battery LAND ROVER DISCOVERY 1999 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 329 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-30 DESCRIPTION AND OPERATION

Heated Oxygen Sensors (HO2S) (C0642)

The market requirement dictates how many HO

2S are fitted to the vehicle.

l4 sensors are fitted to all NAS and EU-3 vehicles.

l2 sensors fitted to all UK, European, Australia and Japanese pre EU-3 specification vehicles.

lNo sensors fitted to ROW vehicles.

The HO

2S monitor the oxygen content of the exhaust gases. By positioning the sensors one for each bank upstream

of the catalytic converter in the exhaust pipe, the ECM can control fuelling on each bank independently of the other.

This allows greater control of the air:fuel ratio and maintains optimum catalyst efficiency. On NAS vehicles the ECM

also uses two HO

2S positioned downstream of the catalytic converters in the exhaust pipe to monitor catalytic

converter efficiency. The ECM is able to achieve this by comparing the values of the upstream HO

2S and the down

stream sensor for the same bank. These comparative values form part of the ECM OBD strategy.

The HO

2S uses zirconium contained in a galvanic cell surrounded by a gas permeable ceramic, this produces an

output voltage proportional to the ratio difference between the oxygen in the exhaust gases and to the ambient

oxygen.

The HO

2S operates at approximately 350 °C (662 °F). To achieve this temperature the HO2S incorporate a heating

element which is controlled by a PWM signal from the ECM. The elements are activated immediately after engine

starts and also under low engine load conditions when the exhaust gas temperature is insufficient to maintain the

required HO

2S temperature. If the heater fails, the ECM will not allow closed loop fuelling to be implemented until the

sensor has achieved the required temperature.

This value equates to an HO

2S output of 450 to 500 mV. A richer mixture can be shown as λ = 0.97, this pushes the

HO

2S output voltage towards 1000 mV. A leaner mixture can be shown as λ = 1.10, this pushes the HO2S output

voltage towards 100 mV.

From cold start, the ECM runs an open loop fuelling strategy. The ECM keeps this strategy in place until the HO

2S is

at a working temperature of 350 °C (662 °F). At this point the ECM starts to receive HO

2S information and it can then

switch into closed loop fuelling as part of its adaptive strategy. The maximum working temperature of the tip of the

HO

2S is 930 °C (1706 °F), temperatures above this will damage the sensor.

HO

2S age with use, this increases their response time to switch from rich to lean and from lean to rich. This can lead

to increased exhaust emissions over a period of time. The switching time of the upstream sensors are monitored by

the ECM. If a pre-determined threshold is exceeded, a failure is detected and the MIL illuminated.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Exhaust Emission Control System.

Input/Output

The upstream and downstream HO

2S are colour coded to prevent incorrect fitting. The tips of the upstream sensors

are physically different to the tips of the downstream sensors.

The HO

2S are colour coded as follows:

lUpstream sensors (both banks) - orange.

lDownstream sensors (both banks) - grey.

The four HO

2S have a direct battery supply to the heater via fuse 2 located in the engine compartment fuse box.

Page 331 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-32 DESCRIPTION AND OPERATION

