LAND ROVER DISCOVERY 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 911 of 1529

RESTRAINT SYSTEMS

75-8 DESCRIPTION AND OPERATION

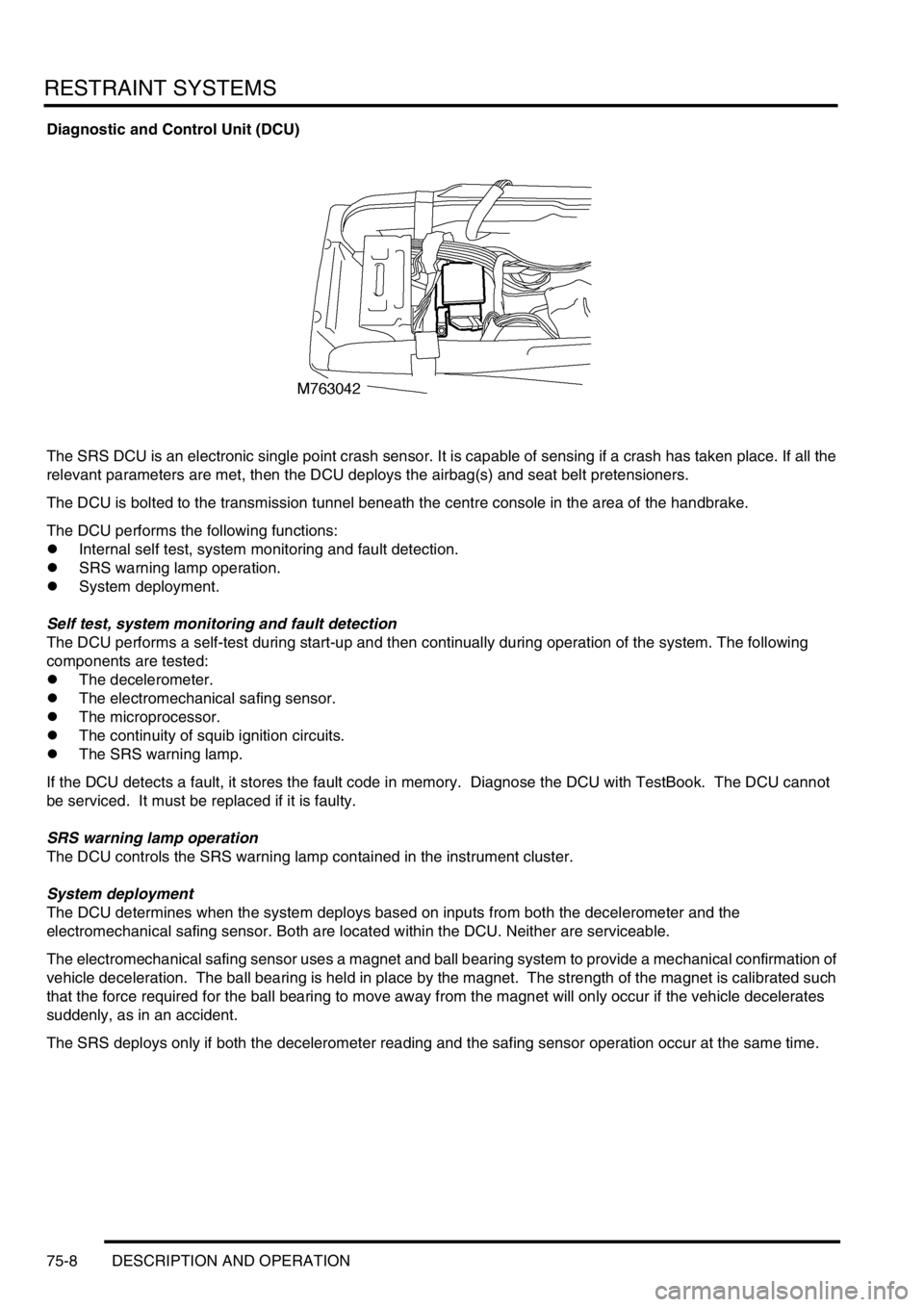

Diagnostic and Control Unit (DCU)

The SRS DCU is an electronic single point crash sensor. It is capable of sensing if a crash has taken place. If all the

relevant parameters are met, then the DCU deploys the airbag(s) and seat belt pretensioners.

