check engine LAND ROVER DISCOVERY 1995 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 246 of 873

MFI

3

FAULT DIAGNOSIS FUEL PRESSURE CHECK

In order to check the fuel pressure it is necessary to

first depressurise the fuel system as follows:

WARNING: Under normal operating

conditions the multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar. When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

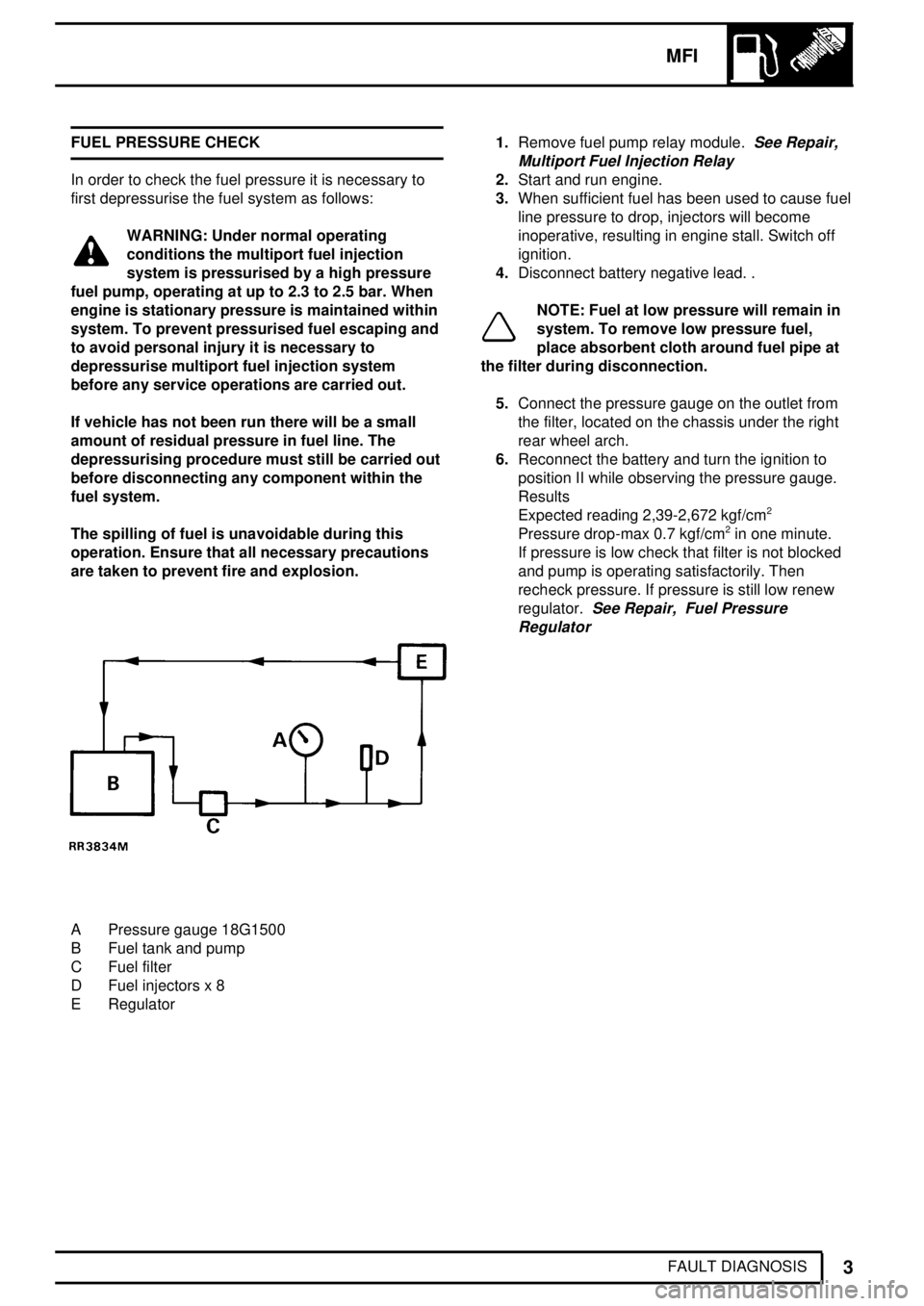

A Pressure gauge 18G1500

B Fuel tank and pump

C Fuel filter

D Fuel injectors x 8

E Regulator1.Remove fuel pump relay module.

See Repair,

Multiport Fuel Injection Relay

2.Start and run engine.

3.When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4.Disconnect battery negative lead. .

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel pipe at

the filter during disconnection.

5.Connect the pressure gauge on the outlet from

the filter, located on the chassis under the right

rear wheel arch.

6.Reconnect the battery and turn the ignition to

position II while observing the pressure gauge.

Results

Expected reading 2,39-2,672 kgf/cm

2

Pressure drop-max 0.7 kgf/cm2in one minute.

If pressure is low check that filter is not blocked

and pump is operating satisfactorily. Then

recheck pressure. If pressure is still low renew

regulator.

