relay LAND ROVER DISCOVERY 1999 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 753 of 1529

FRONT SUSPENSION

60-8 DESCRIPTION AND OPERATION

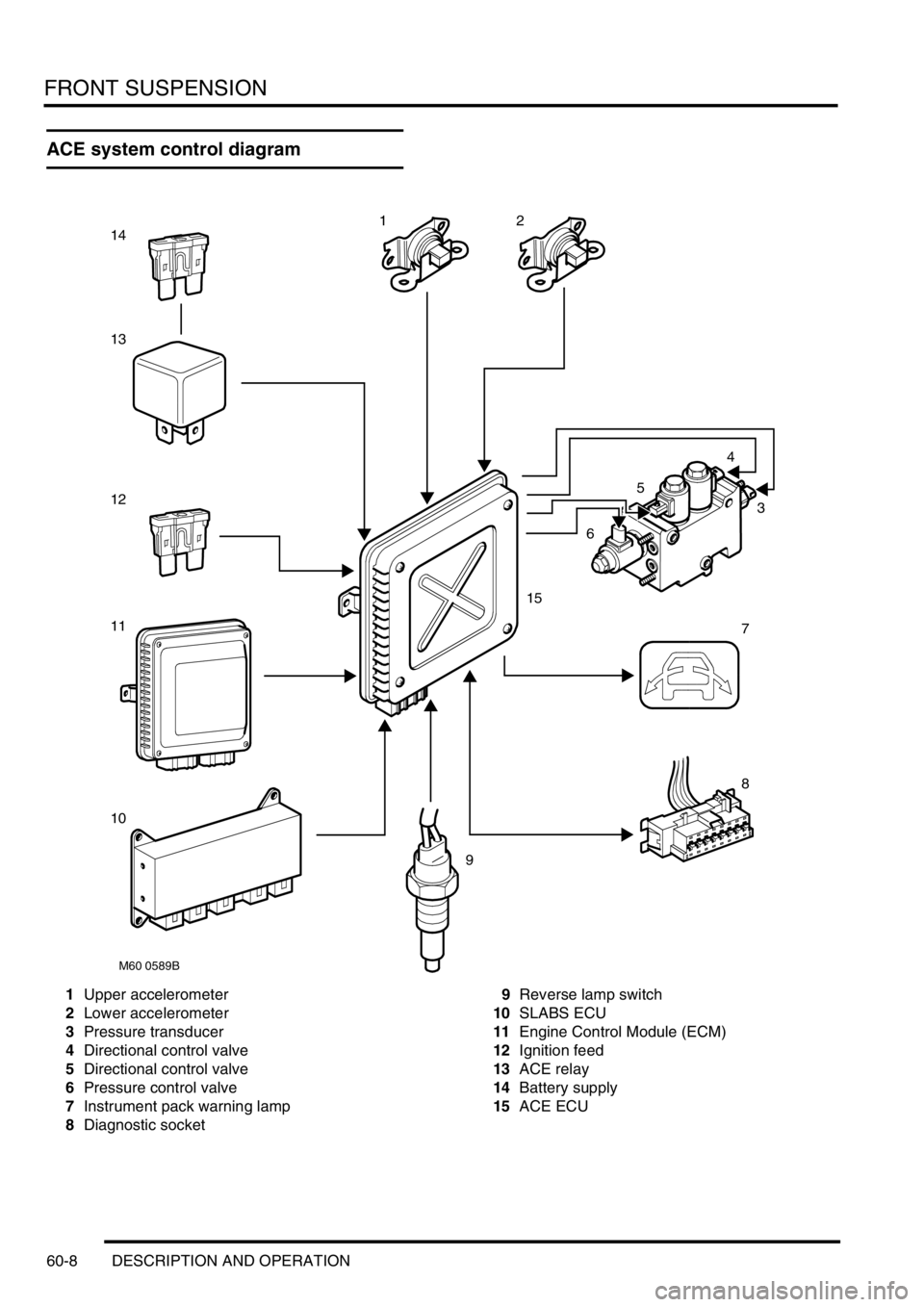

ACE system control diagram

1Upper accelerometer

2Lower accelerometer

3Pressure transducer

4Directional control valve

5Directional control valve

6Pressure control valve

7Instrument pack warning lamp

8Diagnostic socket9Reverse lamp switch

10SLABS ECU

11Engine Control Module (ECM)

12Ignition feed

13ACE relay

14Battery supply

15ACE ECU

M60 0589B

12

5

4

3

6

7

8

9

10

11

12

13

14

15

Page 756 of 1529

FRONT SUSPENSION

DESCRIPTION AND OPERATION 60-11

The ACE system uses a semi-synthetic hydraulic fluid which is the same as the fluid used for the PAS system. The

total capacity of the ACE system is 1.62 litres (0.42 US Gallons).

