wiring LAND ROVER DISCOVERY 1995 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 744 of 873

80HEATING AND VENTILATION

2

REPAIR 8.Disconnect 4 multiplugs and position harness

aside.

NOTE:Do not carry out further

dismantling if component is removed for

access only.

9. Fan speed switch:remove fan speed switch

slide and push out fan speed switch.

10.Pull out light bulb disconnect terminals and

remove fan speed light strip.

11.Unclip 3 heater control cables from control unit.

12. Microswitch:Unclip 3 micro switches.

13.Cut cable tie and release wiring harness from

control unit.

14.Remove heater control unit.

Refit

15.Reverse removal procedure. Check the

satisfactory function of the controls before fitting

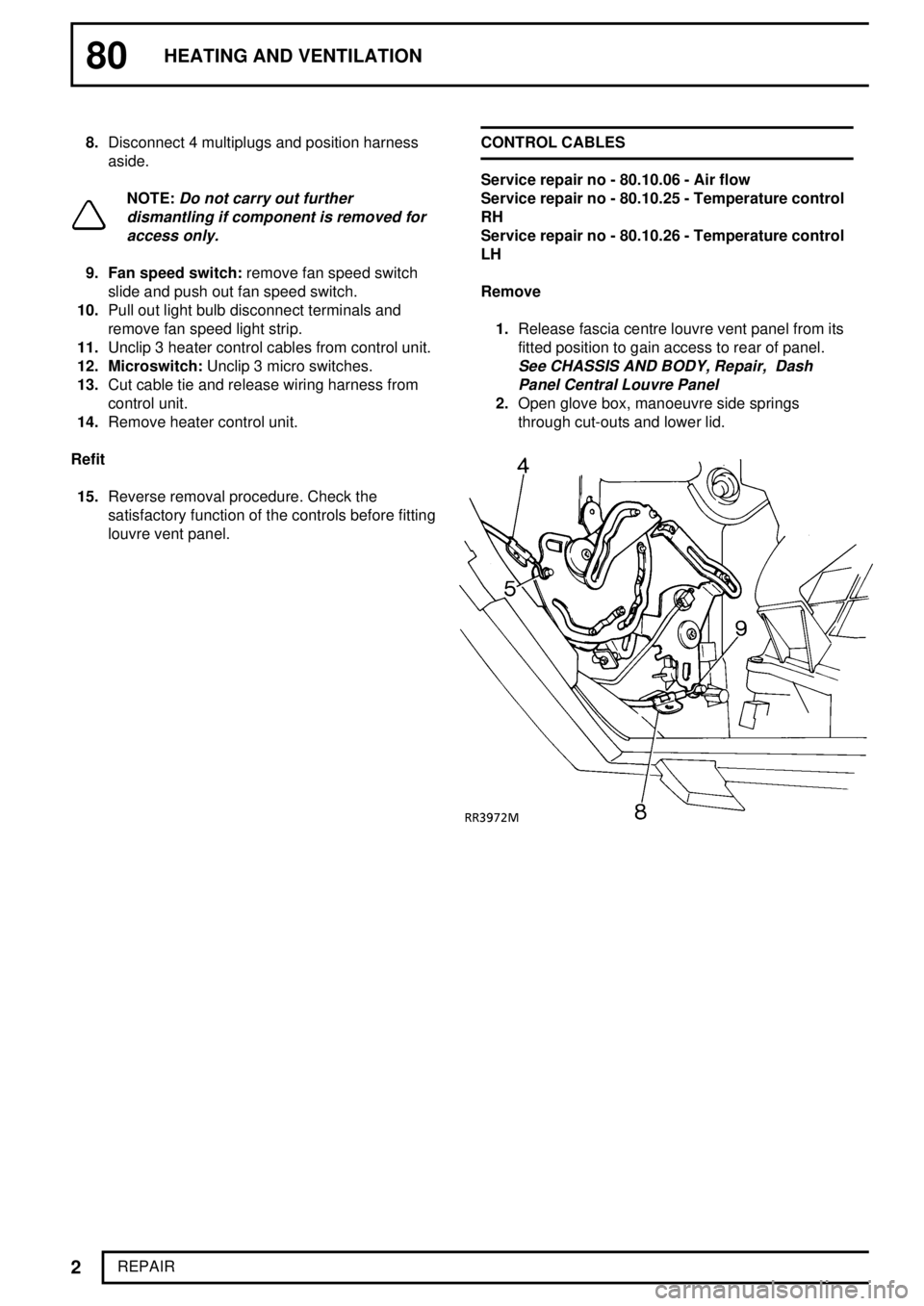

louvre vent panel.CONTROL CABLES

Service repair no - 80.10.06 - Air flow

Service repair no - 80.10.25 - Temperature control

RH

Service repair no - 80.10.26 - Temperature control

LH

Remove

1.Release fascia centre louvre vent panel from its

fitted position to gain access to rear of panel.

