heating LAND ROVER DISCOVERY 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1201 of 1529

AIR CONDITIONING

82-12DESCRIPTION AND OPERATION

Control panel

1LH temperature switch

2Economy mode (ECON) switch

3Blower switch

4Display

5Distribution switch

6External air temperature (EXT) switch7RH temperature switch

8Fresh/Recirculated air switch

9Defrost mode switch

10Automatic mode (AUTO) switch

11A/C on/off switch

14 Driver's blend flaps position Input

15 Passenger's blend flaps position Input

16 LH solar heating load Input

17 RH solar heating load Input

18 Evaporator Input

19 Not used -

20 Not used -

C0793

1 Blower power transistor base current Output

2 Blower relay Output

3 Windscreen heater request Output

4 Rear screen heater request Output

5 Passenger's blend flaps servo motor, drive to hot Output

6 Driver's blend flaps servo motor, drive to hot Output

7 Distribution flaps servo motor, drive to windscreen and side

windows demistOutput

8 Fresh/Recirculated air servo motor, drive to recirculated air Output

9 Cooling fan request (diesel models) Output

10 Power relay Output

11 Compressor clutch request Output

12 Cooling fan request (V8 models) Output

13 Passenger's blend flaps servo motor, drive to cold Output

14 Driver's blend flaps servo motor, drive to cold Output

15 Distribution flaps servo motor, drive to footwells Output

16 Fresh/Recirculated air servo motor, drive to fresh air Output Connector/Pin

No.Description Input/Output

Page 1204 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-15

Dual pressure switch

The dual pressure switch protects the refrigerant system from extremes of pressure. The normally closed switch is

installed in the top of the receiver drier. If minimum or maximum pressure limits are exceeded the switch contacts

open, causing the compressor clutch to be disengaged. The minimum pressure limit protects the compressor, by

preventing operation of the system unless there is a minimum refrigerant pressure (and thus refrigerant and

lubricating oil) in the system. The maximum pressure limit keeps the refrigerant system within a safe operating

pressure.

Dual pressure switch nominal operating pressures

Evaporator temperature sensor

The evaporator temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of the

evaporator air outlet temperature. The evaporator temperature sensor is installed in a clip which locates in the

evaporator matrix in the heater assembly. The ATC ECU uses the input to prevent the formation of ice on the

evaporator.

In-car temperature sensor

The in-car temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of cabin air

temperature. The sensor is integrated into the inlet of an electric fan, which is installed behind a grille in the fascia

outboard of the steering column. The fan runs continuously, while the ignition is on, to draw air through the grille and

across the sensor.

Sunlight sensor

The sunlight sensor consists of two diodes that provide the ATC ECU with inputs of light intensity, one as sensed

coming from the left of the vehicle and one as sensed coming from the right. The inputs are used as a measure of the

solar heating effect on vehicle occupants. The sensor is installed in the centre of the fascia upper surface.

Heater coolant temperature sensor

The heater coolant temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input related

to heater matrix coolant temperature. The sensor is installed in the casing of the heater assembly and presses against

the end tank of the heater matrix.

Ambient temperature sensor

The ambient temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of external

air temperature. The sensor is attached to the cooling fan mounting bracket in front of the condenser.

Limit Opening pressure, bar (lbf.in2) Closing pressure, bar (lbf.in2)

Minimum 2.0 (29.0), pressure decreasing 2.3 (33.4), pressure increasing

Maximum 32 (464), pressure increasing 26 (377), pressure decreasing

Page 1206 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-17

Timed recirculated air

The timed recirculated air mode sets the inlet air source to recirculated air for 5 ± 1 minutes, after which it automatically

reverts to fresh air. Timed recirculated air can be manually selected:

lIn the automatic mode, by pressing the fresh/recirculated air switch for 1.5 seconds or more; the audible warning

sounds twice.

lIn the economy or defrost modes, by pressing the fresh/recirculated air switch for less than 1.5 seconds; the

audible warning sounds once.

Latched recirculated air

The inlet air source can be latched to recirculated air:

lIn the automatic mode, by pressing the fresh/recirculated air switch for less than 1.5 seconds; the audible

warning sounds once.

lIn the economy or defrost modes, by pressing the fresh/recirculated air switch for 1.5 seconds or more; the

audible warning sounds twice.