CAUTION: The ACE hydraulic system is extremely sensitive to the ingress of dirt or debris. The smallest

amount could render the system unserviceable. It is imperative that the following precautions are taken.

lACE components are thoroughly cleaned externally before work commences;

lall opened pipe and module ports are capped immediately;

lall fluid is stored in and administered through clean containers.

In the event of an ECU or hydraulic failure the system will fail safe to a 'locked bars' condition. The 'locked bars'

condition will allow the torsion bars to operate in a similar manner as conventional 'passive' anti-roll bars. Prolonged

cornering forces will allow a progressive increase in roll angle due to hydraulic leakage through the actuators and

valve block. Failures will be relayed to the driver by the illumination of the ACE warning lamp in the instrument pack.

Faults are recorded by the ECU and can be retrieved using TestBook.

When the ignition switch is moved to position II, the warning lamp will illuminate for two seconds to check functionality.

The warning lamp functionality can also be checked using TestBook.

TestBook must also be used to perform a bleeding procedure after maintenance operations have been performed to

ensure that complete system bleeding is performed. Trapped air in the system can seriously reduce the system

performance.

Fluid reservoir

The moulded plastic fluid reservoir is mounted on the left hand side of the engine compartment on a bracket which is

attached to the inner wing. The reservoir is dual purpose, being divided into two separate chambers; one for the ACE

system and one for the PAS system. Each chamber has its own filler neck and cap and is identified by moulded

lettering on the reservoir adjacent to each filler.

A non-serviceable filter assembly is fitted in the base of each chamber. The filter is made from fine stainless steel

mesh which is moulded into the body of the reservoir. The filter removes particulate matter from the fluid before it is

drawn into the hydraulic pump.

Upper and lower fluid level marks are moulded onto the reservoir body. The capacity of the ACE reservoir chamber

to the upper level mark is 0.5 litre (0.13 US Gallon).

