LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 171 of 1529

ENGINE - V8

12-2-16 REPAIRS

17.Using new gaskets, position exhaust manifold

to cylinder head, fit bolts and using sequence

shown, tighten initially to 15 Nm (11 lbf.ft), then

finally to 36 Nm (28 lbf.ft).

18. LH drive models: Fit brake servo heat shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

19.Fit engine harness bolt and tighten to 22 Nm

(16 lbf.ft).

20.Connect ht leads to spark plugs in their correct

fitted order.

21.Fit inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

Gasket - cylinder head - RH

$% 12.29.03

Remove

1.Remove inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

2.Remove bolt securing auxiliary drive belt

tensioner and remove tensioner.

3.Remove 4 bolts securing alternator mounting

bracket and remove bracket.

4.Noting their fitted order, disconnect ht leads

from spark plugs.

5.Remove bolt securing engine earth lead.

Page 172 of 1529

ENGINE - V8

REPAIRS 12-2-17

6. RH drive models: Remove brake servo heat

shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

7.Remove 8 bolts securing exhaust manifold to

cylinder head, release manifold and collect 2

gaskets.

8.Progressively remove 4 bolts securing the

rocker shaft and remove rocker shaft.

9.Remove push rods. Store push rods in their

fitted order. 10. Models with SAI: Using a 9 mm hexagonal

drive bit, remove 2 air injection adapters from

cylinder head; discard adapters.

Note: To release the adapter thread locking

agent and prevent damage to the cylinder

head, remove the adapters by alternately

loosening then tightening slightly. Repeat this

procedure until adapters are removed.

CAUTION: Do not use air tools to remove

adapters.

