LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 651 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-54 REPAIRS

Pressure regulator

$% 44.40.22

Remove

1.Remove valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

2.Release and remove clip securing pressure

regulator solenoid valve harness to valve body.

3.Disconnect multiplug from pressure regulator

solenoid valve.

4.Remove 5 Torx screws securing pressure

regulator to valve body and remove pressure

regulator.Refit

1.Clean pressure regulator and mating face with

a lint free cloth.

2.Position pressure regulator to valve body, fit

Torx screws and tighten to 8 Nm (6 lbf.ft).

3.Connect multiplug to pressure regulator

solenoid valve, fit clip and secure harness to

valve body.

4.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

M44 1351

3

Page 652 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-55

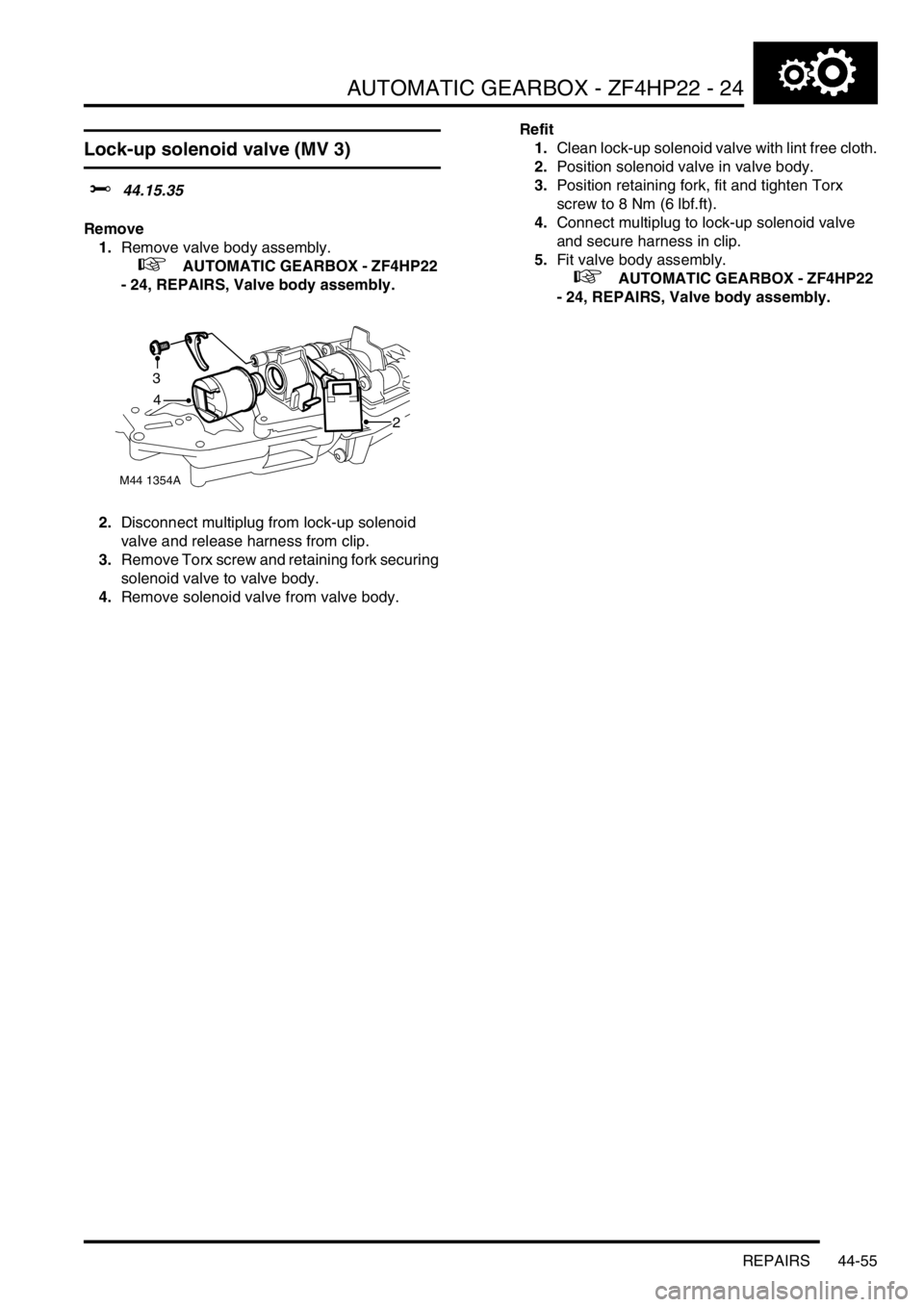

Lock-up solenoid valve (MV 3)

$% 44.15.35

Remove

1.Remove valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

2.Disconnect multiplug from lock-up solenoid

valve and release harness from clip.

3.Remove Torx screw and retaining fork securing

solenoid valve to valve body.

4.Remove solenoid valve from valve body.Refit

1.Clean lock-up solenoid valve with lint free cloth.

2.Position solenoid valve in valve body.

3.Position retaining fork, fit and tighten Torx

screw to 8 Nm (6 lbf.ft).

4.Connect multiplug to lock-up solenoid valve

and secure harness in clip.

5.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

M44 1354A

2

3

4

Page 653 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-56 REPAIRS

Solenoids - shift control valves

(MV 1 & 2)

$% 44.15.45

Remove

1.Remove valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

2.Remove 3 Torx screws securing lock-up

solenoid valve assembly to valve body and

move solenoid aside.

NOTE: This is to gain access to remove Torx

screw and MV2 shift control valve.

3.Note their fitted position and disconnect

multiplugs from shift control valves MV 1 and

MV 2.

4.Remove Torx screw and retaining fork securing

MV2 shift control solenoid valve to valve body.

Note that the tag on the retaining fork faces

towards the valve body.

5.Remove shift control valve from valve body.Refit

