LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 201 of 1529

ENGINE - V8

12-2-46 OVERHAUL

11.Noting fitted position of 4 long screws or multi-

hex bolts, remove and discard 8 screws/bolts

securing rocker covers; remove rocker covers.

CAUTION: Screws/bolts must be replaced

with new 'patched' multi-hex bolts.

12.Remove and discard rocker cover gaskets. 13.Using the sequence shown, remove 12 bolts

securing the inlet manifold.

14.Remove inlet manifold assembly.

Page 202 of 1529

ENGINE - V8

OVERHAUL 12-2-47

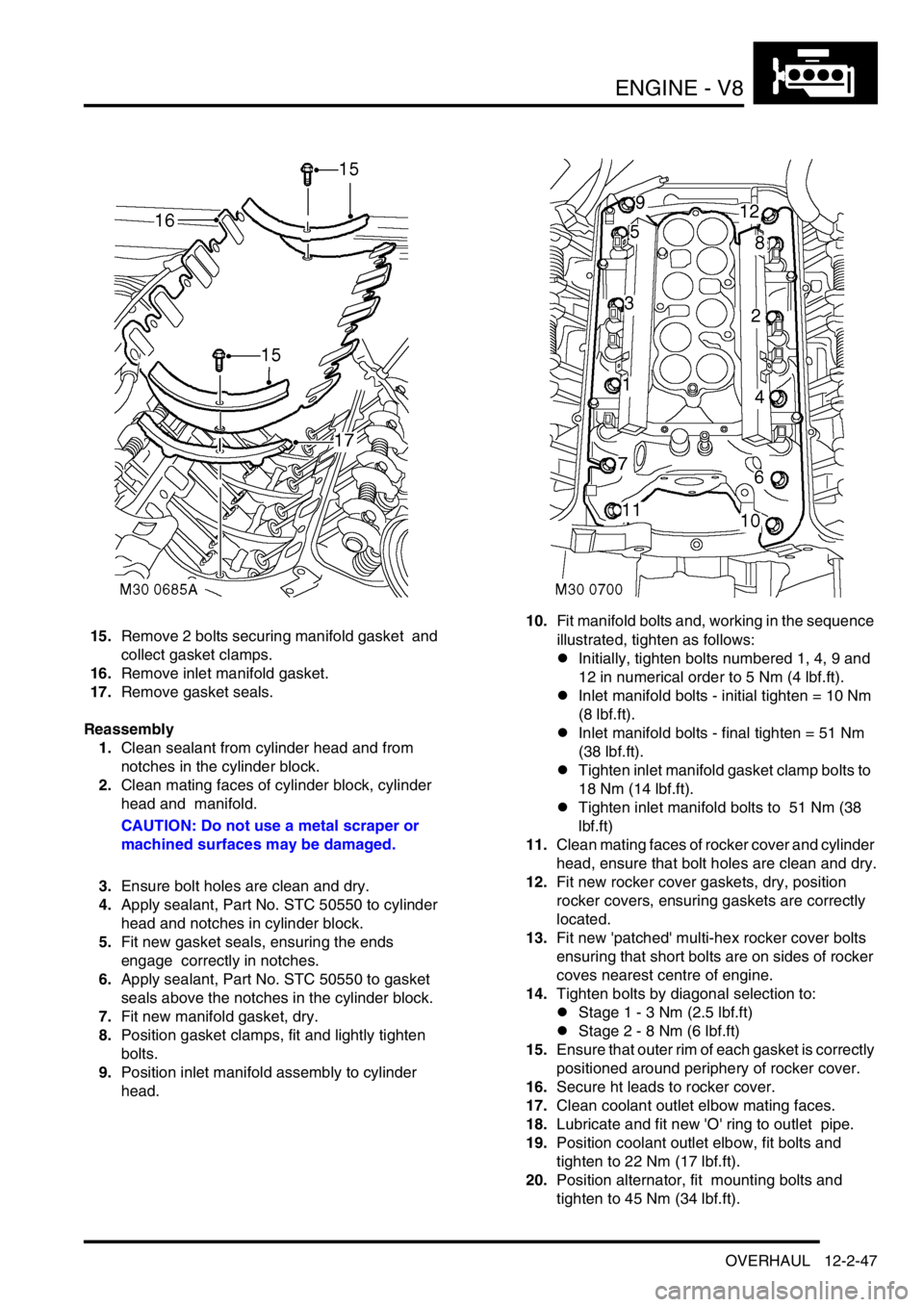

15.Remove 2 bolts securing manifold gasket and

collect gasket clamps.

16.Remove inlet manifold gasket.

17.Remove gasket seals.

Reassembly

1.Clean sealant from cylinder head and from

notches in the cylinder block.

2.Clean mating faces of cylinder block, cylinder

head and manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

3.Ensure bolt holes are clean and dry.

4.Apply sealant, Part No. STC 50550 to cylinder

head and notches in cylinder block.

5.Fit new gasket seals, ensuring the ends

engage correctly in notches.

6.Apply sealant, Part No. STC 50550 to gasket

seals above the notches in the cylinder block.

7.Fit new manifold gasket, dry.

8.Position gasket clamps, fit and lightly tighten

bolts.

9.Position inlet manifold assembly to cylinder

head. 10.Fit manifold bolts and, working in the sequence

illustrated, tighten as follows:

lInitially, tighten bolts numbered 1, 4, 9 and

12 in numerical order to 5 Nm (4 lbf.ft).

lInlet manifold bolts - initial tighten = 10 Nm

(8 lbf.ft).