Page 763 of 1529

FRONT SUSPENSION

60-18 DESCRIPTION AND OPERATION

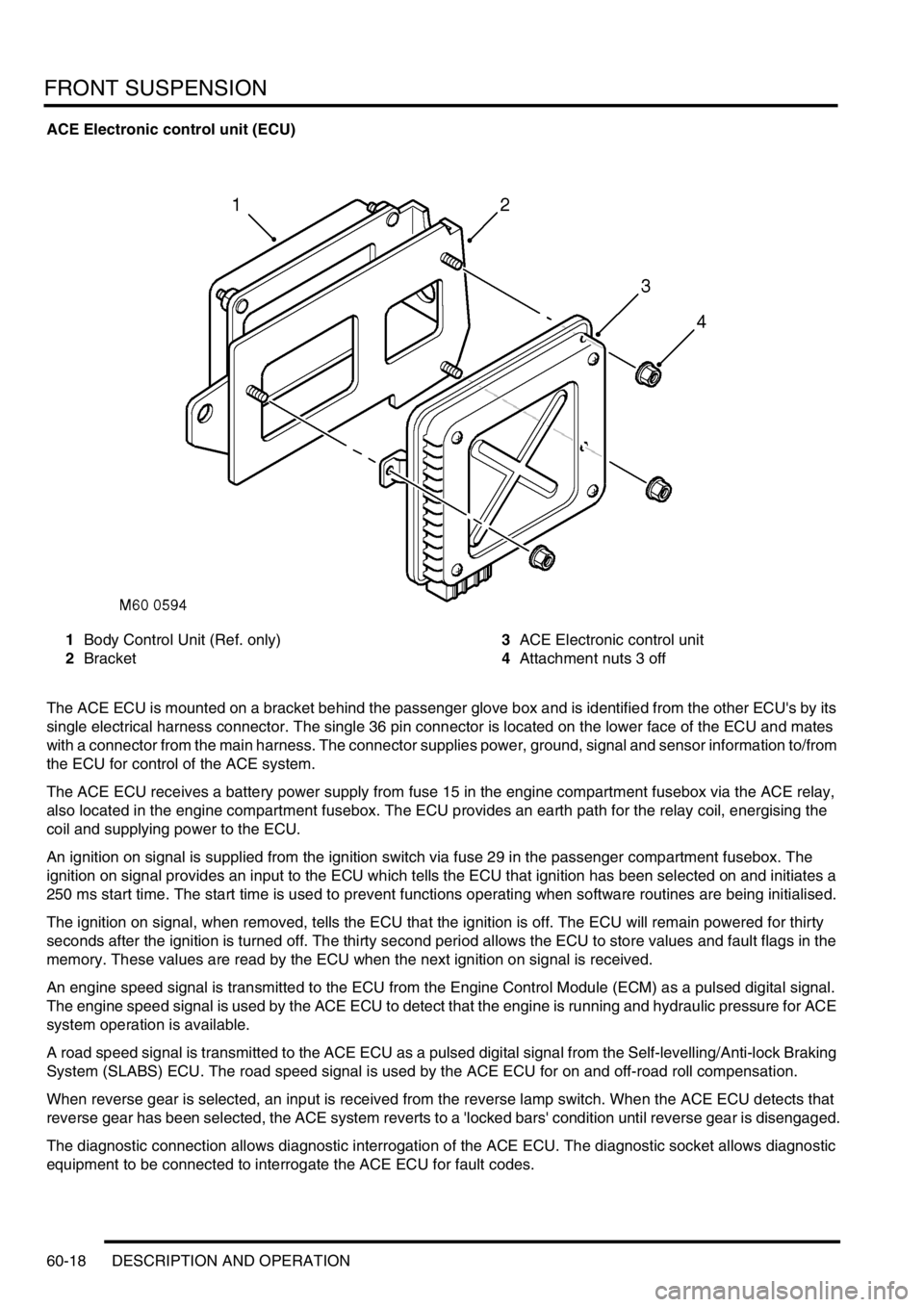

ACE Electronic control unit (ECU)

1Body Control Unit (Ref. only)

2Bracket3ACE Electronic control unit

4Attachment nuts 3 off

The ACE ECU is mounted on a bracket behind the passenger glove box and is identified from the other ECU's by its

single electrical harness connector. The single 36 pin connector is located on the lower face of the ECU and mates

with a connector from the main harness. The connector supplies power, ground, signal and sensor information to/from

the ECU for control of the ACE system.

The ACE ECU receives a battery power supply from fuse 15 in the engine compartment fusebox via the ACE relay,

also located in the engine compartment fusebox. The ECU provides an earth path for the relay coil, energising the

coil and supplying power to the ECU.

An ignition on signal is supplied from the ignition switch via fuse 29 in the passenger compartment fusebox. The

ignition on signal provides an input to the ECU which tells the ECU that ignition has been selected on and initiates a

250 ms start time. The start time is used to prevent functions operating when software routines are being initialised.

The ignition on signal, when removed, tells the ECU that the ignition is off. The ECU will remain powered for thirty

seconds after the ignition is turned off. The thirty second period allows the ECU to store values and fault flags in the

memory. These values are read by the ECU when the next ignition on signal is received.

An engine speed signal is transmitted to the ECU from the Engine Control Module (ECM) as a pulsed digital signal.

The engine speed signal is used by the ACE ECU to detect that the engine is running and hydraulic pressure for ACE

system operation is available.

A road speed signal is transmitted to the ACE ECU as a pulsed digital signal from the Self-levelling/Anti-lock Braking

System (SLABS) ECU. The road speed signal is used by the ACE ECU for on and off-road roll compensation.

When reverse gear is selected, an input is received from the reverse lamp switch. When the ACE ECU detects that

reverse gear has been selected, the ACE system reverts to a 'locked bars' condition until reverse gear is disengaged.

The diagnostic connection allows diagnostic interrogation of the ACE ECU. The diagnostic socket allows diagnostic

equipment to be connected to interrogate the ACE ECU for fault codes.

Page 764 of 1529

FRONT SUSPENSION

DESCRIPTION AND OPERATION 60-19

When system faults are detected by the ECU, the ACE warning lamp in the instrument pack is illuminated by the ECU

continuously in amber for minor faults or flashing red with an audible warning for faults which require the driver to stop

the vehicle immediately.

The ACE ECU supplies a control current to the pressure control valve in the valve block. The current supplied by the

ECU is determined by a number of input signals from the upper and lower accelerometers, road speed etc.. The

pressure control valve controls the hydraulic pressure supplied to the actuators proportional to the current supplied

by the ECU.

Power is supplied to the two solenoid operated directional control valves (DCV's) in the valve block by the ECU.

Together, the DCV's control the direction of flow of hydraulic fluid to the actuators. When the ECU supplies power to

the solenoids the valves open allowing hydraulic fluid to flow to the actuators. When power is removed the valves

close.

The pressure transducer in the valve block receives a 5 V supply from the ECU. The pressure transducer measures

hydraulic pressures in the range of 0 to 180 bar (0 to 2610 lbf.in

2) and returns a linear output voltage to the ECU

dependent on hydraulic pressure.

The ECU supplies a 5 V current to each of the accelerometers. Each accelerometer is capable of measuring lateral

acceleration in the range of ± 1.10 g. An analogue input to the ECU of between 0.5 and 4.5 V relative to the lateral

acceleration sensed is returned by each accelerometer. The ECU processes the two signals received to produce a

'pure' lateral acceleration signal which is then used as the main control signal for the ACE system.

