LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 661 of 1529

PROPELLER SHAFTS

47-6 REPAIRS

Bush - spigot - rear propeller shaft

$% 47.15.16

Remove

1.Remove rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

2.Clean protruding end of spigot bush fitted to

rear propeller shaft.

3. Fit LRT-47-001/1 to exposed end of spigot

bush at rear of propeller shaft and tighten

draw bar.

4.Fit LRT-99-004 to draw bar of LRT-47-001/1,

tighten and with assistance remove bush from

rear propeller shaft.

5.Remove bush and dismantle service tools.Refit

1.Ensure bush bore is clean.

2.Fit spigot bush to LRT-47-001/02 , ensure

spigot bush sealing ring is facing drive flange

on service tool.

3.Align bush to bore of rear propeller shaft and

with assistance drive fully home. Note: Do not

allow the propeller shaft universal joint to

support the load during fitting.

4.Remove service tool.

5.Lubricate bush.

6.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

Page 662 of 1529

PROPELLER SHAFTS

REPAIRS 47-7

Flexible coupling

$% 47.20.08

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.If same components to be refitted, reference

mark flexible coupling and mating components.

3.Remove 3 nuts and bolts securing propeller

shaft to flexible coupling.

4.Move propeller shaft forwards to release from

flexible coupling and differential drive flange

spigot.

5.Tie propeller shaft aside.

6.Remove 3 nuts and bolts securing flexible

coupling to differential drive flange and remove

flexible coupling.Refit

1.Ensure flexible coupling, spigot and drive

flanges are clean.

2.Align the arrows on the flexible coupling with

the securing bolt positions as illustrated. Fit

flexible coupling to differential drive flange and

tighten nuts and bolts to 76 Nm (56 lbf.ft).

3.Fit propeller shaft to spigot and flexible

coupling. Tighten nuts and bolts to 76 Nm (56

lbf.ft).

4.Remove stand(s) and lower vehicle.

Page 663 of 1529

Page 664 of 1529

PROPELLER SHAFTS

OVERHAUL 47-9

OVERHAUL

Propeller shaft

$% 47.15.11

The following bearing replacement procedure

applies to the universal joints of both the front and

rear propeller shafts, including the Hookes joint (i.e.

double universal joint) of the front propeller shaft.

Disassembly

1.Remove propeller shaft:

lFor front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

lFor rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

2.Thoroughly examine the universal joint for

signs of damage or wear.

3.Clean the universal joint bearing cups and

circlips.

CAUTION: Before removal, mark the

position of the spider pin relative to the

journal yoke ears on the propeller shaft

joint. This will ensure correct assembly and

reduce the possibility of imbalance.

4.Remove the circlips.

5.Tap the yokes to eject bearing cups. Remove

bearing cups.

6.Remove spider from yokes.

7.Clean yokes and bearing cup locations. Reassembly

1.Remove bearing cups from new spider.

2.Check all needle rollers are present and

correctly positioned in bearing cups.

3.Enter new spider, with seals, into one of the

yokes.

4.Partially insert one bearing cup into yoke and

enter spider trunnion into bearing cup.

5.Insert opposite bearing cup in yoke.

6.Press both cups into place.

7.Press each cup into its respective location in

yoke up to lower land of circlip groove. Damage

may be caused to cups and seals if cups

pass this point.

8.Fit circlips and check no end float exists.

9.Engage spider in second yoke. Fit bearing cups

and circlips as described in steps 4 to 8.

10.Fit propeller shaft:

lFor front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

lFor rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

Page 665 of 1529

Page 666 of 1529

REAR AXLE

DESCRIPTION AND OPERATION 51-1

REAR AXLE DESCRIPTION AND OPERAT ION

Rear axle component layout

1Drive shaft

2'O' ring

3Hub bearing

4Stake nut

5Hub flange

6Breather tube

7Bolt

8Bolt

9Oil seal10Pinion flange

11Centralising peg

12Bolt

13Washer

14Differential unit

15Drain plug

16Axle casing

17Oil level plug

18'O' ring

Page 667 of 1529

REAR AXLE

51-2 DESCRIPTION AND OPERATION

Description

General

The rear axle consists of an axle casing with a differential unit attached to the right of the vehicle centre line. A wheel

hub is installed in each end of the axle casing and connected to the differential unit by a drive shaft.

Axle casing

The axle casing is of welded construction, with brackets on the casing exterior for attachment to the rear suspension.

A differential cover on the rear of the axle casing contains an oil level plug for checking and replenishment of the

differential unit lubricating oil. A magnetic drain plug is installed on the underside of the axle casing.

The interior of the axle casing is ventilated through a breather tube inserted in a red plastic sleeve in the top of the

casing. The open end of the breather tube is located between the chassis and the left rear wheelarch.

Differential unit

The differential unit is of the spiral bevel type, lubricated by splash oil. The unit consists of a differential carrier

attached to a pinion housing. In the pinion housing, the pinion is splined to a pinion flange which is secured with a bolt

and washer. An oil seal prevents leakage past the pinion flange.

Centralising peg

The centralising peg is a press fit in the centre of the pinion flange and provides a positive location for the rear

propellor shaft to ensure it is centralised with the flange.

Page 668 of 1529

REAR AXLE

DESCRIPTION AND OPERATION 51-3

Wheel hub

Section through wheel hub

1'O' ring

2Hub bearing

3Hub flange

4Wheel stud5Stake nut

6ABS sensor ring

7Drive shaft

8Axle casing

Each wheel hub consists of a hub flange pressed into a hub bearing.

