oil LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 325 of 1672

EMISSION CONTROL - TD5

17-1-4 DESCRIPTION AND OPERATION

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems fitted

to Land Rover vehicles are designed to maintain the emission levels within the legal limits pertaining for the specified

market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order, so that it operates at its optimum condition.

In addition to emissions improvements through engine design and the application of electronic engine management

systems, special emission control systems are used to limit the pollutant levels developed under certain conditions.

Two main types of additional emission control system are utilised with the Td5 engine to reduce the levels of harmful

emissions released into the atmosphere. These are as follows:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust gas recirculation – to reduce NO

2 emissions.

Crankcase emission control

All internal combustion engines generate oil vapour and smoke in the crankcase as a result of high crankcase

temperatures and piston ring and valve stem blow-by, a closed crankcase ventilation system is used to vent

crankcase gases back to the air induction system and so reduce the emission of hydrocarbons.

Gases from the crankcase are drawn into the inlet manifold to be burnt in the combustion chambers with the fresh air/

fuel mixture. The system provides effective emission control under all engine operating conditions.

Crankcase gases are drawn through the breather port in the top of the camshaft cover and routed through the breather

hose and breather valve on the flexible air intake duct to be drawn into the turbocharger intake for delivery to the air

inlet manifold via an intercooler.

An oil separator plate is included in the camshaft cover which removes the heavy particles of oil before the crankcase

gas leaves via the camshaft cover port. The rocker cover features circular chambers which promote swirl in the oil

mist emanating from the cylinder head and camshaft carrier. As the mist passes through the series of chambers

between the rocker cover and oil separator plate, oil particles are thrown against the separator walls where they

condense and fall back into the cylinder head via two air inlet holes located at each end of the rocker cover.

The breather valve is a depression limiting valve which progressively closes as engine speed increases, thereby

limiting the depression in the crankcase. The valve is of moulded plastic construction and has a port on the underside

which plugs into a port in the flexible air intake duct. A port on the side of the breather valve connects to the camshaft

cover port by means of a breather hose which is constructed from a heavy-duty braided rubber hose which is held in

place by hose clips. A corrugated plastic sleeve is used to give further protection to the breather hose. The breather

valve is orientation sensitive, and “TOP” is marked on the upper surface to ensure it is mounted correctly.

It is important that the system is airtight so hose connections to ports should be checked and the condition of the

breather hose should be periodically inspected to ensure it is in good condition.

Page 338 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-1

EMISS ION CONTROL - V8 DESCRIPTION AND OPERAT ION

Crankcase emission control system

1Intake air

2LH rocker cover breather tube

3Oil separator in RH rocker breather tube

Page 346 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-9

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems are

fitted to Land Rover vehicles which are designed to maintain the emission levels within the legal limits pertaining for

the specified market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order so that it operates at its optimal condition. In particular, ignition

timing has an effect on the production of HC and NO

x emissions, with the harmful emissions rising as the ignition

timing is advanced.

CAUTION: In many countries it is against the law for a vehicle owner or an unauthorised dealer to modify or

tamper with emission control equipment. In some cases, the vehicle owner and/or the dealer may even be

liable for prosecution.

The engine management ECM is fundamental for controlling the emission control systems. In addition to controlling

normal operation, the system complies with On Board Diagnostic (OBD) system strategies. The system monitors and

reports on faults detected with ignition, fuelling and exhaust systems which cause an excessive increase in tailpipe

emissions. This includes component failures, engine misfire, catalyst damage, catalyst efficiency, fuel evaporative

loss and exhaust leaks.

When an emission relevant fault is determined, the fault condition is stored in the ECM memory. For NAS vehicles,

the MIL warning light on the instrument pack will be illuminated when the fault is confirmed. Confirmation of a fault

condition occurs if the fault is still found to be present during the driving cycle subsequent to the one when the fault

was first detected.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The following types of supplementary control system are used to reduce harmful emissions released into the

atmosphere from the vehicle:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust emission control – to limit the undesirable by-products of combustion.

3Fuel vapour evaporative loss control – to restrict the emission of fuel through evaporation from the fuel

system.

