fuse box LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 50 of 1529

GENERAL INFORMATION

03-15

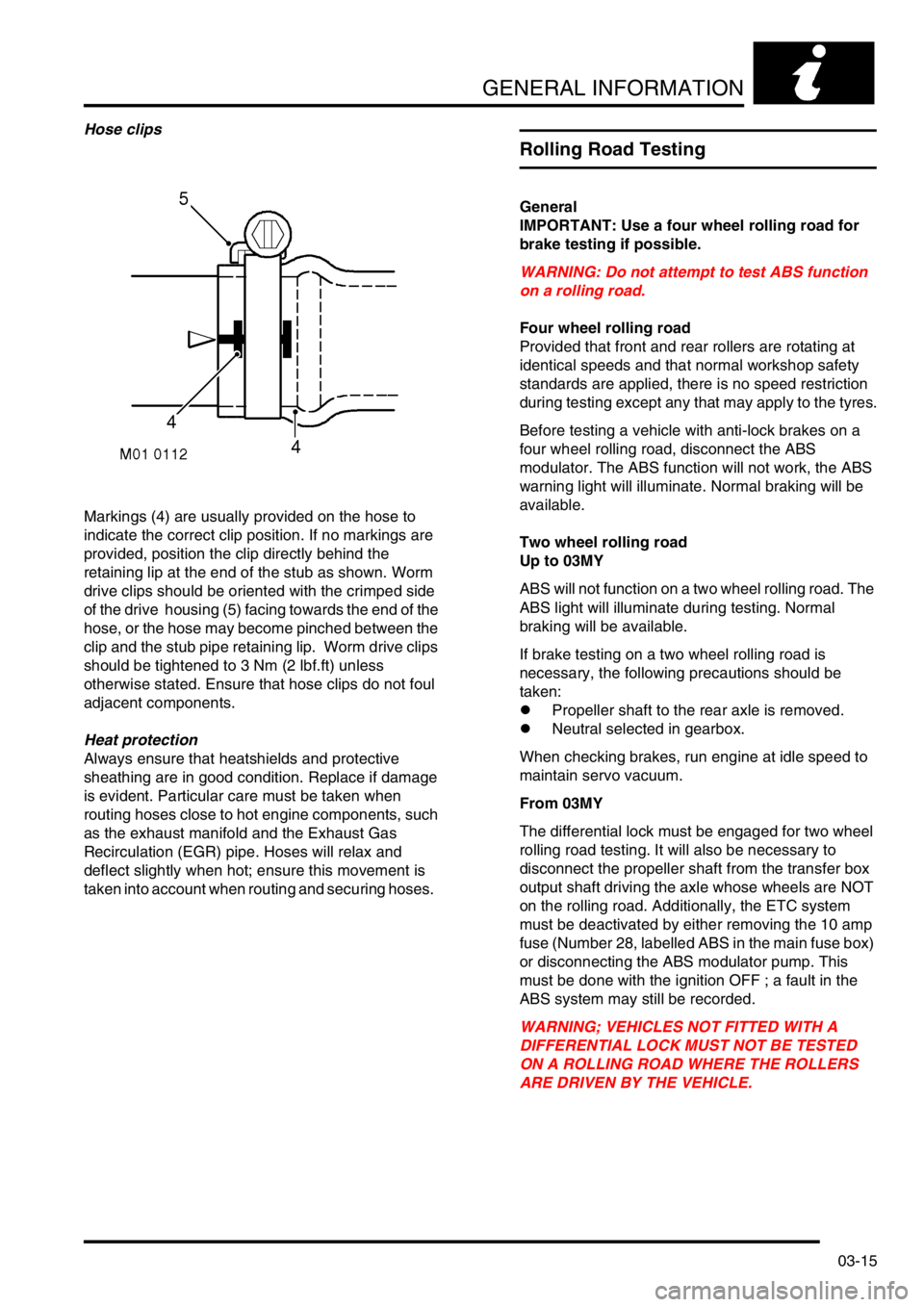

Hose clips

Markings (4) are usually provided on the hose to

indicate the correct clip position. If no markings are

provided, position the clip directly behind the

retaining lip at the end of the stub as shown. Worm

drive clips should be oriented with the crimped side

of the drive housing (5) facing towards the end of the

hose, or the hose may become pinched between the

clip and the stub pipe retaining lip. Worm drive clips

should be tightened to 3 Nm (2 lbf.ft) unless

otherwise stated. Ensure that hose clips do not foul

adjacent components.