Blower control

The ATC ECU operates a blower relay, power transistor and power relay to run the blower at one of 31 stepped

speeds. All speed steps are available in the automatic modes of blower control. In the manual mode, speed steps 3,

10, 16, 22 and 31 are used to provide slow, three intermediate and fast blower speeds. The ATC ECU energises the

blower relay and modulates the power transistor to operate the blower for speed steps 1 to 30. For speed step 31, the

ATC ECU energises the power relay, which switches the earth side of the blower motor direct to earth, bypassing the

power transistor.

In the automatic, economy and defrost modes, blower speed is corrected for vehicle speed to compensate for the

increase in ram effect on the inlet air as the vehicle speed increases. Correction begins at approximately 50 km/h,

when blower speed is progressively decreased as vehicle speed increases, until a maximum decrease of 13 steps

occurs at 123 km/h. Similarly, blower speed increases as vehicle speed decreases down to approximately 50 km/h.

In the automatic and economy modes, if the LH or RH temperature is set to LO or HI, the blower runs at maximum

speed with correction only for vehicle speed. If both the LH and RH outlet air temperatures are set to a specific

temperature, blower speed corrections are added to compensate for the heater coolant temperature, external air

temperature, and the solar load acting on the vehicle:

lDuring warm-up, the blower speed is set to 3 while the heater coolant temperature is below approximately 20 °C

(68 °F). From approximately 20 °C (68 °F), the blower speed is progressively increased as the coolant

temperature increases, until maximum speed is set at approximately 50 °C (122 °F).

lDuring cool down, blower speed is set to 3, for 5 seconds after the system is switched on. Over the following 6

seconds, the blower speed is progressively increased up to maximum speed.

lAs the temperature in the cabin approaches the selected temperatures, blower speed is progressively reduced

until, once the selected temperatures have been established, blower speed stabilises at approximately 6.

lSolar heating correction is employed when air distribution is set to face level or to face and footwells. The

correction progressively increases the blower speed, up to a maximum of 9 steps, with increasing values of solar

heating.

Page 1208 of 1529

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-19

Diagnostics

The ATC ECU performs a diagnostic check each time the ignition is switched on. To avoid nuisance fault indications

at low light levels, the sunlight sensor is omitted from the diagnostic check. If a fault is detected, the audible warning

sounds three times and the AUTO window on the control panel display flashes for 20 seconds. The ATC ECU then

reverts to normal control but uses a default value or strategy for the detected fault. Faults are identified by performing

a manual diagnostic check of the system.

A manual diagnostic check includes a check of the sunlight sensor, and is initiated by pressing and holding the AUTO

switch and the air distribution switch, then turning the ignition switch from off to on. The audible warning sounds once

and the indications on the control panel display illuminate. FC is shown in the LH temperature window and the results

of the check are shown as a two digit fault code in the RH temperature window. If a fault is detected, the audible

warning sounds three times and the AUTO window on the display flashes on and off for 20 seconds. If more than one

fault is detected, the fault codes cycle in numerical order, at 1 Hz. The audible warning sounds as each fault code is

shown. In low light conditions, to avoid false sunlight sensor fault indications, the sunlight sensor should be illuminated

with a strong light source.