See Repair, Fuel Pressure

Regulator

Page 252 of 873

19FUEL SYSTEM

6

REPAIR ENGINE COOLANT TEMPERATURE SENSOR

Service repair no - 19.22.18

Remove

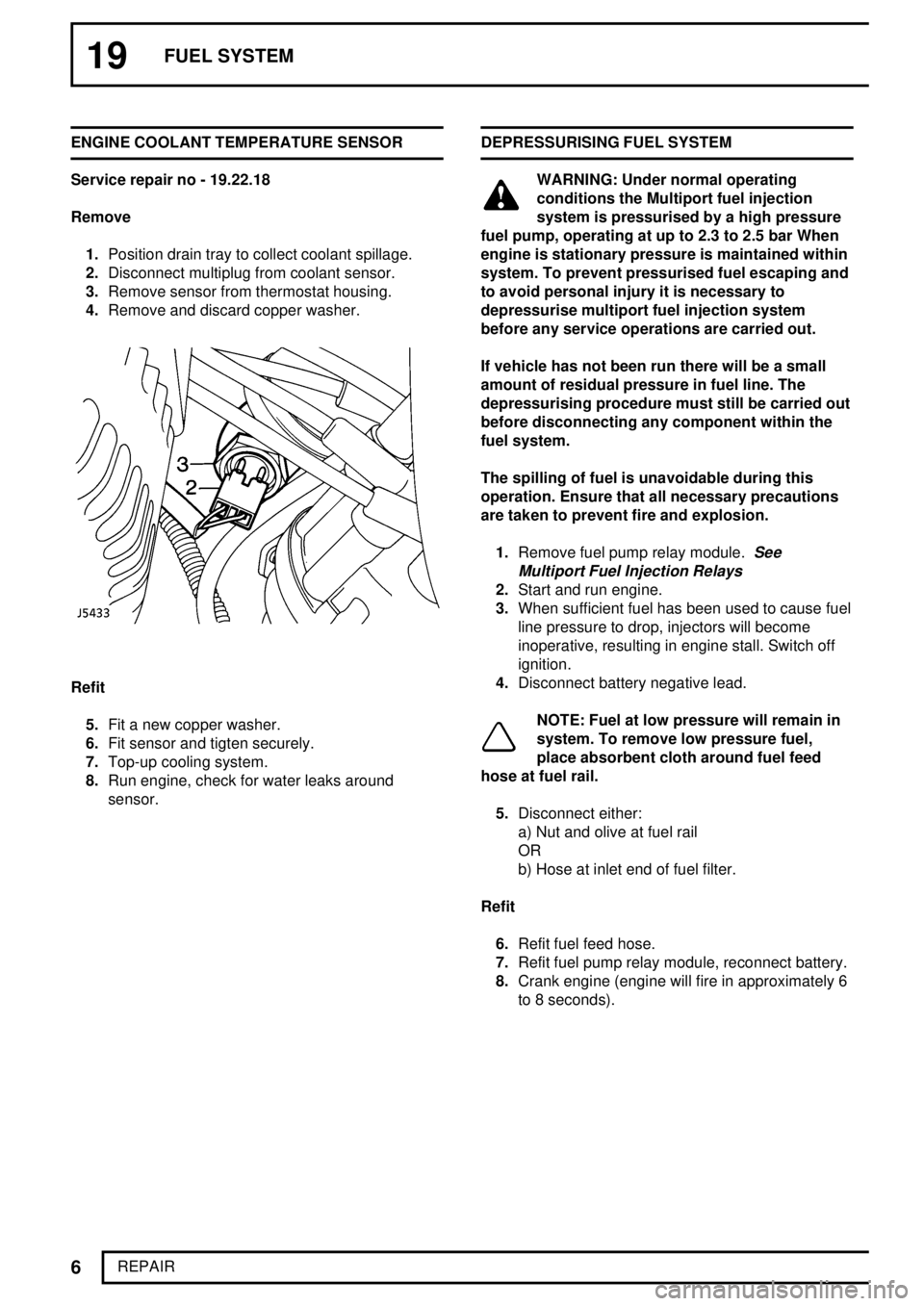

1.Position drain tray to collect coolant spillage.

2.Disconnect multiplug from coolant sensor.

3.Remove sensor from thermostat housing.

4.Remove and discard copper washer.

Refit

5.Fit a new copper washer.

6.Fit sensor and tigten securely.

7.Top-up cooling system.

8.Run engine, check for water leaks around

sensor.DEPRESSURISING FUEL SYSTEM

WARNING: Under normal operating

conditions the Multiport fuel injection

system is pressurised by a high pressure

fuel pump, operating at up to 2.3 to 2.5 bar When

engine is stationary pressure is maintained within

system. To prevent pressurised fuel escaping and

to avoid personal injury it is necessary to

depressurise multiport fuel injection system

before any service operations are carried out.

If vehicle has not been run there will be a small

amount of residual pressure in fuel line. The

depressurising procedure must still be carried out

before disconnecting any component within the

fuel system.

The spilling of fuel is unavoidable during this

operation. Ensure that all necessary precautions

are taken to prevent fire and explosion.

1.Remove fuel pump relay module.

See

Multiport Fuel Injection Relays

2.Start and run engine.

3.When sufficient fuel has been used to cause fuel

line pressure to drop, injectors will become

inoperative, resulting in engine stall. Switch off

ignition.

4.Disconnect battery negative lead.

NOTE: Fuel at low pressure will remain in

system. To remove low pressure fuel,

place absorbent cloth around fuel feed

hose at fuel rail.

5.Disconnect either:

a) Nut and olive at fuel rail

OR

b) Hose at inlet end of fuel filter.

Refit

6.Refit fuel feed hose.

7.Refit fuel pump relay module, reconnect battery.

8.Crank engine (engine will fire in approximately 6

to 8 seconds).

Page 262 of 873

19FUEL SYSTEM

16

REPAIR Refit

1.Clean mating faces of cylinder heads, cylinder

block and intake manifold.

2.Locate NEW seals in position with ends

engaged in notches formed between the cylinder

heads and block.

3.Apply RTV sealant between ends of seals,

cylinder head and block.

