LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 881 of 1529

Page 882 of 1529

BRAKES

ADJUSTMENTS 70-29

ADJUST ME NTS

Handbrake

$% 70.45.09

Check

1.Apply the handbrake lever 3 notches on the

ratchet. The handbrake should be fully

operational.

2.If the handbrake is not fully operational, the

brake shoes and/or the handbrake cable need

adjusting.

Adjust

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Ensure handbrake lever is fully released.

3.Tighten brake shoe adjusting bolt until brake

drum is locked, then back off adjusting bolt 1.5

turns. Check that the brake drum is free to

rotate.

4.Recheck handbrake operation.If handbrake is

not fully applied with 3 notches on the

ratchet, the handbrake cable requires

adjustment.

5.Remove switch panel from centre console.

+ WINDOWS, REPAIRS, Switch -

console.

6.Release handbrake lever gaiter from centre

console.7.Rotate adjuster anti-clockwise to increase

cable tension (reduce notches) or clockwise to

decrease cable tension (increase notches).

8.Recheck handbrake operation.

9.Secure handbrake lever gaiter to centre

console.

10.Fit switch panel to centre console.

+ WINDOWS, REPAIRS, Switch -

console.

11.Remove stand(s) and lower vehicle.

Page 883 of 1529

BRAKES

70-30 ADJUSTMENTS

Brake system bleeding

$% 70.25.02

Bleeding of the brake system can be carried out

using the procedures given on TestBook, or by

following the manual procedure given below.

WARNING: If any components upstream of brake

modulator, including the modulator itself are

replaced, the brake system must be bled using

the procedure on TestBook/T4, to ensure that all

air is expelled from the new component(s).

WARNING: Do not allow brake fluid to come into

contact with eyes or skin.

Bleed

NOTE: This procedure covers bleeding the

complete system, but where only the primary or

secondary circuit have been disturbed in

isolation, it should only be necessary to bleed

that circuit. Partial bleeding of the hydraulic

system is only permissible if a brake pipe or

hose has been disconnected with only minor

loss of fluid.

1.Do not allow fluid level in master cylinder to fall

below 'MIN' mark during bleeding.

2.Do not fill reservoir above 'MAX' level.

3.Raise front and rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Check all pipe and hose connections are tight

and there are no signs of leakage.

5.Top-up fluid level in brake reservoir to 'MAX'

mark.

WARNING: Do not allow dirt or foreign

liquids to enter the reservoir. Use only new

DOT 4 brake fluid from airtight containers.

Do not mix brands of brake fluid as they

may not be compatible.6.Attach bleed tube to the bleed screw on front

brake caliper on the passenger side, submerge

free end in a clear container containing brake

fluid.

7.Apply pressure to brake pedal several times,

then apply steady pressure.

8.Loosen bleed screw to release brake fluid and

air. Allow pedal to return unassisted.

9.Depress brake pedal steadily through its full

stroke and allow to return unassisted. Repeat

procedure until a flow of clean air-free fluid is

purged into container then, whilst holding

pedal at end of downward stroke, tighten brake

caliper bleed screw to 10 Nm (7 lbf.ft).

CAUTION: Ensure the fluid in the reservoir

is maintained between the minimum and

maximum levels throughout the bleed

procedure using new brake fluid.

10.Top-up brake fluid level to 'MAX' mark.

Page 884 of 1529

BRAKES

ADJUSTMENTS 70-31

Bleed sequence LHD

Bleed sequence RHD

11.Working in the sequence illustrated, repeat

steps 5 to 9 on remaining calipers.

WARNING: Braking efficiency may be

seriously impaired if the incorrect bleed

sequence is used.

12. Apply brakes and check for leakage.

13.Remove stand(s) and lower vehicle.

14.Road test vehicle. Check brake pedal for short

firm travel when brakes are applied.

Page 885 of 1529

Page 886 of 1529

BRAKES

REPAIRS 70-33

REPAIRS

Brake disc - front

$% 70.12.10

Brake discs must be renewed in pairs, unless

one disc requires changing before 1000 miles

(1500 km) from new.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove 2 bolts securing brake caliper to

swivel hub.

