sensor LAND ROVER DISCOVERY 1999 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 324 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-25

In the event of a MAF sensor signal failure any of the following symptoms may be observed:

lDuring driving engine rev/min may dip, before recovering.

lDifficult starting.

lEngine stalls after starting.

lDelayed throttle response.

lEmissions control inoperative.

lIdle speed control inoperative.

lReduced engine performance.

lMAF sensor signal offset.

There are two types of MAF sensor diagnostic check:

lThe MAF sensor signal is less than the minimum threshold for specific speed range – the engine must have

exceeded 200 rev/min for longer than 300 ms and remain above 400 rev/min. The signal must be less than the

threshold mapped against engine speed for longer than 500 ms.

lThe MAF sensor signal is greater than the maximum threshold for specific speed range – the engine must have

exceeded 200 rev/min for longer than 10 ms. The signal must be greater than the threshold mapped against

engine speed for longer than 300 ms.

If the MAF sensor fails the following fault codes will be produced and can be retrieved by TestBook:

P code J2012 description Land Rover description

P0102 Mass or volume air flow low input MAF signal < minimum threshold, which is speed

dependent

P0103 Mass or volume air flow circuit high input MAF signal > maximum threshold, which is speed

dependent

Page 325 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-26 DESCRIPTION AND OPERATION

Intake air temperature (IAT) sensor

The intake air temperature (IAT) sensor utilises a thermistor with a negative temperature coefficient (NTC); as

temperature rises, the thermistor resistance decreases. The change in resistance causes a change in input voltage

at the ECM. The ECM converts the voltage value it receives to provide an indication of the temperature of the inlet air.

Normal operating parameters of the IAT sensor are as follows:

IAT output

Should the IAT sensor fail, the ECM defaults to an assumed air temperature of 45 °C (113 °F).

The IAT sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lIncreased sensor resistance.

lDamaged sensor element.

In the event of an IAT sensor signal failure any of the following symptoms may be observed:

lAdaptive fuelling disabled.

lIdle speed adaption disabled.

lCatalyst monitoring affected due to exhaust temperature model.

lIdle speed actuator test disabled.

lWarm up ignition angle affected.

lCondenser fan hot restart inhibited.

Page 326 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-27

There are two types of IAT sensor diagnostic checks:

lThe IAT sensor signal is less than the minimum threshold – the engine has to have been running for longer than

180 seconds, and idle speed control must have been operational for longer than 10 seconds. No fuel cut off is

active. The IAT sensor signal must be less than -35°C (-31°F) for longer than 200 ms.

lThe IAT sensor signal is greater than the maximum threshold – the ECM has to be powered up (engine does not

need to be running), and the signal must be greater than 140°C (284°F) for longer than 200 ms.

If the IAT sensor fails the following fault codes will be produced and can be retrieved by TestBook:

