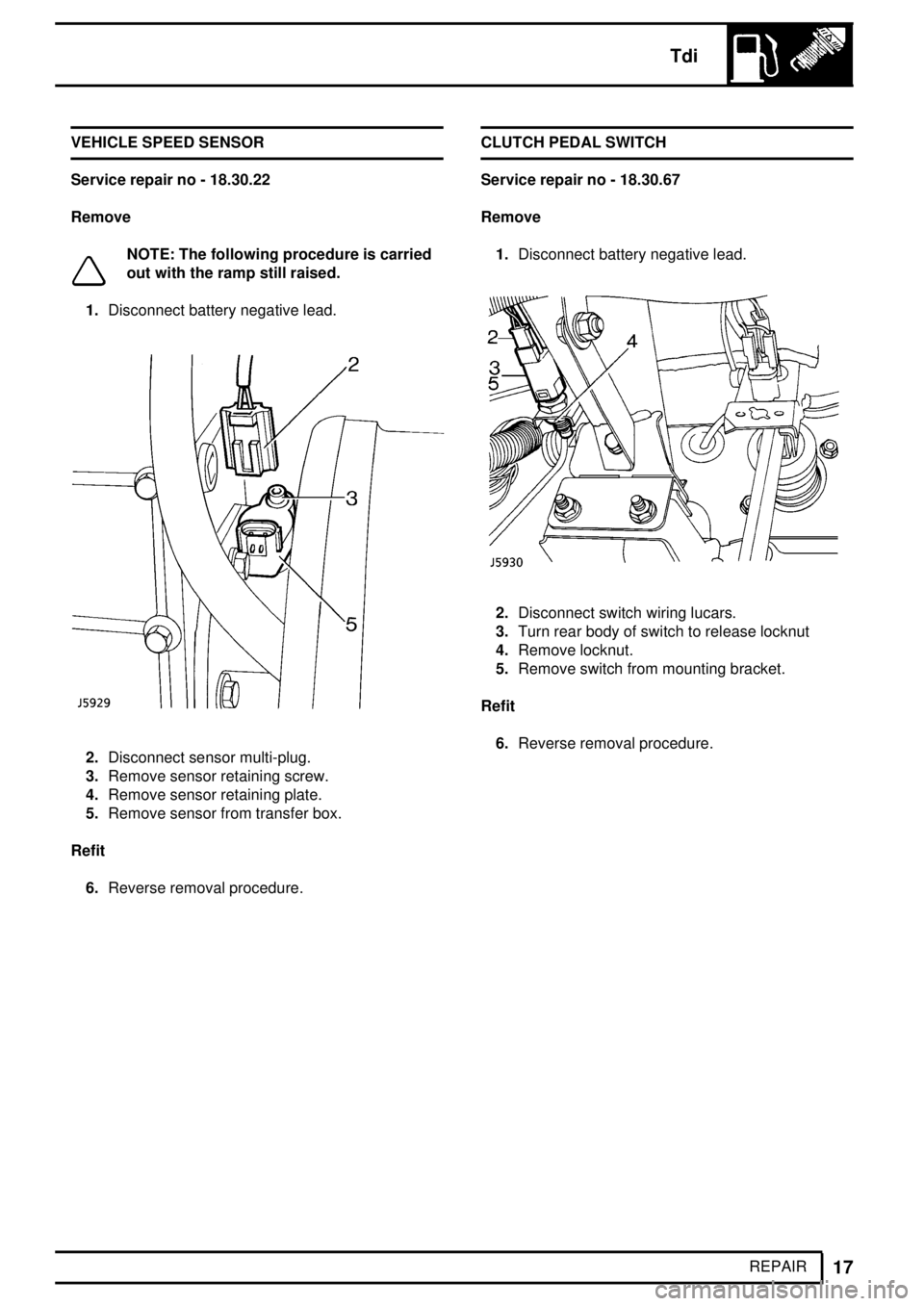

Tdi

17

REPAIR VEHICLE SPEED SENSOR

Service repair no - 18.30.22

Remove

NOTE: The following procedure is carried

out with the ramp still raised.

