LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 631 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-34 REPAIRS

25.Position gearbox support jack and secure tool

LRT-99-008A to support plate on jack.

26.Position a second support jack under engine

using a block between engine sump and jack to

prevent damage to sump.

27.Remove 4 bolts and nut, remove engine LH

rear mounting.

28.Remove 4 bolts and nut, remove engine RH

rear mounting. 29.Remove bolt securing gearbox oil cooler pipe

clips to engine.

30.Remove bolt and 2 nuts securing clamps to oil

cooler pipes and remove clamps.

31.Loosen gearbox oil cooler pipe unions, release

pipes from gearbox and discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 632 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-35

32.Remove 'C' clip securing selector cable to

gearbox bracket.

33.Remove nut securing selector lever to inhibitor

switch and release lever.

34.Disconnect multiplug from inhibitor switch.

35.Loosen gearbox multiplug locking ring and

disconnect plug.

36.Lower gearbox sufficiently to access bell

housing bolts, take care not to trap any pipes or

cables when lowering gearbox.

37.Remove 14 bolts securing gearbox to engine.

38.With assistance remove gearbox from engine.39.Fit suitable strap to retain torque converter.

Refit

1.Clean gearbox to engine mating faces.

2.Remove torque converter retaining strap.

3.With assistance position gearbox to engine.

4.Fit gearbox bell housing bolts and tighten to 46

Nm (34 lbf.ft)..

5.Connect multiplug to gearbox and tighten

locking ring.

6.Connect inhibitor switch multiplug.

7. If fitted: Connect and adjust differential lock

selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.

8.Position selector lever to inhibitor switch and

tighten nut to 25 Nm (18 lbf.ft).

9.Position selector cable to gearbox and secure

with 'C' clip.

10.Clean oil pipe unions and fit new 'O' rings.

11.Position and tighten pipe unions to gearbox.

12.Position and tighten oil cooler pipe clamps.

13.Position and tighten oil cooler pipe clip to

engine sump.

14.Position engine RH and LH rear mountings

and tighten bolts to 85 Nm (63 lbf.ft) and nuts to

85 Nm (63 lbf.ft).

15.Secure gearbox breather pipes to bulkhead

clip.

16. Up to 03 Model Year - If fitted: Connect 2

Lucars to differential lock warning lamp switch

and multiplugs to high/low ratio switch and

neutral sensor.

17. 03 Model Year onwards - If fitted: Connect

differential lock warning lamp switch multiplugs

to main harness.

18.Position cable tie and multiplug to transfer

gearbox bracket.

19.Connect high/low ratio selector cable to

selector lever and secure with clevis pin.

20.Position high/low ratio selector cable to

abutment bracket and secure with 'C' clip.

Page 633 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-36 REPAIRS

21. Models fitted with high/low shift interlock

solenoid: Position interlock solenoid harness

to high/low shift cable, fit sleeve around cable

and harness, secure sleeve.

22. Models fitted with high/low shift interlock

solenoid: Connect solenoid multiplug to main

harness and secure multiplug to bracket.

23.Position hand brake back plate and tighten

bolts to 75 Nm (55 lbf.ft).

24.Fit hand brake drum and tighten screw.

25.Remove bolts securing tool LRT-99-008A to

gearbox.

26.Rotate engine to align torque converter, fit new

bolts and tighten to 50 Nm (37 lbf.ft).

27.Fit access plug to torque converter housing.

28.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

29.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

30.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

31.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

32.Position intermediate silencer and secure to

mounting rubbers.

33.Clean silencer and tail pipe mating faces.

34.Position new gasket to tail pipe and tighten nuts

to 40 Nm (30 lbf.ft).

35.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

36.Position centre cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

37.Connect battery earth lead.

38.Fit battery cover and secure fixings.

39.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, ADJUSTMENTS, Cable - selector.