Heat protection

Always ensure that heatshields and protective

sheathing are in good condition. Replace if damage

is evident. Particular care must be taken when

routing hoses close to hot engine components, such

as the exhaust manifold and the Exhaust Gas

Recirculation (EGR) pipe. Hoses will relax and

deflect slightly when hot; ensure this movement is

taken into account when routing and securing hoses.

Rolling Road Testing

General

IMPORTANT: Use a four wheel rolling road for

brake testing if possible.

WARNING: Do not attempt to test ABS function

on a rolling road.

Four wheel rolling road

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing except any that may apply to the tyres.

Before testing a vehicle with anti-lock brakes on a

four wheel rolling road, disconnect the ABS

modulator. The ABS function will not work, the ABS

warning light will illuminate. Normal braking will be

available.

Two wheel rolling road

Up to 03MY

ABS will not function on a two wheel rolling road. The

ABS light will illuminate during testing. Normal

braking will be available.

If brake testing on a two wheel rolling road is

necessary, the following precautions should be

taken:

lPropeller shaft to the rear axle is removed.

lNeutral selected in gearbox.

When checking brakes, run engine at idle speed to

maintain servo vacuum.

From 03MY

The differential lock must be engaged for two wheel

rolling road testing. It will also be necessary to

disconnect the propeller shaft from the transfer box

output shaft driving the axle whose wheels are NOT

on the rolling road. Additionally, the ETC system

must be deactivated by either removing the 10 amp

fuse (Number 28, labelled ABS in the main fuse box)

or disconnecting the ABS modulator pump. This

must be done with the ignition OFF ; a fault in the

ABS system may still be recorded.

WARNING; VEHICLES NOT FITTED WITH A

DIFFERENTIAL LOCK MUST NOT BE TESTED

ON A ROLLING ROAD WHERE THE ROLLERS

ARE DRIVEN BY THE VEHICLE.

Page 182 of 1529

ENGINE - V8

REPAIRS 12-2-27

11.Remove bolt securing oil cooling pipes to PAS

pump housing and remove saddle clamp.

12.Release PAS pump high and low pressure

pipes and position aside.

CAUTION: Always fit plugs to open

connections to prevent contamination.

13.Release clips securing hose to coolant pump

and coolant rail, release hose and position

aside.

14.Release 2 harness clips from coolant rail.

15.Remove bolt securing coolant rail and position

rail aside. 16.Remove bolt securing engine earth lead and

position earth lead aside.

17.Remove nut securing engine harness positive

lead to battery, release lead and position

aside.

18.Release clips and remove fuse box cover.

19.Remove bolt securing starter lead to fuse box,

release lead and position aside.

20.Disconnect 2 engine harness multiplugs from

fuse box.

Page 185 of 1529

ENGINE - V8

12-2-30 REPAIRS

Refit

1.Clean mating faces of engine and gearbox,

dowel and dowel holes.

2.Lubricate splines and bearing surface on first

motion shaft with grease.

3.With assistance position engine in engine bay,

align to gearbox and locate on dowels.

4.Position support brackets, fit bell housing bolts

and tighten to 50 Nm (37 lbf.ft).

5.Position engine mountings, fit nuts and tighten

to 85 Nm (63 lbf.ft).

6.Lower lifting equipment and remove from

engine.

7. Models with automatic gearbox: Align torque

converter to drive plate, fit bolts and tighten to

50 Nm (37 lbf.ft). Fit access plug.

8.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

9.Position oil cooling pipe saddle clamps and

tighten bolts.

10.Position engine harness into foot well.

11.Connect 5 multiplugs to ECM.

12.Fit toe board and secure with trim fixings.

13.Connect engine harness earth to body and

secure with nut.

14.Connect engine harness to main harness

multiplug.

15.Connect multiplug to EVAP purge valve.

16.Connect engine harness multiplugs to fuse

box.

17.Connect starter lead to fuse box and secure

with nut.

18.Connect engine harness positive lead to

battery and tighten nut.

19.Fit fuse box cover.

20.Position engine earth lead and secure with

bolt.

21.Position coolant rail and secure with bolt.

22.Connect harness clips to coolant rail.

23.Connect hose to coolant rail and coolant pump

and secure with clips.

24.Connect PAS pump high and low pressure

pipes and secure with clips.

25.Position oil cooling pipe saddle clamp to PAS

pump housing and secure with bolt.

26.Clean A/C compressor and housing mating

faces, dowels and dowel holes.

27.Position A/C compressor, fit bolts and tighten

to 22 Nm (16 lbf.ft).

28.Connect multiplug to A/C compressor.

29.Clean ACE pump and housing mating faces,

dowels and dowel holes.