1.Disconnect battery negative lead.

2.Disconnect sensor multi-plug.

3.Remove sensor retaining screw.

4.Remove sensor retaining plate.

5.Remove sensor from transfer box.

Refit

6.Reverse removal procedure.CLUTCH PEDAL SWITCH

Service repair no - 18.30.67

Remove

1.Disconnect battery negative lead.

2.Disconnect switch wiring lucars.

3.Turn rear body of switch to release locknut

4.Remove locknut.

5.Remove switch from mounting bracket.

Refit

6.Reverse removal procedure.

Page 235 of 873

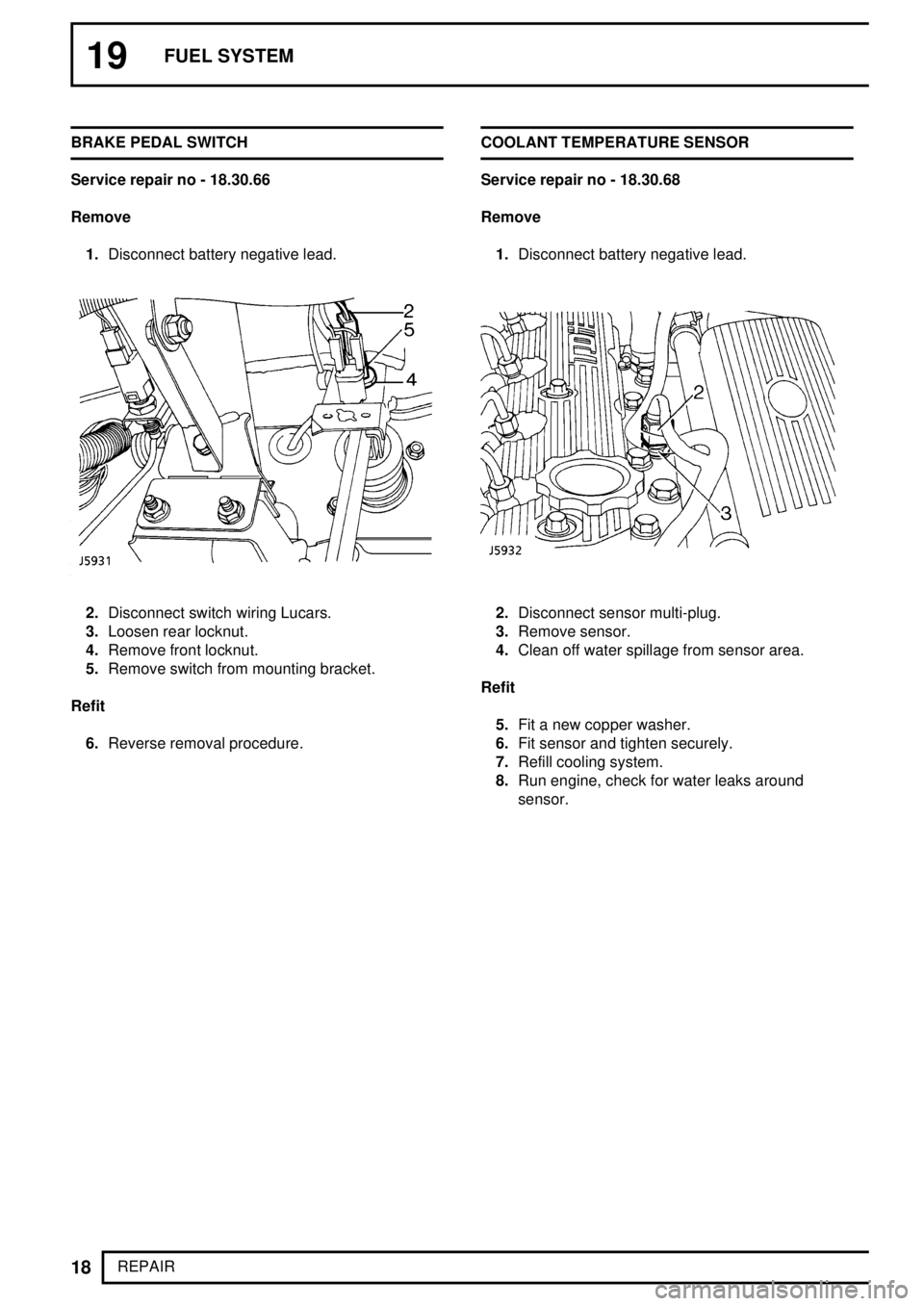

19FUEL SYSTEM

18

REPAIR BRAKE PEDAL SWITCH

Service repair no - 18.30.66

Remove

1.Disconnect battery negative lead.

2.Disconnect switch wiring Lucars.

3.Loosen rear locknut.

4.Remove front locknut.

5.Remove switch from mounting bracket.

Refit

6.Reverse removal procedure.COOLANT TEMPERATURE SENSOR

Service repair no - 18.30.68

Remove

1.Disconnect battery negative lead.2.Disconnect sensor multi-plug.

3.Remove sensor.

4.Clean off water spillage from sensor area.

Refit

5.Fit a new copper washer.

6.Fit sensor and tighten securely.

7.Refill cooling system.

8.Run engine, check for water leaks around

sensor.

Page 277 of 873

19FUEL SYSTEM

6

DESCRIPTION AND OPERATION REV: 09/95 Idle air control (IAC)

Idle speed is controlled by a stepper motor which

consists of two coils. When energised in the correct

sequence the coils move a plunger which opens and

closes the throttle bypass controlling the quantity of

idle air. The stepper motor controls idle speed by

moving the plunger a set distance called a step. Fully

open is zero steps and fully closed 180 steps. Failure

of the stepper motor will result in low or high idle

speed, poor idle, engine stall or non start. The fault is

indicated by illumination of the malfunction indicator

light (MIL) on North American specification vehicles.Heated oxygen sensor (HO2S)

The oxygen sensors consist of a titanium metal

sensor surrounded by a gas permeable ceramic