The DCU is bolted to the transmission tunnel beneath the centre console in the area of the handbrake.

The DCU performs the following functions:

lInternal self test, system monitoring and fault detection.

lSRS warning lamp operation.

lSystem deployment.

Self test, system monitoring and fault detection

The DCU performs a self-test during start-up and then continually during operation of the system. The following

components are tested:

lThe decelerometer.

lThe electromechanical safing sensor.

lThe microprocessor.

lThe continuity of squib ignition circuits.

lThe SRS warning lamp.

If the DCU detects a fault, it stores the fault code in memory. Diagnose the DCU with TestBook. The DCU cannot

be serviced. It must be replaced if it is faulty.

SRS warning lamp operation

The DCU controls the SRS warning lamp contained in the instrument cluster.

System deployment

The DCU determines when the system deploys based on inputs from both the decelerometer and the

electromechanical safing sensor. Both are located within the DCU. Neither are serviceable.

The electromechanical safing sensor uses a magnet and ball bearing system to provide a mechanical confirmation of

vehicle deceleration. The ball bearing is held in place by the magnet. The strength of the magnet is calibrated such

that the force required for the ball bearing to move away from the magnet will only occur if the vehicle decelerates

suddenly, as in an accident.

The SRS deploys only if both the decelerometer reading and the safing sensor operation occur at the same time.

Page 912 of 1529

RESTRAINT SYSTEMS

DESCRIPTION AND OPERATION 75-9

Operation - SRS

The diagnostic and control unit (DCU) controls the SRS system. The DCU is located beneath the centre console close

to the handbrake area. The DCU contains both an electronic deceleration sensor as well as an electromechanical

safing sensor. When the electronic deceleration sensor within the DCU detects rapid deceleration of the vehicle, it

compares the deceleration rate with stored values in its' memory. If the deceleration rate exceeds the stored value

and the electromechanical safing sensor triggers, the DCU deploys the airbag and the seat belt pretensioners. The

DCU will not deploy the airbags and seat belt pretensioners unless both sensors trigger.

The SRS has diagnostic capabilities through TestBook. In the event that a fault is detected, the DCU alerts the driver

by illuminating a warning lamp in the instrument cluster.

The DCU controls the following:

lSRS warning lamp.

lDrivers airbag module.

lPassenger airbag module (where fitted).

lDriver seat belt pretensioner.

lPassenger seat belt pretensioner.

WARNING: The integrity of the SRS system are critical for safety reasons. Ensure the following precautions

are always adhered to:

lNever install used SRS components from another vehicle or attempt to repair an SRS component.

lWhen repairing an SRS system only use genuine new parts.

lNever apply electrical power to an SRS component unless instructed to do so as part of an approved test

procedure.

lSpecial Torx bolts are necessary for installing the airbag module - do not use other bolts. Ensure bolts

are tightened to the correct torque.

lAlways use new fixings when replacing an SRS component.

lEnsure the SRS Diagnostic Control Unit (DCU) is always installed correctly. There must not be any gap

between the DCU and the bracket to which it is mounted. An incorrectly mounted DCU could cause the

system to malfunction.

System deployment

The airbag and seat belt pretensioners deploy to protect the front seat occupants when the DCU senses a rapid

vehicle deceleration. The system deploys when the following conditions are met:

lThe ignition switch is on.

lThe vehicle decelerates beyond a threshold defined within the DCU.

lThe electromechanical safing sensor within the DCU triggers.

When all of the above conditions are met, the DCU deploys the airbag(s) and seat belt pretensioners. If the above

conditions are not met, the DCU will not deploy the system.