30.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft). 31.Clean all pulley 'V's, fit auxiliary drive belt,

using a 15mm spanner, release belt tensioner

secure belt and re-tension drive belt .

32.Ensure auxiliary drive belt is correctly located

on all pulleys.

33.Fit radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

34.Fit top hose and secure with clips.

35.Connect fuel pipe to fuel rail.

36.Position ignition coils and connect ht leads.

37.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

38.Fit new oil filter and refill engine with oil.

+ ENGINE - V8, REPAIRS, Filter - oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

39.Top up gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 238 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-5

Evaporative emission system control

diagram

1Battery

2Fuse 13 (engine compartment fusebox)

3Inertia switch

4Main relay (engine compartment fusebox)

5Engine Control Module (ECM)

6Purge Valve (black harness connector)

7Canister vent solenoid (CVS) valve – NAS

vehicles with vacuum type EVAP system leak

detection capability only8Leak detection pump – NAS vehicles with

positive pressure type EVAP system leak

detection capability only

9Fuel tank pressure sensor – NAS vehicles with

vacuum type EVAP system leak detection

capability only

10Instrument pack (MIL warning light)

M17 0210

12

3

4

5

6

7

9

8

10

Page 241 of 1529

EMISSION CONTROL - V8

17-2-8 DESCRIPTION AND OPERATION

Secondary air injection system control

diagram

1Fuselink 2 (engine compartment fusebox)

2SAI pump relay

3SAI pump

4SAI vacuum solenoid valve

(grey harness connector)5Engine Control Module (ECM)

6Battery

7Fuse 13 (engine compartment fusebox)

8Inertia switch

9Main relay

9

M17 0207

1

2

3

4

5

7

6

8

Page 247 of 1529

EMISSION CONTROL - V8

17-2-14 DESCRIPTION AND OPERATION

The heated oxygen sensor is screwed into threaded mountings welded into the top of the front exhaust pipes at

suitable locations. They are used to detect the level of residual oxygen in the exhaust gas to provide an instantaneous

indication of whether combustion is complete. By positioning sensors in the stream of exhaust gases from each

separate bank of the exhaust manifold, the engine management system is better able to control the fuelling

requirements on each bank independently of the other, so allowing much closer control of the air:fuel ratio and

optimising catalytic converter efficiency.

Two pre-catalytic converter heated oxygen sensors are mounted in the front pipes for monitoring the oxygen content

of the exhaust gas. NAS models also have two additional post-catalytic converter heated oxygen sensors in the

exhaust front pipe.

CAUTION: HO2 sensors are easily damaged by dropping, over torquing, excessive heat or contamination.

Care must be taken not to damage the sensor housing or tip.

The oxygen sensors consist of a ceramic body (Galvanic cell) which is a practically pure oxygen-ion conductor made

from a mixed oxide of zirconium and yttrium. The ceramic is then coated with gas-permeable platinum, which when

heated to a sufficiently high temperature (≥ 350° C) generates a voltage which is proportional to the oxygen content

in the exhaust gas stream.

The heated oxygen sensor is protected by an outer tube with a restricted flow opening to prevent the sensor's

ceramics from being cooled by low temperature exhaust gases at start up. The post-catalytic sensors have improved

signal quality, but a slower response rate.

The pre-catalytic and post-catalytic converter sensors are not interchangeable, and although it is possible to mount

them in transposed positions, their harness connections are of different gender and colour. It is important not to

confuse the sensor signal pins; the signal pins are gold plated, whilst the heater supply pins are tinned,

mixing them up will cause contamination and adversely affect system performance.

Each of the heated oxygen sensors have a four pin connector with the following wiring details:

lSensor signal ground (grey wire – connects to engine management ECM)

lSensor signal (black wire – connects to engine management ECM)

lHeater drive (white wire – connects to engine management ECM)

lHeater supply (white wire – connects to fuse 2, underbonnet fuse box)