lInlet manifold bolts - final tighten = 51 Nm

(38 lbf.ft).

lTighten inlet manifold gasket clamp bolts to

18 Nm (14 lbf.ft).

lTighten inlet manifold bolts to 51 Nm (38

lbf.ft)

11.Clean mating faces of rocker cover and cylinder

head, ensure that bolt holes are clean and dry.

12.Fit new rocker cover gaskets, dry, position

rocker covers, ensuring gaskets are correctly

located.

13.Fit new 'patched' multi-hex rocker cover bolts

ensuring that short bolts are on sides of rocker

coves nearest centre of engine.

14.Tighten bolts by diagonal selection to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

15.Ensure that outer rim of each gasket is correctly

positioned around periphery of rocker cover.

16.Secure ht leads to rocker cover.

17.Clean coolant outlet elbow mating faces.

18.Lubricate and fit new 'O' ring to outlet pipe.

19.Position coolant outlet elbow, fit bolts and

tighten to 22 Nm (17 lbf.ft).

20.Position alternator, fit mounting bolts and

tighten to 45 Nm (34 lbf.ft).

Page 203 of 1529

ENGINE - V8

12-2-48 OVERHAUL

21.Position alternator cables and tighten terminal

B+ to 18 Nm (13 lbf.ft) and terminal D+ to 5 Nm

(3.5 lbf.ft).

22.Position auxiliary housing, fit bolts and tighten

to 40 Nm (30 lbf.ft). Fit nut and tighten to 22 Nm

(17 lbf.ft).

23.Clean jockey pulley mating faces.

24.Position jockey pulley and tighten bolt to 50 Nm

(37 lbf.ft).

25.Clean PAS pump pulley mating faces.

26.Position PAS pump pulley, fit bolts and tighten

to 22 Nm (17 lbf.ft).

27.Secure injector harness and connect injector

multiplugs.

28.Connect multiplug to coolant thermistor.