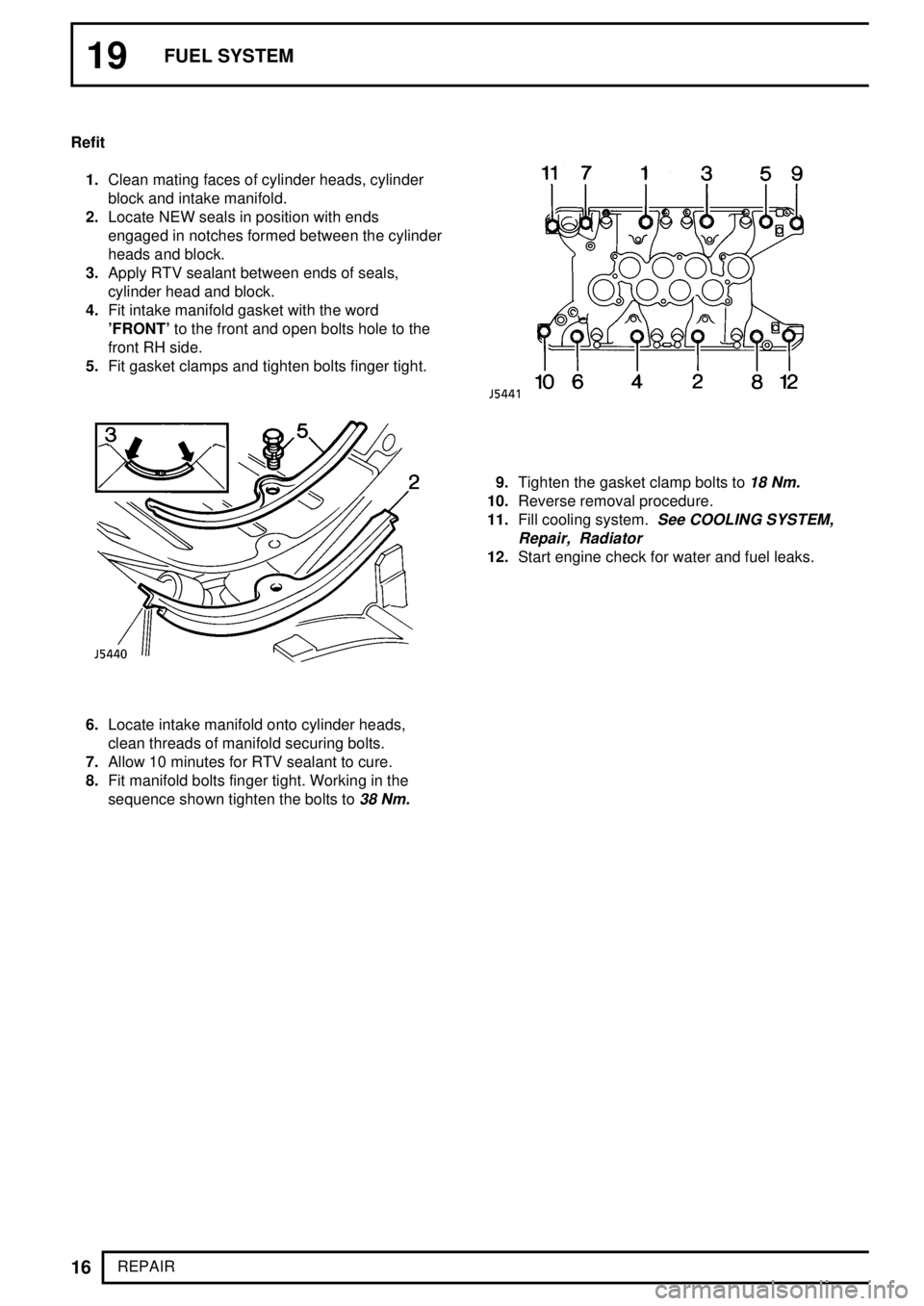

4.Fit intake manifold gasket with the word

'FRONT'to the front and open bolts hole to the

front RH side.

5.Fit gasket clamps and tighten bolts finger tight.

6.Locate intake manifold onto cylinder heads,

clean threads of manifold securing bolts.

7.Allow 10 minutes for RTV sealant to cure.

8.Fit manifold bolts finger tight. Working in the

sequence shown tighten the bolts to

38 Nm.

9.Tighten the gasket clamp bolts to18 Nm.

10.Reverse removal procedure.

11.Fill cooling system.

See COOLING SYSTEM,

Repair, Radiator

12.Start engine check for water and fuel leaks.