See CHASSIS AND BODY, Repair, Dash

Panel Central Louvre Panel

2.Open glove box, manoeuvre side springs

through cut-outs and lower lid.

Page 748 of 873

80HEATING AND VENTILATION

6

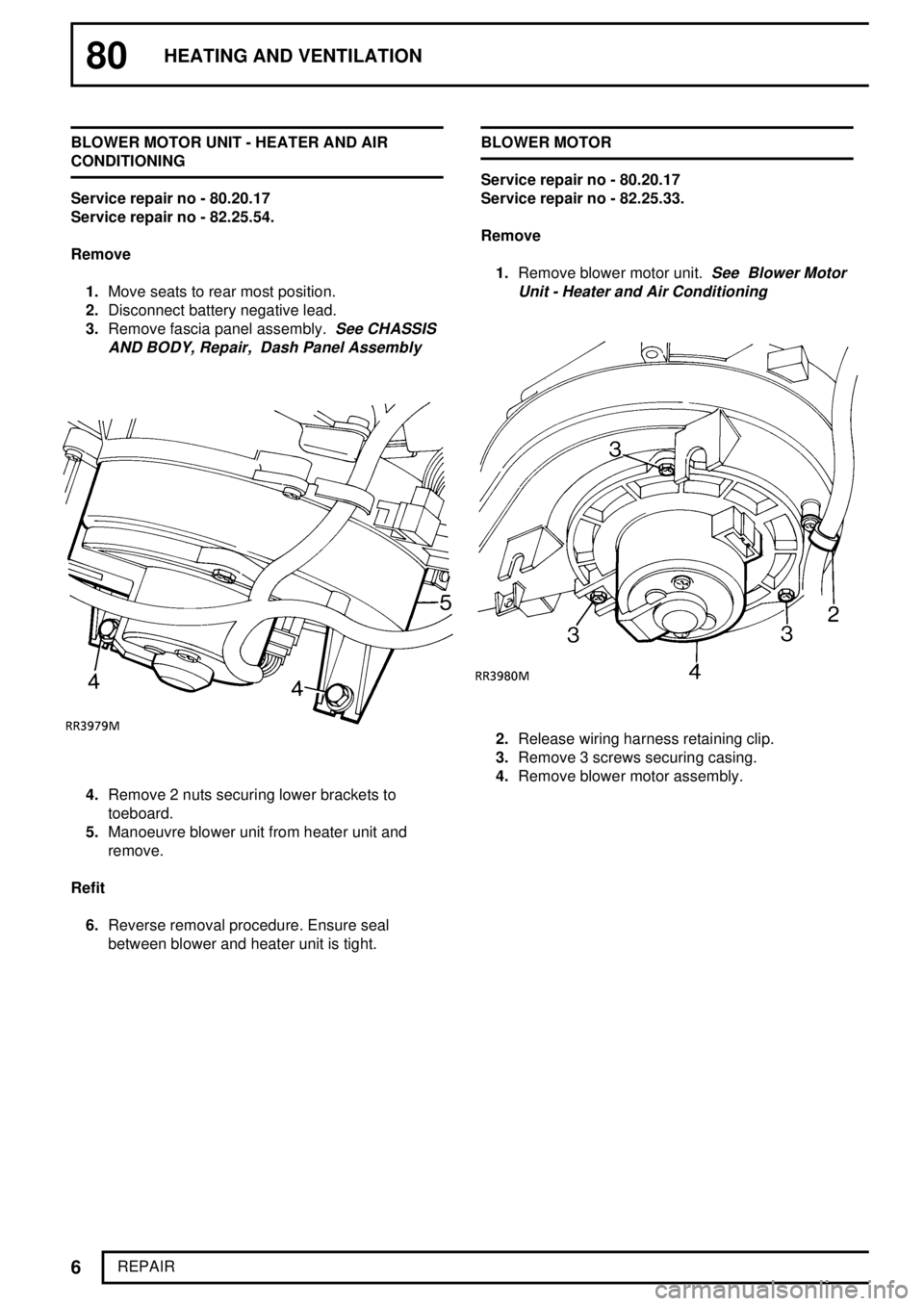

REPAIR BLOWER MOTOR UNIT - HEATER AND AIR

CONDITIONING

Service repair no - 80.20.17

Service repair no - 82.25.54.

Remove

1.Move seats to rear most position.

2.Disconnect battery negative lead.

3.Remove fascia panel assembly.

See CHASSIS

AND BODY, Repair, Dash Panel Assembly

4.Remove 2 nuts securing lower brackets to

toeboard.