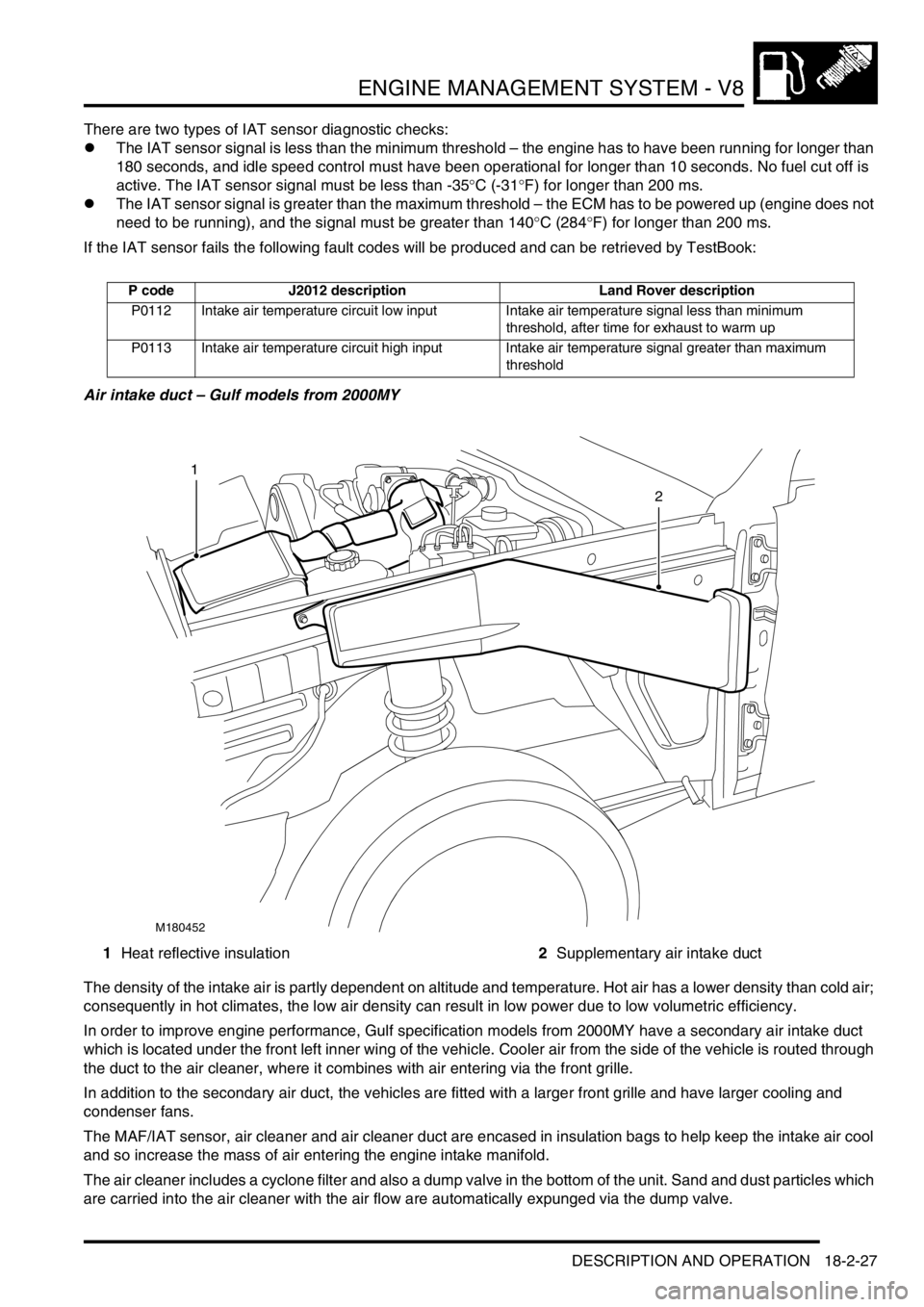

Air intake duct – Gulf models from 2000MY

1Heat reflective insulation2Supplementary air intake duct

The density of the intake air is partly dependent on altitude and temperature. Hot air has a lower density than cold air;

consequently in hot climates, the low air density can result in low power due to low volumetric efficiency.

In order to improve engine performance, Gulf specification models from 2000MY have a secondary air intake duct

which is located under the front left inner wing of the vehicle. Cooler air from the side of the vehicle is routed through

the duct to the air cleaner, where it combines with air entering via the front grille.

In addition to the secondary air duct, the vehicles are fitted with a larger front grille and have larger cooling and

condenser fans.

The MAF/IAT sensor, air cleaner and air cleaner duct are encased in insulation bags to help keep the intake air cool

and so increase the mass of air entering the engine intake manifold.

The air cleaner includes a cyclone filter and also a dump valve in the bottom of the unit. Sand and dust particles which

are carried into the air cleaner with the air flow are automatically expunged via the dump valve.