4Fuel leak detection system (NAS only) – there are two types of system which may be used to check the

evaporative emission system for the presence of leaks from the fuel tank to purge valve.

aVacuum leak detection test – checks for leaks down to 1 mm (0.04 in.) in diameter.

bPositive pressure leak detection test – utilises a leak detection pump to check for leaks down to 0.5 mm (0.02

in.) in diameter.

5Secondary air injection system (NAS only) – to reduce emissions experienced during cold starting.

Crankcase emission control system

The concentration of hydrocarbons in the crankcase of an engine is much greater than that in the vehicle's exhaust

system. In order to prevent the emission of these hydrocarbons into the atmosphere, crankcase emission control

systems are employed and are a standard legal requirement.

The crankcase ventilation system is an integral part of the air supply to the engine combustion chambers and it is

often overlooked when diagnosing problems associated with engine performance. A blocked ventilation pipe or filter

or excessive air leak into the inlet system through a damaged pipe or a leaking gasket can affect the air:fuel mixture,

performance and efficiency of the engine. Periodically check the ventilation hoses are not cracked and that they are

securely fitted to form airtight connections at their relevant ports.

The purpose of the crankcase ventilation system is to ensure that any noxious gas generated in the engine crankcase

is rendered harmless by complete burning of the fuel in the combustion chamber. Burning the crankcase vapours in

a controlled manner decreases the HC pollutants that could be emitted and helps to prevent the development of

sludge in the engine oil as well as increasing fuel economy.

Page 347 of 1672

EMISSION CONTROL - V8

17-2-10 DESCRIPTION AND OPERATION

A spiral oil separator is located in the stub pipe to the ventilation hose on the right hand cylinder head rocker cover,

where oil is separated and returned to the cylinder head. The rubber ventilation hose from the right hand rocker cover

is routed to a port on the right hand side of the inlet manifold plenum chamber where the returned gases mix with the

fresh inlet air passing through the throttle butterfly valve. The stub pipe on the left hand rocker cover does not contain

an oil separator, and the ventilation hose is routed to the throttle body housing at the air inlet side of the butterfly valve.

The ventilation hoses are attached to the stub pipe by metal band clamps.

Exhaust emission control system

The fuel injection system provides accurately metered quantities of fuel to the combustion chambers to ensure the

most efficient air to fuel ratio under all operating conditions. A further improvement to combustion is made by

measuring the oxygen content of the exhaust gases to enable the quantity of fuel injected to be varied in accordance

with the prevailing engine operation and ambient conditions; any unsatisfactory composition of the exhaust gas is

then corrected by adjustments made to the fuelling by the ECM.

The main components of the exhaust emission system are two catalytic converters which are an integral part of the

front exhaust pipe assembly. The catalytic converters are included in the system to reduce the emission to

atmosphere of carbon monoxide (CO), oxides of nitrogen (NO

x) and hydrocarbons (HC). The active constituents of

the catalytic converters are platinum (Pt), palladium (PD) and rhodium (Rh). Catalytic converters for NAS low

emission vehicles (LEVs) from 2000MY have active constituents of palladium and rhodium only. The correct

functioning of the converters is dependent upon close control of the oxygen concentration in the exhaust gas entering

the catalyst.

The two catalytic converters are shaped differently to allow sufficient clearance between the body and transmission,

but they remain functionally identical since they have the same volume and use the same active constituents.

The basic control loop comprises the engine (controlled system), the heated oxygen sensors (measuring elements),

the engine management ECM (control) and the injectors and ignition (actuators). Other factors also influence the

calculations of the ECM, such as air flow, air intake temperature and throttle position. Additionally, special driving

conditions are compensated for, such as starting, acceleration, deceleration, overrun and full load.

The reliability of the ignition system is critical for efficient catalytic converter operation, since misfiring will lead to

irreparable damage of the catalytic converter due to the overheating that occurs when unburned combustion gases

are burnt inside it.

CAUTION: If the engine is misfiring, it should be shut down immediately and the cause rectified. Failure to do

so will result in irreparable damage to the catalytic converter.

CAUTION: Ensure the exhaust system is free from leaks. Exhaust gas leaks upstream of the catalytic

converter could cause internal damage to the catalytic converter.

CAUTION: Serious damage to the engine may occur if a lower octane number fuel than recommended is used.

Serious damage to the catalytic converter and oxygen sensors will occur if leaded fuel is used.