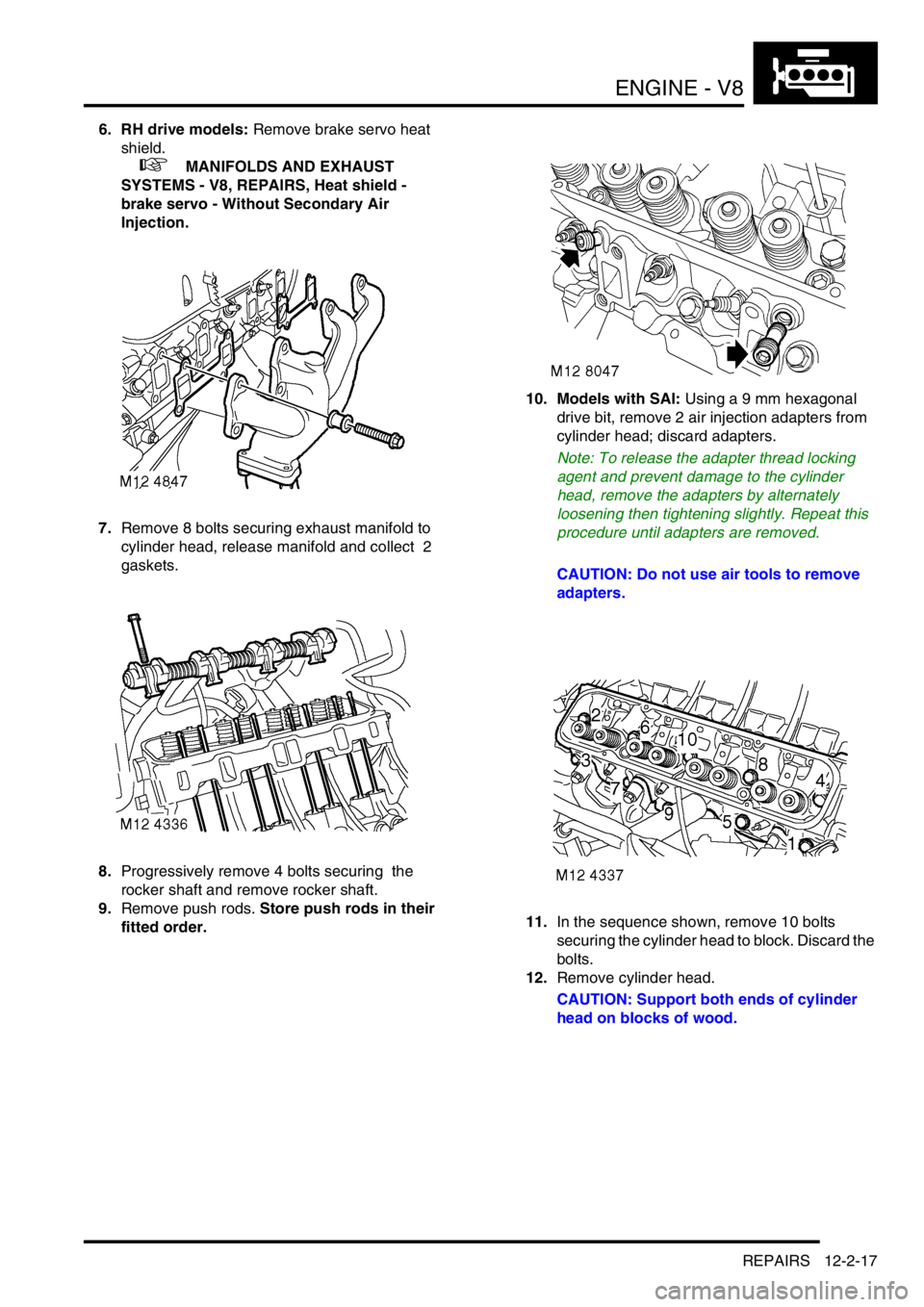

11.In the sequence shown, remove 10 bolts

securing the cylinder head to block. Discard the

bolts.

12.Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

Page 173 of 1529

ENGINE - V8

12-2-18 REPAIRS

13.Remove cylinder head gasket.

Refit

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry. Clean mating faces of

cylinder head and exhaust manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Check head and block faces for warping and

pitting. If out of specification, renew head.

3. Models with SAI: Using a 5/8 in x 20 TPI

(threads per inch) UNF tap having a class 2A

thread, remove deposits from secondary air

injection adapter tappings in cylinder head.

CAUTION: Ensure that tap used has 20 TPI.

4.Fit cylinder head gasket with the word 'TOP'

uppermost.

CAUTION: Gasket must be fitted dry.

5.Carefully fit cylinder head and locate on

dowels.