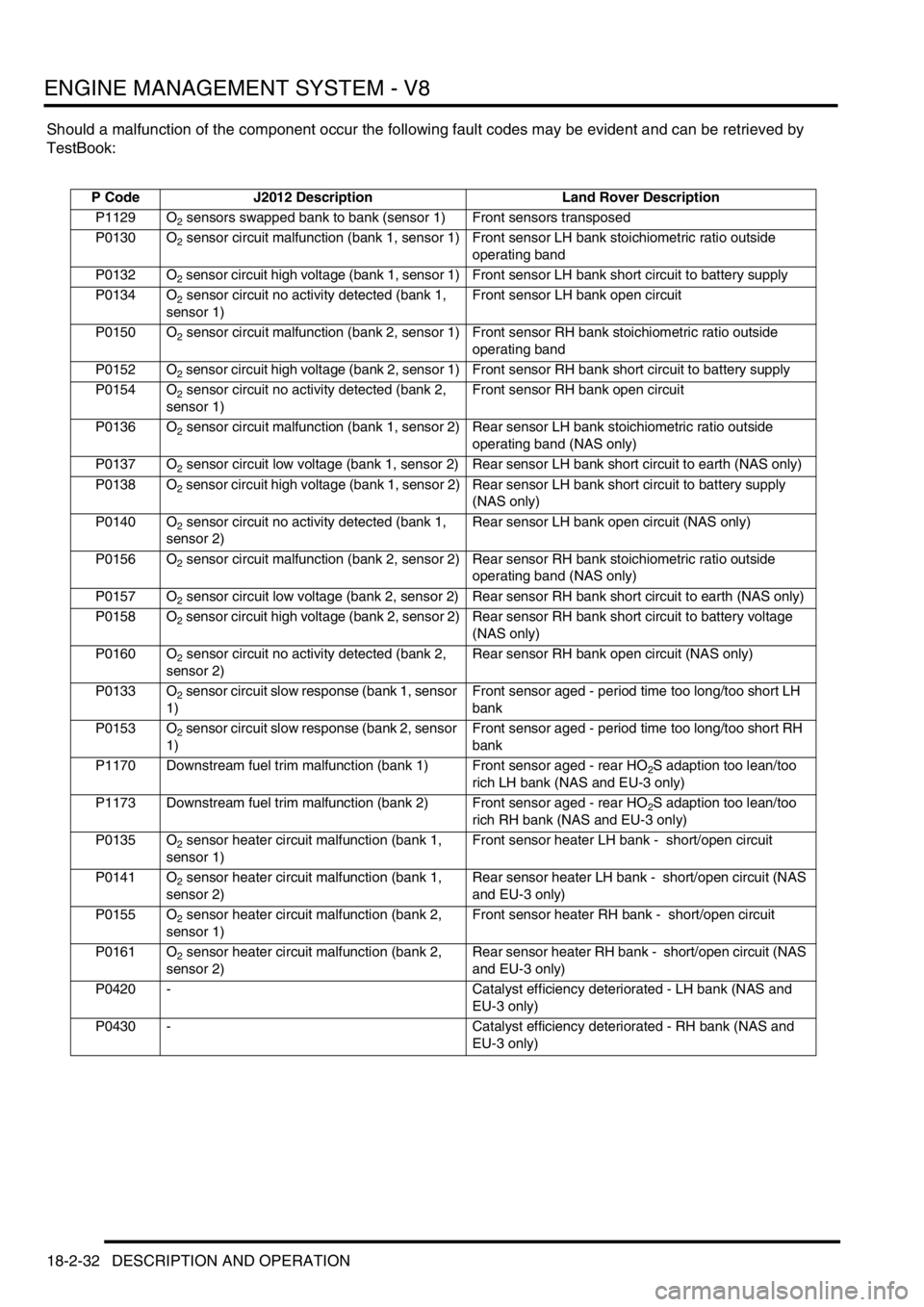

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

P Code J2012 Description Land Rover Description

P1129 O

2 sensors swapped bank to bank (sensor 1) Front sensors transposed

P0130 O

2 sensor circuit malfunction (bank 1, sensor 1) Front sensor LH bank stoichiometric ratio outside

operating band

P0132 O

2 sensor circuit high voltage (bank 1, sensor 1) Front sensor LH bank short circuit to battery supply

P0134 O

2 sensor circuit no activity detected (bank 1,

sensor 1)Front sensor LH bank open circuit

P0150 O

2 sensor circuit malfunction (bank 2, sensor 1) Front sensor RH bank stoichiometric ratio outside

operating band

P0152 O

2 sensor circuit high voltage (bank 2, sensor 1) Front sensor RH bank short circuit to battery supply

P0154 O

2 sensor circuit no activity detected (bank 2,

sensor 1)Front sensor RH bank open circuit

P0136 O

2 sensor circuit malfunction (bank 1, sensor 2) Rear sensor LH bank stoichiometric ratio outside

operating band (NAS only)

P0137 O

2 sensor circuit low voltage (bank 1, sensor 2) Rear sensor LH bank short circuit to earth (NAS only)