Diagnostic fault codes and fault descriptions

Code Component Fault Default value/strategy

00 - No fault found -

11 In-car temperature sensor Open or short circuit 25°C (77°F)

12 Ambient temperature sensor Open or short circuit 10°C (50°F)

Cooling fan permanently on

Display shows "- -" if external air

temperature selected

13 Thermistor Open or short circuit 0°C (32°F)

14 Heater coolant temperature sensor Open or short circuit 70°C (158°F)

21 Sunlight sensor, left output Open or short circuit No solar heating correction

22 Sunlight sensor, right output Open or short circuit No solar heating correction

31 LH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

32 RH temperature servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

33 Distribution servo motor Open or short circuit

Motor or flap mechanism seizedServo motor locked in position

Page 1227 of 1529

AIR CONDITIONING

82-38REPAIRS

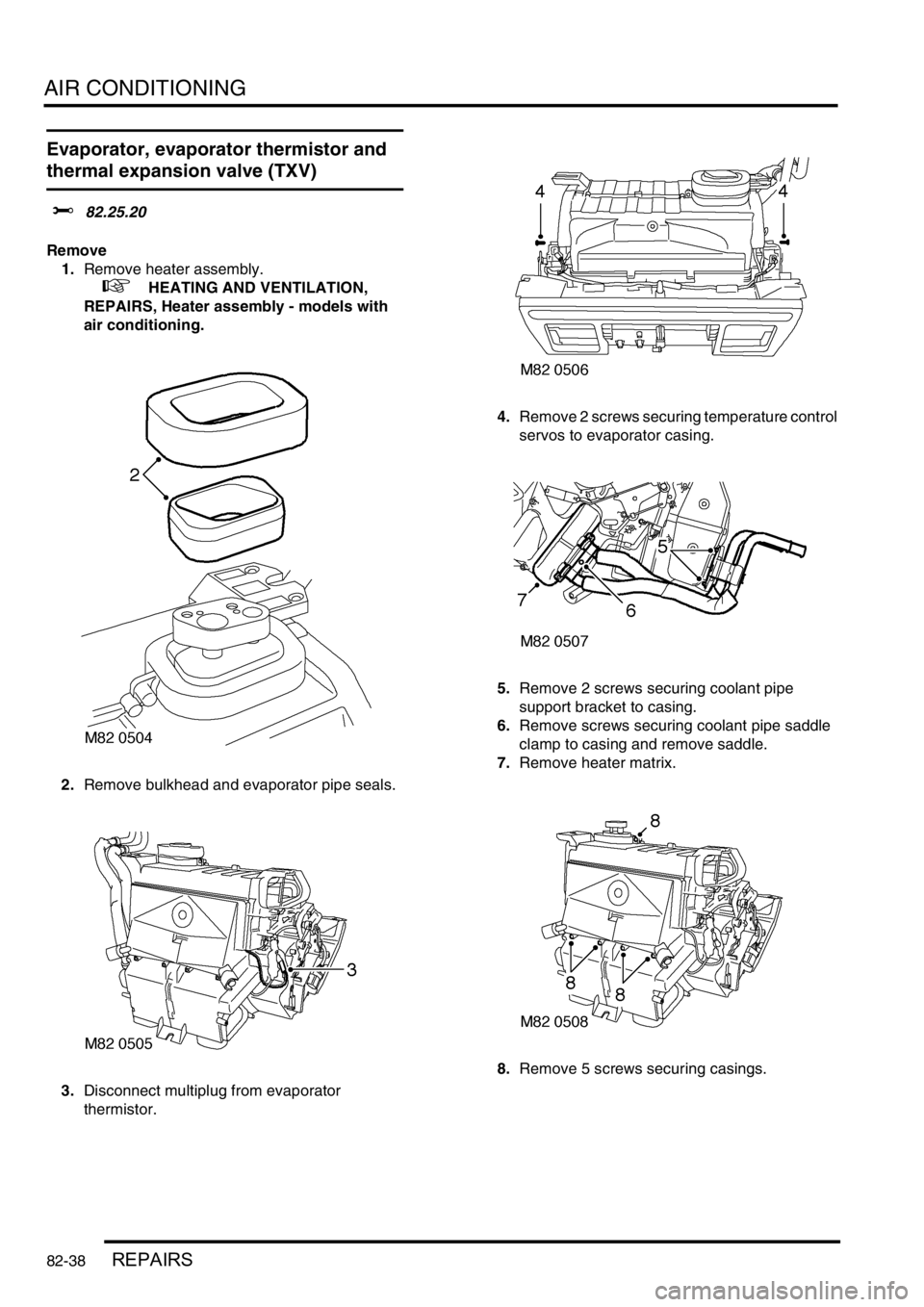

Evaporator, evaporator thermistor and

thermal expansion valve (TXV)

$% 82.25.20

Remove

1.Remove heater assembly.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models with

air conditioning.

2.Remove bulkhead and evaporator pipe seals.

3.Disconnect multiplug from evaporator

thermistor. 4.Remove 2 screws securing temperature control

servos to evaporator casing.