Page 634 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-37

Torque converter and oil seal

$% 44.17.07

Remove

1.Remove automatic gearbox.

l

+ AUTOMATIC GEARBOX -

ZF4HP22 - 24, REPAIRS, Gearbox -

convertor and transfer gearbox - Diesel.

l

+ AUTOMATIC GEARBOX -

ZF4HP22 - 24, REPAIRS, Gearbox -

convertor and transfer gearbox - V8.

2.Remove retaining strap from torque convertor.

3.Fit tool LRT-44-010 to torque converter and

remove torque converter from gearbox.

4.Remove tool LRT-44-010 from converter.

5.Remove oil seal from converter housing. Refit

1.Clean oil seal running surfaces.

2.Lubricate oil seal with transmission fluid.

3.Fit new seal into converter housing using tool

LRT-44-001.

4.Fit tool LRT-44-010 to torque converter.

5.Align oil pump drive and fit torque converter to

gearbox.

6.Remove tool LRT-44-010 from torque

converter.

7.Fit torque converter retaining strap.

8.Fit automatic gearbox.

l

+ AUTOMATIC GEARBOX -

ZF4HP22 - 24, REPAIRS, Gearbox -

convertor and transfer gearbox - Diesel.

l

+ AUTOMATIC GEARBOX -

ZF4HP22 - 24, REPAIRS, Gearbox -

convertor and transfer gearbox - V8.

Page 635 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-38 REPAIRS

Housing - torque converter

$% 44.17.01

Remove

1.Remove torque converter oil seal.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Torque converter and oil

seal.

2.Remove 18 bolts and plain washers securing

torque converter and intermediate plate to

gearbox casing. Note the position of the 4 bolts

that have sealant applied to the bolt threads

and 6 bolts, (outer ring), which are shorter.

3.Hold input shaft in position and carefully

remove the converter housing and intermediate

plate from gearbox casing.

4.Note the position of the Torrington race on the

forward clutch hub and the thrust washer which

will stay attached to the intermediate plate by

fluid adhesion.

5.Remove and discard intermediate plate gasket.

6.Remove thrust washer from intermediate plate.

7.Separate converter housing from intermediate

plate.Refit

1.Clean converter housing, intermediate plate

and gearbox casing mating faces.

2.Clean bolts and plain washers and sealant from

4 bolt threads.

3.Apply Petroleum Jelly to new gasket and

position on gearbox casing.

4.Apply Petroleum Jelly to thrust washer and

Torrington race.

5.Correctly position Torrington race and thrust

washer to forward clutch hub.

6.Position intermediate plate and converter

housing to gearbox casing.

7.Apply sealant, Part No. STC 50553 to 4 longer

bolt threads and fit bolts in the positions shown.

8.Fit remaining bolts and tighten progressively in

a diagonal sequence to 46 Nm (34 lbf.ft).

9.Place LRT-44-003/1 into pump housing, tighten

screws to secure LRT-44-003/1 to input shaft.

10.Clamp a suitable steel base to converter

housing flange.

11.Mount DTI gauge and position gauge probe

onto LRT-44-003/1 and zero gauge.

M44 1343

M44 1345

M44 1343

M44 1358

LRT-44-003/1

Page 636 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-39

12.Check that the axial end-float is between 0.2 to

0.4 mm. If end-float is not within limits, replace

existing thrust washer, positioned at rear of

intermediate plate, with a suitable thickness

thrust washer to give the required end-float.

13.Remove DTI gauge and base plate.

14.Fit torque converter oil seal.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Torque converter and oil

seal.

Gasket - intermediate plate

$% 44.20.11

Remove

1.Remove torque converter oil seal.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Torque converter and oil

seal.