P0138 O

2 sensor circuit high voltage (bank 1, sensor 2) Rear sensor LH bank short circuit to battery supply

(NAS only)

P0140 O

2 sensor circuit no activity detected (bank 1,

sensor 2)Rear sensor LH bank open circuit (NAS only)

P0156 O

2 sensor circuit malfunction (bank 2, sensor 2) Rear sensor RH bank stoichiometric ratio outside

operating band (NAS only)

P0157 O

2 sensor circuit low voltage (bank 2, sensor 2) Rear sensor RH bank short circuit to earth (NAS only)

P0158 O

2 sensor circuit high voltage (bank 2, sensor 2) Rear sensor RH bank short circuit to battery voltage

(NAS only)

P0160 O

2 sensor circuit no activity detected (bank 2,

sensor 2)Rear sensor RH bank open circuit (NAS only)

P0133 O

2 sensor circuit slow response (bank 1, sensor

1)Front sensor aged - period time too long/too short LH

bank

P0153 O

2 sensor circuit slow response (bank 2, sensor

1)Front sensor aged - period time too long/too short RH

bank

P1170 Downstream fuel trim malfunction (bank 1) Front sensor aged - rear HO

2S adaption too lean/too

rich LH bank (NAS and EU-3 only)

P1173 Downstream fuel trim malfunction (bank 2) Front sensor aged - rear HO

2S adaption too lean/too

rich RH bank (NAS and EU-3 only)

P0135 O

2 sensor heater circuit malfunction (bank 1,

sensor 1)Front sensor heater LH bank - short/open circuit

P0141 O

2 sensor heater circuit malfunction (bank 1,

sensor 2)Rear sensor heater LH bank - short/open circuit (NAS

and EU-3 only)

P0155 O

2 sensor heater circuit malfunction (bank 2,

sensor 1)Front sensor heater RH bank - short/open circuit

P0161 O

2 sensor heater circuit malfunction (bank 2,

sensor 2)Rear sensor heater RH bank - short/open circuit (NAS

and EU-3 only)

P0420 - Catalyst efficiency deteriorated - LH bank (NAS and

EU-3 only)

P0430 - Catalyst efficiency deteriorated - RH bank (NAS and

EU-3 only)

Page 332 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-33

Fuel injectors

The fuel injectors are located beneath the air inlet manifold. They utilise an electrical solenoid to lift the injector needle

off its seat to allow fuel injection to take place. The fuel injectors provide excellent fuel atomisation in the lower portion

of the inlet manifold, the air/fuel mixture can then be drawn into the cylinders to give good combustion characteristics

and therefore excellent driveability.

There are eight fuel injectors one per cylinder that the ECM operates sequentially. All the injectors are fed from a

common fuel rail as part of the returnless fuel system. Fuel pressure is maintained at a constant 3.5 bar (52 lbf.in

2) by

a regulator that is integral with the fuel pump.

+ FUEL DELIVERY SYSTEM - V8, DESCRIPTION AND OPERATION, Description.

Input/Output

All eight fuel injectors are supplied with battery voltage via fuse number 1 located in engine compartment fuse box.

The ECM controls the individual earth path for each injector via its own pin at connector C0636 of the ECM multiplug.

This facility allows the ECM to control the fuel injectors so that sequential fuel injection can take place.

Typical hot engine injector pulse width values:

lIdle = 2.5 ms.

lPeak torque (3000 rev/min) = 7 ms The ECM controls injector earth as follows:

lCylinder No 1 - pin 41 of connector C0636 of the ECM multiplug.

lCylinder No 2 - pin 1 of connector C0636 of the ECM multiplug.

lCylinder No 3 - pin 27 of connector C0636 of the ECM multiplug.

lCylinder No 4 - pin 40 of connector C0636 of the ECM multiplug.

lCylinder No 5 - pin 2 of connector C0636 of the ECM multiplug.

lCylinder No 6 - pin 15 of connector C0636 of the ECM multiplug.

lCylinder No 7 - pin 14 of connector C0636 of the ECM multiplug.

lCylinder No 8 - pin 28 of connector C0636 of the ECM multiplug.