Page 265 of 873

MFI

19

REPAIR THROTTLE CABLE

Service repair no - 19.20.06

Remove

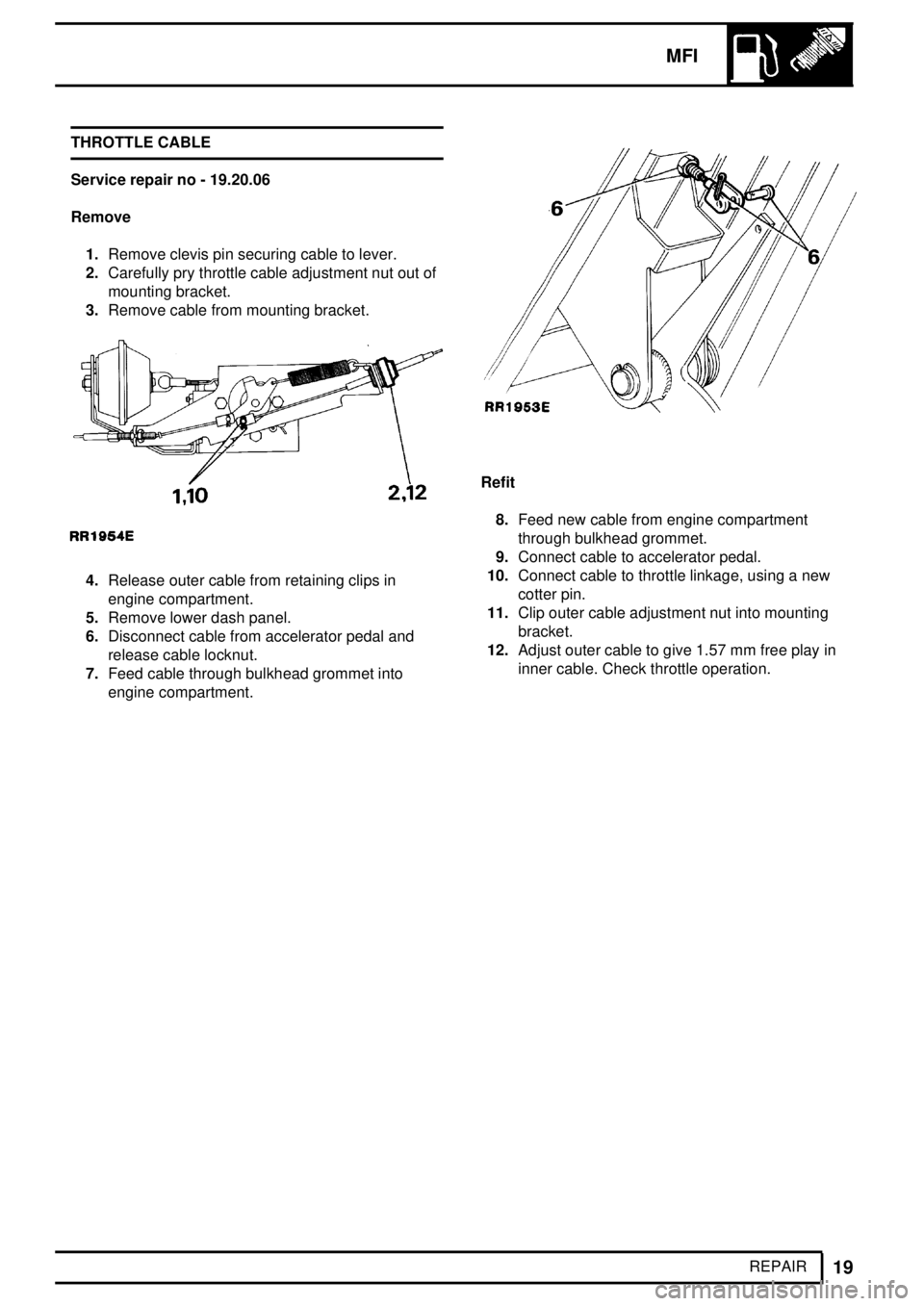

1.Remove clevis pin securing cable to lever.

2.Carefully pry throttle cable adjustment nut out of

mounting bracket.

3.Remove cable from mounting bracket.

4.Release outer cable from retaining clips in

engine compartment.

5.Remove lower dash panel.

6.Disconnect cable from accelerator pedal and

release cable locknut.

7.Feed cable through bulkhead grommet into

engine compartment.

Refit

8.Feed new cable from engine compartment

through bulkhead grommet.

9.Connect cable to accelerator pedal.

10.Connect cable to throttle linkage, using a new

cotter pin.

11.Clip outer cable adjustment nut into mounting

bracket.

12.Adjust outer cable to give 1.57 mm free play in

inner cable. Check throttle operation.

Page 267 of 873

MFI

21

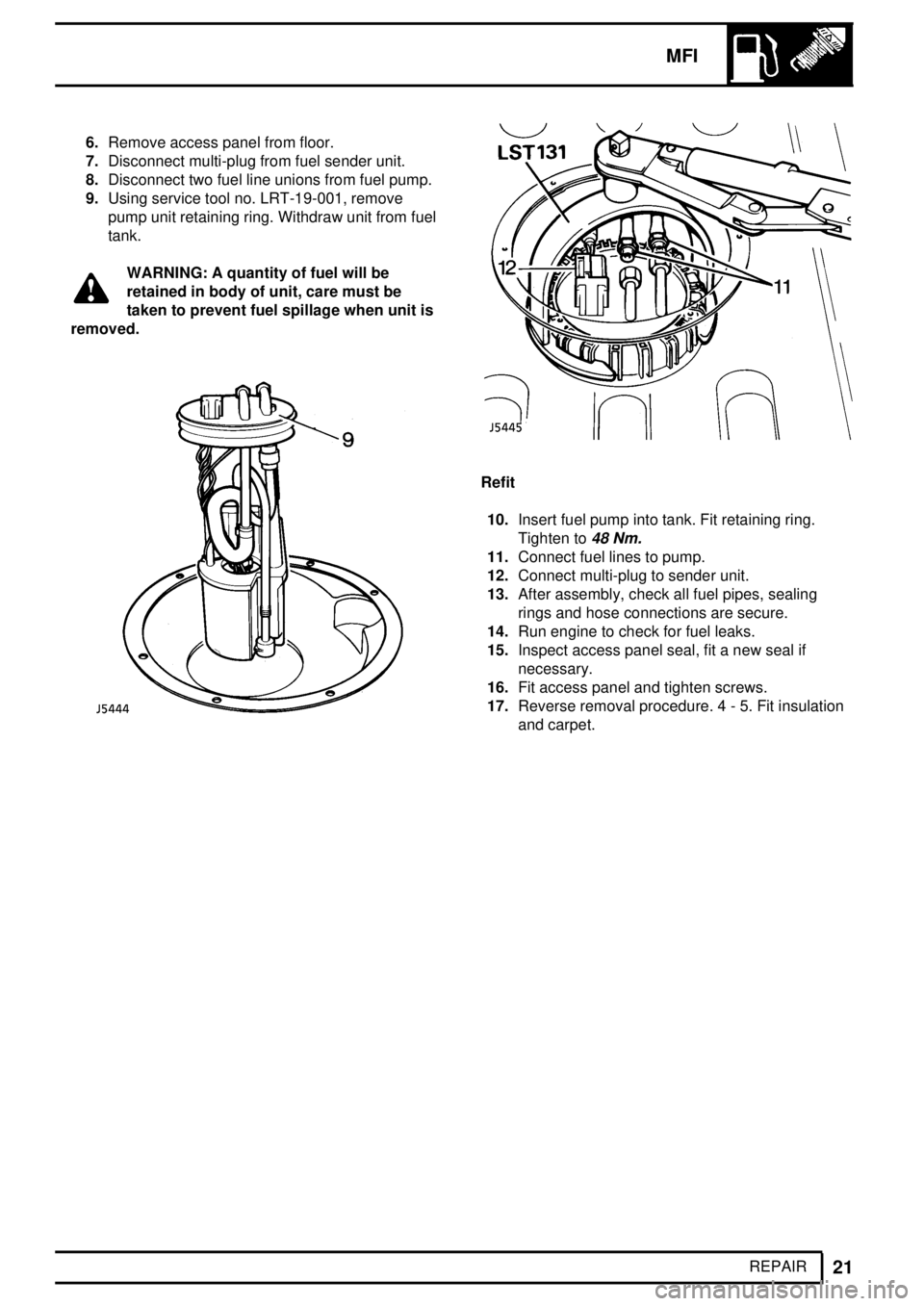

REPAIR 6.Remove access panel from floor.