5.Manoeuvre blower unit from heater unit and

remove.

Refit

6.Reverse removal procedure. Ensure seal

between blower and heater unit is tight.BLOWER MOTOR

Service repair no - 80.20.17

Service repair no - 82.25.33.

Remove

1.Remove blower motor unit.

See Blower Motor

Unit - Heater and Air Conditioning

2.Release wiring harness retaining clip.

3.Remove 3 screws securing casing.

4.Remove blower motor assembly.

Page 758 of 873

AIR CONDITIONING

3

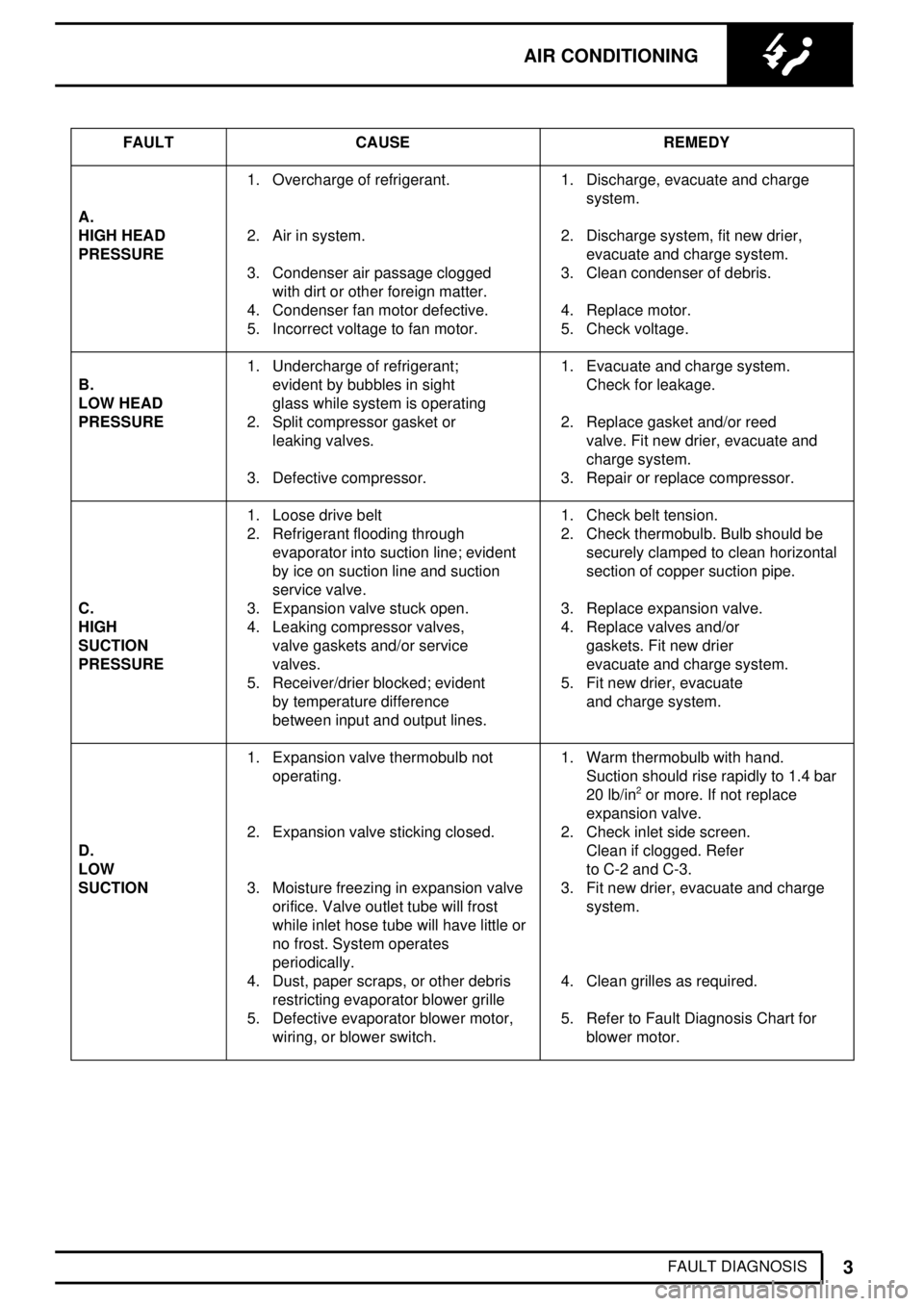

FAULT DIAGNOSIS FAULT CAUSE REMEDY

1. Overcharge of refrigerant. 1. Discharge, evacuate and charge

system.

A.

HIGH HEAD2. Air in system. 2. Discharge system, fit new drier,

PRESSUREevacuate and charge system.