5.Remove 2 screws securing coolant pipe

support bracket to casing.

6.Remove screws securing coolant pipe saddle

clamp to casing and remove saddle.

7.Remove heater matrix.

8.Remove 5 screws securing casings.

Page 1229 of 1529

AIR CONDITIONING

82-40REPAIRS

13.Remove covering from TX valve, release 2

clips securing TX valve to pipe.

14.Release 2 unions securing TX valve, remove

TX valve, remove and discard 'O' rings.

15.Release pipe union, remove pipe and discard

'O' ring. Refit

1.Using a new 'O' ring, position pipe to

evaporator and tighten union.

2.Using new 'O' rings, position TX valve. Connect

pressure pipe union and tighten to 22 Nm (16

lbf. ft). Connect evaporator pipe and tighten to

32 Nm (24 lbf.ft).

3.Position TX valve sensor to pipe and secure

with clips.

4.Fit sensor covering.

5.Fit evaporator thermistor.

6.Fit evaporator assembly.

7.Fit insulation to evaporator casing and fit

casing.

8.Secure spring clips.

9.Fit and tighten casing screws.

10.Fit heater matrix, ensuring matrix temperature

is correctly positioned.

11.Fit coolant pipe saddle, fit and tighten screws

securing saddle and pipe bracket.

12.Fit and tighten temperature servo screws.

13.Connect multiplug to evaporator thermistor.

14.Clean any bulk head seal from casing.

15.Fit bulkhead and evaporator pipe seals.

16.Fit heater assembly.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models with

air conditioning.

Page 1260 of 1529

WIPERS AND WASHERS

REPAIRS 84-25

Motor and linkage - wiper - windscreen

$% 84.15.11

Remove

1.Remove plenum air intake.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

2.Remove 4 nuts and one bolt securing motor

mounting plate to body.

3.Remove nut and bolt securing linkage to body.

4.Release motor and linkage from body and

disconnect multiplug from windscreen wiper

motor.

5.Remove motor and linkage. 6.Remove nut securing linkage connecting rod to

wiper motor spindle.

7.Release link from motor spindle.

8.Remove 3 bolts securing motor to mounting

plate and remove motor.

Refit

1.Fit new wiper motor to mounting plate and

secure with bolts.

2.Connect link to motor spindle and tighten nut to

7 Nm (5.2 lbf.ft).

3.Fit motor and linkage to body, connect

multiplug. Tighten all fixings to 2.5 Nm (1.8

lbf.ft).

4.Fit plenum air intake.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

Page 1420 of 1529

HARNESSES

REPAIRS 86-7-15

21.Disconnect multiplugs from A/C compressor,

turbocharger solenoid valve, AAP sensor and

MAF sensor.

22.Release harness clips from coolant hose and

PAS hose.

23.Note the route of the engine harness, release

from underneath of inlet manifold and remove

from engine.

Refit

1.Position harness on engine.

2.Connect multiplugs to A/C compressor,

turbocharger solenoid valve, AAP and MAF

sensors.

3.Position harness clips to coolant and PAS

hoses.

4.Connect multiplug to ECT sensor.

5.Position harness to front of cylinder head and

tighten bolts to 10 Nm (7 lbf.ft).

6.Connect injector multiplug.

7.Connect multiplug and position battery cable to

alternator and tighten nut.

8.Connect multiplug to fuel temperature sensor.

9.Connect multiplug to MAP sensor.

10.Connect glow plugs.

11.Connect CKP sensor multiplug.

12.Connect Lucar to starter solenoid.

13.Connect battery lead to starter solenoid and

tighten nut to 10 Nm (7 lbf.ft).

14.Position harness clip to coolant pipe.

15.Locate harness over bell housing and connect

multiplug to oil pressure switch.

16.Connect 2 multiplugs to EGR solenoids.

17.Connect engine harness multiplug to ECM and

main harness.

18.Connect engine harness multiplugs to fuse

box.

19.Position glow plug lead to fuse box and tighten

bolt to 3.5 Nm (2.6 lbf.ft).

20.Position battery and alternator leads to fuse

box and tighten bolts to 6 Nm (4.4 lbf.ft).