7.Disconnect multi-plug from fuel sender unit.

8.Disconnect two fuel line unions from fuel pump.

9.Using service tool no. LRT-19-001, remove

pump unit retaining ring. Withdraw unit from fuel

tank.

WARNING: A quantity of fuel will be

retained in body of unit, care must be

taken to prevent fuel spillage when unit is

removed.

Refit

10.Insert fuel pump into tank. Fit retaining ring.

Tighten to

48 Nm.

11.Connect fuel lines to pump.

12.Connect multi-plug to sender unit.

13.After assembly, check all fuel pipes, sealing

rings and hose connections are secure.

14.Run engine to check for fuel leaks.

15.Inspect access panel seal, fit a new seal if

necessary.

16.Fit access panel and tighten screws.

17.Reverse removal procedure. 4 - 5. Fit insulation

and carpet.

Page 269 of 873

MFI

23

REPAIR

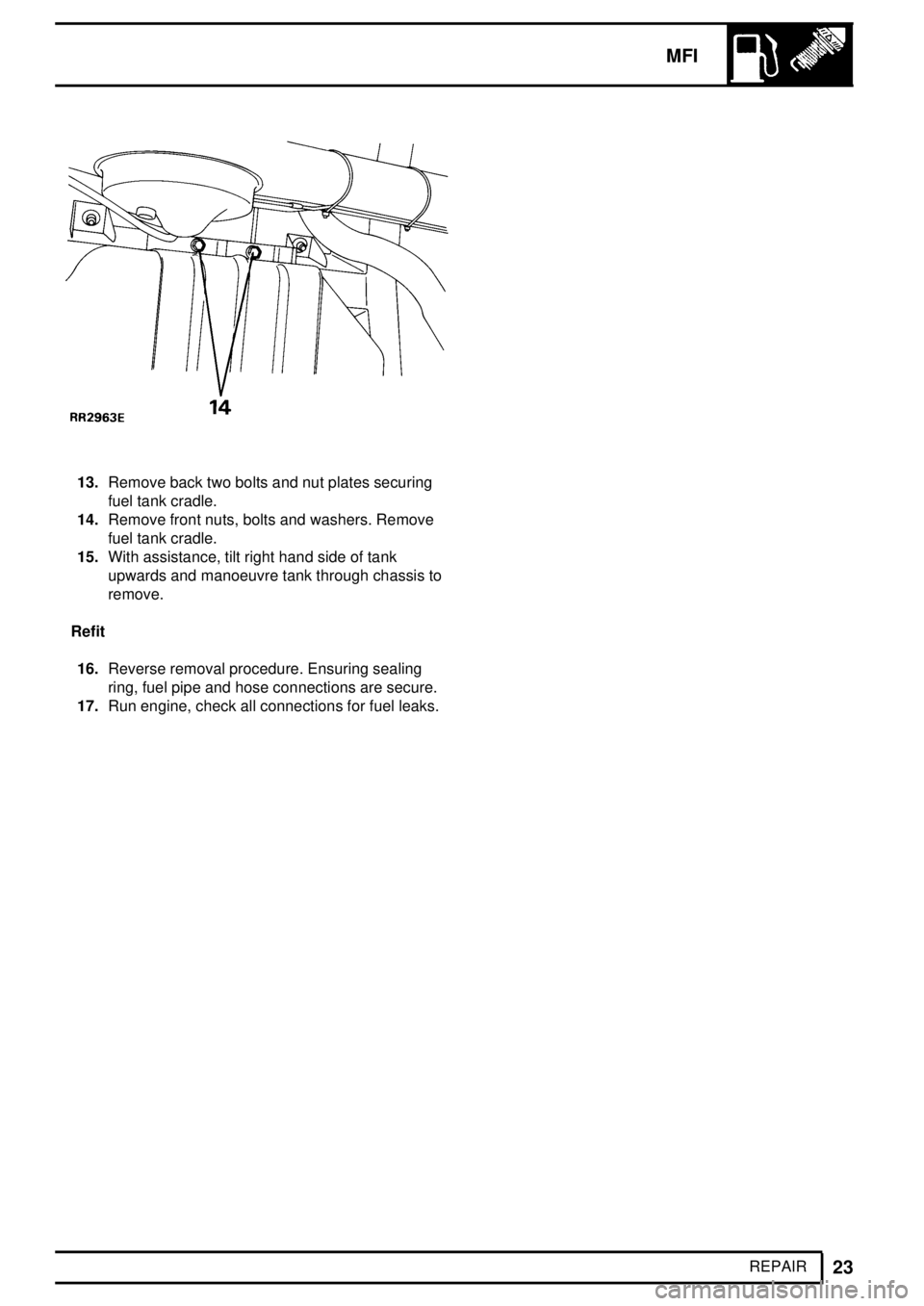

13.Remove back two bolts and nut plates securing

fuel tank cradle.

14.Remove front nuts, bolts and washers. Remove

fuel tank cradle.

15.With assistance, tilt right hand side of tank

upwards and manoeuvre tank through chassis to

remove.