P code J2012 description Land Rover description

P0112 Intake air temperature circuit low input Intake air temperature signal less than minimum

threshold, after time for exhaust to warm up

P0113 Intake air temperature circuit high input Intake air temperature signal greater than maximum

threshold

M180452

1

2

Page 327 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-28 DESCRIPTION AND OPERATION

Throttle Position (TP) sensor (C0175)

The TP sensor is located on the throttle body assembly in the engine compartment. The ECM is able to determine the

position of the throttle plate and the rate of change of its angle. The ECM processes the signal received from the TP

sensor.

The TP sensor consists of a resistance track and a sliding contact connected to the throttle plate assembly. As the

throttle is opened and closed the sliding contact moves along the resistance track to change the output voltage of the

sensor. The ECM determines throttle plate position by processing this output voltage. The connection of the sensor

to the throttle plate assembly is via a shaft.

The ECM is able to determine the closed throttle position, this enables the TP sensor to be fitted without the need for

prior adjustment. The TP sensor signal has input into the ECM's fuelling strategy and also to determine closed throttle

position for idle speed control. The TP sensor also supplies the ECM with information to enable the overrun fuel cut

off strategy to be implemented. When the ECM receives closed throttle information from the TP sensor it closes the

injectors for the duration of the closed throttle time.

The TP sensor signal is also used by the Electronic Automatic Transmission (EAT) ECU to determine the correct point

for gear shifts and acceleration kickdown. The ECM also supplies the SLABS ECU with this TP sensor information as

a PWM signal.

Input/Output

The TP sensor has electrical input and output. Input is a 5 volt supply via pin 10 of connector C0636 of the ECM. The

signal output is via pin 24 of connector C0636 and is a varying voltage, less than 0.5V (closed throttle) and greater

than 4.5V (wide open throttle) depending on throttle plate position. The TP sensor earth is via pin 25 of connector

C0636 of the ECM, this acts as a screen to protect the integrity of the TP sensor signal.

The connector and sensor terminals are gold plated for corrosion and temperature resistance, care must be exercised

while probing the connector and sensor terminals.

If the TP sensor signal fails, the ECM uses a default value derived from engine load and speed.

The TP sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lSignal out of parameters.

lBlocked air filter (load monitoring, ratio of the TP sensor to air flow).

lRestriction in air inlet (load monitoring, ratio of the TP sensor to air flow).

lVacuum leak

Page 328 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-29

In the event of a TP sensor signal failure any of the following symptoms may be observed:

lEngine performance concern.

lDelayed throttle response.

lFailure of emission control.

lClosed loop idle speed control inoperative.

lAutomatic gearbox kickdown inoperative.

lIncorrect altitude adaptation.

lMIL illuminated (NAS only).

There are three throttle position sensor diagnostic checks:

lTP sensor signal is greater than the maximum threshold value – the engine speed must be greater than 400 rev/

min for longer than 2 seconds and the signal must be greater than 96% for longer than 50 ms.

lTP sensor signal is less than the minimum threshold – the engine speed must be greater than 400 rev/min for

longer than 2 seconds and the signal must be less than 4% for longer than 50 ms.

lRatio of throttle position to mass of air flow – the calculated throttle angle must be outside limits when the engine

speed is between 800 rev/min and 4000 rev/min, the engine load is between 2 and 6.5 and the coolant

temperature is above -10°C (14°F).

Should a malfunction of the TP sensor occur the following fault codes may be evident and can be retrieved by

TestBook.

P code J2012 description Land Rover description

P0101 Mass or volume air flow circuit range/

performance problemLoad monitoring, the ratio of throttle position to air flow

P0122 TPS a circuit low input Signal < minimum threshold

P0123 TPS a circuit high input Signal > maximum threshold

Page 329 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-30 DESCRIPTION AND OPERATION

Heated Oxygen Sensors (HO2S) (C0642)

The market requirement dictates how many HO

2S are fitted to the vehicle.

l4 sensors are fitted to all NAS and EU-3 vehicles.

l2 sensors fitted to all UK, European, Australia and Japanese pre EU-3 specification vehicles.

lNo sensors fitted to ROW vehicles.

