LAND ROVER DISCOVERY 1999 Workshop Manual

DISCOVERY 1999

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57247/w960_57247-0.png

LAND ROVER DISCOVERY 1999 Workshop Manual

Trending: change key battery, battery replacement, ignition, fuel consumption, AUX, window, wheel size

Page 231 of 1529

ENGINE - V8

12-2-76 OVERHAUL

19.Attach a DTI to front of cylinder block, move

crankshaft rearwards, position stylus of gauge

on end of crankshaft and zero gauge.

20.Move crankshaft forwards, measure and

record end-float obtained.

l Crankshaft end-float = 0.08 to 0.26 mm

(0.003 to 0.01 in).

21.Fit connecting rod bearings.

+ ENGINE - V8, OVERHAUL, Bearings

- connecting rods.

22.Clean timing chain and gears.

23.Clean ends of crankshaft and camshaft.

24.Lubricate timing chain assembly with clean

engine oil.

25.Align timing marks and fit timing chain

assembly.

26.Fit camshaft gear bolt and tighten to 50 Nm (37

lbf.ft).

27.Fit timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

28.Clean crankshaft pulley.

29.Fit crankshaft pulley.

30.Fit crankshaft pulley bolt and tighten to 270 Nm

(200 lbf.ft).

31.Remove tool LRT-12-080 from crankshaft

pulley.

32.Clean oil filter and mating face.

33.Lubricate oil filter seal and fit filter to oil pump.

34.Ensure drive belt pulleys are clean and

damage free.

35.Fit auxiliary drive belt to pulleys.

36.Fit crankshaft rear oil seal.

+ ENGINE - V8, OVERHAUL, Seal -

crankshaft - rear - automatic models.

Page 232 of 1529

ENGINE - V8

OVERHAUL 12-2-77

Camshaft

$% 12.13.02.01

Disassembly

1.Remove inlet manifold gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

inlet manifold.

2.Progressively loosen and remove 8 bolts

securing rocker shaft assemblies.

3.Mark each rocker shaft in relation to original

head.

4.Remove rocker shaft assemblies.

5.Remove push rods and store in their fitted

order.

6.Remove tappets.

CAUTION: Store tappets upright and in their

fitted order.

7.Remove timing chain and gears.

+ ENGINE - V8, OVERHAUL, Timing

chain and gears.8.Temporarily fit camshaft gear and lightly tighten

bolt.

9. Attach a dial test indicator (DTI) to front of

cylinder block with stylus of DTI contacting

camshaft gear.

10.Push camshaft rearwards and zero the DTI.

11.Using the camshaft gear, pull camshaft

forwards and note reading on DTI. End-float

should be from 0.075 to 0.25 mm (0.003 to

0.010 in).

12.If end-float is incorrect, fit a new thrust plate. If

end-float is still incorrect, a new camshaft/gear

must be fitted.

13.Remove camshaft bolt and gear.

14.Remove 2 bolts securing camshaft thrust plate

and remove thrust plate.

15.Carefully remove the camshaft avoiding

damage to the camshaft bearings.

Page 233 of 1529

ENGINE - V8

12-2-78 OVERHAUL

Reassembly

1.Clean camshaft bearings in block.

2.Clean camshaft.

3.Wipe camshaft bearing faces and lobes.

4.Clean thrust plate and mating face.

5.Lubricate camshaft bearings with clean engine

oil.

6.Fit camshaft, take care not to damage camshaft

bearings.

7.Lubricate thrust plate and mating face with

clean engine oil.

8.Position thrust plate, fit and tighten bolts to 22

Nm (17 lbf.ft).

9.Fit timing chain and gears.

+ ENGINE - V8, OVERHAUL, Timing

chain and gears.

10.Immerse tappets in engine oil. Before fitting,

pump the inner sleeve of tappet several times

using a push rod to prime the tappets.

11.Clean tappet bores.

12.Lubricate tappets and tappet bores with clean

engine oil.

13.Fit tappets.