Refit

16.Reverse removal procedure. Ensuring sealing

ring, fuel pipe and hose connections are secure.

17.Run engine, check all connections for fuel leaks.

Page 283 of 873

SFI

1

ADJUSTMENT ENGINE TUNING

Service repair no - 19.22.13

The position of the Idle Air Control (IAC) valve can be

checked using TestBook and adjusted if necessary

through the by-pass screw in the plenum chamber.

The bypass screw is covered by a tamper proof plug

which can be extracted using a self tapping screw.

All vehicles:

1.Ensure air conditioning and all electical loads are

off. Vehicle must be in neutral or park with air

suspension in kneel and disabled.

2.Carry out tuning or base idle setting procedure

as applicable using TestBook.

Page 285 of 873

19FUEL SYSTEM

2

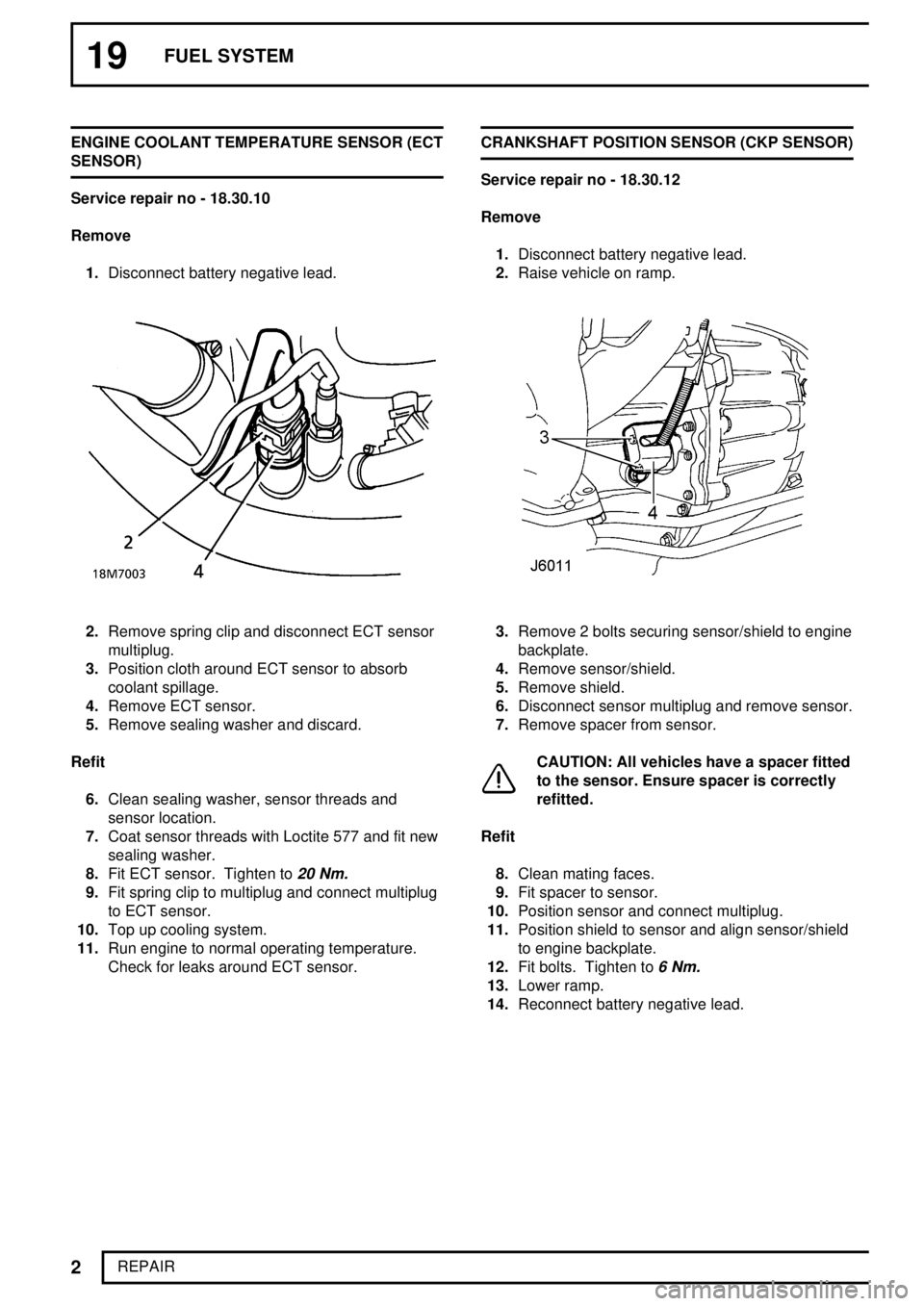

REPAIR ENGINE COOLANT TEMPERATURE SENSOR (ECT

SENSOR)

Service repair no - 18.30.10

Remove

1.Disconnect battery negative lead.

2.Remove spring clip and disconnect ECT sensor

multiplug.

3.Position cloth around ECT sensor to absorb

coolant spillage.

4.Remove ECT sensor.

5.Remove sealing washer and discard.

Refit

6.Clean sealing washer, sensor threads and

sensor location.

7.Coat sensor threads with Loctite 577 and fit new

sealing washer.

8.Fit ECT sensor. Tighten to

20 Nm.

9.Fit spring clip to multiplug and connect multiplug

to ECT sensor.

10.Top up cooling system.

11.Run engine to normal operating temperature.

Check for leaks around ECT sensor.CRANKSHAFT POSITION SENSOR (CKP SENSOR)

Service repair no - 18.30.12

Remove

1.Disconnect battery negative lead.

2.Raise vehicle on ramp.

3.Remove 2 bolts securing sensor/shield to engine

backplate.

4.Remove sensor/shield.

5.Remove shield.

6.Disconnect sensor multiplug and remove sensor.

7.Remove spacer from sensor.

CAUTION: All vehicles have a spacer fitted

to the sensor. Ensure spacer is correctly

refitted.