The HO

2S monitor the oxygen content of the exhaust gases. By positioning the sensors one for each bank upstream

of the catalytic converter in the exhaust pipe, the ECM can control fuelling on each bank independently of the other.

This allows greater control of the air:fuel ratio and maintains optimum catalyst efficiency. On NAS vehicles the ECM

also uses two HO

2S positioned downstream of the catalytic converters in the exhaust pipe to monitor catalytic

converter efficiency. The ECM is able to achieve this by comparing the values of the upstream HO

2S and the down

stream sensor for the same bank. These comparative values form part of the ECM OBD strategy.

The HO

2S uses zirconium contained in a galvanic cell surrounded by a gas permeable ceramic, this produces an

output voltage proportional to the ratio difference between the oxygen in the exhaust gases and to the ambient

oxygen.

The HO

2S operates at approximately 350 °C (662 °F). To achieve this temperature the HO2S incorporate a heating

element which is controlled by a PWM signal from the ECM. The elements are activated immediately after engine

starts and also under low engine load conditions when the exhaust gas temperature is insufficient to maintain the

required HO

2S temperature. If the heater fails, the ECM will not allow closed loop fuelling to be implemented until the

sensor has achieved the required temperature.

This value equates to an HO

2S output of 450 to 500 mV. A richer mixture can be shown as λ = 0.97, this pushes the

HO

2S output voltage towards 1000 mV. A leaner mixture can be shown as λ = 1.10, this pushes the HO2S output

voltage towards 100 mV.

From cold start, the ECM runs an open loop fuelling strategy. The ECM keeps this strategy in place until the HO

2S is

at a working temperature of 350 °C (662 °F). At this point the ECM starts to receive HO

2S information and it can then

switch into closed loop fuelling as part of its adaptive strategy. The maximum working temperature of the tip of the

HO

2S is 930 °C (1706 °F), temperatures above this will damage the sensor.

HO

2S age with use, this increases their response time to switch from rich to lean and from lean to rich. This can lead

to increased exhaust emissions over a period of time. The switching time of the upstream sensors are monitored by

the ECM. If a pre-determined threshold is exceeded, a failure is detected and the MIL illuminated.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Exhaust Emission Control System.

Input/Output

The upstream and downstream HO

2S are colour coded to prevent incorrect fitting. The tips of the upstream sensors

are physically different to the tips of the downstream sensors.

The HO

2S are colour coded as follows:

lUpstream sensors (both banks) - orange.

lDownstream sensors (both banks) - grey.

The four HO

2S have a direct battery supply to the heater via fuse 2 located in the engine compartment fuse box.

Page 330 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-31

The heater is driven by the ECM providing an earth path for the circuit as follows:

lUpstream LH bank via pin 19 of connector C0635 of the ECM.

lUpstream RH bank via pin 13 of connector C0635 of the ECM.

lDownstream LH bank via pin 7 of connector C0635 of the ECM.

lDownstream RH bank via pin 1 of connector C0635 of the ECM.

The HO

2S output signal is measured by the ECM as follows:

lUpstream LH bank via pin 15 of connector C0635 of the ECM.

lUpstream RH bank via pin 16 of connector C0635 of the ECM.

lDownstream LH bank via pin 17 of connector C0635 of the ECM.

lDownstream RH bank via pin 14 of connector C0635 of the ECM.

The HO

2S earth path for the signal is supplied by the ECM as follows:

lUpstream LH bank via pin 9 of connector C0635 of the ECM.

lUpstream RH bank via pin 10 of connector C0635 of the ECM.

lDownstream LH bank via pin 11 of connector C0635 of the ECM.

lDownstream RH bank via pin 8 of connector C0635 of the ECM.