4.Release caliper and tie aside clear of brake

disc.

CAUTION: Do not allow caliper to hang on

brake hose.

5.Remove screw securing disc to drive flange.

6.Remove brake disc from drive flange Refit

1.Clean mating faces of drive flange and new

disc.

2.Fit brake disc to drive flange, fit screw and

tighten to 13 Nm (10 lbf.ft).

3.Clean mating faces of caliper and hub.

4.Fit caliper, and tighten bolts to 175 Nm (129

lbf.ft).

5.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

6.Remove stand(s) and lower vehicle.

Page 887 of 1529

BRAKES

70-34 REPAIRS

Brake disc - rear

$% 70.12.33

Brake discs must be renewed in pairs, unless

one disc requires changing before 1000 miles

(1500 km) from new.

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Remove 2 bolts securing brake caliper to rear

hub.

4.Release caliper and tie aside clear of brake

disc.

CAUTION: Do not allow caliper to hang on

brake hose.

5.Remove screw securing disc to drive flange.

6.Remove brake disc from drive flange. Refit

1.Clean mating faces of drive flange and new

disc.

2.Fit brake disc to drive flange, fit screw and

tighten to 13 Nm (10 lbf.ft).

3.Clean mating faces of caliper and hub.

4.Fit caliper and tighten bolts to 95 Nm (70 lbf.ft).

5.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

6.Remove stand(s) and lower vehicle.

Page 888 of 1529

BRAKES

REPAIRS 70-35

Master cylinder - brake

$% 70.30.08

Remove

1.Disconnect multiplug from fluid level switch.

2.Position cloth under master cylinder to absorb

spilled fluid.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

3.Disconnect secondary system pipe union from

master cylinder.

4.Disconnect primary system pipe union from

master cylinder.

5. Manual gearbox only: Release clip and

disconnect clutch fluid supply hose from

reservoir.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 2 nuts and washers securing master

cylinder to servo.

7.Remove master cylinder. Refit

1.Clean master cylinder and servo mating

surfaces.

2.Align push rod and position master cylinder to

servo.

3.Fit nuts and washers securing master cylinder

to servo and tighten to 25 Nm (18 lbf.ft).

4.Connect primary and secondary brake pipes,

and tighten unions to 25 Nm (18 lbf.ft).

5. Manual gearbox only: Connect clutch fluid

hose to reservoir, secure with clip.

6.Connect fluid level switch multiplug.

7.Bleed brake system using TestBook/T4.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Page 889 of 1529

BRAKES

70-36 REPAIRS

Cable - handbrake

$% 70.35.25

Remove

1.Remove centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

2.Remove clip and clevis pin securing cable to

hand brake lever.

3.Remove brake shoes from hand brake

assembly.

+ BRAKES, REPAIRS, Brake shoes -

handbrake.

4.From below the vehicle, pull handbrake cable

through transmission tunnel.

5.Release handbrake cable from backplate. Refit

1.Fit and secure handbrake cable to backplate.

2.Position hand brake cable through

transmission tunnel.

3.Fit brake shoes to hand brake assembly.

+ BRAKES, REPAIRS, Brake shoes -

handbrake.

4.Align cable to hand brake lever and secure with

clip and clevis pin.

5.Fit centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

6.Adjust handbrake.

+ BRAKES, ADJUSTMENTS,

Handbrake.