1.Clean MV2 shift control solenoid valve with lint

free cloth.

2.Position MV2 shift control solenoid valve to

valve body.

3.Position retaining fork, fit Torx screw and

tighten to 8 Nm (6 lbf.ft).

4.Connect multiplugs to both shift control

solenoid valves.

5.Clean lock-up solenoid valve assembly with a

lint-free cloth.

6.Position lock-up valve assembly, fit and tighten

Torx screws to 8 Nm (6 lbf.ft).

7.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

M44 13521

M44 1353A

Page 654 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-57

Harness - solenoid valves

$% 44.15.52

Remove

1.Remove valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

2.Release and remove clip securing pressure

regulator solenoid harness to valve body.

3.Disconnect multiplug from pressure regulator

solenoid valve.

4.Disconnect multiplugs from lock-up solenoid

valve, shift control solenoid valves MV 1 and

MV 2.

5.Release harness from 5 clips on valve body

and remove harness.6.Disconnect and remove speed sensor from

harness.

Refit

1.Connect speed sensor to harness multiplug.

2.Position harness to valve body.

3.Connect multiplugs to shift control solenoid

valves MV 1 and MV 2 and lock-up solenoid

valve.

4.Connect multiplug to pressure regulator

solenoid valve and secure solenoid valve

harness with clip to valve body.

5.Position and secure harness in clips on valve

body.

6.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

M44 1350

M44 1355

M44 1359

Page 655 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-58 REPAIRS

Electronic control unit - automatic

transmission

$% 44.15.46

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 screws and trim clip securing lower

trim casing to LH front seat.

4.Remove 3 nuts securing speaker power

amplifier bracket to the body.

5.Disconnect multiplug from automatic

transmission ECU located on underside of

amplifier mounting bracket.6.Remove 2 nuts securing ECU to mounting

bracket and remove ECU.

Refit

1.Position ECU to mounting bracket and secure

with nuts.

2.Connect multiplug to ECU.

3.Position speaker power amplifier mounting

bracket to body and secure with nuts.

4.Position lower trim casing to seat and secure

with screws and trim clip.

5.Connect battery earth lead.