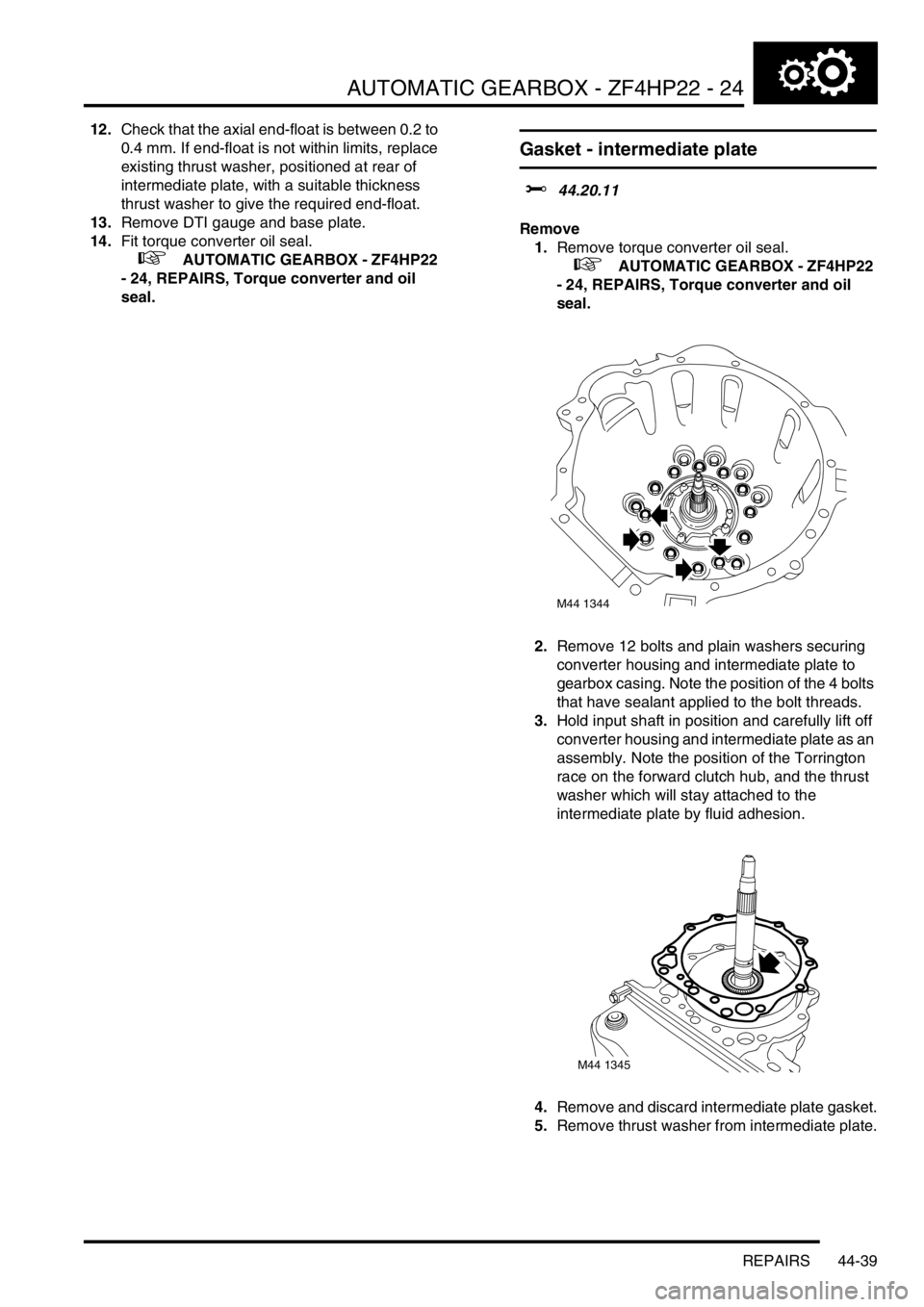

2.Remove 12 bolts and plain washers securing

converter housing and intermediate plate to

gearbox casing. Note the position of the 4 bolts

that have sealant applied to the bolt threads.