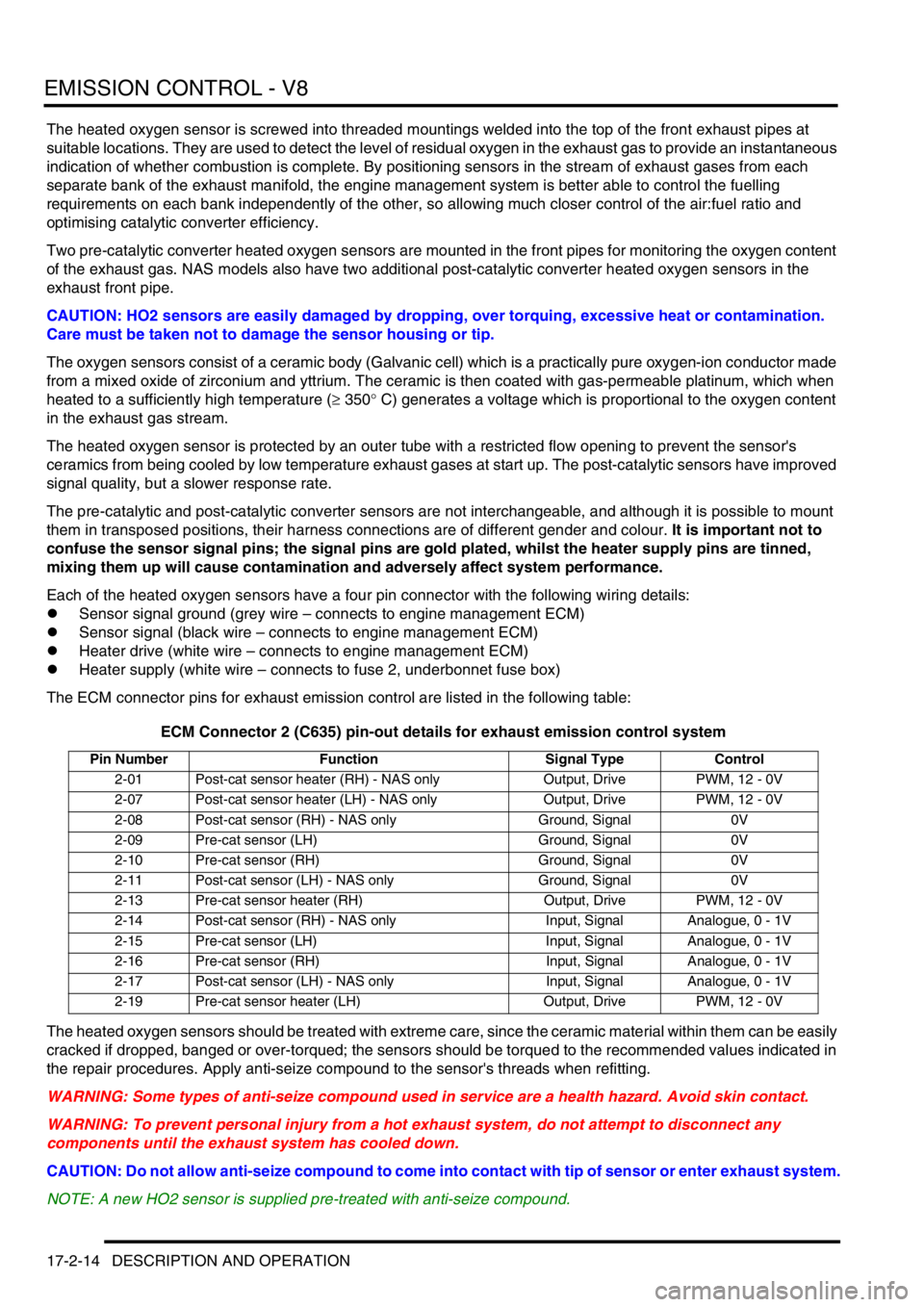

The ECM connector pins for exhaust emission control are listed in the following table:

ECM Connector 2 (C635) pin-out details for exhaust emission control system

The heated oxygen sensors should be treated with extreme care, since the ceramic material within them can be easily

cracked if dropped, banged or over-torqued; the sensors should be torqued to the recommended values indicated in

the repair procedures. Apply anti-seize compound to the sensor's threads when refitting.

WARNING: Some types of anti-seize compound used in service are a health hazard. Avoid skin contact.

WARNING: To prevent personal injury from a hot exhaust system, do not attempt to disconnect any

components until the exhaust system has cooled down.

CAUTION: Do not allow anti-seize compound to come into contact with tip of sensor or enter exhaust system.

NOTE: A new HO2 sensor is supplied pre-treated with anti-seize compound.

Pin Number Function Signal Type Control

2-01 Post-cat sensor heater (RH) - NAS only Output, Drive PWM, 12 - 0V

2-07 Post-cat sensor heater (LH) - NAS only Output, Drive PWM, 12 - 0V

2-08 Post-cat sensor (RH) - NAS only Ground, Signal 0V

2-09 Pre-cat sensor (LH) Ground, Signal 0V

2-10 Pre-cat sensor (RH) Ground, Signal 0V

2-11 Post-cat sensor (LH) - NAS only Ground, Signal 0V

2-13 Pre-cat sensor heater (RH) Output, Drive PWM, 12 - 0V

2-14 Post-cat sensor (RH) - NAS only Input, Signal Analogue, 0 - 1V

2-15 Pre-cat sensor (LH) Input, Signal Analogue, 0 - 1V

2-16 Pre-cat sensor (RH) Input, Signal Analogue, 0 - 1V

2-17 Post-cat sensor (LH) - NAS only Input, Signal Analogue, 0 - 1V

2-19 Pre-cat sensor heater (LH) Output, Drive PWM, 12 - 0V

Page 253 of 1529

EMISSION CONTROL - V8

17-2-20 DESCRIPTION AND OPERATION

For NAS vehicles with positive pressure, EVAP system leak detection capability, the atmosphere vent line from the