Component replacement policy

After an impact which deploys the airbags and pretensioners, the following components must be renewed:

lDCU.

lDriver and passenger airbag modules.

lDriver and passenger buckle pretensioners.

lRotary coupler.

lFlyleads (where applicable) connecting airbags and pre-tensioners to SRS harness

SRS warning lamp

The SRS warning lamp illuminates for 5 seconds during system readiness check on starting the engine. The SRS

warning lamp extinguishes for one second after the system readiness check is performed. If a fault is present the

warning lamp then illuminates continuously. If no fault is present, the SRS warning lamp remains extinguished. If a

system fault occurs in excess of two seconds after the readiness check has been completed, the SRS warning lamp

illuminates for that ignition cycle. It remains illuminated for a minimum of 12 seconds ± 4 seconds for all fault

conditions.

The SRS warning lamp will only illuminate for low voltage concerns while the low voltage condition is present. If the

low voltage condition is corrected, the SRS warning lamp extinguishes and the fault is recorded in the DCU's memory.

Page 913 of 1529

Page 914 of 1529

RESTRAINT SYSTEMS

DESCRIPTION AND OPERATION 75-11

DESCRIPTION AND OPERAT ION

Description - seat belts

An inertia reel, three point seat belt is installed at each seat position. The inertia reels incorporate a liftshaft locking

system with webbing sensor and car sensor activating mechanisms. The webbing sensor activates the locking system

if the webbing is subjected to a sharp pull. The car sensor activates the locking system if the vehicle is subjected to

sudden deceleration or a severe tilt angle.

Front seat belts

The inertia reel of each front seat belt is attached to the related B/C post, behind the finishers. The webbing runs from

the inertia reel, through a height adjuster, to an anchor point at the base of the B/C post. The buckle assembly for

each belt is attached to the inboard side of the seat and contains the SRS pretensioner.

Rear seat belts

The inertia reels for the outboard rear seats are attached to the body behind the loadspace side trim casings. The

webbing runs from each inertia reel through an upper mounting, suspended from the cantrail, to an anchor point on

the rear wheel arch.

The inertia reel of the centre rear seat is mounted in the back of the seat. The webbing runs through a guide on the

top of the seat and is anchored to one of the seat hinge points. The buckles for the rear seat belts are also attached

to the seat hinge points.

Third row seat belts

The inertia reel of each third row rear seat belt is attached to the related E post, behind the loadspace side trim

casing.The webbing runs from the inertia reel, through an upper mounting on the E post to an anchor point on the

loadspace floor. The buckle is mounted on the inboard side of the seat.

Page 915 of 1529

Page 916 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-13

REPAIRS

Seat belt - front

$% 76.73.13

Remove

1.Remove 'B' post lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - lower - 'B' post.

2.Remove bolt securing seat belt to front seat.

3.Remove bolt securing seat belt reel to 'B' post.

4.Remove seat belt upper anchorage nut.

5.Remove seat belt.

Refit

1.Fit seat belt upper anchorage and tighten nut to

32 Nm (24 lbf.ft).

2.Fit seat belt reel to 'B' post and tighten bolt to 50

Nm (37 lbf.ft).

3.Fit seat belt to front seat and tighten bolt to 32

Nm (24 lbf.ft).

4.Fit 'B' post lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - lower - 'B' post.

Seat belt - rear - centre

$% 76.73.20

Remove

1.Carefully pull front carpet away from RH rear

seat base to gain access to mounting brackets.

2.Remove 2 front Torx bolts securing RH rear

seat to floor.

3.Recline and fold RH rear seat.

4.Remove 2 rear Torx bolts securing RH rear

seat to floor.

5.Remove RH rear seat.

Page 917 of 1529

RESTRAINT SYSTEMS

75-14 REPAIRS

6.Remove 11 clips securing seat back finisher to

RH rear seats.