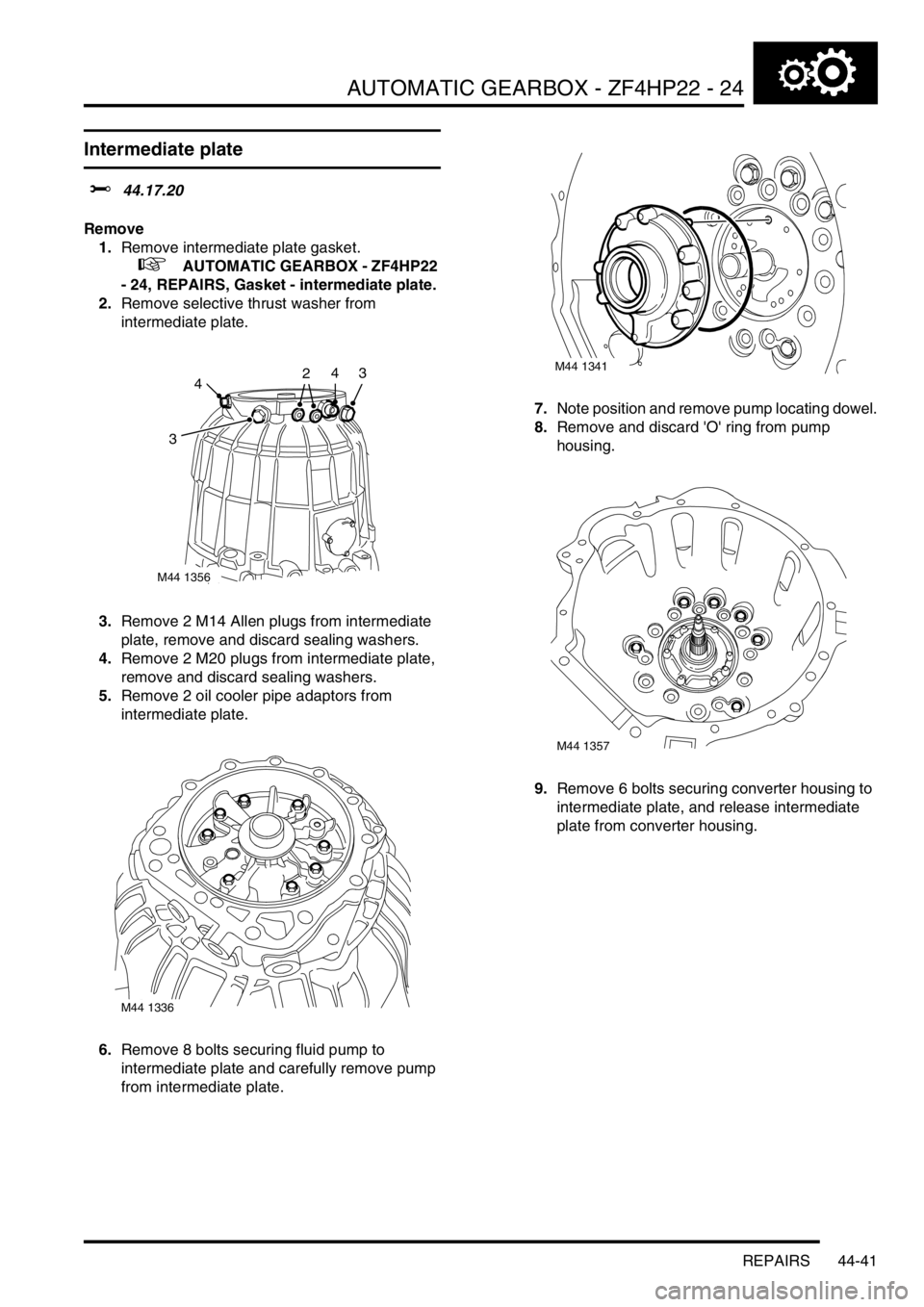

3.Hold input shaft in position and carefully lift off

converter housing and intermediate plate as an

assembly. Note the position of the Torrington

race on the forward clutch hub, and the thrust

washer which will stay attached to the

intermediate plate by fluid adhesion.

4.Remove and discard intermediate plate gasket.

5.Remove thrust washer from intermediate plate.

M44 1344

M44 1345

Page 637 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-40 REPAIRS

Refit

1.Clean intermediate plate and mating face on

gearbox casing.