Gasket - exhaust manifold

$% 30.15.12.01

Disassembly

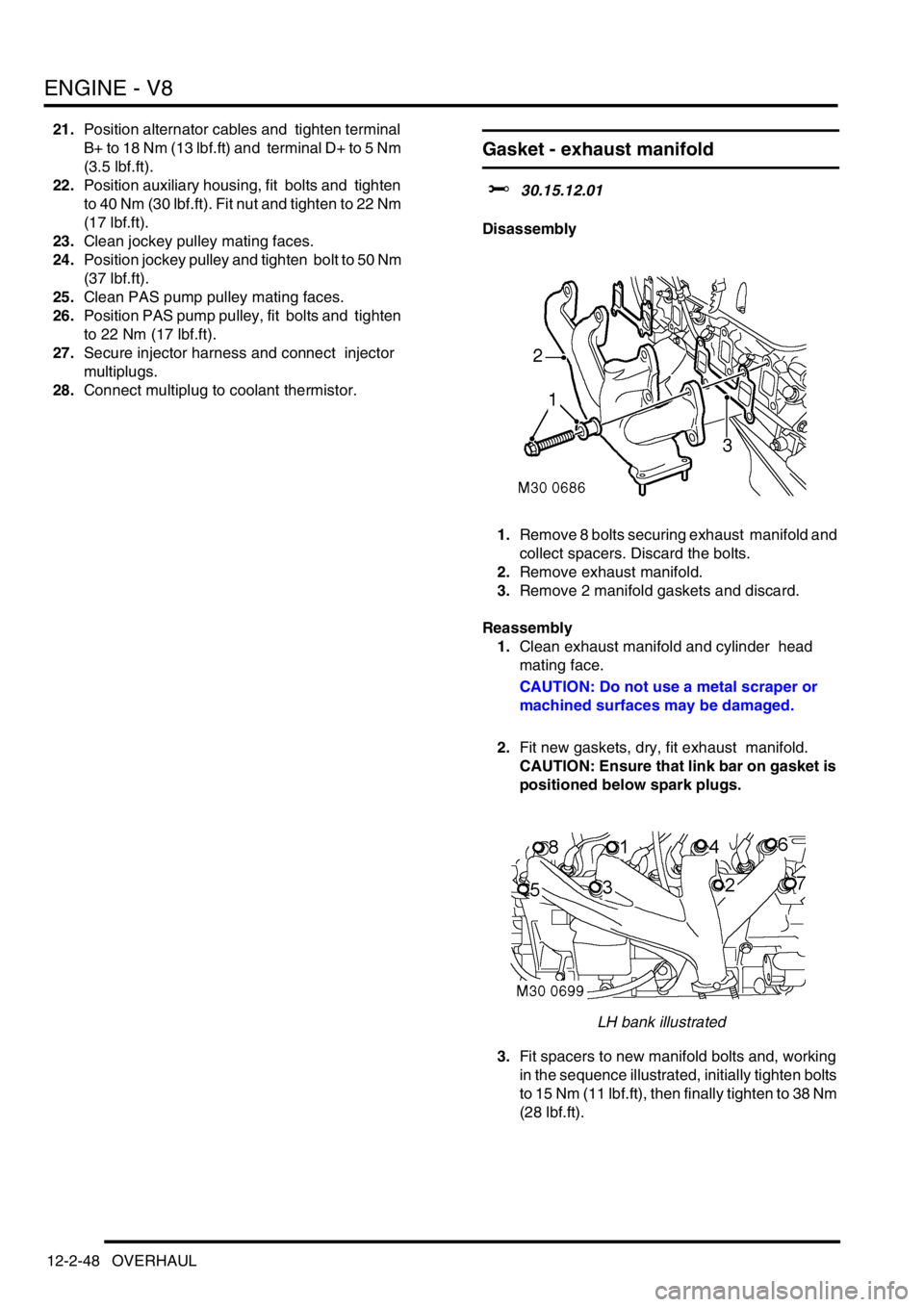

1.Remove 8 bolts securing exhaust manifold and

collect spacers. Discard the bolts.

2.Remove exhaust manifold.

3.Remove 2 manifold gaskets and discard.

Reassembly

1.Clean exhaust manifold and cylinder head

mating face.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Fit new gaskets, dry, fit exhaust manifold.

CAUTION: Ensure that link bar on gasket is

positioned below spark plugs.