6.Lightly lubricate new cylinder head bolt threads

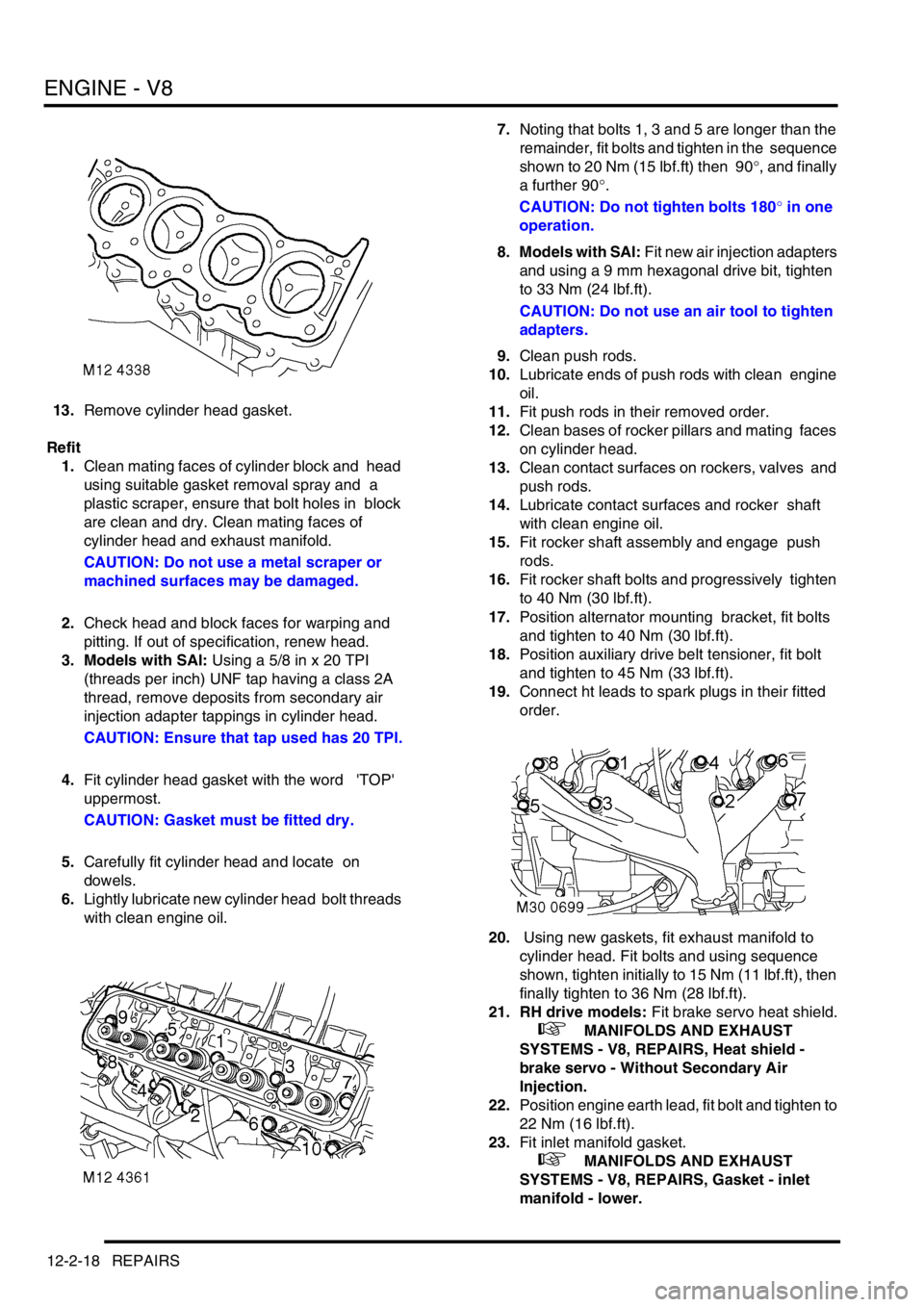

with clean engine oil. 7.Noting that bolts 1, 3 and 5 are longer than the

remainder, fit bolts and tighten in the sequence

shown to 20 Nm (15 lbf.ft) then 90°, and finally

a further 90°.

CAUTION: Do not tighten bolts 180° in one

operation.

8. Models with SAI: Fit new air injection adapters

and using a 9 mm hexagonal drive bit, tighten

to 33 Nm (24 lbf.ft).

CAUTION: Do not use an air tool to tighten

adapters.

9.Clean push rods.

10.Lubricate ends of push rods with clean engine

oil.

11.Fit push rods in their removed order.

12.Clean bases of rocker pillars and mating faces

on cylinder head.

13.Clean contact surfaces on rockers, valves and

push rods.

14.Lubricate contact surfaces and rocker shaft

with clean engine oil.

15.Fit rocker shaft assembly and engage push

rods.

16.Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft).

17.Position alternator mounting bracket, fit bolts

and tighten to 40 Nm (30 lbf.ft).

18.Position auxiliary drive belt tensioner, fit bolt

and tighten to 45 Nm (33 lbf.ft).

19.Connect ht leads to spark plugs in their fitted

order.

20. Using new gaskets, fit exhaust manifold to

cylinder head. Fit bolts and using sequence

shown, tighten initially to 15 Nm (11 lbf.ft), then

finally tighten to 36 Nm (28 lbf.ft).

21. RH drive models: Fit brake servo heat shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

22.Position engine earth lead, fit bolt and tighten to

22 Nm (16 lbf.ft).

23.Fit inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

Page 174 of 1529

ENGINE - V8

REPAIRS 12-2-19

Gasket - rocker cover - LH

$% 12.29.40

Remove

1.Remove upper inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

2. Models with air conditioning: Release 4

clips and remove fan cowl.

3. Models with air conditioning: Release

tension on auxiliary drive belt and remove belt

from air conditioning compressor. Disconnect

compressor multiplug. Remove 4 bolts

securing compressor and position compressor

aside. 4.Release ht leads from rocker cover clips.