Refit

8.Clean mating faces.

9.Fit spacer to sensor.

10.Position sensor and connect multiplug.

11.Position shield to sensor and align sensor/shield

to engine backplate.

12.Fit bolts. Tighten to

6 Nm.

13.Lower ramp.

14.Reconnect battery negative lead.

Page 289 of 873

19FUEL SYSTEM

6

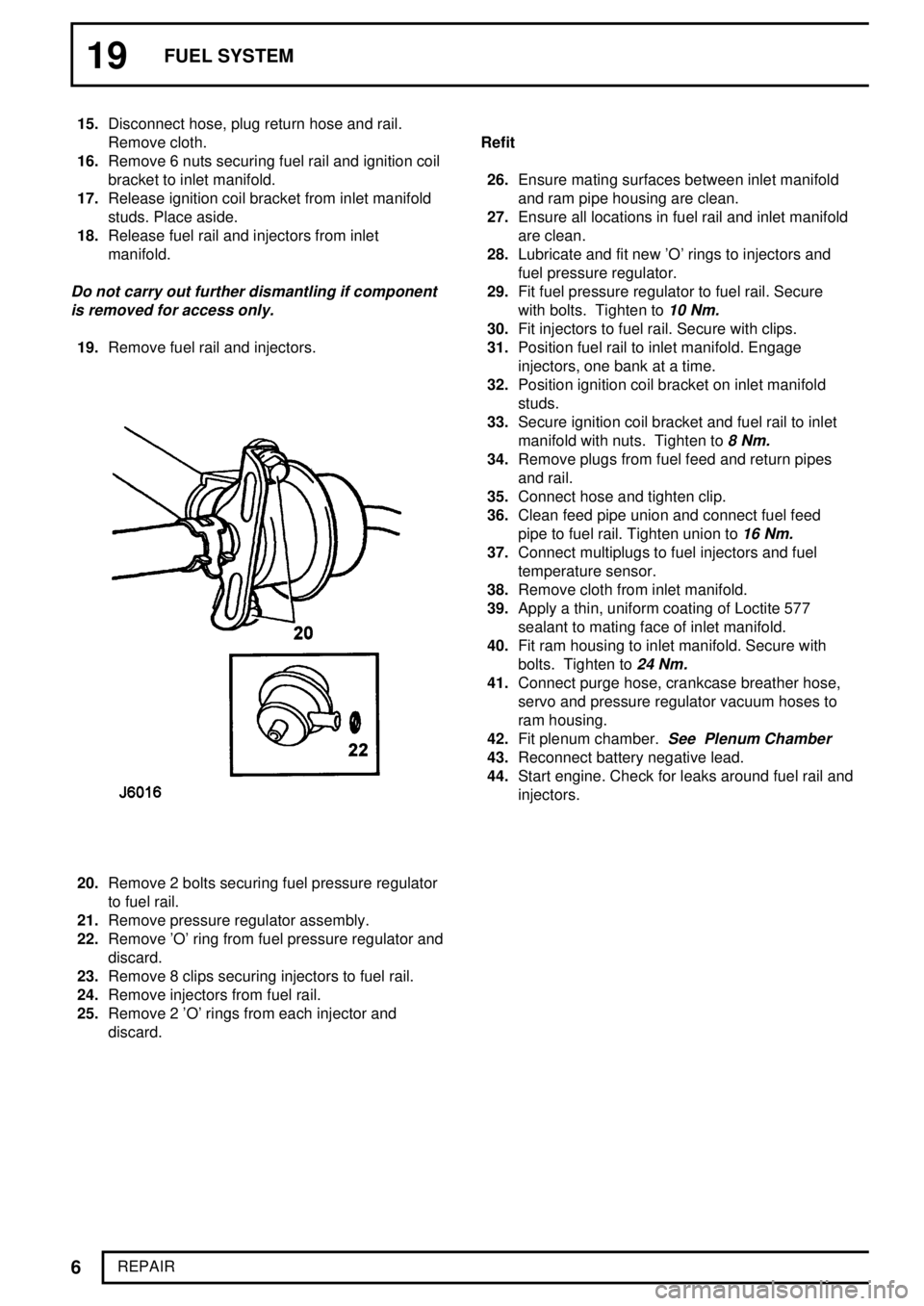

REPAIR 15.Disconnect hose, plug return hose and rail.

Remove cloth.

16.Remove 6 nuts securing fuel rail and ignition coil

bracket to inlet manifold.

17.Release ignition coil bracket from inlet manifold

studs. Place aside.

18.Release fuel rail and injectors from inlet

manifold.

Do not carry out further dismantling if component

is removed for access only.

19.Remove fuel rail and injectors.

20.Remove 2 bolts securing fuel pressure regulator

to fuel rail.

21.Remove pressure regulator assembly.

22.Remove 'O' ring from fuel pressure regulator and

discard.

23.Remove 8 clips securing injectors to fuel rail.

24.Remove injectors from fuel rail.

25.Remove 2 'O' rings from each injector and

discard.Refit

26.Ensure mating surfaces between inlet manifold

and ram pipe housing are clean.

27.Ensure all locations in fuel rail and inlet manifold

are clean.

28.Lubricate and fit new 'O' rings to injectors and

fuel pressure regulator.

29.Fit fuel pressure regulator to fuel rail. Secure

with bolts. Tighten to

10 Nm.

30.Fit injectors to fuel rail. Secure with clips.

31.Position fuel rail to inlet manifold. Engage

injectors, one bank at a time.

32.Position ignition coil bracket on inlet manifold

studs.

33.Secure ignition coil bracket and fuel rail to inlet

manifold with nuts. Tighten to

8 Nm.

34.Remove plugs from fuel feed and return pipes

and rail.

35.Connect hose and tighten clip.

36.Clean feed pipe union and connect fuel feed

pipe to fuel rail. Tighten union to

16 Nm.

37.Connect multiplugs to fuel injectors and fuel

temperature sensor.