3. Condenser air passage clogged 3. Clean condenser of debris.

with dirt or other foreign matter.

4. Condenser fan motor defective. 4. Replace motor.

5. Incorrect voltage to fan motor. 5. Check voltage.

1. Undercharge of refrigerant; 1. Evacuate and charge system.

B.evident by bubbles in sight Check for leakage.

LOW HEADglass while system is operating

PRESSURE2. Split compressor gasket or 2. Replace gasket and/or reed

leaking valves. valve. Fit new drier, evacuate and

charge system.

3. Defective compressor. 3. Repair or replace compressor.

1. Loose drive belt 1. Check belt tension.

2. Refrigerant flooding through

evaporator into suction line; evident

by ice on suction line and suction

service valve.2. Check thermobulb. Bulb should be

securely clamped to clean horizontal

section of copper suction pipe.

C.3. Expansion valve stuck open. 3. Replace expansion valve.

HIGH4. Leaking compressor valves, 4. Replace valves and/or

SUCTIONvalve gaskets and/or service gaskets. Fit new drier

PRESSUREvalves. evacuate and charge system.

5. Receiver/drier blocked; evident 5. Fit new drier, evacuate

by temperature difference and charge system.

between input and output lines.

1. Expansion valve thermobulb not 1. Warm thermobulb with hand.

operating. Suction should rise rapidly to 1.4 bar

20 lb/in

2or more. If not replace

expansion valve.

2. Expansion valve sticking closed. 2. Check inlet side screen.

D.Clean if clogged. Refer

LOWto C-2 and C-3.

SUCTION3. Moisture freezing in expansion valve

orifice. Valve outlet tube will frost

while inlet hose tube will have little or

no frost. System operates

periodically.3. Fit new drier, evacuate and charge

system.

4. Dust, paper scraps, or other debris

restricting evaporator blower grille4. Clean grilles as required.

5. Defective evaporator blower motor,

wiring, or blower switch.5. Refer to Fault Diagnosis Chart for

blower motor.

Page 772 of 873

AIR CONDITIONING

7

REPAIR

12.Disconnect receiver/drier pipes at condenser

unions.

13.Remove retaining bracket from side pipe.

14.Remove LH pipe from condenser and discard 'O'

ring.

15.Remove 2 screws securing receiver/drier

bracket.

16.Release pipes from lower clips and remove

receiver/drier assembly.

17.Remove 'O' ring from RH pipe

18.Remove 2 screws securing lower end of each

fan motor.

19.Remove 2 bolts and remove condenser lower

mounting bracket.

20.Remove 2 bolts and securing condenser upper

mounting bracket.

21.Remove upper mounting bracket and fan motor

assembly.

22.Remove 2 screws securing each side mounting

bracket and remove the brackets.

23.Transfer parts removed to new condenser.

24.Add 40 ml of refrigerant oil to new compressor to

compensate for oil loss.

Refit

25.Reverse removal procedure. 3 to 11.

26.Evacuate and recharge air conditioning system.

See Adjustment, Refrigerant Recovery

Recycling Recharging

27.Carry out leak test on disturbed joints.See

Adjustment, Leak Test System

28.Check air conditioning operation by carrying out

a System Test.

See Adjustment, System Test

CONDENSER FANS AND MOTORS

Service repair no - 82.15.01 - Motor

Service repair no - 82.15.03 - Fan

Remove

1.Remove condenser assembly.

See Condenser

2.Remove 4 bolts securing fan cowl to condenser.

3.Remove 3 bolts securing fan motor to cowl.

4.Remove fan motor assembly.

5.Remove 3 screws securing fan blades to motor.

6.Remove fan blades.

Refit

7.Reverse removal procedure. Ensuring that wiring

is clipped and no fouling of fan blade can occur.

Page 775 of 873

82AIR CONDITIONING

10

REPAIR 2.Disconnect 2 Lucar connectors from thermostat.

3.Position wiring aside.

4.Remove 2 screws securing heater pipe bracket

and position pipes aside.

5.Remove 10 clips retaining upper and lower

casings.

6.Remove 5 screws retaining upper casing.

7.Remove lower casing and evaporator.

8.Remove 4 clips securing evaporator top cover.

9.Remove evaporator top cover.

10.Remove thermostat sensor from evaporator

matrix.

11.Remove evaporator assembly from lower casing.

12.Remove bulkhead seal from case.

Expansion valve

13.Remove insulation from evaporator and

expansion valve connections.

14.Remove expansion valve sensor retaining clip.

15.Unscrew 2 pipe unions. Discard 'O' ring seals.

CAUTION: Use a second wrench to

support pipe adapters and plug

connections.

16.Remove expansion valve.