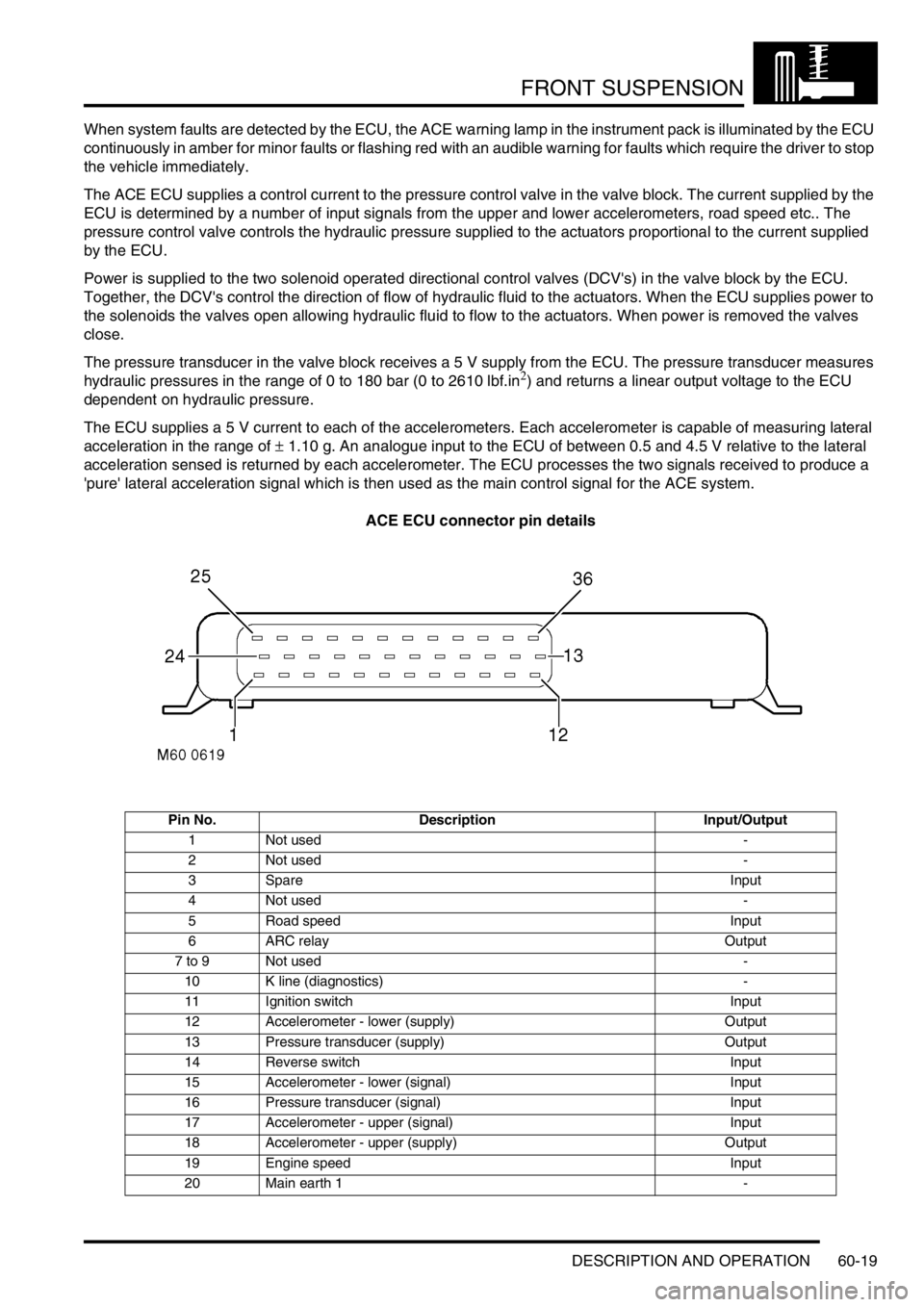

ACE ECU connector pin details

Pin No. Description Input/Output

1 Not used -

2 Not used -

3 Spare Input

4 Not used -

5 Road speed Input

6ARC relay Output

7 to 9 Not used -

10 K line (diagnostics) -

11 Ignition switch Input

12 Accelerometer - lower (supply) Output

13 Pressure transducer (supply) Output

14 Reverse switch Input

15 Accelerometer - lower (signal) Input

16 Pressure transducer (signal) Input

17 Accelerometer - upper (signal) Input

18 Accelerometer - upper (supply) Output

19 Engine speed Input

20 Main earth 1 -

Page 820 of 1529

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-11

1Battery supply (via SLABS relay)