coating. Oxygen in the exhaust gas diffuses through

the ceramic coating on the sensor, and reacts with the

titanium wire altering the resistance of the wire. From

this resistance change the ECM calculates the

amount of oxygen in the exhaust gas. The injected

fuel quantity is then adjusted to achieve the correct

air/fuel ratio, thus reducing the emissions of carbon

monoxide (CO), hydrocarbons (HC),and oxides of

nitrogen (NO

2). Two HO2 sensors are fitted, one in

each exhaust downpipe just ahead of the catalyst.

Note that if the wiring to these sensors is crossed, the

vehicle will start and idle correctly until the sensors

reach operating temperature. Then the ECM will read

the signals from them and send one bank of cylinders

very rich and the other very weak. The engine will

misfire, have a rough idle and emit black smoke, with

possible catalyst damage.

In the event of sensor failure, the system will default to

'open loop'. Operation and fuelling will be calculated

using signals from the remaining ECM inputs.

The fault is indicated by illumination of the malfunction

indicator light (MIL). ECM diagnostics also uses HO2

sensors to detect catalyst damage, misfire and fuel

system faults.

North American vehicles have two extra HO2 sensors

mounted one after each catalyst. These are used to

determine whether the catalysts are operating

efficently.

CAUTION: Although robust within the

vehicle environment, HO2 sensors are

easily damaged by dropping, excessive

heat and contamination. Care must be exercised

when working on the exhaust system not to

damage the sensor housing or tip.

Page 328 of 873

Mpi

5

REPAIR 6.Remove nut securing throttle cable bracket to

brake servo and release cable.

7.Release grommet from bulkhead and withdraw

cable.

8.Locate cable in bulkhead.

9.Connect cable to throttle pedal.

10.Connect cable to cam.

11.Adjust throttle cable.THROTTLE POTENTIOMETER

Service repair no - 19.22.49

Remove

1.Disconnect throttle potentiometer multiplug.