2.Apply Petroleum Jelly to new gasket and

position on gearbox casing.

3.Apply Petroleum Jelly to thrust washer and

Torrington race.

4.Correctly position Torrington race and thrust

washer to forward clutch hub.

5.Position converter housing and intermediate

plate assembly to gearbox casing.

6.Clean bolts and plain washers and old sealant

from 4 bolt threads.

7.Apply sealant, Part No. STC 50553 to 4 longer

bolt threads and fit bolts in position shown.

8.Fit remaining bolts and tighten progressively in

a diagonal sequence to 46 Nm (34 lbf.ft).

9.Place LRT-44-003/1 into pump housing, tighten

screws to secure LRT-44-003/1 to input shaft.

10.Clamp a suitable steel base to converter

housing flange.11.Mount DTI gauge and position gauge probe

onto LRT-44-003/1 and zero gauge.

12.Check that the axial end-float is between 0.2 to

0.4 mm (0.008 to 0.016 in). If end-float in not

within limits, replace existing thrust washer,

positioned at rear of intermediate plate, with a

suitable thickness thrust washer to give the

required end-float.

13.Remove DTI gauge and base plate.

14.Fit torque converter oil seal.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Torque converter and oil

seal.

M44 1344

M44 1358

LRT-44-003/1

Page 638 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-41

Intermediate plate

$% 44.17.20

Remove

1.Remove intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

2.Remove selective thrust washer from

intermediate plate.

3.Remove 2 M14 Allen plugs from intermediate

plate, remove and discard sealing washers.

4.Remove 2 M20 plugs from intermediate plate,

remove and discard sealing washers.

5.Remove 2 oil cooler pipe adaptors from

intermediate plate.

6.Remove 8 bolts securing fluid pump to

intermediate plate and carefully remove pump

from intermediate plate.7.Note position and remove pump locating dowel.

8.Remove and discard 'O' ring from pump

housing.

9.Remove 6 bolts securing converter housing to

intermediate plate, and release intermediate

plate from converter housing.