7.Remove seat back finisher.

8.Remove 15 clips securing seat base finisher to

RH rear seats.

9.Remove seat base finisher. 10.Remove bolt securing seat belt lower

anchorage to frame of RH rear seats.

11.Remove 2 screws securing guide cover to RH

rear seats

12.Remove guide cover.

13.Remove bolt securing seat belt reel to frame of

RH rear seats.

14.Remove seat belt.

Refit

1.Fit seat belt reel and tighten bolt to 32 Nm (24

lbf.ft).

2.Position seat belt through guide on top of RH

rear seats.

3.Fit seat belt lower anchorage to frame of seats

and tighten bolt to 32 Nm (24 lbf.ft).

4.Position guide cover to RH rear seats and

secure with screws.

5.Position seat base finisher to RH rear seats and

secure with clips.

6.Position seat back finisher to RH rear seats and

secure with clips.

7.Position RH rear seats and secure rear

mounting brackets to floor with Torx bolts

tightened to 45 Nm (33 lbf.ft).

8.Put RH rear seats in upright position and

secure front mounting brackets to floor with

Torx bolts tightened to 45 Nm (33 lbf.ft).

9.Position front carpet.

Page 918 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-15

Seat belt - rear - side

$% 76.73.23

Remove

1.Remove 'D' post trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - 'D' post.

2.Remove loadspace side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

3.Remove cap from seat belt lower anchorage

bolt.

4.Remove lower anchorage bolt.

5.Remove cover from seat belt upper anchorage

bolt.

6.Remove upper anchorage bolt.

7.Remove bolt securing seat belt reel to body.

8.Remove seat belt.

Refit

1.Fit seat belt reel to body and tighten bolt to 32

Nm (24 lbf.ft).

2.Fit seat belt upper anchorage to body and

tighten bolt to 50 Nm (37 lbf.ft).

3.Fit cover to upper anchorage bolt.

4.Fit seat belt lower anchorage to body and

tighten bolt to 32 Nm (24 lbf.ft).

5.Fit cap to lower anchorage bolt.

6.Fit loadspace side trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

7.Fit 'D' post trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - 'D' post.

Page 919 of 1529

RESTRAINT SYSTEMS

75-16 REPAIRS

Mounting - seat belt - 'B' post

$% 76.73.26

Remove

1.Release front door aperture seal from 'B' post.

2.Release rear door aperture seal from 'B' post.

3.Release clip securing upper 'B' post trim.

4.Remove 'B' post upper trim.

5.Remove nut securing seat belt upper

anchorage to mounting. 6.Remove 2 Torx bolts securing mounting to 'B'

post.

7.Remove mounting.

Refit

1.Fit mounting to 'B' post and tighten Torx bolts to

22 Nm (16 lbf.ft).

2.Fit seat belt upper anchorage to mounting and

tighten nut to 32 Nm (24 lbf.ft).

3.Secure trim casing to 'B' post with clip.

4.Fit front and rear door aperture seals to 'B'

post.

Page 920 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-17

Seat belts - third row

$% 76.73.28/21

Remove

1.Remove 'D' post trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - 'D' post.

2.Remove seat belt upper anchorage bolt and

collect spacer.

3.Release access panel from loadspace side trim

casing.

4.Remove access panel.

5.Remove bolt securing seat belt reel to body.

6.Remove cap from seat belt lower anchorage

bolt.

7.Remove lower anchorage bolt and collect

washers.

8.Remove seat belt.Refit

1.Fit seat belt lower anchorage to body and

tighten bolt to 32 Nm (24 lbf.ft). Fit cap to bolt.

2.Fit seat belt reel to body and tighten bolt to 50

Nm (37 lbf.ft).

3.Fit seat belt upper anchorage and tighten bolt

to 50 Nm (37 lbf.ft).

4.Fit access panel to luggage compartment side

trim casing.

5.Fit 'D' post trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - 'D' post.