2.Remove 2 screws securing throttle

potentiometer, remove potentiometer.

Refit

3.Clean mating faces of throttle potentiometer and

throttle housing.

4.Fit throttle potentiometer, fit and tighten screws.

CAUTION: Ensure throttle potentiometer is

correctly engaged with throttle cam and

that wiring outlet faces downwards.

5.Connect multiplug.

6.Check with diagnostic equipment.

Page 340 of 873

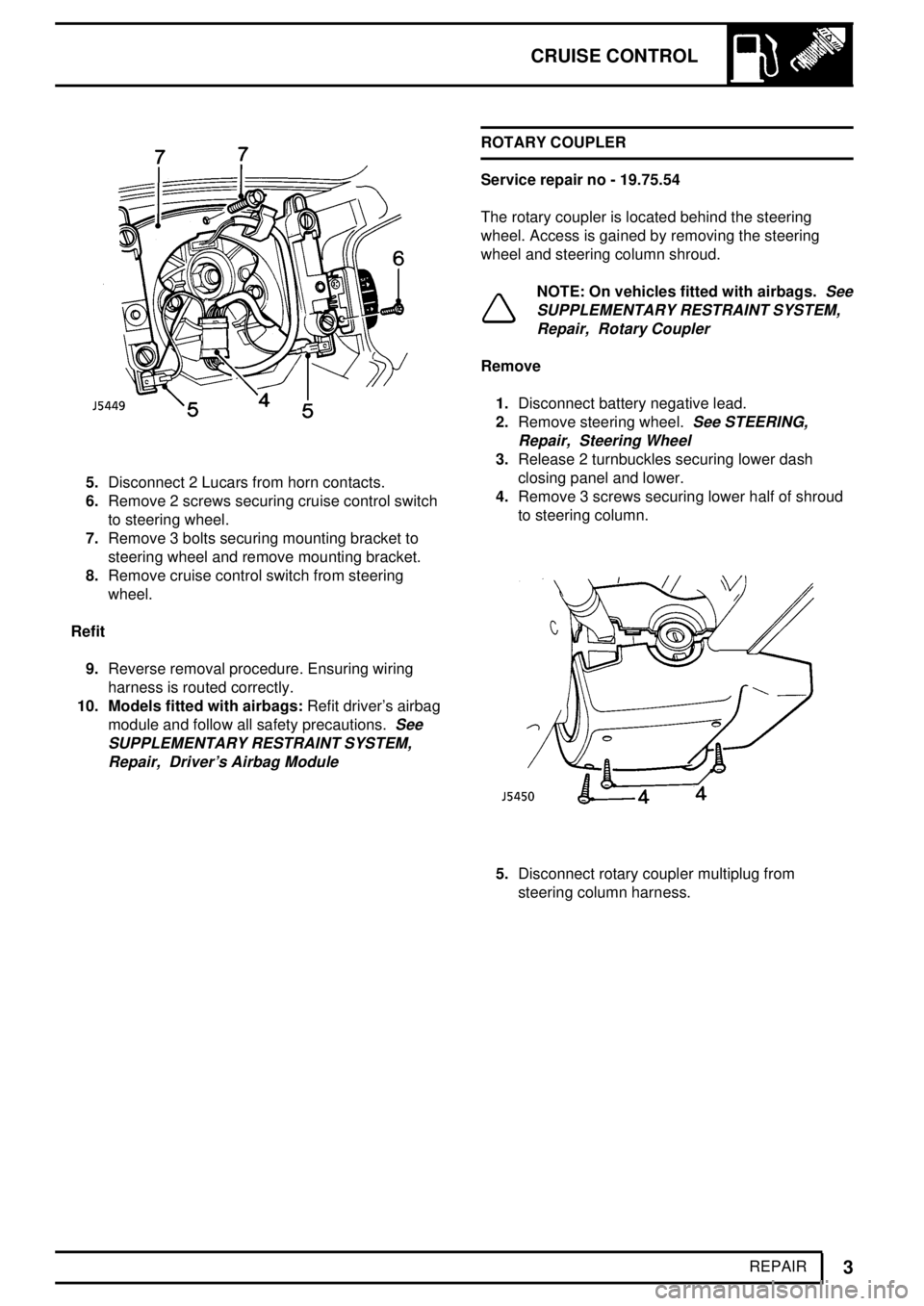

CRUISE CONTROL

3

REPAIR

5.Disconnect 2 Lucars from horn contacts.