EVAP canister connects to a port on the fuel leak detection pump via a short, large bore hose which is secured to the

component ports by crimped metal clips at each end. A large bore plastic hose from the top of the leak detection pump

is routed to the RH side of the engine bay where it connects to an air filter canister. Under normal operating conditions

(when the fuel leak detection solenoid valve is not energised), the EVAP canister is able to take in clean air via the

air filter, through the pipework and past the open solenoid valve to allow normal purge operation to take place and

release any build up of EVAP system pressure to atmosphere.

The EVAP system pipes are clipped at various points along the pipe runs and tied together with tie straps at suitable

points along the runs.

The NAS and ROW EVAP canisters are of similar appearance, but use charcoal of different consistency. The ROW

vehicles use granular charcoal of 11 bwc (butane working capacity) and NAS vehicles use pelletised charcoal with a

higher absorption capacity of 15 bwc. All canisters are of rectangular shape and have capacities of 1.8 litres (3 1/8

imp. pts) with purge foam retention.

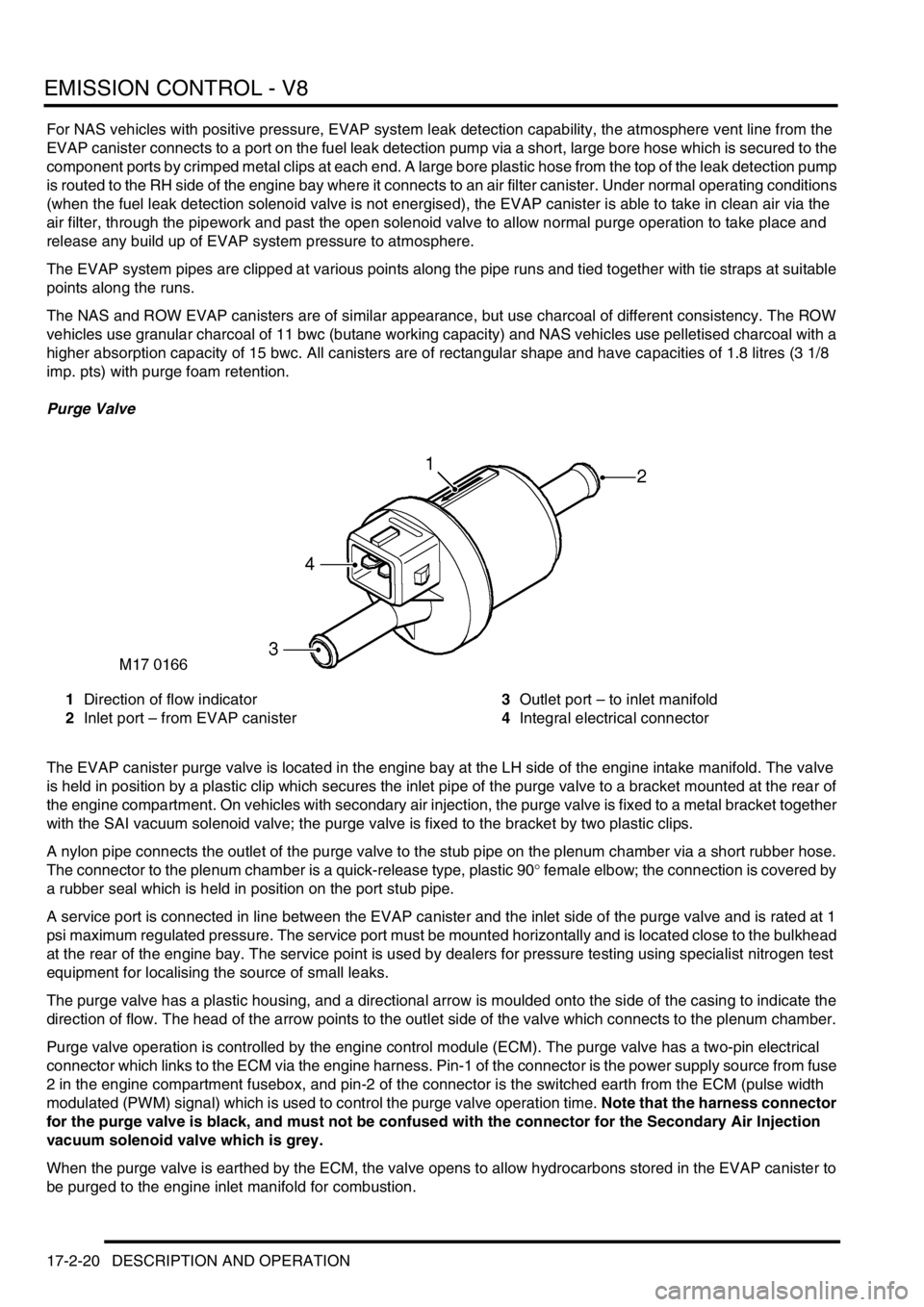

Purge Valve

1Direction of flow indicator

2Inlet port – from EVAP canister3Outlet port – to inlet manifold

4Integral electrical connector

The EVAP canister purge valve is located in the engine bay at the LH side of the engine intake manifold. The valve

is held in position by a plastic clip which secures the inlet pipe of the purge valve to a bracket mounted at the rear of

the engine compartment. On vehicles with secondary air injection, the purge valve is fixed to a metal bracket together

with the SAI vacuum solenoid valve; the purge valve is fixed to the bracket by two plastic clips.

A nylon pipe connects the outlet of the purge valve to the stub pipe on the plenum chamber via a short rubber hose.

The connector to the plenum chamber is a quick-release type, plastic 90° female elbow; the connection is covered by

a rubber seal which is held in position on the port stub pipe.

A service port is connected in line between the EVAP canister and the inlet side of the purge valve and is rated at 1

psi maximum regulated pressure. The service port must be mounted horizontally and is located close to the bulkhead

at the rear of the engine bay. The service point is used by dealers for pressure testing using specialist nitrogen test

equipment for localising the source of small leaks.

The purge valve has a plastic housing, and a directional arrow is moulded onto the side of the casing to indicate the