21.Fit engine compartment fuse box cover.

22.Fit battery carrier.

23.Fit engine acoustic cover.

Harness - main

$% 86.70.07

Remove

1.Remove heater assembly.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models with

air conditioning.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models

without air conditioning.

2.Remove 4 clips securing LH and RH trim

panels to lower 'A' post.

3.Remove both lower 'A' post trim panels.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

5.Remove battery tray.

6.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

Page 1426 of 1529

HARNESSES

REPAIRS 86-7-21

48.Disconnect multiplug from bonnet switch.

49.Disconnect 3 multiplugs from ABS modulator

and multiplug from ABS sensor. 50.Release LH indicator repeater lamp.

51.Disconnect multiplug from repeater lamp.

52.Remove repeater lamp.

53.Attach draw string to repeater lamp harness.

54.Pull harness into engine bay, remove draw

string and secure.

55.Disconnect multiplug from fuel cut-off switch.

56.Remove plenum moulding.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

Page 1432 of 1529

HARNESSES

REPAIRS 86-7-27

94.Disconnect 3 multiplugs from LH rear door

harness.

95.Withdraw harness to interior.

96.Manoeuvre harness over steering column

support bracket.

97.With assistance remove main harness.

Refit

1.With assistance position main harness to body

and manoeuvre over steering column support

bracket.

2.Lay harness in position and secure to floor

clips and retainers.

3.Connect LH and RH rear door multiplugs.

4.Connect CD player multiplug.

5.Position centre console earth headers and

secure with nuts.

6.Fit rear carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - rear.

7.Connect DCU multiplug.

8.Connect Lucar to handbrake switch.

9.Fit and tighten nuts securing harness to

transmission tunnel.

10.Secure harness to pedal box.

11.Position footwell earth header and secure with

nut.

12.Feed RH side of harness into engine bay.

13.Position carpet.

14.Connect wiper motor multiplug, position

mechanism and secure with nuts and bolts.

15.Connect ECM multiplug.

16.Position RH lower 'A' post earth header and

secure with nut, connect cruise control

multiplug.

17.Connect RH front door and RH side body

harness multiplugs. 18.Secure multiplugs to steering column support

bracket and connect brake and clutch pedal

multiplugs.

19.Connect multiplugs to column switch and

passive coil.

20.Position passenger compartment fusebox,

connect multiplugs, fit fusebox to fascia and

secure with nut.

21.Connect ignition switch multiplug to fuse box.

22.With assistance feed LH side of harness into

engine bay.

23.Connect multiplugs to front door harness and

body harness.

24.Position earth headers to LH lower 'A' post and

secure with nuts.

25.Connect multiplugs to ECU pack.

26.Position harness in engine bay.

27.Connect and secure heated front screen

multiplugs.

28.Fit plenum molding.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

29.Connect multiplugs to ABS sensor and fuel

cut-off switch.

30.Using draw string feed harness through inner

wing, remove draw string, connect repeater

lamp multiplug and fit lamp.

31.Connect multiplugs to ABS modulator.

32.Feed harness through to front panel.

33.Position body earth leads and secure with

bolts.

34.Connect washer reservoir multiplugs and

pipes, secure pipes with clips.

35.Secure fog lamp multiplug.

36.Secure earth header behind headlamp.

37.Connect multiplugs to headlamp level motor,

headlamp and side lamp.

38.Fit indicator lamp

+ LIGHTING, REPAIRS, Lamp - front

repeater - up to 03MY.

39.Connect multiplug to LH horn.

40.Feed harness to ACE accelerometer, connect

multiplug and secure with cable ties.

41.Connect cruise control, ABS sensor and brake

fluid level switch multiplugs.

42.Connect engine harness multiplug and feed

harness along RH wing to fuse box.

43.Using draw string pull harness through inner

wing, remove draw string, connect repeater

lamp multiplug and fit lamp.

44.Connect chassis harness multiplugs.

45.Position engine bay fuse box and connect

multiplugs, fit fuse box and secure with screws.

46.Connect multiplugs to front of fuse box.

47.Position battery and starter cables and secure

with screws.

48.Fit fuse box cover.

49.Position earth lead and secure with nut.