The hub flange is splined to accept the outboard end of the drive shaft, which is secured to the hub flange with a stake

nut. Five studs are installed in the hub flange for the wheel nuts, and a threaded hole is provided for the brake disc

securing screw.

The outer race of the hub bearing is bolted to the end of the axle casing. An 'O' ring seals the joint between the outer

race and the axle casing to prevent leakage of differential lubricating oil. The hub bearing is a sealed unit which

contains twin opposed roller bearings, pre-packed with grease during manufacture. A toothed ABS sensor ring is

integrated into the inner race of the hub bearing. An opening in the outer race of the hub bearing accommodates the

ABS sensor.

Drive shaft

Each drive shaft consists of a solid rod, splined at both ends.

Page 669 of 1529

Page 670 of 1529

REAR AXLE

REPAIRS 51-5

REPAIRS

Differential - assembly

$% 51.15.01

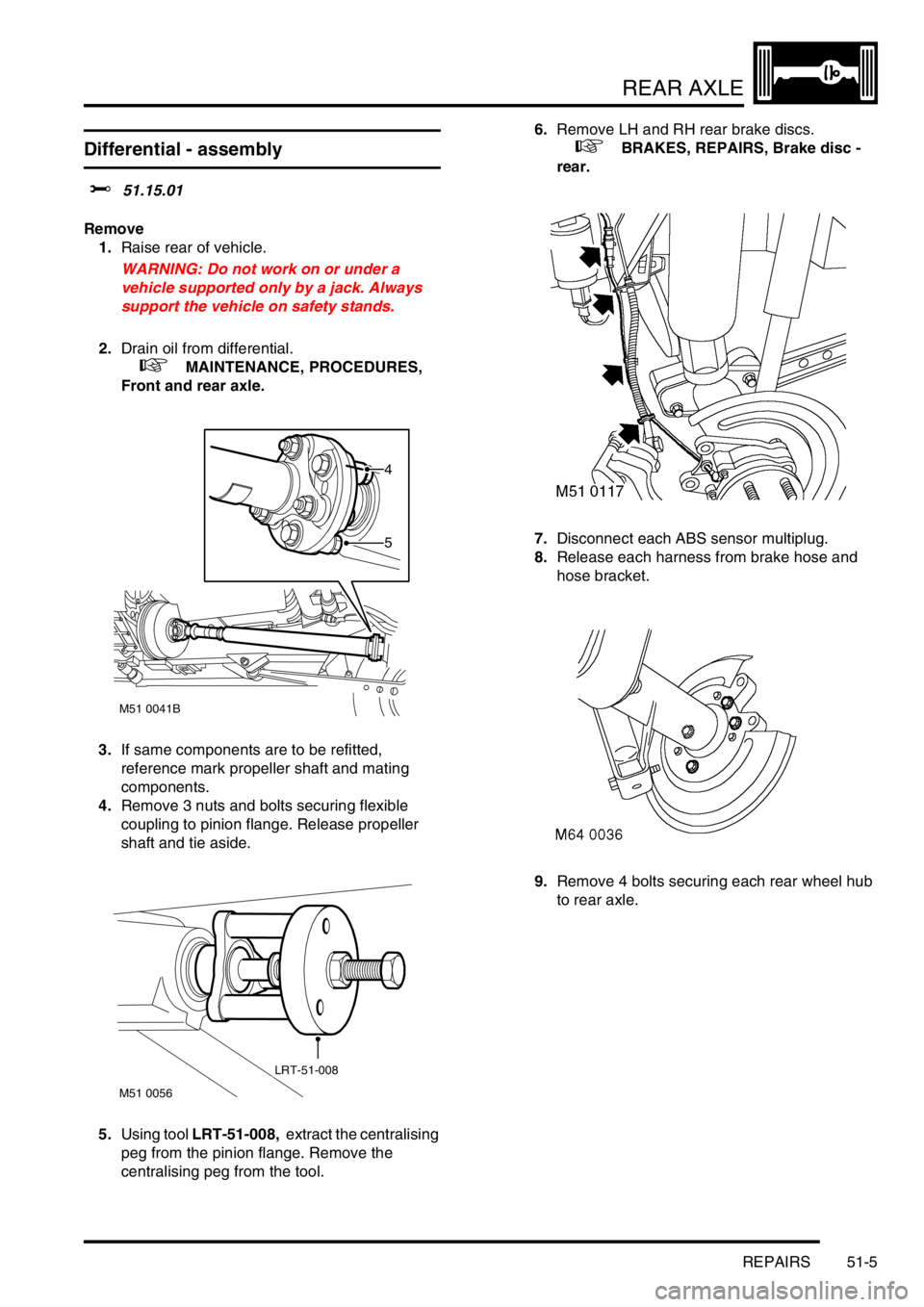

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Drain oil from differential.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

3.If same components are to be refitted,

reference mark propeller shaft and mating

components.

4.Remove 3 nuts and bolts securing flexible

coupling to pinion flange. Release propeller

shaft and tie aside.

5.Using tool LRT-51-008, extract the centralising

peg from the pinion flange. Remove the

centralising peg from the tool.6.Remove LH and RH rear brake discs.

+ BRAKES, REPAIRS, Brake disc -

rear.

7.Disconnect each ABS sensor multiplug.

8.Release each harness from brake hose and

hose bracket.

9.Remove 4 bolts securing each rear wheel hub

to rear axle.

M51 0041B

5

4

M51 0056

LRT-51-008