5.Remove screw securing dip stick tube.

6.Noting fitted position of 2 long screws or multi-

hex bolts, remove and discard screws/bolts

securing rocker cover; remove rocker cover.

CAUTION: Screws/bolts must be replaced

with new 'patched' multi-hex bolts.

7.Remove and discard rocker cover gasket.

Page 175 of 1529

ENGINE - V8

12-2-20 REPAIRS

Refit

1.Clean mating faces of rocker cover and

cylinder head, ensure bolt holes are clean and

dry.

2.Fit a new gasket dry, position rocker cover

ensuring gasket is correctly located.

3.Fit new 'patched' multi-hex rocker cover bolts

ensuring that 2 short bolts are on side of rocker

cover nearest centre of engine.

4.Tighten bolts by diagonal selection to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

5.Ensure that outer rim of gasket is correctly

positioned around periphery of rocker cover.

6.Fit and tighten screw securing dip stick tube.

7.Secure ht leads in rocker cover clips.

8. Models with air conditioning: Clean

compressor dowels and dowel holes. Position

compressor, fit bolts and tighten to 22 Nm (16

lbf.ft). Release auxiliary drive belt tensioner

and fit belt to compressor.

9. Models with air conditioning: Position fan

cowl and secure clips.

10.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

Gasket - rocker cover - RH

$% 12.29.41

Remove

1.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2.Remove upper inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

3. Models with SAI: Disconnect 2 air manifold

unions from adapters in cylinder head and

remove manifold.

CAUTION: Take care that air manifold pipes

are not damaged during removal of union

nuts.

4.Remove 2 bolts securing coolant rails to inlet

manifold.

Page 176 of 1529

ENGINE - V8

REPAIRS 12-2-21

5.Release coolant rail from inlet manifold and

discard 'O' ring.

6.Remove nuts securing alternator cables and

release cables from alternator.

7.Disconnect multiplugs from RH bank of

injectors and release harness from fuel rail.

8.Release ht leads from clips on rocker cover.

9.Noting fitted position of 2 long screws or multi-

hex bolts, remove and discard screws/bolts

securing rocker cover; remove rocker cover.

10.Remove and discard rocker cover gasket. Refit

1.Clean mating faces of rocker cover and

cylinder head, ensure bolt holes are clean and

dry.

2.Fit a new gasket dry, position rocker cover

ensuring gasket is correctly located.

3.Fit new 'patched' multi-hex rocker cover bolts

ensuring that 2 short bolts are on side of rocker

cover nearest centre of engine.

4.Tighten bolts by diagonal selection to:

lStage 1 - 3 Nm (2.5 lbf.ft)

lStage 2 - 8 Nm (6 lbf.ft)

5.Ensure that outer rim of gasket is correctly

positioned around periphery of rocker cover.

6.Secure ht leads in rocker cover clips.

7.Secure injector harness to fuel rail and connect

multiplugs to injectors.

8.Position alternator cables, and tighten terminal

B+ nut to 18 Nm (13 lbf.ft) and terminal D+ nut

to 5 Nm (3 lbf.ft).

9.Clean coolant rail 'O' ring recess.

10.Lubricate and fit new 'O' ring to coolant rail,

position coolant rails, fit bolts and tighten to 22

Nm (16 lbf.ft).

11. Models with SAI: Apply a small amount of

engine oil to top of air manifold union nuts and

around air manifold pipes.

12. Models with SAI:Position air manifold and

finger tighten both air manifold union nuts.

CAUTION: Finger tighten union nuts as far

as possible, damage to air manifold pipes or

adapters may result if this is not done.

13. Models with SAI: Tighten both union nuts to

25 Nm (18 lbf.ft).

CAUTION: Ensure that air manifold pipes

are not distorted during tightening

operation.

14.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

15.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 177 of 1529

ENGINE - V8

12-2-22 REPAIRS

Mounting - front - LH

$% 12.45.01

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

5.Position a jack beneath the sump, and support

the engine on the jack.

CAUTION: To prevent damage to

components, cushion the jack pad with a

block of wood or hard rubber.

6.Remove 2 nuts securing engine mountings to

chassis.