17.Unscrew pipe union. Discard 'O' ring seal.

18.Remove evaporator pipe.

Refit

19.Reverse removal procedure. Use new 'O' rings,

insulation and bulkhead seal.

NOTE: Use refrigerant oil on all 'O' rings

and mating surfaces. Tighten connection

See Specifications, torque, Torque Values

20.Wrap all exposed metal at hose connections with

prestite tape.

21.Evacuate and recharge system.

See

Adjustment, Refrigerant Recovery Recycling

Recharging

22.Leak test any disturbed joints.See Adjustment,

Leak Test System

23.Perform a functional check.

24.Disconnect service unit.

Page 796 of 873

WIPERS AND WASHERS

1

FAULT DIAGNOSIS WIPER MOTOR CHECKING

NOTE: These instructions apply to

windscreen and rear window wiper motor.

If unsatisfactory operation of wiping equipment is

experienced, a systematic check to determine fault

should be carried out:

1.Check blades for signs of excessive friction. This

reduces wiping speed of motor and cause

increased current draw which may damage

armature. Check by substitution.

2.Check windscreen wiper motor light running

current and speed with motor coupling link

disconnected from wiper shaft transmission

linkage.

Check rear window glass wiper motor with wiper

connected and glass wet. Connect an ammeter in

series with motor supply. Measure current

consumption when motor is switched on. Check

operating speed by timing speed of rotation of motor

coupling link. The results should compare with figures

given in 'General Specification Data'.

NOTE: If vehicle wiring connections are

disconnected and an alternative supply

source is applied it is essential that

correct polarity is observed. Failure to observe

this will cause motor to rotate in reverse direction,

which may result in limit switch contacts being

damaged.

3.If motor does not run satisfactorily or takes

higher than normal current, a fault exists and

must be remedied.

4.If current consumption and speed of motor are

satisfactory. A check should be carried out for

proper functioning of transmission linkage and

wiper arm shafts.

NOTE: Service parts are not available for

windscreen and rear window wiper motors

with exception of windscreen wiper rotary

connecting link.