LH bank illustrated

3.Fit spacers to new manifold bolts and, working

in the sequence illustrated, initially tighten bolts

to 15 Nm (11 lbf.ft), then finally tighten to 38 Nm

(28 lbf.ft).

Page 204 of 1529

ENGINE - V8

OVERHAUL 12-2-49

Seal - crankshaft - rear - automatic

models

$% 12.21.20.01

Disassembly

1.Remove CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

Note: Later engines are fitted with a modified

starter ring gear which incorporates the reluctor

plate, spacer and hub. The modified ring gear

may be fitted as a replacement to early

engines.

2. Early engines: Remove 4 bolts securing drive

plate clamp ring and remove ring.

3. Early engines: Remove drive plate from hub.

4. Early engines: Remove 6 Allen bolts securing

hub and starter ring gear, remove hub, starter

ring gear and collect spacer.

Note: On early engines, balance weights are on

engine side of drive plate, replacement drive

plates will have balance weights on torque

converter side of drive plate.5. Later engines: Remove 4 bolts securing drive

plate clamp ring and remove ring.

6. Later engines: Remove drive plate.

7. Later engines: Remove 6 Allen bolts securing

starter ring gear to crankshaft, remove starter

ring gear.

8.Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft.

Page 205 of 1529

ENGINE - V8

12-2-50 OVERHAUL

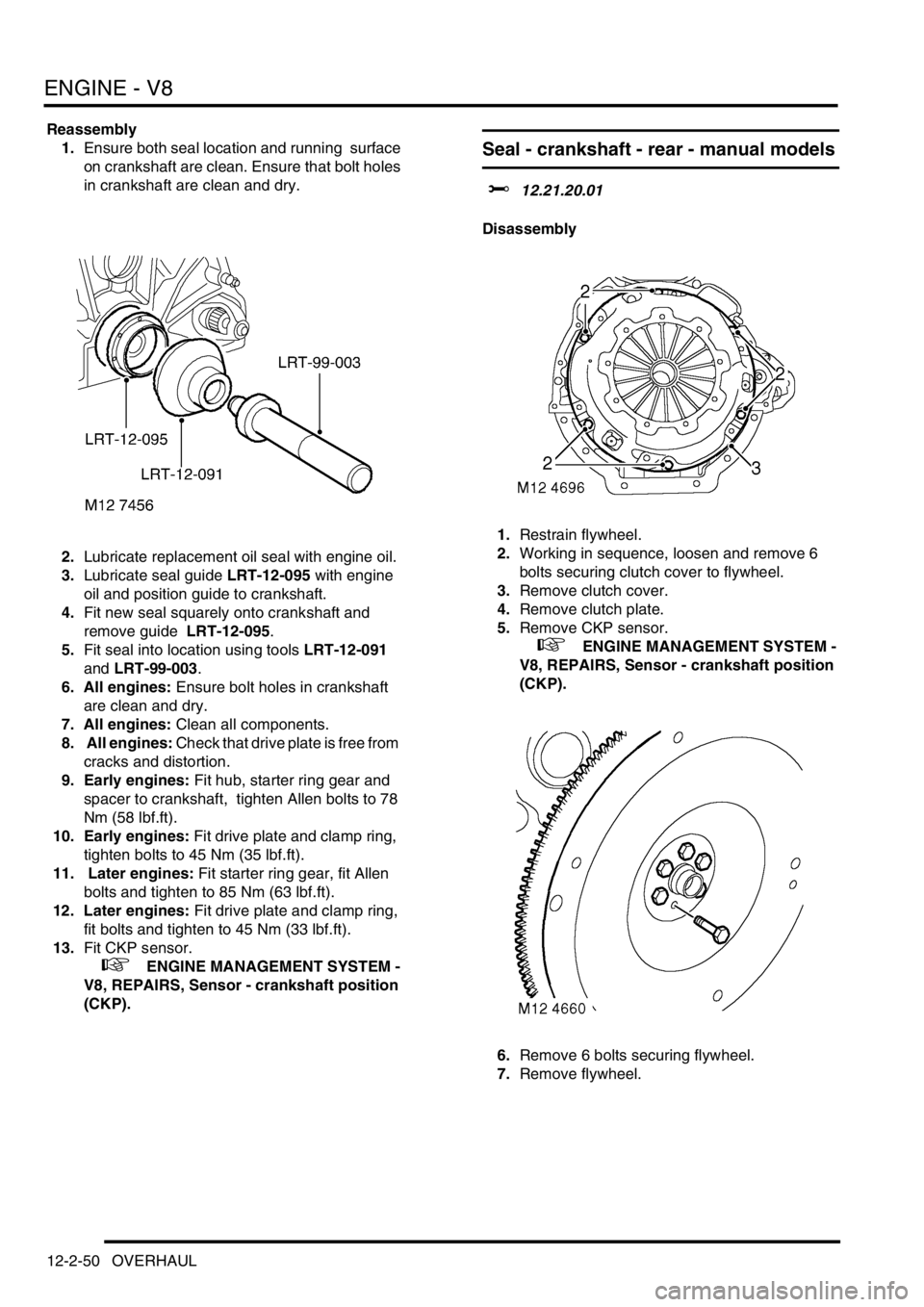