Individual injectors can be measured for resistance using a multimeter. An acceptable injector resistance is as follows:

l14.5 ± 0.7 ohms at 20 °C (68 °F).

The fuel injectors can fail in the following ways or supply incorrect signal:

lInjector actuator open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lBlocked injector.

lRestricted injector.

lLow fuel pressure.

Page 333 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-34 DESCRIPTION AND OPERATION

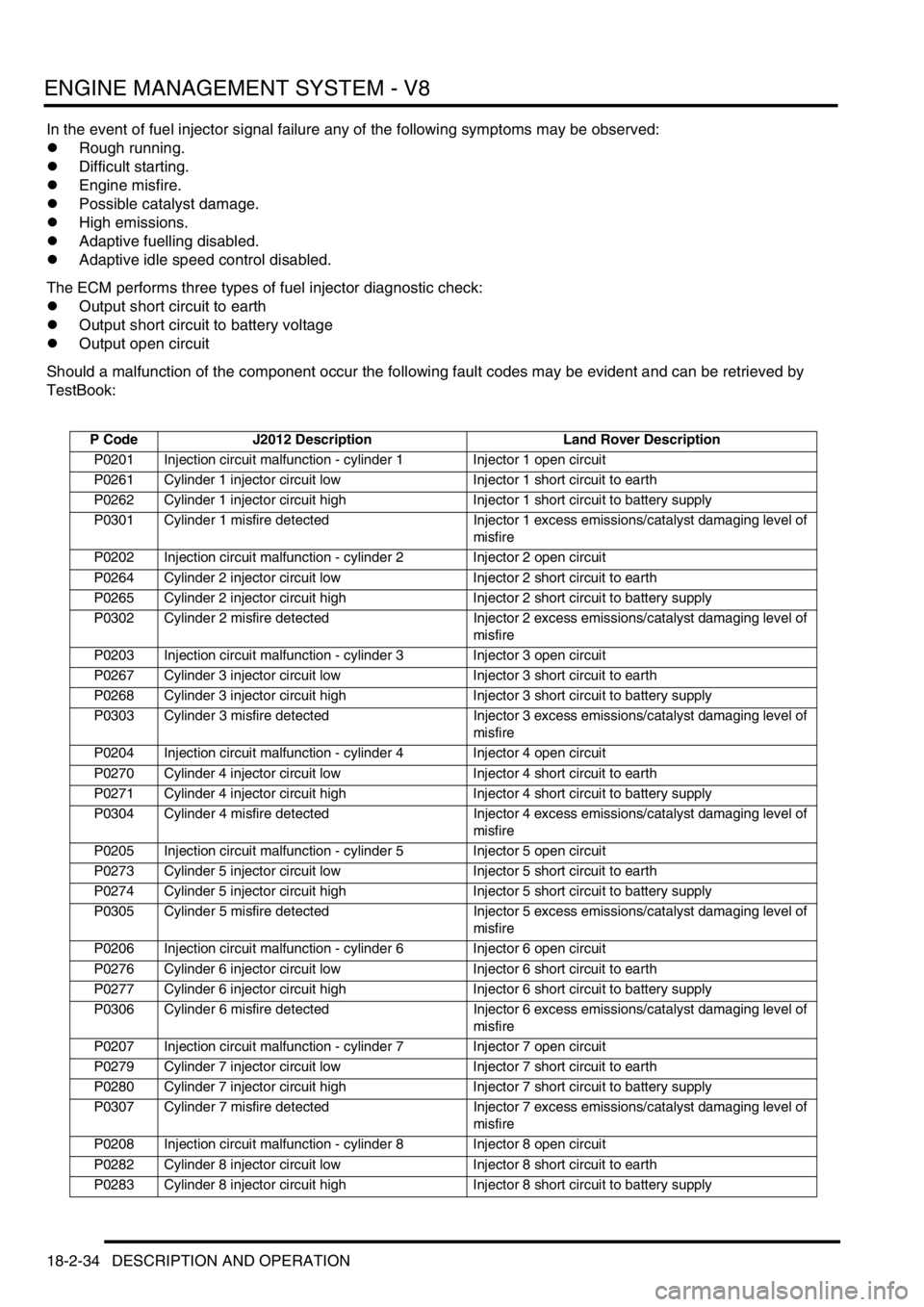

In the event of fuel injector signal failure any of the following symptoms may be observed:

lRough running.

lDifficult starting.

lEngine misfire.

lPossible catalyst damage.

lHigh emissions.

lAdaptive fuelling disabled.

lAdaptive idle speed control disabled.