14.Clean push rods.

15.Lubricate tappet end of push rods with clean

engine oil.

16.Fit push rods.

17.Clean bases of rocker pillars and mating faces.

18.Clean contact surfaces on rockers and valves.

19.Lubricate contact surfaces on rockers and

valves with clean engine oil.

20.Fit rocker shafts and engage push rods. Ensure

rockers shafts are fitted to the correct cylinder

head.

21.Fit and progressively tighten rocker shaft bolts

to 40 Nm (30 lbf.ft).

22.Fit inlet manifold gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

inlet manifold.

Page 234 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-1

EMISS ION CONTROL - V8 DESCRIPTION AND OPERAT ION

Crankcase emission control system

1Intake air

2LH rocker cover breather tube3Oil separator in RH rocker breather tube

Page 235 of 1529

EMISSION CONTROL - V8

17-2-2 DESCRIPTION AND OPERATION

Exhaust emission control

1RH catalytic converter

2Heated oxygen sensors – post-catalytic

converter (2 off – NAS only)3LH catalytic converter

4Heated oxygen sensors – pre-catalytic

converter (2 off)

Page 236 of 1529

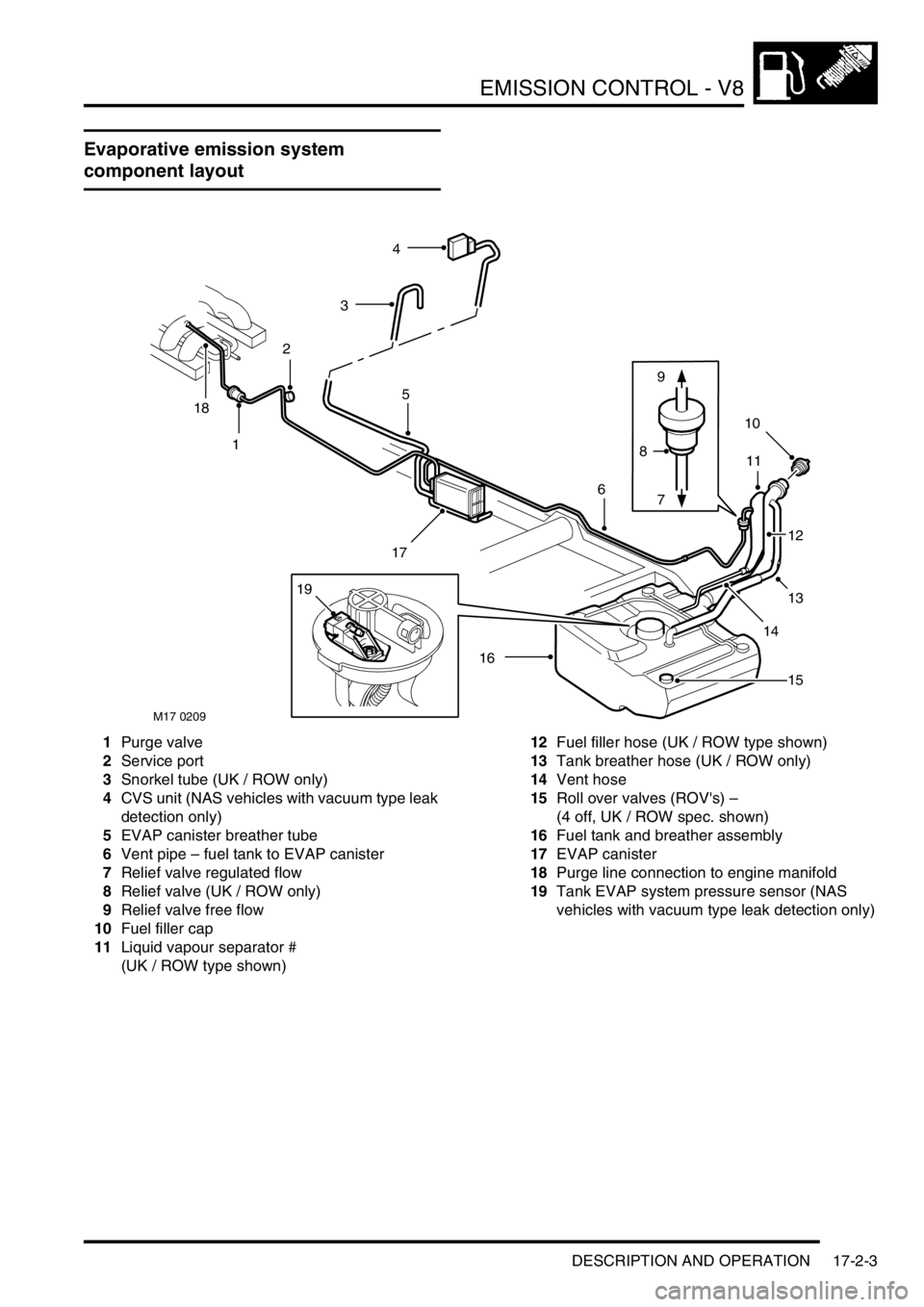

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-3

Evaporative emission system

component layout

1Purge valve

2Service port

3Snorkel tube (UK / ROW only)

4CVS unit (NAS vehicles with vacuum type leak

detection only)

5EVAP canister breather tube

6Vent pipe – fuel tank to EVAP canister

7Relief valve regulated flow

8Relief valve (UK / ROW only)

9Relief valve free flow

10Fuel filler cap

11Liquid vapour separator #

(UK / ROW type shown)12Fuel filler hose (UK / ROW type shown)

13Tank breather hose (UK / ROW only)

14Vent hose

15Roll over valves (ROV's) –

(4 off, UK / ROW spec. shown)

16Fuel tank and breather assembly

17EVAP canister

18Purge line connection to engine manifold

19Tank EVAP system pressure sensor (NAS