Reassembly

1.Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

in crankshaft are clean and dry.

2.Lubricate replacement oil seal with engine oil.

3.Lubricate seal guide LRT-12-095 with engine

oil and position guide to crankshaft.

4.Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5.Fit seal into location using tools LRT-12-091

and LRT-99-003.

6. All engines: Ensure bolt holes in crankshaft

are clean and dry.

7. All engines: Clean all components.

8. All engines: Check that drive plate is free from

cracks and distortion.

9. Early engines: Fit hub, starter ring gear and

spacer to crankshaft, tighten Allen bolts to 78

Nm (58 lbf.ft).

10. Early engines: Fit drive plate and clamp ring,

tighten bolts to 45 Nm (35 lbf.ft).

11. Later engines: Fit starter ring gear, fit Allen

bolts and tighten to 85 Nm (63 lbf.ft).

12. Later engines: Fit drive plate and clamp ring,

fit bolts and tighten to 45 Nm (33 lbf.ft).

13.Fit CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

Seal - crankshaft - rear - manual models

$% 12.21.20.01

Disassembly

1.Restrain flywheel.

2.Working in sequence, loosen and remove 6

bolts securing clutch cover to flywheel.

3.Remove clutch cover.

4.Remove clutch plate.

5.Remove CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

6.Remove 6 bolts securing flywheel.

7.Remove flywheel.