The HO

2S voltage is difficult to measure using a multimeter, the output can be monitored using TestBook. A rich

mixture would read 500 to 1000 mV, a weak mixture would read 100 mV to 500 mV, the reading should switch from

rich to weak. The open loop default voltage is 450 mV, this is used by the ECM to set the air/ fuel ratio until the tip of

the HO

2S reaches operating temperature.

The HO

2S can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lSensor disconnected.

lStoichiometric ratio outside the correct operating band.

lContamination from leaded fuel.

lAir leak into the exhaust system.

lWiring loom damage.

lSensors fitted incorrectly or cross wired.

In the event of a HO

2S signal failure any of the following symptoms may be observed:

lDefault to open loop fuelling on defective bank.

lIf the sensors are crossed over (LH bank to RH bank), the engine will run normally after initial start up, but

performance will become progressively worse as the sensors go towards maximum rich for one bank of cylinders

and maximum lean for the other. The ECM will eventually default into open loop fuelling.

lHigh CO reading.

lExcess emissions.

lStrong hydrogen sulphide (H

2S) smell until the ECM defaults to open loop fuelling. .

lMIL illuminated (NAS market only).

A number of diagnostic tests are performed by the ECM with regards to the HO

2sensors:

lHO

2 sensor and system diagnostics

lHO

2 sensor heater diagnostics

lHO

2 sensor switching period (ageing) diagnostics

lRear HO

2 sensor adaption diagnostic (NAS only)

lCatalyst monitoring diagnostic

For further details of the heated oxygen sensors and exhaust emission control, refer to the V8 Emission Control

section of this manual.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Exhaust Emission Control System.

Page 331 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-32 DESCRIPTION AND OPERATION