vehicles with vacuum type leak detection only)

M17 0209

4

3

1

6

5

16

10

8

13

17

9

7

11

12

15

14

18

2

19

Page 237 of 1529

EMISSION CONTROL - V8

17-2-4 DESCRIPTION AND OPERATION

Evaporative emission system (with

positive pressure leak detection)

component layout (NAS only)

1Purge valve

2Service port

3Air filter canister

4EVAP canister breather tube

5Leak detection pump

6EVAP canister

7Vent pipe – fuel tank to EVAP canister

8Liquid vapour separator (metal)9Fuel filler cap

10Fuel filler

11Fuel tank breather assembly

12Vent hose

13Roll over valves (inside fuel tank)

14Fuel tank

15Purge line connection to engine manifold

M17 0208

3

1

7

4

14

11

6

8

10

13

12

15

2

5

9

Page 238 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-5

Evaporative emission system control

diagram

1Battery

2Fuse 13 (engine compartment fusebox)

3Inertia switch

4Main relay (engine compartment fusebox)

5Engine Control Module (ECM)

6Purge Valve (black harness connector)

7Canister vent solenoid (CVS) valve – NAS

vehicles with vacuum type EVAP system leak

detection capability only8Leak detection pump – NAS vehicles with

positive pressure type EVAP system leak

detection capability only

9Fuel tank pressure sensor – NAS vehicles with

vacuum type EVAP system leak detection

capability only

10Instrument pack (MIL warning light)

M17 0210

12

3

4

5

6

7

9

8

10

Page 239 of 1529

EMISSION CONTROL - V8

17-2-6 DESCRIPTION AND OPERATION

Secondary air injection system

component layout

M17 0206

1234

56

8

7

Page 240 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-7

1Engine Control Module (ECM)

2SAI vacuum solenoid valve

3Purge valve

4Vacuum reservoir (up to 2003 model year

location shown)

5SAI control valve (2 off)

6SAI pump

7SAI pump relay

8Main relay

Trending: fuel pump, fuel type, height adjustment, fuel, service, door lock, maintenance