The ECM performs three types of fuel injector diagnostic check:

lOutput short circuit to earth

lOutput short circuit to battery voltage

lOutput open circuit

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

P Code J2012 Description Land Rover Description

P0201 Injection circuit malfunction - cylinder 1 Injector 1 open circuit

P0261 Cylinder 1 injector circuit low Injector 1 short circuit to earth

P0262 Cylinder 1 injector circuit high Injector 1 short circuit to battery supply

P0301 Cylinder 1 misfire detected Injector 1 excess emissions/catalyst damaging level of

misfire

P0202 Injection circuit malfunction - cylinder 2 Injector 2 open circuit

P0264 Cylinder 2 injector circuit low Injector 2 short circuit to earth

P0265 Cylinder 2 injector circuit high Injector 2 short circuit to battery supply

P0302 Cylinder 2 misfire detected Injector 2 excess emissions/catalyst damaging level of

misfire

P0203 Injection circuit malfunction - cylinder 3 Injector 3 open circuit

P0267 Cylinder 3 injector circuit low Injector 3 short circuit to earth

P0268 Cylinder 3 injector circuit high Injector 3 short circuit to battery supply

P0303 Cylinder 3 misfire detected Injector 3 excess emissions/catalyst damaging level of

misfire

P0204 Injection circuit malfunction - cylinder 4 Injector 4 open circuit

P0270 Cylinder 4 injector circuit low Injector 4 short circuit to earth

P0271 Cylinder 4 injector circuit high Injector 4 short circuit to battery supply

P0304 Cylinder 4 misfire detected Injector 4 excess emissions/catalyst damaging level of

misfire

P0205 Injection circuit malfunction - cylinder 5 Injector 5 open circuit

P0273 Cylinder 5 injector circuit low Injector 5 short circuit to earth

P0274 Cylinder 5 injector circuit high Injector 5 short circuit to battery supply

P0305 Cylinder 5 misfire detected Injector 5 excess emissions/catalyst damaging level of

misfire

P0206 Injection circuit malfunction - cylinder 6 Injector 6 open circuit

P0276 Cylinder 6 injector circuit low Injector 6 short circuit to earth

P0277 Cylinder 6 injector circuit high Injector 6 short circuit to battery supply

P0306 Cylinder 6 misfire detected Injector 6 excess emissions/catalyst damaging level of

misfire

P0207 Injection circuit malfunction - cylinder 7 Injector 7 open circuit

P0279 Cylinder 7 injector circuit low Injector 7 short circuit to earth

P0280 Cylinder 7 injector circuit high Injector 7 short circuit to battery supply

P0307 Cylinder 7 misfire detected Injector 7 excess emissions/catalyst damaging level of

misfire

P0208 Injection circuit malfunction - cylinder 8 Injector 8 open circuit

P0282 Cylinder 8 injector circuit low Injector 8 short circuit to earth

P0283 Cylinder 8 injector circuit high Injector 8 short circuit to battery supply

Page 336 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-37

There are eight IACV diagnostic checks performed by the ECM:

lOutput short circuit to earth – opening coil

lOutput short circuit to battery supply – opening coil

lOutput open circuit – opening coil

lOutput short circuit to earth – closing coil

lOutput short circuit to battery voltage – closing coil

lOutput open circuit – closing coil

lBlocked IACV – rev/min error low (engine speed must be 100 rev/min less than the target speed, engine load

less than 2.5 and the measured air flow more than 10 kg/h less than the expected air flow for a fault condition to

be flagged).

lBlocked IACV – rev/min error high (the engine speed must be more than 180 rev/min greater than the target

speed and the measured air flow more than 10 kg/h greater than the expected air flow for a fault condition to be

flagged).