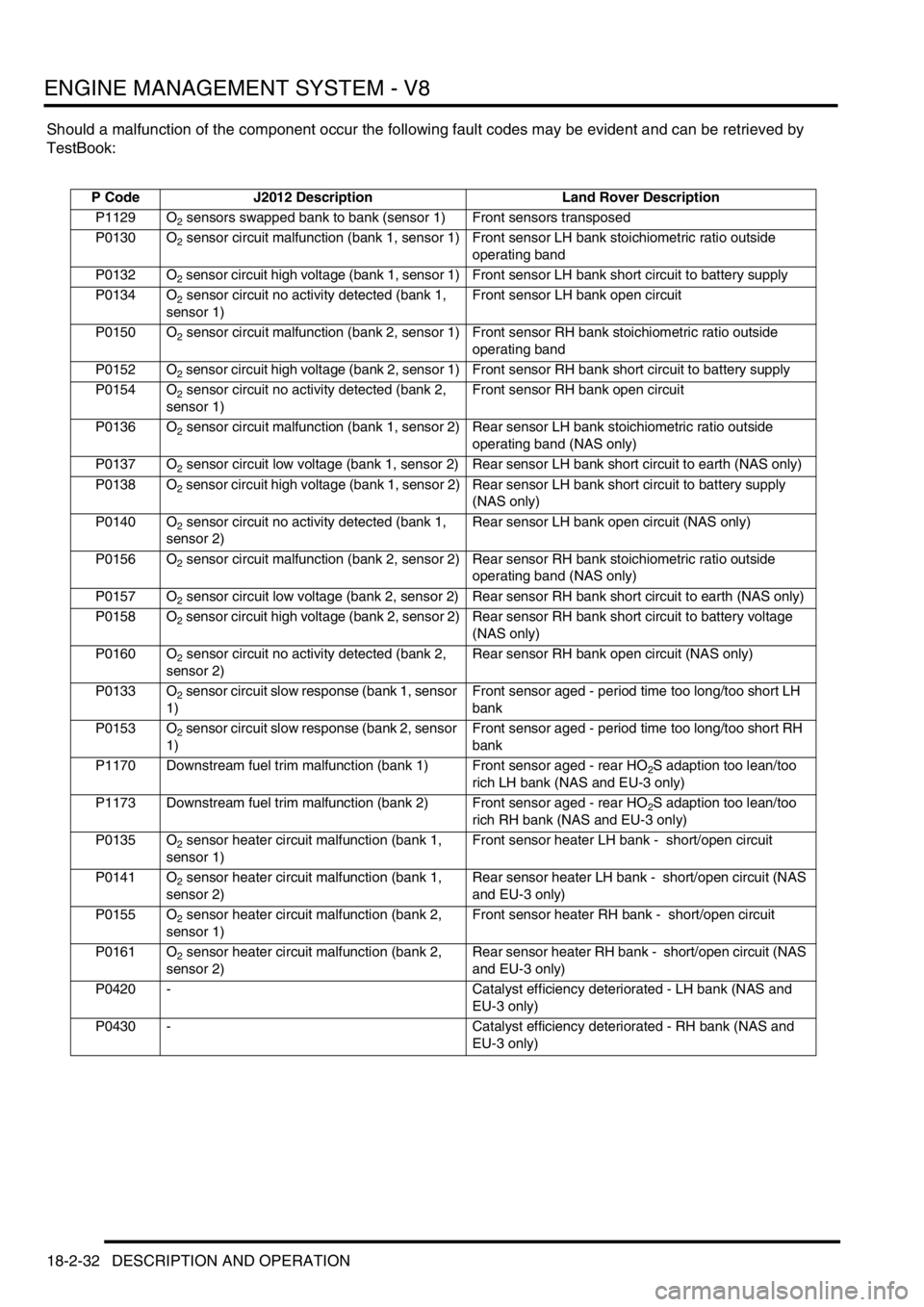

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

P Code J2012 Description Land Rover Description

P1129 O

2 sensors swapped bank to bank (sensor 1) Front sensors transposed

P0130 O

2 sensor circuit malfunction (bank 1, sensor 1) Front sensor LH bank stoichiometric ratio outside

operating band

P0132 O

2 sensor circuit high voltage (bank 1, sensor 1) Front sensor LH bank short circuit to battery supply

P0134 O

2 sensor circuit no activity detected (bank 1,

sensor 1)Front sensor LH bank open circuit

P0150 O

2 sensor circuit malfunction (bank 2, sensor 1) Front sensor RH bank stoichiometric ratio outside

operating band

P0152 O

2 sensor circuit high voltage (bank 2, sensor 1) Front sensor RH bank short circuit to battery supply

P0154 O

2 sensor circuit no activity detected (bank 2,

sensor 1)Front sensor RH bank open circuit

P0136 O

2 sensor circuit malfunction (bank 1, sensor 2) Rear sensor LH bank stoichiometric ratio outside

operating band (NAS only)

P0137 O

2 sensor circuit low voltage (bank 1, sensor 2) Rear sensor LH bank short circuit to earth (NAS only)

P0138 O

2 sensor circuit high voltage (bank 1, sensor 2) Rear sensor LH bank short circuit to battery supply

(NAS only)

P0140 O

2 sensor circuit no activity detected (bank 1,

sensor 2)Rear sensor LH bank open circuit (NAS only)

P0156 O

2 sensor circuit malfunction (bank 2, sensor 2) Rear sensor RH bank stoichiometric ratio outside

operating band (NAS only)

P0157 O

2 sensor circuit low voltage (bank 2, sensor 2) Rear sensor RH bank short circuit to earth (NAS only)

P0158 O

2 sensor circuit high voltage (bank 2, sensor 2) Rear sensor RH bank short circuit to battery voltage

(NAS only)

P0160 O

2 sensor circuit no activity detected (bank 2,

sensor 2)Rear sensor RH bank open circuit (NAS only)

P0133 O

2 sensor circuit slow response (bank 1, sensor

1)Front sensor aged - period time too long/too short LH

bank

P0153 O

2 sensor circuit slow response (bank 2, sensor

1)Front sensor aged - period time too long/too short RH

bank

P1170 Downstream fuel trim malfunction (bank 1) Front sensor aged - rear HO

2S adaption too lean/too

rich LH bank (NAS and EU-3 only)