direction of flow. The head of the arrow points to the outlet side of the valve which connects to the plenum chamber.

Purge valve operation is controlled by the engine control module (ECM). The purge valve has a two-pin electrical

connector which links to the ECM via the engine harness. Pin-1 of the connector is the power supply source from fuse

2 in the engine compartment fusebox, and pin-2 of the connector is the switched earth from the ECM (pulse width

modulated (PWM) signal) which is used to control the purge valve operation time. Note that the harness connector

for the purge valve is black, and must not be confused with the connector for the Secondary Air Injection

vacuum solenoid valve which is grey.

When the purge valve is earthed by the ECM, the valve opens to allow hydrocarbons stored in the EVAP canister to

be purged to the engine inlet manifold for combustion.

Page 254 of 1529

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-21

If the purge valve breaks or becomes stuck in the open or closed position, the EVAP system will cease to function

and there are no default measures available. The ECM will store the fault in memory and illuminate the MIL warning

lamp if the correct monitoring conditions have been achieved (i.e. valve status unchanged for 45 seconds after engine

has been running for 15 minutes). If the purge valve is stuck in the open position, a rich air:fuel mixture is likely to

result at the intake manifold, this could cause the engine to misfire and the fuelling adaptions will change.

The following failure modes are possible:

lSticking valve

lValve blocked

lConnector or harness wiring fault (open or short circuit)

lValve stuck open

If the purge valve malfunctions, the following fault codes may be stored in the ECM diagnostic memory, which can be

retrieved using TestBook/T4:

Canister Vent Solenoid (CVS) Unit – (NAS with vacuum type, fuel evaporation leak detection system only)

1CVS unit

2Mounting bracket3Spring clips to pipe from EVAP canister

4Harness connector

The canister vent solenoid (CVS) valve is mounted on a slide-on bracket which is riveted to the cruise control bracket

at the right hand side of the engine compartment. The vent pipe from the EVAP canister is connected to a stub pipe

on the CVS unit via a hose and plastic pipe combination. A two-pin connector links to the engine management ECM

via the engine harness for solenoid control; one of the wires is the supply feed from fuse No.2 in the engine

compartment fusebox, the other wire is the valve drive line to the ECM. The solenoid is operated when the ECM

grounds the circuit.