6.Remove 2 screws securing cruise control switch

to steering wheel.

7.Remove 3 bolts securing mounting bracket to

steering wheel and remove mounting bracket.

8.Remove cruise control switch from steering

wheel.

Refit

9.Reverse removal procedure. Ensuring wiring

harness is routed correctly.

10. Models fitted with airbags:Refit driver's airbag

module and follow all safety precautions.

See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Driver's Airbag Module

ROTARY COUPLER

Service repair no - 19.75.54

The rotary coupler is located behind the steering

wheel. Access is gained by removing the steering

wheel and steering column shroud.

NOTE: On vehicles fitted with airbags.See

SUPPLEMENTARY RESTRAINT SYSTEM,

Repair, Rotary Coupler

Remove

1.Disconnect battery negative lead.

2.Remove steering wheel.

See STEERING,

Repair, Steering Wheel

3.Release 2 turnbuckles securing lower dash

closing panel and lower.

4.Remove 3 screws securing lower half of shroud

to steering column.

5.Disconnect rotary coupler multiplug from

steering column harness.

Page 378 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Remove

Catalysts - remove and refit 1 to 5

1.Raise vehicle on a ramp [hoist].

2. Catalyst vehicles only:Disconnect two heated

oxygen sensor wiring connectors.

NO LAND ROVER DISCOVERY 1995 Workshop Manual 30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Remove

Catalysts - remove and refit 1 to 5

1.Raise vehicle on a ramp [hoist].

2. Catalyst vehicles only:Disconnect two heated

oxygen sensor wiring connectors.

NO](/img/64/57248/w960_57248-377.png)

30MANIFOLD AND EXHAUST SYSTEM

2

REPAIR Remove

Catalysts - remove and refit 1 to 5

1.Raise vehicle on a ramp [hoist].

2. Catalyst vehicles only:Disconnect two heated

oxygen sensor wiring connectors.

NOTE: NAS models have four heated

oxygen sensors fitted.

3.Remove two nuts securing rear exhaust

assembly to front exhaust assembly.

4.Remove nuts and release front downpipes from

manifolds. Discard gaskets.

5.Lower front exhaust assembly with catalysts (if

fitted), retain olive.

NOTE: Assistance is required for removing

and refitting rear exhaust assembly.

6.Remove bolts securing three hanger brackets to

chassis. Lower exhaust assembly onto rear axle.

Detach rubbers from hanging brackets.

7.Place extended axle stands underneath chassis,

in front of chassis mounted rear towing brackets.

8.Lower ramp[hoist] until vehicle weight is

supported securely on stands.

9.Lower ramp [hoist] until rear shock absorbers

are ALMOST fully extended.

10.Move rear exhaust to a diagonal position, centre

silencer to right of vehicle.

11.Facing rear of vehicle, twist assembly

anti-clockwise clear of rear axle.

12.Remove rear exhaust assembly from vehicle.

Refit

13.Position rear exhaust assembly over rear axle in

a diagonal position, as for removing.

14.Twist assembly clockwise until it is in mounting

position.

15.Reverse removal procedure. 1. to 9. using new

manifold gaskets and applying exhaust sealer to

system joint.

16.Examine system for leaks, ensuring that system

does not foul underbody components. Rectify if

necessary.EXHAUST MANIFOLD - V8i

Service repair no - Left hand - 30.15.10

Service repair no - Right hand - 30.15.11

Remove

1.Disconnect front exhaust pipe(s) from

manifold(s).