Page 816 of 873

86ELECTRICAL

2

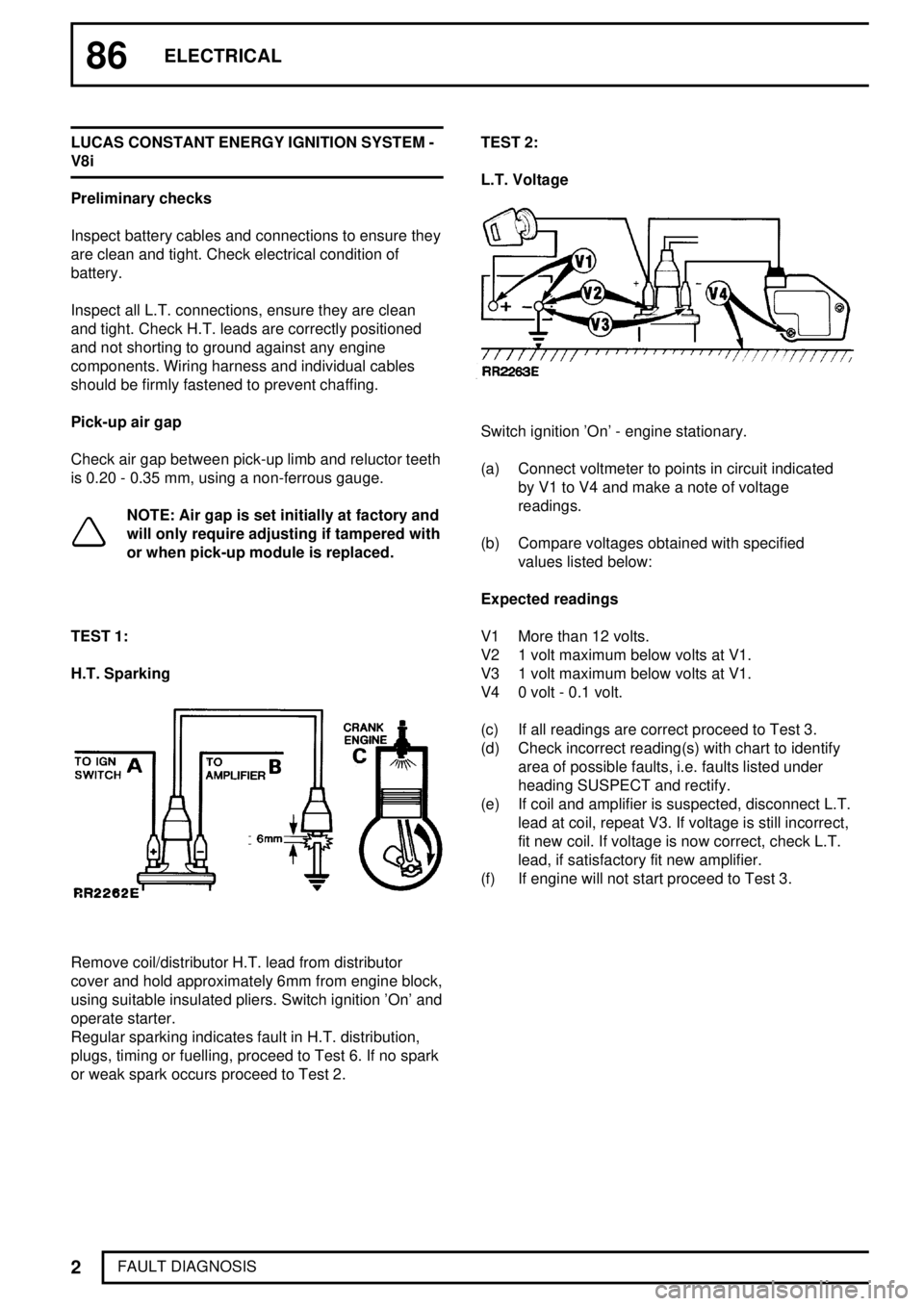

FAULT DIAGNOSIS LUCAS CONSTANT ENERGY IGNITION SYSTEM -

V8i

Preliminary checks

Inspect battery cables and connections to ensure they

are clean and tight. Check electrical condition of

battery.

Inspect all L.T. connections, ensure they are clean

and tight. Check H.T. leads are correctly positioned

and not shorting to ground against any engine

components. Wiring harness and individual cables

should be firmly fastened to prevent chaffing.

Pick-up air gap

Check air gap between pick-up limb and reluctor teeth

is 0.20 - 0.35 mm, using a non-ferrous gauge.

NOTE: Air gap is set initially at factory and

will only require adjusting if tampered with

or when pick-up module is replaced.

TEST 1:

H.T. Sparking

Remove coil/distributor H.T. lead from distributor

cover and hold approximately 6mm from engine block,

using suitable insulated pliers. Switch ignition 'On' and

operate starter.

Regular sparking indicates fault in H.T. distribution,

plugs, timing or fuelling, proceed to Test 6. If no spark

or weak spark occurs proceed to Test 2.TEST 2:

L.T. Voltage

Switch ignition 'On' - engine stationary.

(a) Connect voltmeter to points in circuit indicated

by V1 to V4 and make a note of voltage

readings.

(b) Compare voltages obtained with specified

values listed below:

Expected readings

V1 More than 12 volts.

V2 1 volt maximum below volts at V1.

V3 1 volt maximum below volts at V1.

V4 0 volt - 0.1 volt.

(c) If all readings are correct proceed to Test 3.

(d) Check incorrect reading(s) with chart to identify

area of possible faults, i.e. faults listed under

heading SUSPECT and rectify.

(e) If coil and amplifier is suspected, disconnect L.T.

lead at coil, repeat V3. If voltage is still incorrect,

fit new coil. If voltage is now correct, check L.T.

lead, if satisfactory fit new amplifier.

(f) If engine will not start proceed to Test 3.

Page 817 of 873

ELECTRICAL

3

FAULT DIAGNOSIS 1 2 3 4 SUSPECT

L * * * DISCHARGED BATTERY

* L L * IGN. SWITCH AND/OR

WIRING

* * L * COIL OR AMPLIFIER

* * * H AMPLIFIER GROUND

Key

*Expected Voltage

HVoltage higher than expected

LVoltage lower than expectedTEST 3:

Amplifier Switching

Connect voltmeter between battery positive (+ve)

terminal and H.T. coil negative (-ve) terminal.

Voltmeter should register 0 volts.

Switch ignition 'On', voltmeter should still register 0

volts.

Crank engine, voltmeter reading should increase

when cranking, in which case proceed to Test 5.

If no increase in voltage during cranking proceed to

Test 4.