P-code Description

P0440Purge valve not sealing

P0444Purge valve open circuit

P0445Purge valve short circuit to ground

P0443Purge valve short circuit to battery voltage

Page 257 of 1529

EMISSION CONTROL - V8

17-2-24 DESCRIPTION AND OPERATION

Leak Detection Pump (NAS vehicles with positive pressure EVAP system leakage test only)

1Harness connector

2Leak detection pump motor

3Atmosphere connection to/from EVAP canister4Atmosphere connection to/from air filter

5Leak detection pump solenoid valve

The fuel evaporation leak detection pump is mounted forward of the EVAP canister on a bracket fitted beneath the

vehicle on the RH side of the vehicle chassis. The leak detection pump is fixed to the bracket by three screws through

the bottom of the bracket.

A short hose connects between the atmosphere vent port of the EVAP canister and a port at the rear of the fuel

evaporation leak detection pump. The hose is secured to the ports at each end by crimped metal band clips.

An elbowed quick fit connector on the top of the fuel evaporation leak detection pump connects to atmosphere via a

large bore pipe. The pipe is routed along the underside of the vehicle chassis and up into the RH side of the engine

compartment where it connects to an air filter canister.

The leak detection pump incorporates a 3–pin electrical connector. Pin-1 is the earth switched supply to the ECM for

control of the pump solenoid valve. Pin-2 is the earth switched supply to the ECM for the operation of the pump motor.

Pin-3 is the power supply to the pump motor and solenoid valve and is switched on at system start up via the main

relay and fuse 2 in the engine compartment fusebox.

Under normal circumstances (i.e. when the leak detection pump is not operating and the solenoid is not energised),

the EVAP canister vent port is connected to atmosphere via the open solenoid valve.

The pump is operated at the end of a drive cycle when the vehicle is stationary and the ignition is switched off.

The leak detection pump module contains an integral air by-pass circuit with restrictor (reference-leak orifice) which

is used for providing a reference value for the leak detection test. The restrictor corresponds to an air leak equivalent

to 0.5 mm (0.02 in) diameter. With the solenoid valve open and the purge valve closed, the pump forces pressurised

air through the orifice while the current drawn by the leak detection pump motor is monitored to obtain the reference

value. The orifice must be kept free from contamination, otherwise the reference restriction may appear less than for

a 0.5 mm leak and consequently adversely affect the diagnostic results.

M17 0213

3

4

5

1

2

Page 261 of 1529

EMISSION CONTROL - V8

17-2-28 DESCRIPTION AND OPERATION

The air delivery pipe is a flexible plastic type, and is connected to the air pump outlet via a plastic quick-fit connector.

The other end of the flexible plastic pipe connects to the fixed metal pipework via a short rubber hose. The part of the

flexible plastic pipe which is most vulnerable to engine generated heat is protected by heat reflective sleeving. The

metal delivery pipe has a fabricated T-piece included where the pressurised air is split for delivery to each exhaust

manifold via the SAI control valves.

The pipes from the T-piece to each of the SAI control valves are approximately the same length, so that the pressure

and mass of the air delivered to each bank will be equal. The ends of the pipes are connected to the inlet port of each

SAI control valve through short rubber hose connections.

The T-piece is mounted at the rear of the engine (by the ignition coils) and features a welded mounting bracket which

is fixed to the engine by two studs and nuts.

The foam filter in the air intake of the SAI pump provides noise reduction and protects the pump from damage due to

particulate contamination. In addition, the pump is fitted on rubber mountings to help prevent noise which is generated

by pump operation from being transmitted through the vehicle body into the passenger compartment.