38.Remove cloth from inlet manifold.

39.Apply a thin, uniform coating of Loctite 577

sealant to mating face of inlet manifold.

40.Fit ram housing to inlet manifold. Secure with

bolts. Tighten to

24 Nm.

41.Connect purge hose, crankcase breather hose,

servo and pressure regulator vacuum hoses to

ram housing.

42.Fit plenum chamber.

See Plenum Chamber

43.Reconnect battery negative lead.

44.Start engine. Check for leaks around fuel rail and

injectors.

Page 295 of 873

19FUEL SYSTEM

12

REPAIR Refit

15.Ensure locations on fuel pressure regulator and

fuel rail are clean.

16.Fit new spacer ring and 'O' ring to fuel pressure

regulator. Lubricate 'O' ring with silicone grease.

17.Fit pressure regulator assembly to fuel rail.

18.Secure regulator connecting pipe in clip.

19.Secure with bolts. Tighten to

10 Nm.

20.Align ignition coil bracket to inlet manifold studs.

21.Secure ignition coil bracket and fuel rail to inlet

manifold with nuts. Tighten to

8 Nm.

22.Remove plugs.

23.Connect return pipe to regulator connecting pipe.

Secure with clip.

24.Connect vacuum hose to fuel pressure regulator.

25.Remove cloth.

26.Reconnect battery negative lead.

27.Start engine. Check for leaks around fuel

pressure regulator, fuel feed and fuel return

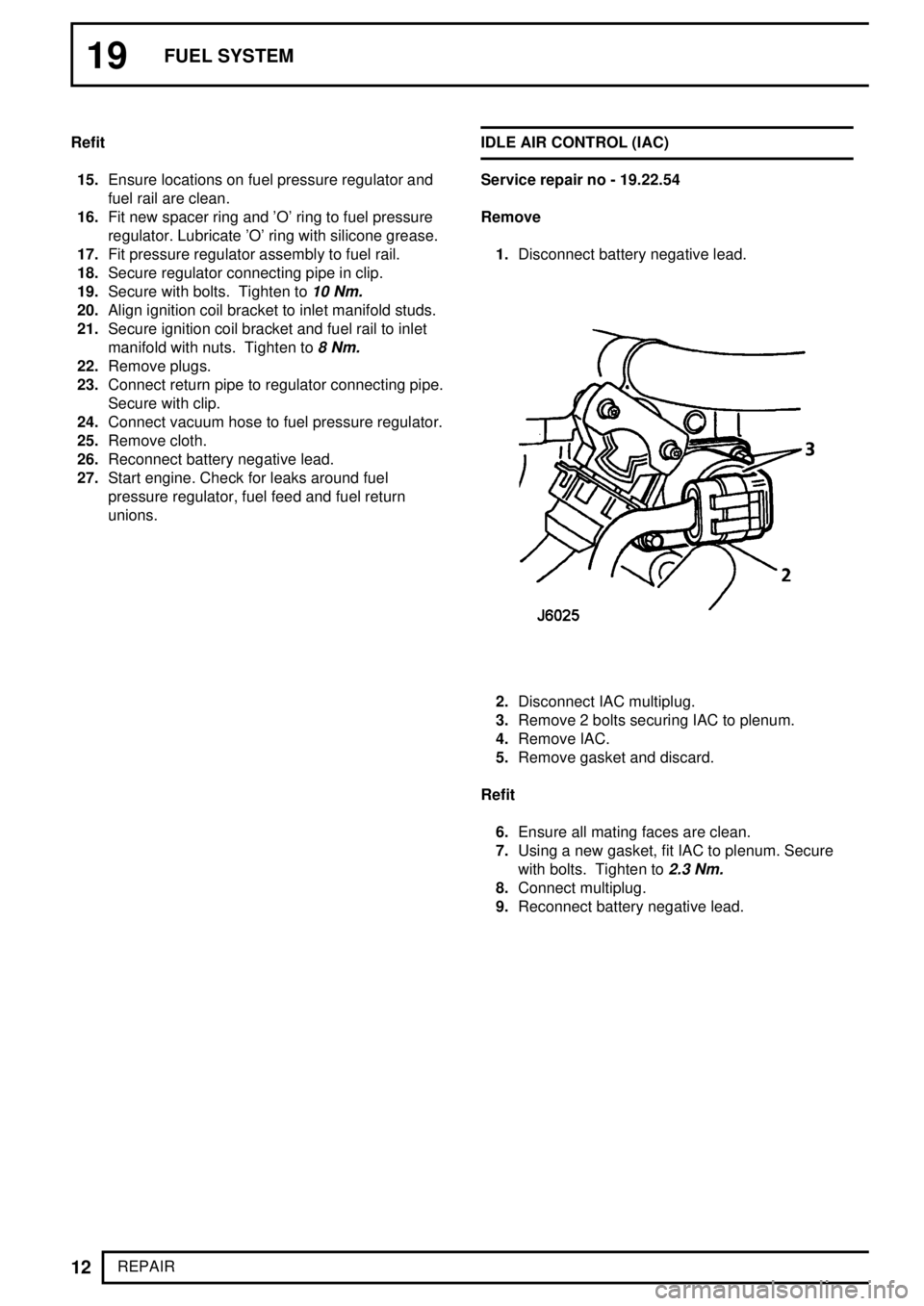

unions.IDLE AIR CONTROL (IAC)

Service repair no - 19.22.54

Remove

1.Disconnect battery negative lead.

2.Disconnect IAC multiplug.

3.Remove 2 bolts securing IAC to plenum.

4.Remove IAC.

5.Remove gasket and discard.

Refit

6.Ensure all mating faces are clean.

7.Using a new gasket, fit IAC to plenum. Secure

with bolts. Tighten to

2.3 Nm.

8.Connect multiplug.

9.Reconnect battery negative lead.