7.Remove nut securing LH mounting to cylinder

block.

8.Raise engine sufficiently to allow engine

mounting to be removed, take care not to trap

any cables, pipes or harness.

9.Remove engine mounting. Collect heat shield,

if fitted.Refit

1.Fit heat shield to engine mounting, if fitted.

2.Fit engine mounting ensuring dowel is located.

3.Lower the jack and engage engine mounting

studs in chassis.

4.Fit nuts securing LH engine mounting and

tighten to 85 Nm (63 lbf.ft).

5.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Remove stand(s) and lower vehicle.

7.Connect battery earth lead.

8.Fit battery cover and secure turnbuckles.

Page 178 of 1529

ENGINE - V8

REPAIRS 12-2-23

Mounting - front - RH

$% 12.45.03

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

5.Position a jack beneath the sump, and support

the engine on the jack.

CAUTION: To prevent damage to

components, cushion the jack pad with a

block of wood or hard rubber.

6.Remove 2 nuts securing engine mountings to

chassis.

7.Remove nut securing RH mounting to cylinder

block.

8.Raise engine sufficiently to allow engine

mounting to be removed. Take care not to trap

any cables, pipes or harness.

9.Remove engine mounting.

10.Collect heat shield. Refit

1.Position heat shield.

2.Fit engine mounting ensuring dowel is located.

3.Lower the jack and engage engine mounting

studs in chassis.

4.Fit engine mounting nuts and tighten to 85 Nm

(63 lbf.ft).

5.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Remove stand(s) and lower vehicle.

7.Connect battery earth lead.

8.Fit battery cover and secure turnbuckles.

Page 179 of 1529

ENGINE - V8

12-2-24 REPAIRS

Mounting - rear - LH

$% 12.45.07

Remove

1.Raise vehicle on lift.

2.Remove 8 bolts securing rear cross member

and remove cross member.

3.Support transfer gearbox on jack.

CAUTION: To prevent damage to

components, cushion the jack pad with a

block of wood or hard rubber.

4.Release and disconnect HO2S multiplug.5.Remove nut securing mounting to body

bracket.

6.Remove nut securing mounting to mounting

bracket.

7.Remove 4 bolts securing mounting bracket to

gearbox.

8.Remove mounting and mounting bracket

assembly.

9.Remove mounting rubber.

10.Remove heat shield, if fitted.

Refit

1.If fitted position heatshield, fit mounting rubber

to mounting bracket, fit nut but do not tighten.

2.Position mounting bracket assembly, fit bolts

securing mounting bracket to gearbox and

tighten to 85 Nm (63 lbf.ft).

3.Fit nut securing mounting to body bracket and

tighten to 48 Nm (35 lbf.ft).

4.Tighten nut securing mounting to gearbox

bracket to 48 Nm (35 lbf.ft).

5.Connect HO2S multiplug and secure to support

bracket.

6.Position rear cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

7.Lower vehicle.

Page 180 of 1529

ENGINE - V8

REPAIRS 12-2-25

Mounting - rear - RH

$% 12.45.09

Remove

1.Raise vehicle on lift.

2.Remove 8 bolts securing rear cross member

and remove cross member.

3.Support transfer gearbox on jack.

CAUTION: To prevent damage to

components, cushion the jack pad with a

block of wood or hard rubber.

4.Remove nut securing mounting to body

bracket.

5.Remove nut securing mounting to mounting

bracket.

6.Remove 4 bolts securing mounting bracket to

gearbox.

7.Remove mounting and mounting bracket

assembly.

8.Remove mounting rubber.

9.Remove heat shield, if fitted.Refit

1.If fitted, position heatshield, fit mounting rubber

to mounting bracket, fit nut but do not tighten.

2.Position mounting bracket assembly, fit bolts

securing mounting bracket to gearbox and

tighten to 85 Nm (63 lbf.ft).

3.Fit nut securing mounting to body bracket and

tighten to 48 Nm (35 lbf.ft).

4.Tighten nut securing mounting to gearbox

bracket to 48 Nm (35 lbf.ft).

5.Position rear cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

6.Lower vehicle.