Page 890 of 1529

BRAKES

REPAIRS 70-37

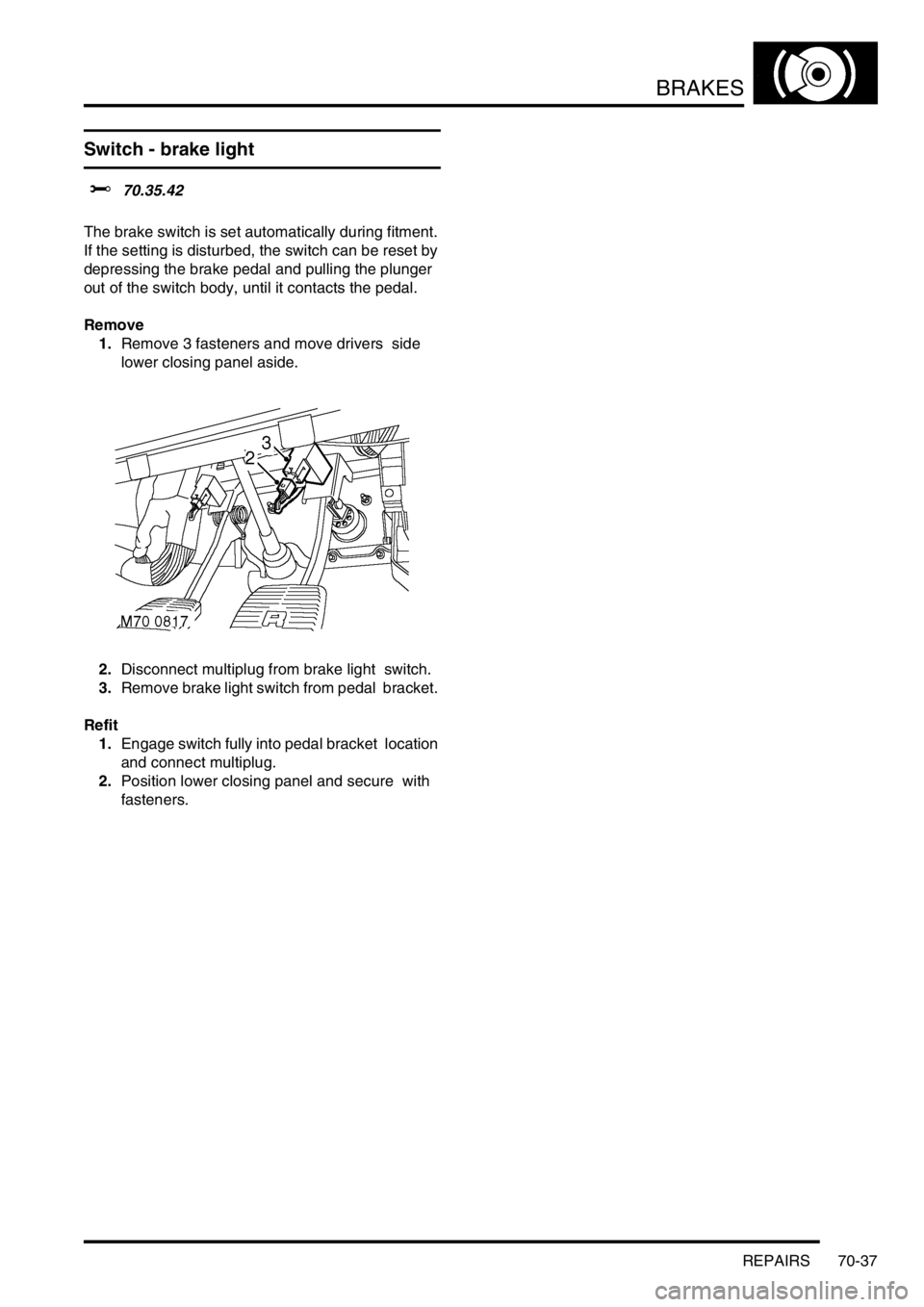

Switch - brake light

$% 70.35.42

The brake switch is set automatically during fitment.

If the setting is disturbed, the switch can be reset by

depressing the brake pedal and pulling the plunger

out of the switch body, until it contacts the pedal.

Remove

1.Remove 3 fasteners and move drivers side

lower closing panel aside.

2.Disconnect multiplug from brake light switch.

3.Remove brake light switch from pedal bracket.

Refit

1.Engage switch fully into pedal bracket location

and connect multiplug.

2.Position lower closing panel and secure with

fasteners.