Should a malfunction of the component occur, the following fault codes may be evident and can be retrieved by

TestBook.

P Code J2012 Description Land Rover Description

P1510 IACV opening coil malfunction Short circuit to battery supply - opening winding

P1513 IACV opening coil malfunction Short circuit to earth - opening winding

P1514 IACV opening coil malfunction Open circuit - opening winding

P1553 IACV closing coil malfunction Short circuit to battery supply - closing winding

P1552 IACV closing coil malfunction Short circuit to earth - closing winding

P1551 IACV closing coil malfunction Open circuit - closing winding

P0505 Idle control system malfunction Blocked IACV - high or low rev/min error

Page 337 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-38 DESCRIPTION AND OPERATION

Fuel pump relay

The fuel pump relay is located in the engine compartment fuse box. It is a 4 pin normally open relay. Input from the

ECM allows the fuel pump relay to control the electrical input to the fuel pump, regulating the fuel supply to the fuel

injectors. When the ignition is switched on and the engine is cranked, the fuel pump relay is activated by the ECM,

allowing the fuel system to be pressurised to 3.5 bar (52 lbf.in

2). The ECM then deactivates the relay until the engine

has started.

If the fuel pump runs, but the fuel pressure is out of limits, adaptive fuel faults will be stored.

Input/Output

The input value for the relay windings is battery voltage, the input value for the switching contacts comes from fuse

10 in the engine compartment fuse box. The output control of the switching contacts is direct to the fuel pump motor,

and the relay windings are controlled by pin number 18 of connector C0635 of the ECM.

At ignition 'on' (position II) the fuel pump relay contacts remain open until the ECM supplies an earth path for the relay

windings via pin number 18 of connector C0635 of the ECM. At this point, the relay windings are energised, drawing

the relay contacts closed. This allows voltage from fuse 10 in the passenger compartment fuse box to pass directly

to the fuel pump.

The fuel pump relay can fail the following ways or supply incorrect signal:

lRelay drive open circuit.

lShort circuit to vehicle earth.

lShort circuit to vehicle supply.

lComponent failure.

In the event of a fuel pump relay failure any of the following symptoms may be observed:

lEngine stalls or will not start.

lNo fuel pressure at the fuel injectors.

The ECM performs three types of diagnostic test to confirm the fuel pump relay integrity:

lOutput short circuit to earth

lOutput short circuit to battery voltage

lOutput open circuit

Page 338 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-39

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

Evaporative emissions

Refer to Emissions section for description of the evaporative emissions system components.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative Emission Control System.

Secondary air injection (NAS only)

Refer to Emissions section for description of the secondary air injection system components.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Secondary Air Injection System.

Fuel tank pressure sensor (NAS only)

Refer to Fuel Delivery section for description of the fuel system components.

+ FUEL DELIVERY SYSTEM - V8, DESCRIPTION AND OPERATION, Description.

Refer to Emissions section for description of the fuel tank pressure sensor.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative Emission Control System.

P Code J2012 Description Land Rover Description

P1230 Fuel pump relay malfunction Fuel pump relay open circuit - not the fuel pump

P1231 Fuel pump relay circuit low Fuel pump relay short circuit to battery supply - not the

fuel pump

P1232 Fuel pump relay circuit high Fuel pump relay short circuit to earth - not the fuel pump

Page 339 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-40 DESCRIPTION AND OPERATION

Ignition coils

Two double ended ignition coils are located at the rear of the engine, below the inlet plenum camber mounted on a

bracket. The ignition system operates on the wasted spark principle. When the ECM triggers an ignition coil to spark,

current from the coil travels to one spark plug jumping the gap at the spark plug electrodes igniting the mixture in the

cylinder. Current continues to travel along the earth path (via the cylinder head) to the spark plug negative electrode

at the cylinder that is on the exhaust stroke. The current jumps across the spark plug electrodes and back to the coil

completing the circuit. Since it has sparked simultaneously in a cylinder that is on the exhaust stroke it has not done

any work, therefore it is wasted.