2Ignition supply

3RH height sensor

4LH height sensor

5Off-road mode warning lamp

6Audible warning speaker

7Instrument pack

8SLS warning lamp

9Fusible link 9

10SLS relay

11Air supply unit

12RH air valve

13LH air valve

14Exhaust valve

15Diagnostic socket

16Off-road mode switch

17SLS remote handset

18Body Control Unit (BCU)

19Door switches

20SLABS ECU

21Engine Control Module (ECM)

Page 827 of 1529

REAR SUSPENSION

64-18 DESCRIPTION AND OPERATION

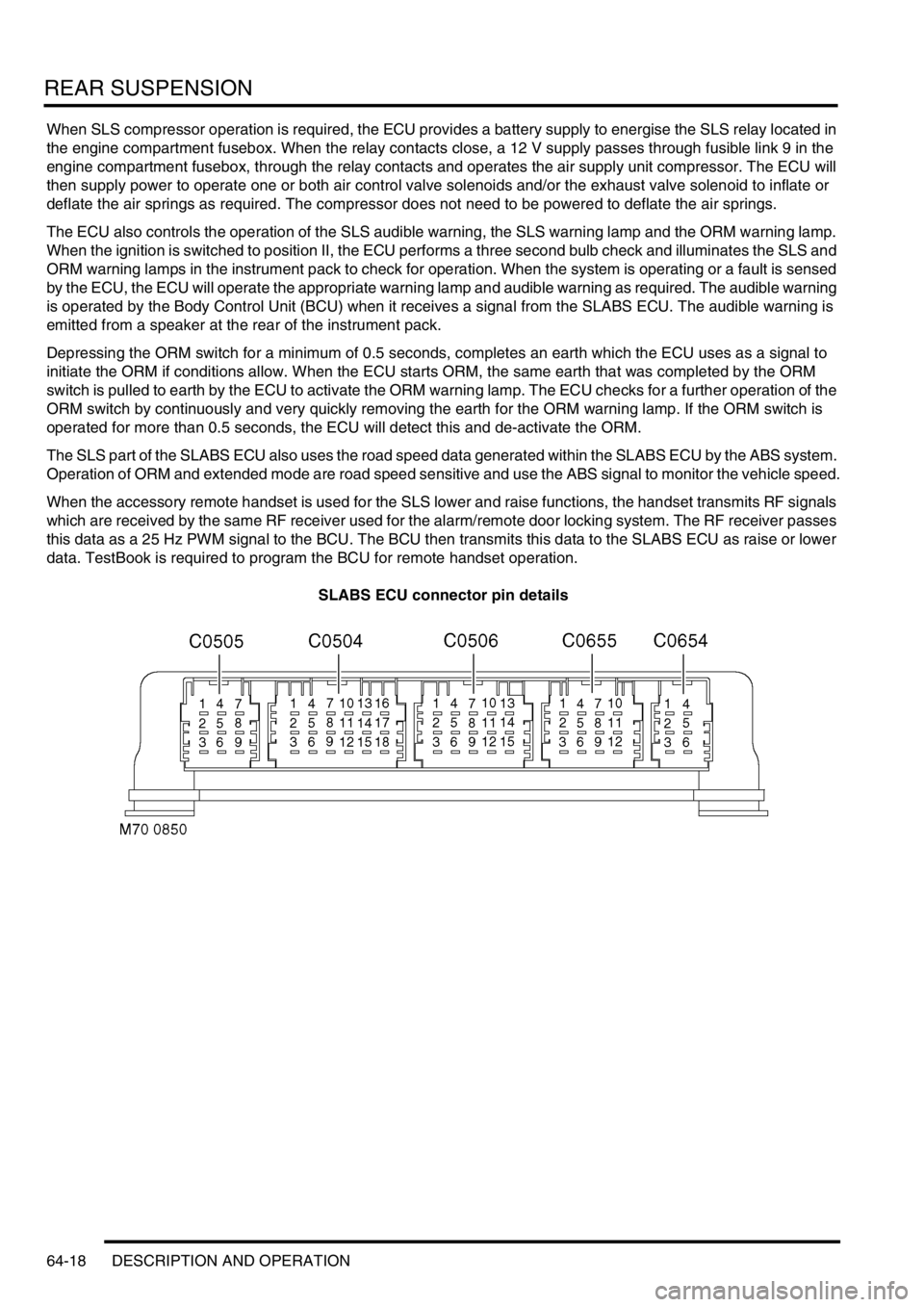

When SLS compressor operation is required, the ECU provides a battery supply to energise the SLS relay located in

the engine compartment fusebox. When the relay contacts close, a 12 V supply passes through fusible link 9 in the

engine compartment fusebox, through the relay contacts and operates the air supply unit compressor. The ECU will

then supply power to operate one or both air control valve solenoids and/or the exhaust valve solenoid to inflate or

deflate the air springs as required. The compressor does not need to be powered to deflate the air springs.