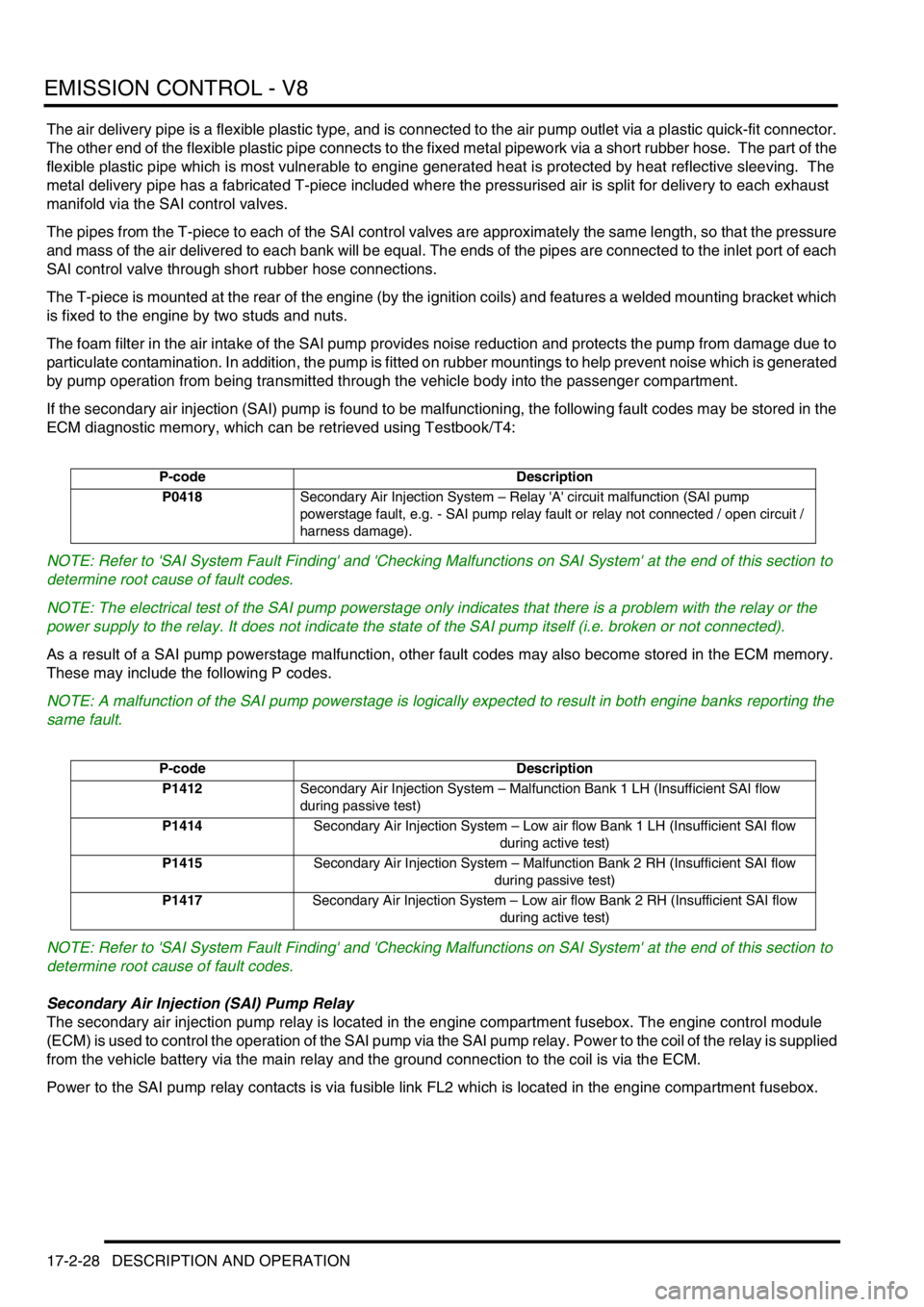

If the secondary air injection (SAI) pump is found to be malfunctioning, the following fault codes may be stored in the

ECM diagnostic memory, which can be retrieved using Testbook/T4:

NOTE: Refer to 'SAI System Fault Finding' and 'Checking Malfunctions on SAI System' at the end of this section to

determine root cause of fault codes.

NOTE: The electrical test of the SAI pump powerstage only indicates that there is a problem with the relay or the

power supply to the relay. It does not indicate the state of the SAI pump itself (i.e. broken or not connected).

As a result of a SAI pump powerstage malfunction, other fault codes may also become stored in the ECM memory.

These may include the following P codes.

NOTE: A malfunction of the SAI pump powerstage is logically expected to result in both engine banks reporting the

same fault.

NOTE: Refer to 'SAI System Fault Finding' and 'Checking Malfunctions on SAI System' at the end of this section to

determine root cause of fault codes.

Secondary Air Injection (SAI) Pump Relay

The secondary air injection pump relay is located in the engine compartment fusebox. The engine control module

(ECM) is used to control the operation of the SAI pump via the SAI pump relay. Power to the coil of the relay is supplied

from the vehicle battery via the main relay and the ground connection to the coil is via the ECM.

Power to the SAI pump relay contacts is via fusible link FL2 which is located in the engine compartment fusebox.

P-code Description

P0418Secondary Air Injection System – Relay 'A' circuit malfunction (SAI pump

powerstage fault, e.g. - SAI pump relay fault or relay not connected / open circuit /

harness damage).

P-code Description

P1412Secondary Air Injection System – Malfunction Bank 1 LH (Insufficient SAI flow

during passive test)

P1414Secondary Air Injection System – Low air flow Bank 1 LH (Insufficient SAI flow

during active test)

P1415Secondary Air Injection System – Malfunction Bank 2 RH (Insufficient SAI flow

during passive test)

P1417Secondary Air Injection System – Low air flow Bank 2 RH (Insufficient SAI flow

during active test)