P1173 Downstream fuel trim malfunction (bank 2) Front sensor aged - rear HO

2S adaption too lean/too

rich RH bank (NAS and EU-3 only)

P0135 O

2 sensor heater circuit malfunction (bank 1,

sensor 1)Front sensor heater LH bank - short/open circuit

P0141 O

2 sensor heater circuit malfunction (bank 1,

sensor 2)Rear sensor heater LH bank - short/open circuit (NAS

and EU-3 only)

P0155 O

2 sensor heater circuit malfunction (bank 2,

sensor 1)Front sensor heater RH bank - short/open circuit

P0161 O

2 sensor heater circuit malfunction (bank 2,

sensor 2)Rear sensor heater RH bank - short/open circuit (NAS

and EU-3 only)

P0420 - Catalyst efficiency deteriorated - LH bank (NAS and

EU-3 only)

P0430 - Catalyst efficiency deteriorated - RH bank (NAS and

EU-3 only)

Page 338 of 1529

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-39

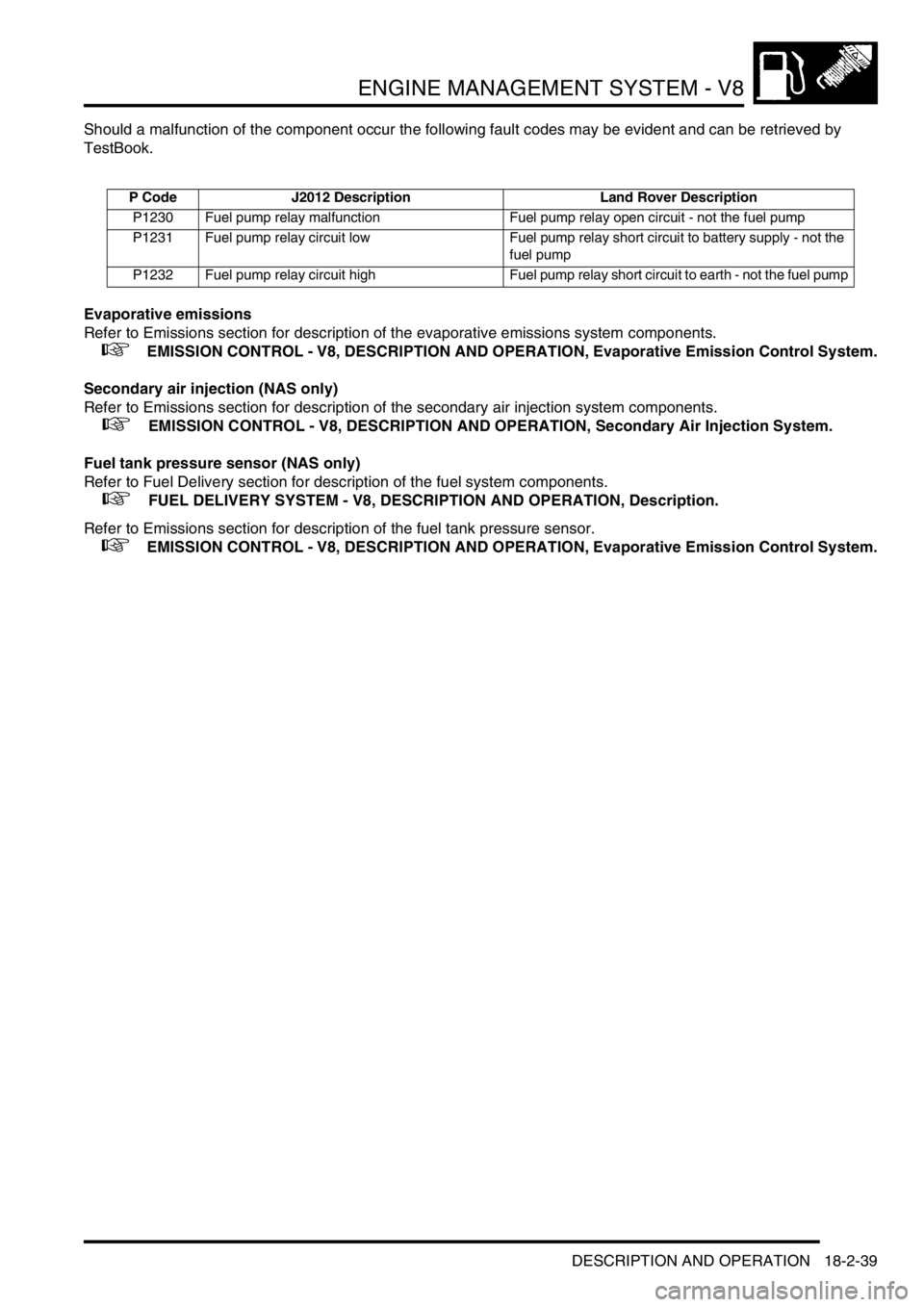

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook.

Evaporative emissions

Refer to Emissions section for description of the evaporative emissions system components.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative Emission Control System.

Secondary air injection (NAS only)

Refer to Emissions section for description of the secondary air injection system components.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Secondary Air Injection System.

Fuel tank pressure sensor (NAS only)

Refer to Fuel Delivery section for description of the fuel system components.

+ FUEL DELIVERY SYSTEM - V8, DESCRIPTION AND OPERATION, Description.

Refer to Emissions section for description of the fuel tank pressure sensor.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Evaporative Emission Control System.

P Code J2012 Description Land Rover Description

P1230 Fuel pump relay malfunction Fuel pump relay open circuit - not the fuel pump

P1231 Fuel pump relay circuit low Fuel pump relay short circuit to battery supply - not the

fuel pump

P1232 Fuel pump relay circuit high Fuel pump relay short circuit to earth - not the fuel pump

Page 341 of 1529