Air : fuel ratio

The theoretical ideal air:fuel ratio to ensure complete combustion and minimise emissions in a spark-ignition engine

is 14.7:1 and is referred to as the stoichiometric ratio.

The excess air factor is denoted by the Lambda symbol

λ, and is used to indicate how far the air:fuel mixture ratio

deviates from the theoretical optimum during any particular operating condition.

lWhen

λ = 1, the air to fuel ratio corresponds to the theoretical optimum of 14.7:1 and is the desired condition for

minimising emissions.

lWhen

λ > 1, (i.e. λ = 1.05 to λ = 1.3) there is excess air available (lean mixture) and lower fuel consumption can

be attained at the cost of reduced performance. For mixtures above

λ = 1.3, the mixture ceases to be ignitable.

lWhen

λ < 1, (i.e. λ = 0.85 to λ = 0.95) there is an air deficiency (rich mixture) and maximum output is available,

but fuel economy is impaired.

The engine management system used with V8 engines operates in a narrower control range about the stoichiometric

ideal between

λ = 0.97 to 1.03 using closed-loop control techniques. When the engine is warmed up and operating

under normal conditions, it is essential to maintain

λ close to the ideal (λ = 1) to ensure the effective treatment of

exhaust gases by the three-way catalytic converters installed in the downpipes from each exhaust manifold.

Page 365 of 1672

EMISSION CONTROL - V8

17-2-28 DESCRIPTION AND OPERATION

The SAI pump is attached to a bracket at the rear RH side of the engine compartment and is fixed to the bracket by

three studs and nuts. The pump is electrically powered from a 12V battery supply via a dedicated relay and supplies

approximately 35kg/hr of air when the vehicle is at idle in Neutral/Park on a start from 20

°C (68°F).

Air is drawn into the pump through vents in its front cover and is then passed through a foam filter to remove

particulates before air injection. The air is delivered to the exhaust manifold on each side of the engine through a

combination of plastic and metal pipes.

The air delivery pipe is a flexible plastic type, and is connected to the air pump outlet via a plastic quick-fit connector.

The other end of the flexible plastic pipe connects to the fixed metal pipework via a short rubber hose. The part of the

flexible plastic pipe which is most vulnerable to engine generated heat is protected by heat reflective sleeving. The

metal delivery pipe has a fabricated T-piece included where the pressurised air is split for delivery to each exhaust

manifold via the SAI control valves.

The pipes from the T-piece to each of the SAI control valves are approximately the same length, so that the pressure

and mass of the air delivered to each bank will be equal. The ends of the pipes are connected to the inlet port of each

SAI control valve through short rubber hose connections.

The T-piece is mounted at the rear of the engine (by the ignition coils) and features a welded mounting bracket which

is fixed to the engine by two studs and nuts.

The foam filter in the air intake of the SAI pump provides noise reduction and protects the pump from damage due to

particulate contamination. In addition, the pump is fitted on rubber mountings to help prevent noise which is generated

by pump operation from being transmitted through the vehicle body into the passenger compartment.

If the secondary air injection pump malfunctions, the following fault codes may be stored in the ECM diagnostic

memory, which can be retrieved using 'Testbook':

Secondary air injection (SAI) pump relay

The secondary air injection pump relay is located in the engine compartment fusebox. The engine control module

(ECM) is used to control the operation of the SAI pump via the SAI pump relay. Power to the coil of the relay is supplied

from the vehicle battery via the main relay and the ground connection to the coil is via the ECM.

Power to the SAI pump relay contacts is via fusible link FL2 which is located in the engine compartment fusebox.

P-code Description

P0418Secondary air injection pump powerstage fault (e.g. - SAI pump relay fault / SAI

pump or relay not connected / open circuit / harness damage).