Page 206 of 1529

ENGINE - V8

OVERHAUL 12-2-51

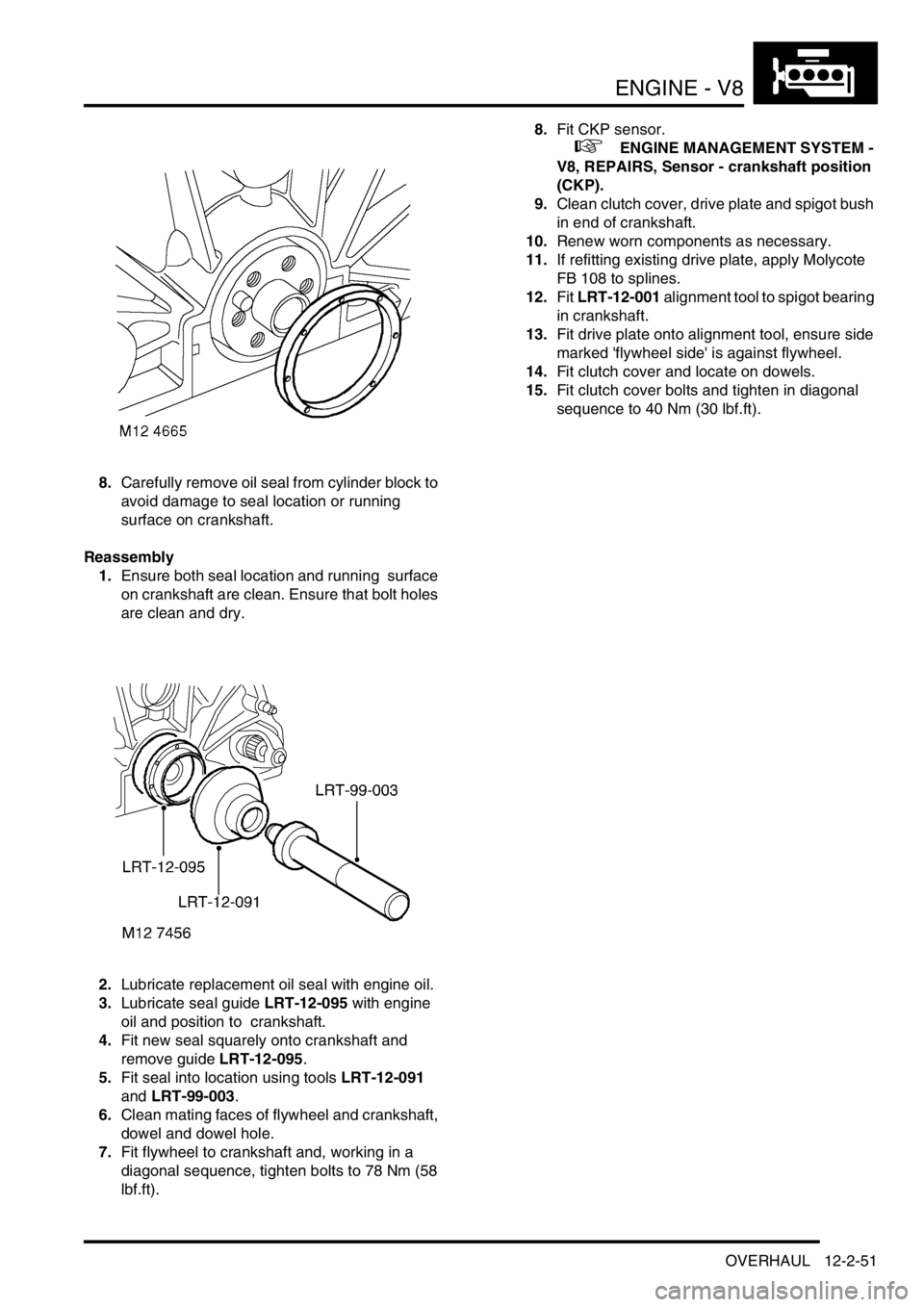

8.Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft.

Reassembly

1.Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

are clean and dry.

2.Lubricate replacement oil seal with engine oil.

3.Lubricate seal guide LRT-12-095 with engine

oil and position to crankshaft.

4.Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5.Fit seal into location using tools LRT-12-091

and LRT-99-003.

6.Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

7.Fit flywheel to crankshaft and, working in a

diagonal sequence, tighten bolts to 78 Nm (58

lbf.ft). 8.Fit CKP sensor.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Sensor - crankshaft position

(CKP).

9.Clean clutch cover, drive plate and spigot bush

in end of crankshaft.

10.Renew worn components as necessary.

11.If refitting existing drive plate, apply Molycote

FB 108 to splines.

12.Fit LRT-12-001 alignment tool to spigot bearing

in crankshaft.

13.Fit drive plate onto alignment tool, ensure side

marked 'flywheel side' is against flywheel.

14.Fit clutch cover and locate on dowels.

15.Fit clutch cover bolts and tighten in diagonal

sequence to 40 Nm (30 lbf.ft).

Page 207 of 1529

ENGINE - V8

12-2-52 OVERHAUL

Bearing - spigot - crankshaft

$% 12.21.45.01

Disassembly

1.Remove 6 bolts securing clutch cover.