ENGINE MANAGEMENT SYSTEM - V8

18-2-42 DESCRIPTION AND OPERATION

Knock Sensor (KS)

The ECM uses two knock sensors located between the centre two cylinders of each bank to detect pre-ignition. The

knock sensors consist of piezo ceramic crystals that oscillate to create a voltage signal. During pre-ignition the

frequency of crystal oscillation increases, which alters the signal output to the ECM. The ECM compares the signal

to known signal profiles in its memory. If pre-ignition is detected the ECM retards ignition timing for a number of cycles.

If no more pre-ignition is detected, the timing is gradually advanced to the original setting.

The ignition is calibrated to run on 95 RON premium fuel, but the system will run satisfactorily on 91 RON regular fuel.

If the vehicle is refuelled with a lower grade fuel, some audible detonation will initially be heard. This is non-damaging

and ceases when the system adaption is completed.

Input/Output

Because of the nature of its operation, the knock sensors do not require any electrical input source. The KS output

for LH bank (cylinders 1, 3, 5, 7) is measured via pin 49 of connector C0636 of the ECM. The KS output for RH bank

(cylinders 2, 4, 6, 8) is measured via pin 36 of connector C0636 of the ECM. Both knock sensors have a screened

earth to protect the integrity of the sensor signals. The KS earth for LH bank (cylinders 1, 3, 5, 7) is via pin 48 of

connector C0636 of the ECM. The KS earth for RH bank (cylinders 2, 4, 6, 8) is via pin 35 of connector C0636 of the

ECM.

The connector and sensor terminals are gold plated for corrosion and temperature resistance, care must be exercised

while probing the connector and sensor terminals.

The KS can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle battery supply.

lShort circuit to vehicle earth.

lFaulty component.

lIncorrectly tightened sensor.

In the event of a KS signal failure any of the following symptoms may be observed:

lKS disabled, the ECM refers to a 'safe ignition map'.

lRough running.

lEngine performance concern.