The ECU also controls the operation of the SLS audible warning, the SLS warning lamp and the ORM warning lamp.

When the ignition is switched to position II, the ECU performs a three second bulb check and illuminates the SLS and

ORM warning lamps in the instrument pack to check for operation. When the system is operating or a fault is sensed

by the ECU, the ECU will operate the appropriate warning lamp and audible warning as required. The audible warning

is operated by the Body Control Unit (BCU) when it receives a signal from the SLABS ECU. The audible warning is

emitted from a speaker at the rear of the instrument pack.

Depressing the ORM switch for a minimum of 0.5 seconds, completes an earth which the ECU uses as a signal to

initiate the ORM if conditions allow. When the ECU starts ORM, the same earth that was completed by the ORM

switch is pulled to earth by the ECU to activate the ORM warning lamp. The ECU checks for a further operation of the

ORM switch by continuously and very quickly removing the earth for the ORM warning lamp. If the ORM switch is

operated for more than 0.5 seconds, the ECU will detect this and de-activate the ORM.

The SLS part of the SLABS ECU also uses the road speed data generated within the SLABS ECU by the ABS system.

Operation of ORM and extended mode are road speed sensitive and use the ABS signal to monitor the vehicle speed.

When the accessory remote handset is used for the SLS lower and raise functions, the handset transmits RF signals

which are received by the same RF receiver used for the alarm/remote door locking system. The RF receiver passes

this data as a 25 Hz PWM signal to the BCU. The BCU then transmits this data to the SLABS ECU as raise or lower

data. TestBook is required to program the BCU for remote handset operation.