Page 829 of 873

ELECTRICAL

9

REPAIR

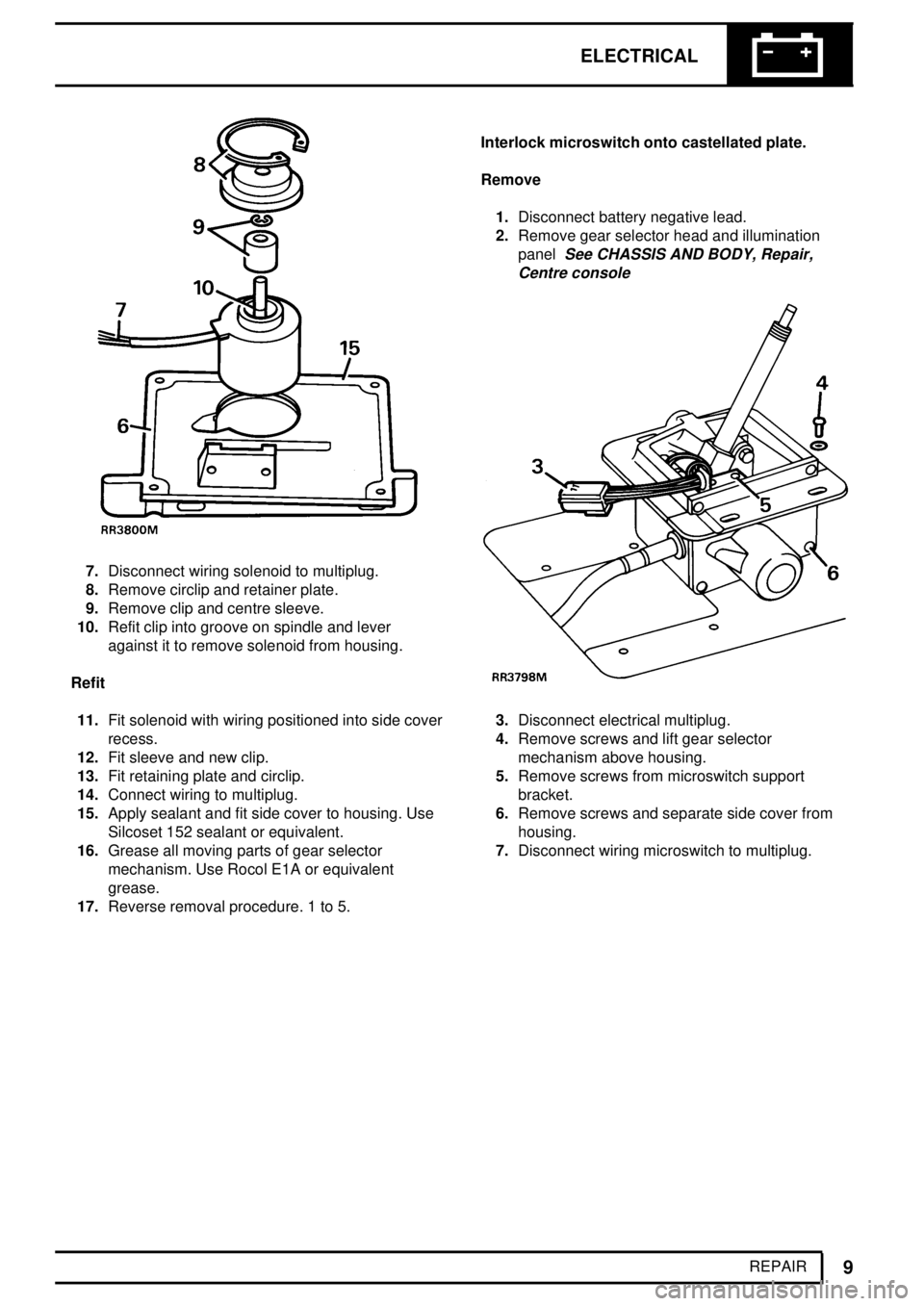

7.Disconnect wiring solenoid to multiplug.

8.Remove circlip and retainer plate.

9.Remove clip and centre sleeve.

10.Refit clip into groove on spindle and lever

against it to remove solenoid from housing.

Refit

11.Fit solenoid with wiring positioned into side cover

recess.

12.Fit sleeve and new clip.

13.Fit retaining plate and circlip.

14.Connect wiring to multiplug.

15.Apply sealant and fit side cover to housing. Use

Silcoset 152 sealant or equivalent.

16.Grease all moving parts of gear selector

mechanism. Use Rocol E1A or equivalent

grease.

17.Reverse removal procedure. 1 to 5.Interlock microswitch onto castellated plate.

Remove

1.Disconnect battery negative lead.

2.Remove gear selector head and illumination

panel

See CHASSIS AND BODY, Repair,

Centre console

3.Disconnect electrical multiplug.

4.Remove screws and lift gear selector

mechanism above housing.

5.Remove screws from microswitch support

bracket.

6.Remove screws and separate side cover from

housing.

7.Disconnect wiring microswitch to multiplug.