2.Remove clutch cover.

3.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

4.Fit extractor to bush.

5.Remove bush from crankshaft. Reassembly

1.Clean bush register in rear of crankshaft.

2.Using a suitable drift, fit new bush to crankshaft

so that it is flush with or up to a maximum of 1.6

mm (0.06 in) below the end of the crankshaft.

3.Ream spigot bush to 19.117 + 0.025 − 0.00 mm

(0.75 + 0.001 − 0.00 in) .

4.Remove all traces of swarf on completion.

5.Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

6.Fit clutch cover to flywheel and tighten bolts by

diagonal slection to 40 Nm (30 lbf.ft).

Page 208 of 1529

ENGINE - V8

OVERHAUL 12-2-53

Gasket - engine sump

$% 12.60.38.01

Disassembly

1.Remove 3 nuts and 14 bolts securing sump to

cylinder block.

2.Remove sump.

3.Remove and discard gasket.

Reassembly

1.Clean all traces of sealant from the sump and

sump mating faces, using a solvent cleaner or

plastic scraper.

2.Ensure that bolt holes in cylinder block are

clean and dry.

3.Apply a 5 mm (0.2 in) wide bead of sealant, Part

No. STC 50550 across the cylinder block to

front cover joint and across the cylinder block to

rear main bearing joint. Apply a globule of

sealant to cover the ends of the cruciform

seals, (see illustration above).

4.Fit new sump gasket, dry, ensure location tags

are correctly positioned.

5.Fit the sump to the cylinder block.6. Noting that the two parts of the tool are

handed, fit tool LRT- 12-183 to the engine

back plate using bell housing nuts and bolts.

7.Secure the tool to the sump using the bolts

which are part of the tool. The holes in the tool

are larger than the diameter of the bolts,

allowing the tool and the sump to move as

the sump bolts are tightened.

8.Fit the sump nuts and bolts, and working in the

sequence shown, tighten to 22 Nm (16 lbf.ft).

9.Remove tool LRT-12-183.

M12 5741

M12 5713

14106248

12

16

17

15

117315913

Page 209 of 1529

ENGINE - V8

12-2-54 OVERHAUL

Strainer - oil pick-up

$% 12.60.20.01

Disassembly

1.Remove sump gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

engine sump.

2.Remove 2 bolts and 1 nut securing oil pick up

strainer.

3.Remove oil pick up strainer.

4.Collect spacer.

5.Remove and discard 'O' ring. Reassembly

1.Clean oil pick up strainer and 'O' ring recess.

2.Lubricate new 'O' ring with clean engine oil and

fit to recess.

3.Locate spacer on stud.

4.Position oil pick up strainer, fit bolts and tighten

to 10 Nm (7 lbf.ft). Fit nut and tighten to 22 Nm

(16 lbf.ft).

5.Fit new sump gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

engine sump.

Page 210 of 1529

ENGINE - V8

OVERHAUL 12-2-55

Seal - timing gear cover

$% 12.65.05.01

Disassembly

1.Secure tool LRT-12-080 to crankshaft pulley

with 2 bolts.

2.Remove crankshaft pulley bolt.

3.Remove crankshaft pulley.

4.Using tool LRT-12-088, remove oil seal from

timing gear cover and discard. Reassembly

1.Clean seal register in timing gear cover and

crankshaft pulley.

2.Ensure that bolt holes are clean and dry.

3.Apply smear of Retinax LX grease to seal

running surface on crankshaft.

CAUTION: Replacement oil seal is pre-

greased, do not apply additional lubricant.

4. Fit seal to timing gear cover using tool LRT-12-

089 .

5.Secure tool LRT-12-080 to crankshaft pulley

with 2 bolts. Fit crankshaft pulley.

6.Fit crankshaft pulley bolt and tighten to 270 Nm

(200 lbf.ft).

7.Remove tool LRT-12-080 from crankshaft

pulley.