6.Fit battery cover and secure fixings.

Page 656 of 1529

PROPELLER SHAFTS

DESCRIPTION AND OPERATION 47-1

PROPELLER SH AFTS DESCRIPTION AND OPERAT ION

Propeller shaft component layout

1Rear axle and brake discs

2Transfer box

3Front axle and brake discs4Front propeller shaft

5Rear propeller shaft

M47 0237B

1

2

3

4

5

Page 657 of 1529

PROPELLER SHAFTS

47-2 DESCRIPTION AND OPERATION

Description

General

Front and rear propeller shafts transmit the drive from the transfer box to the axles.

On vehicles from 03 model year fitted with the 4.6l V8 engine and 4HP24 transmission, the front propeller shaft is 15

mm (0.6 in) longer and the rear propeller shaft is 15mm (0.6 in) shorter than those used on vehicles with the 4.0l V8

and Td5 engines. This is to accomodate an increase in length of the 4HP24 transmission.

Page 658 of 1529

PROPELLER SHAFTS

DESCRIPTION AND OPERATION 47-3

Front propeller shaft

1Hookes joint

2Grease nipple

3Universal joint4Gaiter/Sliding spline joint

5Lubrication point

The front propeller shaft consists of a tube with a universal joint and a sliding spline joint at the front end, and a

Hookes joint at the rear end. The universal joint is bolted to the pinion flange of the front axle differential. The Hookes

joint is bolted to the front output shaft of the transfer box.

The Hookes joint is lubricated during manufacture and sealed for life. A grease nipple is installed in the universal joint

to lubricate the serviceable, sealed needle bearings of the joint. The sliding spline joint is sealed with a gaiter and

lubricated through a lubrication point on the tube. Because of the proximity of a chassis crossmember to the front

propeller shaft, the lubrication point is normally sealed with a grub screw. During maintenance, the grub screw is

temporarily replaced by a slave grease nipple to lubricate the sliding spline joint.

Page 659 of 1529

PROPELLER SHAFTS

47-4 DESCRIPTION AND OPERATION

Rear propeller shaft

1Flexible coupling

2Grease nipple

3Universal joint4Gaiter/Sliding spline joint

5Grease nipple

The rear propeller shaft consists of a tube with a universal joint and a sliding spline joint at the front end, and a flexible

coupling bolted to the rear end. The universal joint is bolted to the rear output shaft of the transfer box. The flexible

coupling is bolted to the pinion flange of the rear axle differential.

A grease nipple is installed in the universal joint for lubrication of the serviceable, sealed needle bearings in the joint.

The sliding spline joint is sealed with a gaiter and lubricated through a grease nipple in the tube.

Page 660 of 1529

PROPELLER SHAFTS

REPAIRS 47-5

REPAIRS

Propeller shaft - front

$% 47.15.02

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.If same components to be refitted, reference

mark propeller shaft and mating components.

3.Remove 8 nuts and bolts securing propeller

shaft to differential and transfer gearbox

flanges.

4.Remove propeller shaft.

Refit

1.Clean propeller shaft flanges and mating

faces.

2.Position propeller shaft to transfer gearbox

and differential and tighten nuts and bolts to 47

Nm (35 lbf. ft).

3.Remove stand(s) and lower vehicle.

Propeller shaft - rear

$% 47.15.03

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.If same components are to be refitted,

reference mark propeller shaft and mating

components.

3.Remove 4 nuts and bolts securing propellor

shaft to transfer gearbox flange.

4.Remove 3 nuts and bolts securing propeller

shaft to flexible coupling.

5.Remove propeller shaft.

Refit

1.Clean propeller shaft flanges and mating

faces.

2.Position propeller shaft to transfer gearbox and

flexible coupling.

3.Fit nuts and bolts securing propeller shaft to

transfer gearbox and tighten to 47 Nm (35

lbf.ft).

4.Fit nuts and bolts securing propeller shaft to

flexible coupling and tighten to 76 Nm (56 lbf.ft).

5.Lower vehicle.

M51 0043A

2

3