The coils are paired in the following cylinder order:

l1 and 6.

l8 and 5.

l4 and 7.

l3 and 2.

The ECM calculates the dwell timing from battery voltage, and engine speed to ensure constant secondary energy.

This ensures sufficient spark energy is always available without excessive primary current flow and thus avoiding

overheating or damage to the coils. Individual cylinder spark timing is calculated from the following signals:

lEngine speed.

lEngine load.

lEngine temperature.

lKnock control.

lAutomatic gearbox shift control.

lIdle speed control.

During engine warm up ignition timing should be an expected value of 12° BTDC.

TestBook can not directly carry out diagnostics on the high-tension side of the ignition system. Ignition related faults

are monitored indirectly by the misfire detection system.

Page 340 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-41

Input/Output

Input to the low tension side of the ignition coils comes from Fuse 14 located in the passenger compartment fuse box.

This fuse provides battery power for two ignition coils.

It is possible to test both primary and secondary coils of the ignition coils for resistance using a multimeter as follows:

lExpected primary coil resistance: 0.5 ± 0.05 Ω at 20 °C (68 °F).

lExpected secondary coil resistance: 13.3 ± 1.3 kΩ at 20 °C (68 °F).

The ECM provides the earth control for each coil on separate pins as follows:

LH Bank (cylinders 1, 3, 5, 7)

lCylinder 1 - pin 6 of connector C0638 of the ECM multiplug.

lCylinder 3 - pin 2 of connector C0638 of the ECM multiplug.

lCylinder 5 - pin 8 of connector C0638 of the ECM multiplug.

lCylinder 7 - pin 7 of connector C0638 of the ECM multiplug.

RH Bank (cylinders 2, 4, 6, 8)

lCylinder 2 - pin 2 of connector C0638 of the ECM multiplug.

lCylinder 4 - pin 7 of connector C0638 of the ECM multiplug.

lCylinder 6 - pin 6 of connector C0638 of the ECM multiplug.

lCylinder 8 - pin 8 of connector C0638 of the ECM multiplug.

The ignition coil can fail the following ways or supply incorrect signal:

lCoil open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lFaulty component.

In the event of ignition coil failure any of the following symptoms may be observed:

lEngine misfire on specific cylinders.

lEngine will not start.

Page 341 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-42 DESCRIPTION AND OPERATION

Knock Sensor (KS)

The ECM uses two knock sensors located between the centre two cylinders of each bank to detect pre-ignition. The

knock sensors consist of piezo ceramic crystals that oscillate to create a voltage signal. During pre-ignition the

frequency of crystal oscillation increases, which alters the signal output to the ECM. The ECM compares the signal

to known signal profiles in its memory. If pre-ignition is detected the ECM retards ignition timing for a number of cycles.

If no more pre-ignition is detected, the timing is gradually advanced to the original setting.

The ignition is calibrated to run on 95 RON premium fuel, but the system will run satisfactorily on 91 RON regular fuel.

If the vehicle is refuelled with a lower grade fuel, some audible detonation will initially be heard. This is non-damaging

and ceases when the system adaption is completed.

Input/Output

Because of the nature of its operation, the knock sensors do not require any electrical input source. The KS output

for LH bank (cylinders 1, 3, 5, 7) is measured via pin 49 of connector C0636 of the ECM. The KS output for RH bank

(cylinders 2, 4, 6, 8) is measured via pin 36 of connector C0636 of the ECM. Both knock sensors have a screened

earth to protect the integrity of the sensor signals. The KS earth for LH bank (cylinders 1, 3, 5, 7) is via pin 48 of

connector C0636 of the ECM. The KS earth for RH bank (cylinders 2, 4, 6, 8) is via pin 35 of connector C0636 of the

ECM.

The connector and sensor terminals are gold plated for corrosion and temperature resistance, care must be exercised

while probing the connector and sensor terminals.

The KS can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lFaulty component.

lIncorrectly tightened sensor.

In the event of a KS signal failure any of the following symptoms may be observed:

lKS disabled, the ECM refers to a 'safe ignition map'.

lRough running.

lEngine performance concern.