2.Tap back bolt locking tabs and remove eight

bolts, lock tabs and washers.

3.Remove manifold(s) and old gaskets.

Refit

4.Ensure that mating surfaces of cylinder head

and exhaust manifold are clean and smooth.

5.Coat threads of each bolt with anti-seize

compound.

6.Place manifold and new gaskets in position on

cylinder head and fit securing bolts, new

lockplates and plain washers. Plain washers are

fitted between manifold and lockplates.

7.Evenly tighten manifold bolts to

20Nmbend

over lockplate tabs.

8.Reconnect front exhaust pipe, using new

exhaust flange gaskets.

Page 444 of 873

ZF

7

REPAIR Accessories removal/fitting

If fitting a replacement transmission assembly to the

vehicle, remove the following items from the existing

assembly and fit to the replacement.

CAUTION: It is important to remove the

spacer from the extension shaft and fit

onto the replacement unit.

50.Breather pipe union and washers from main

gearbox.

51.Breather pipe, union and washers from transfer

gearbox.

52.Main gearbox selector lever.

53.RH mounting bracket assembly.

54.Oil cooler pipe unions.

55.Fit blanks to all apertures where unions have

been removed and blank off pipe ends.

Refit

1.Fit transmission to cradle and hoist.

2.Locate hoist under vehicle and remove torque

convertor retaining strap.

3.Ensure low range gear is engaged.

4.Apply approved sealant to bell housing face.

5.Carefully raise assembly, align bell housing with

flywheel housing and bring mating faces

together.

6.Fit nuts and bolts to secure transmission to

engine.

7.Locate electrical wiring and breather pipes to

position.

8.Secure kick down cable clip to bell housing.

9.Raise hoist sufficiently to take weight.

10.Remove block and jack from engine sump.

11.Fit filler/dipstick tube to gearbox sump and

secure bracket to bell housing.

12.Apply Loctite to torque convertor bolts

13.Working through starter aperture refit the four

torque convertor to flexible drive securing bolts,

rotating crankshaft to gain access to bolt

locations.

14.Refit starter and heatshield.

15.Secure breather pipes and harness with ties.

16.Fit left hand mounting bracket assembly to

gearbox.

17.Raise transmission and support with a suitable

ramp [hoist] jack.

18.Remove two bolts securing transmission to

cradle, lower hoist and remove from under

vehicle.

19.Apply Loctite to above bolts and fit to transfer

gearbox input bearing support plate.

20.Fit chassis cross member.21.Secure gearbox mounting brackets to chassis

cross member.

22.Remove ramp [hoist] jack.

23.Connect electrical leads to differential lock

switch.

24.Connect inhibitor switch multi-plug.

25.Connect selector cable to lever on side of

gearbox.

26.Connect oil cooler pipes to gearbox and secure

retaining bracket to gearbox sump.

27.Secure silencer to chassis and refit exhaust front

pipe.

28.Refit front propeller shaft to transfer gearbox.

29.Refit rear propeller shaft.

See PROPELLER

SHAFTS, Overhaul, Flexible Coupling

30.Connect speedometer cable to transfer gearbox.

31.Refill transfer gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids

32.Lower ramp [hoist] to ground level.

33.Reconnect turbo-charger hose to inter-cooler.

34.Reconnect top hose to radiator.

35.Refill cooling system with correct mixture of

coolant.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

Lubricants and Fluids

36.Reconnect kick down cable to fuel injection

pump.

37.Secure breather pipe clip to rear of cylinder

head.

38.Engage harness with clips along top of

bulkhead.

39.On left hand drive vehicles only, connect

multi-plug to top of brake fluid reservoir.

40.Refit insulation pad to rocker cover and inlet

manifold, secure with oil filler cap.

41.Refit gaiter and knob to transfer gear lever.

42.Select high range gear.

43.Reconnect battery terminals.

44.Refill main gearbox with correct grade of

lubricating oil.

See LUBRICANTS, FLUIDS

AND CAPACITIES, Information,

Recommended Lubricants and Fluids