SLABS ECU connector pin details

Page 828 of 1529

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-19

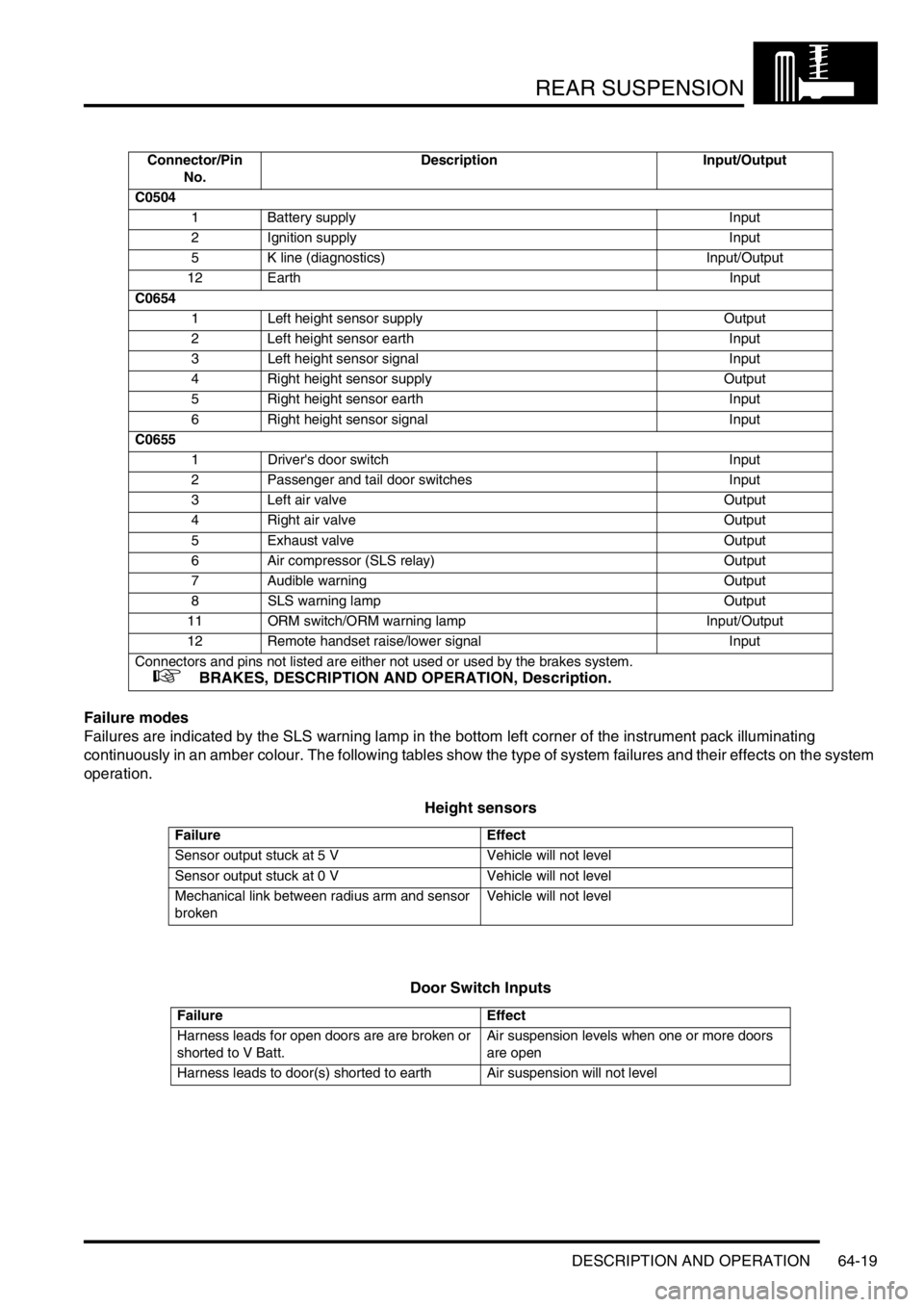

Failure modes

Failures are indicated by the SLS warning lamp in the bottom left corner of the instrument pack illuminating

continuously in an amber colour. The following tables show the type of system failures and their effects on the system

operation.

Height sensors

Door Switch Inputs

Connector/Pin

No.Description Input/Output

C0504

1 Battery supply Input

2 Ignition supply Input

5 K line (diagnostics) Input/Output

12 Earth Input

C0654

1 Left height sensor supply Output

2 Left height sensor earth Input

3 Left height sensor signal Input

4 Right height sensor supply Output

5 Right height sensor earth Input

6 Right height sensor signal Input

C0655

1 Driver's door switch Input

2 Passenger and tail door switches Input

3 Left air valve Output

4 Right air valve Output

5 Exhaust valve Output

6 Air compressor (SLS relay) Output

7 Audible warning Output

8 SLS warning lamp Output

11 ORM switch/ORM warning lamp Input/Output

12 Remote handset raise/lower signal Input

Connectors and pins not listed are either not used or used by the brakes system.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