Page 370 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-33

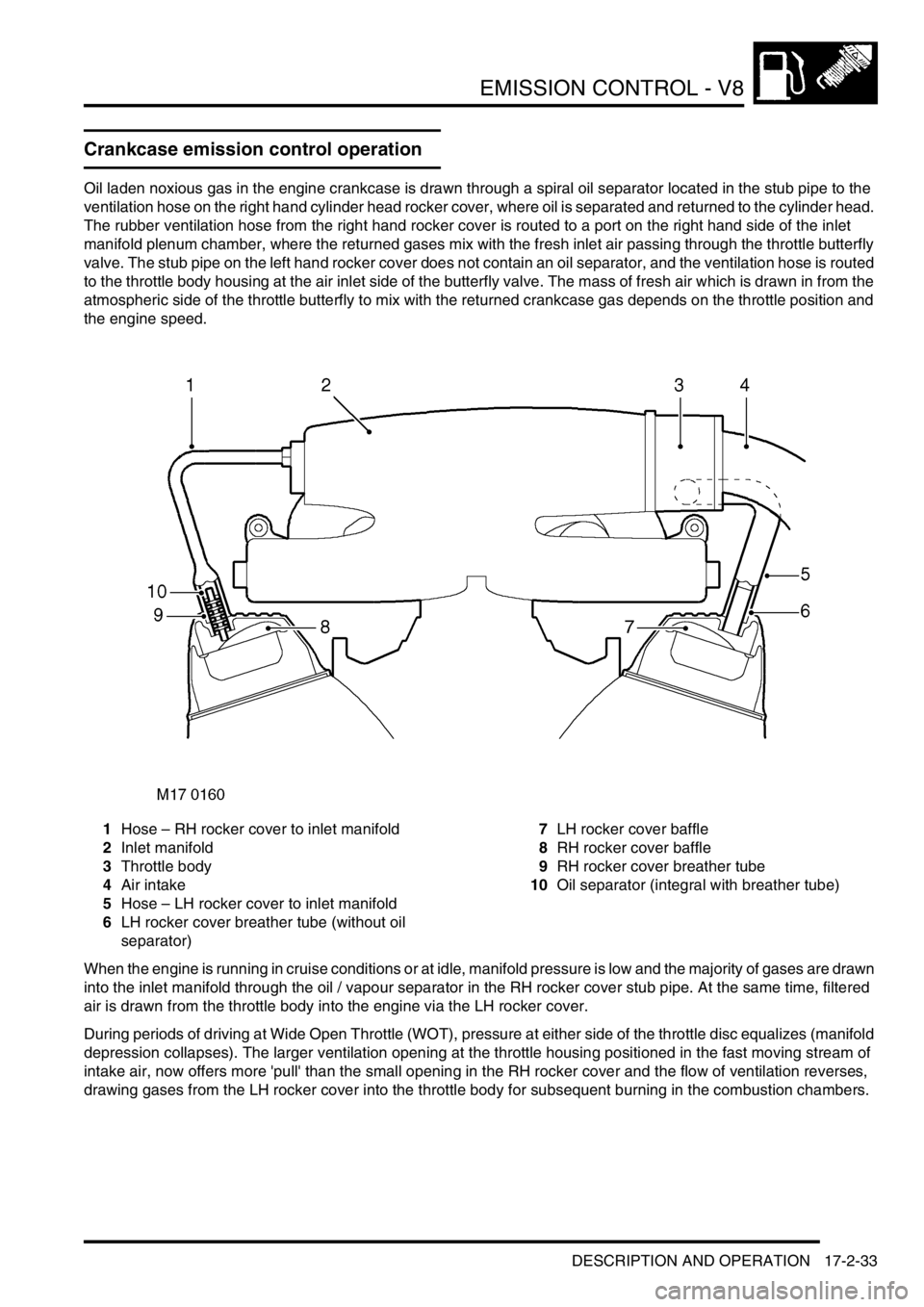

Crankcase emission control operation

Oil laden noxious gas in the engine crankcase is drawn through a spiral oil separator located in the stub pipe to the

ventilation hose on the right hand cylinder head rocker cover, where oil is separated and returned to the cylinder head.

The rubber ventilation hose from the right hand rocker cover is routed to a port on the right hand side of the inlet

manifold plenum chamber, where the returned gases mix with the fresh inlet air passing through the throttle butterfly

valve. The stub pipe on the left hand rocker cover does not contain an oil separator, and the ventilation hose is routed

to the throttle body housing at the air inlet side of the butterfly valve. The mass of fresh air which is drawn in from the

atmospheric side of the throttle butterfly to mix with the returned crankcase gas depends on the throttle position and

the engine speed.