2443

M44 1356

3

M44 1336

M44 1341

M44 1357

Page 639 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-42 REPAIRS

Refit

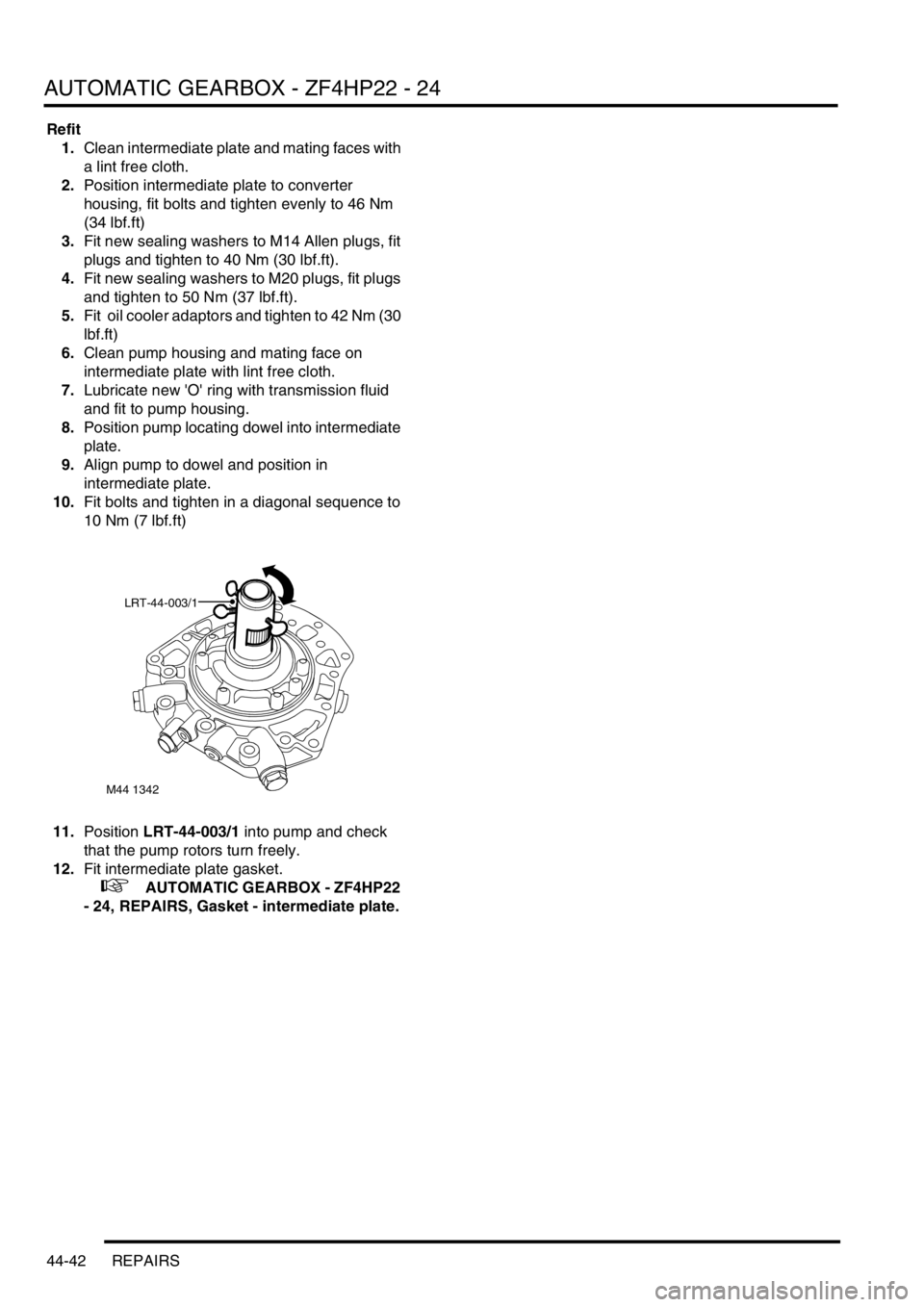

1.Clean intermediate plate and mating faces with

a lint free cloth.

2.Position intermediate plate to converter

housing, fit bolts and tighten evenly to 46 Nm

(34 lbf.ft)

3.Fit new sealing washers to M14 Allen plugs, fit

plugs and tighten to 40 Nm (30 lbf.ft).

4.Fit new sealing washers to M20 plugs, fit plugs

and tighten to 50 Nm (37 lbf.ft).

5.Fit oil cooler adaptors and tighten to 42 Nm (30

lbf.ft)

6.Clean pump housing and mating face on

intermediate plate with lint free cloth.

7.Lubricate new 'O' ring with transmission fluid

and fit to pump housing.

8.Position pump locating dowel into intermediate

plate.

9.Align pump to dowel and position in

intermediate plate.

10.Fit bolts and tighten in a diagonal sequence to

10 Nm (7 lbf.ft)

11.Position LRT-44-003/1 into pump and check

that the pump rotors turn freely.

12.Fit intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

M44 1342

LRT-44-003/1

Page 640 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-43

Pump - fluid

$% 44.32.01

Remove

1.Remove intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

2.Remove 8 bolts securing fluid pump to

intermediate plate and carefully remove pump

from intermediate plate.

3.Note position and remove pump locating dowel.

4.Remove and discard 'O' ring from pump

housing.Refit

1.Clean pump housing and mating face on

intermediate plate with lint free cloth.

2.Lubricate new 'O' ring with transmission fluid

and fit to pump housing.

3.Position pump locating dowel into intermediate

plate.

4.Align fluid pump to dowel and position in

intermediate plate.

5.Fit bolts and tighten in a diagonal sequence to

10 Nm (7 lbf.ft)

6.Position LRT-44-003/1 into pump and check

that the pump rotors turn freely.

7.Fit intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

M44 1336

M44 1341

M44 1342

LRT-44-003/1