Failure Effect

Sensor output stuck at 5 V Vehicle will not level

Sensor output stuck at 0 V Vehicle will not level

Mechanical link between radius arm and sensor

brokenVehicle will not level

Failure Effect

Harness leads for open doors are are broken or

shorted to V Batt.Air suspension levels when one or more doors

are open

Harness leads to door(s) shorted to earth Air suspension will not level

Page 829 of 1529

REAR SUSPENSION

64-20 DESCRIPTION AND OPERATION

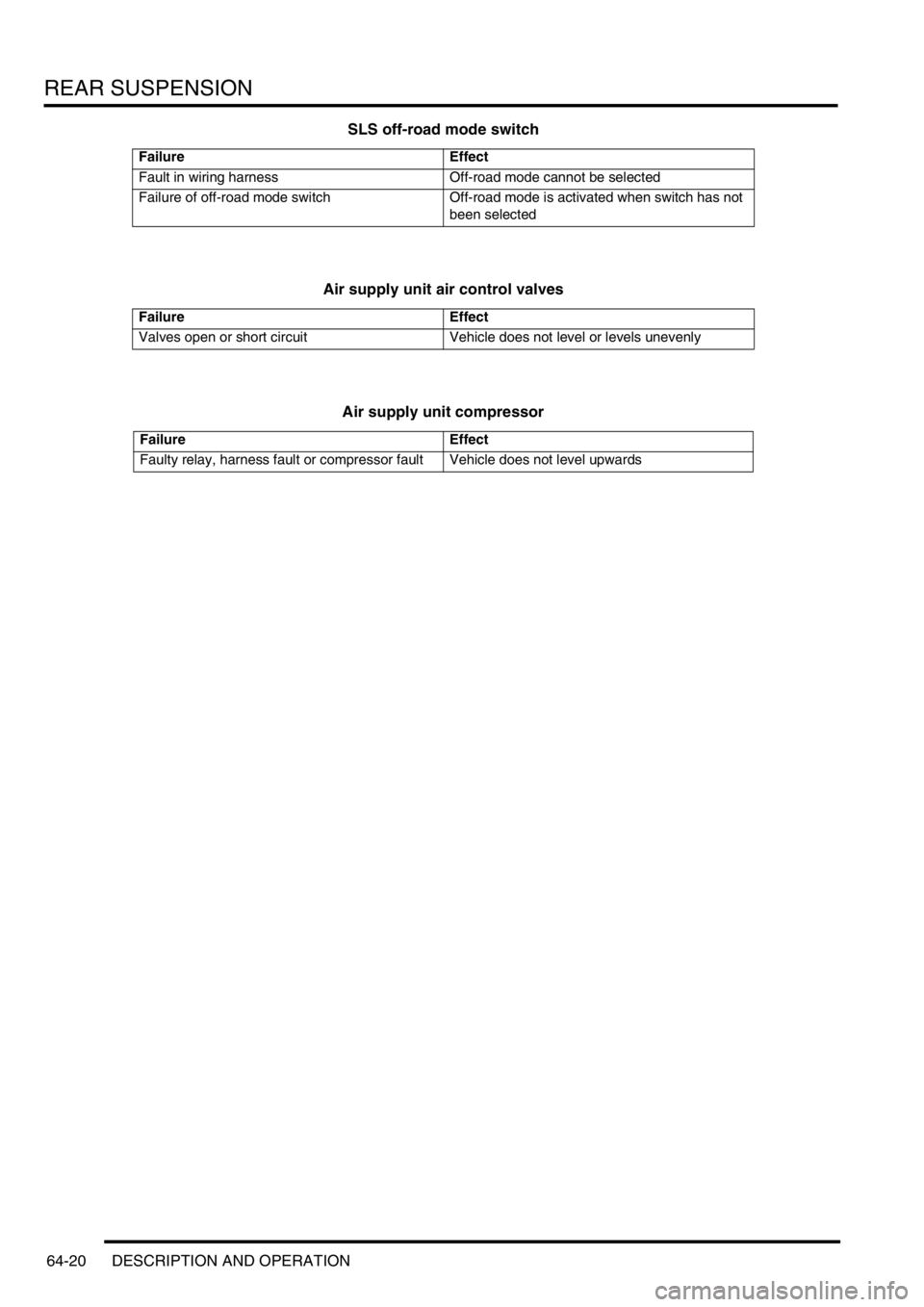

SLS off-road mode switch

Air supply unit air control valves

Air supply unit compressor

Failure Effect

Fault in wiring harness Off-road mode cannot be selected

Failure of off-road mode switch Off-road mode is activated when switch has not

been selected

Failure Effect

Valves open or short circuit Vehicle does not level or levels unevenly

Failure Effect

Faulty relay, harness fault or compressor fault Vehicle does not level upwards

Page 856 of 1529

BRAKES

DESCRIPTION AND OPERATION 70-3

1ABS sensor

2ABS modulator

3Return pump relay

4SLABS ECU

5Brake lamp relay

6Centre high mounted stop lamp

7LH brake lamp

8RH brake lamp

9Instrument pack10Body control unit

11Reverse lamp switch (manual gearbox)

12Diagnostic socket

13HDC switch

14Transmission high/low switch

15Centre differential lock switch

16Engine control module

17Battery power supply

18Ignition power supply

Page 871 of 1529

BRAKES

70-18 DESCRIPTION AND OPERATION

The SLABS ECU continually calculates vehicle speed using the wheel speed inputs from all four ABS sensors. The

calculated vehicle speed is then used as a reference against which individual wheel speeds are monitored for

unacceptable acceleration or deceleration. The ABS sensor inputs are also used by the SLABS ECU to detect vehicle

deceleration rate, vehicle cornering rate and rough terrain.

The engaged forward gear and (on manual gearbox models) the clutch status are computed from the engine data

input, the engine speed input and vehicle speed. Reverse gear status is provided by an input from the reverse lamp

switch (manual gearbox models) or the BCU (automatic gearbox models). On automatic models, the BCU also

provides the neutral selected input.

In addition to controlling the brake related functions, the SLABS ECU:

lControls the operation of the self levelling suspension (SLS) system (where fitted).

+ REAR SUSPENSION, DESCRIPTION AND OPERATION, Description.

lOn V8 models, outputs a rough road signal to the ECM when traversing rough terrain.

lOutputs a vehicle speed signal.

The vehicle speed signal is output to the following systems (where fitted):

lActive Cornering Enhancement.

+ FRONT SUSPENSION, DESCRIPTION AND OPERATION, Description - ACE.

lAir conditioning.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

lCruise control.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

lEngine management.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

lIn-car entertainment.

+ IN CAR ENTERTAINMENT, DESCRIPTION AND OPERATION, Description.

lInstrument pack.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

5 Front right inlet solenoid valve Output

6 Shuttle valve switches Input

7 Rear left outlet solenoid valve Output

8 Rear left inlet solenoid valve Output

9 Centre differential lock switch Input

10 Rear right outlet solenoid valve Output

11 Rear right inlet solenoid valve Output

12 Brake lamp relay Output

15 Return pump relay Output

C0655

7 Audible warning Output

10 Engine speed Input

Connector and pins not listed are either not used or used by the self levelling suspension system.

+ REAR SUSPENSION, DESCRIPTION AND OPERATION, Description.

Connector/Pin

No.Description Input/Output