Page 830 of 873

86ELECTRICAL

10

REPAIR

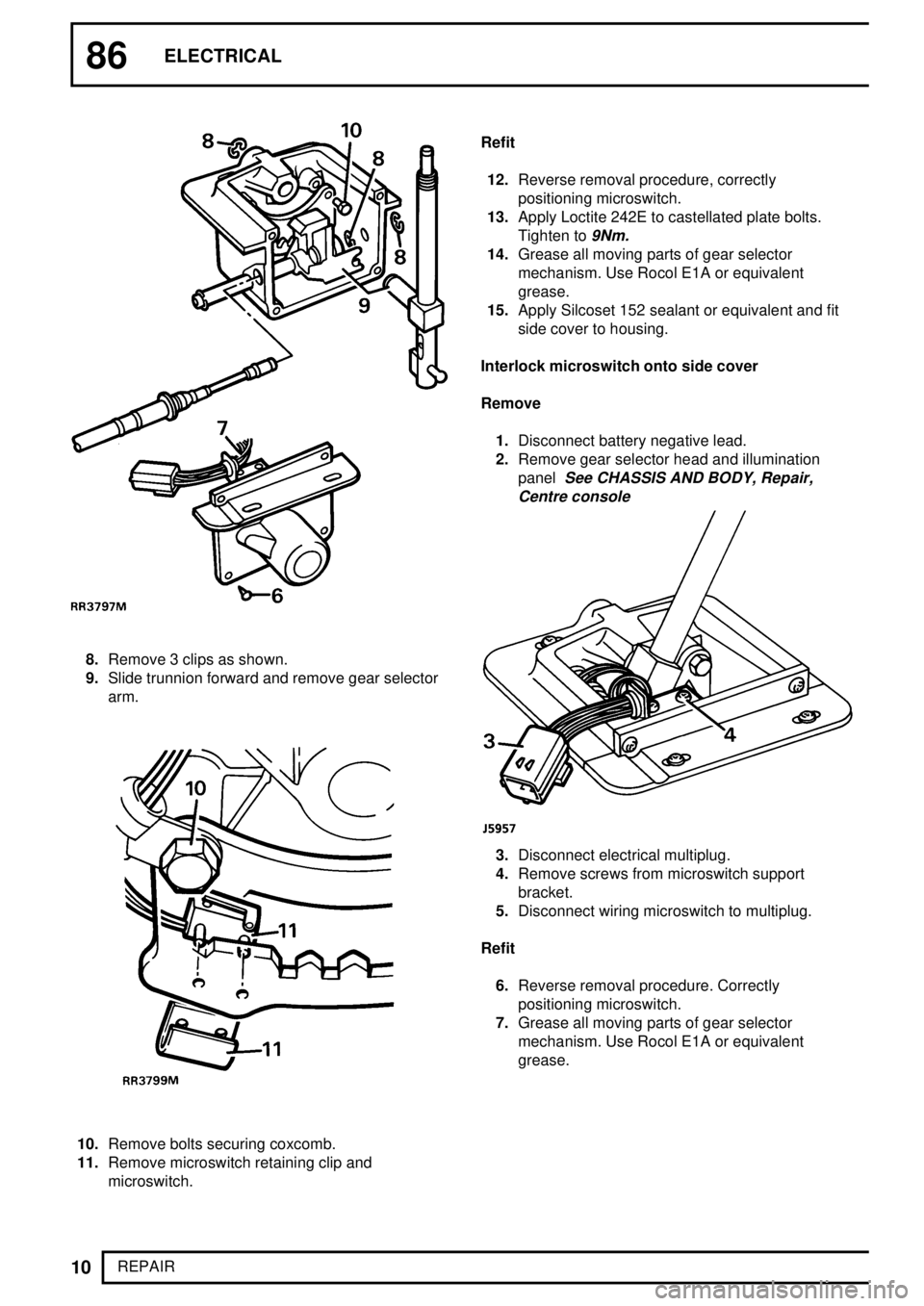

8.Remove 3 clips as shown.

9.Slide trunnion forward and remove gear selector

arm.

10.Remove bolts securing coxcomb.

11.Remove microswitch retaining clip and

microswitch.Refit

12.Reverse removal procedure, correctly

positioning microswitch.

13.Apply Loctite 242E to castellated plate bolts.

Tighten to

9Nm.

14.Grease all moving parts of gear selector

mechanism. Use Rocol E1A or equivalent

grease.

15.Apply Silcoset 152 sealant or equivalent and fit

side cover to housing.

Interlock microswitch onto side cover

Remove

1.Disconnect battery negative lead.

2.Remove gear selector head and illumination

panel

See CHASSIS AND BODY, Repair,

Centre console

3.Disconnect electrical multiplug.

4.Remove screws from microswitch support

bracket.

5.Disconnect wiring microswitch to multiplug.

Refit

6.Reverse removal procedure. Correctly

positioning microswitch.

7.Grease all moving parts of gear selector

mechanism. Use Rocol E1A or equivalent

grease.