1Hose – RH rocker cover to inlet manifold

2Inlet manifold

3Throttle body

4Air intake

5Hose – LH rocker cover to inlet manifold

6LH rocker cover breather tube (without oil

separator)7LH rocker cover baffle

8RH rocker cover baffle

9RH rocker cover breather tube

10Oil separator (integral with breather tube)

When the engine is running in cruise conditions or at idle, manifold pressure is low and the majority of gases are drawn

into the inlet manifold through the oil / vapour separator in the RH rocker cover stub pipe. At the same time, filtered

air is drawn from the throttle body into the engine via the LH rocker cover.

During periods of driving at Wide Open Throttle (WOT), pressure at either side of the throttle disc equalizes (manifold

depression collapses). The larger ventilation opening at the throttle housing positioned in the fast moving stream of

intake air, now offers more 'pull' than the small opening in the RH rocker cover and the flow of ventilation reverses,

drawing gases from the LH rocker cover into the throttle body for subsequent burning in the combustion chambers.

Page 379 of 1672

EMISSION CONTROL - V8

17-2-42 DESCRIPTION AND OPERATION

Secondary air injection system

When the engine is started, the engine control module checks the engine coolant temperature and if it is below 55°

C, the ECM grounds the electrical connection to the coil of the secondary air injection (SAI) pump relay.

A 12V battery supply is fed to the inertia switch via fuse 13 in the engine compartment fusebox. When the inertia

switch contacts are closed, the feed passes through the switch and is connected to the coil of the Main relay. An earth

connection from the Main relay coil is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the Main relay.

The Main and Secondary Air Injection (SAI) pump relays are located in the engine compartment fusebox. When the

contacts of the Main relay are closed, a 12V battery supply is fed to the coil of the SAI pump relay. An earth connection

from the coil of the SAI pump relay is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the SAI pump relay to supply 12V to the SAI pump via fusible link 2 in the engine

compartment fusebox. The SAI pump starts to operate, and will continue to do so until the ECM switches off the earth

connection to the coil of the SAI pump relay.

The SAI pump remains operational for a period determined by the ECM and depends on the starting temperature of

the engine, or for a maximum operation period determined by the ECM if the target engine coolant temperature has

not been reached in the usual time.

When the contacts of the main relay are closed, a 12V battery supply is fed to the SAI solenoid valve via Fuse 2 in

the engine compartment fusebox.

The ECM grounds the electrical connection to the SAI vacuum solenoid valve at the same time as it switches on the

SAI pump motor. When the SAI vacuum solenoid valve is energised, a vacuum is provided to the operation control

ports on both of the vacuum operated SAI control valves at the exhaust manifolds. The control vacuum is sourced

from the intake manifold depression and routed to the SAI control valves via a vacuum reservoir and the SAI vacuum

solenoid valve.

The vacuum reservoir is included in the vacuum supply circuit to prevent vacuum fluctuations caused by changes in

the intake manifold depression affecting the operation of the SAI control valves.

When a vacuum is applied to the control ports of the SAI control valves, the valves open to allow pressurised air from

the SAI pump to pass through to the exhaust ports in the cylinder heads for combustion.

When the ECM has determined that the SAI pump has operated for the desired duration, it switches off the earth paths

to the SAI pump relay and the SAI vacuum solenoid valve. With the SAI vacuum solenoid valve de-energised, the

valve closes, cutting off the vacuum supply to the SAI control valves. The SAI control valves close immediately and

completely to prevent any further pressurised air from the SAI pump entering the exhaust manifolds.

The engine coolant temperature sensor incurs a time lag in respect of detecting a change in temperature and the SAI

pump automatically enters a 'soak period' between operations to prevent the SAI pump overheating. The ECM also

compares the switch off and start up temperatures, to determine whether it is necessary to operate the SAI pump.

This prevents the pump running repeatedly and overheating on repeat starts.

Other factors which may prevent or stop SAI pump operation include the prevailing engine speed / load conditions.

Page 424 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-31

The purpose of the glow plugs is:

lAssist cold engine start.

lReduce exhaust emissions at low engine load/speed.

The main part of the glow plug is a tubular heating element that protrudes into the combustion chamber of the engine.

The heating element contains a spiral filament that is encased in magnesium oxide powder. At the tip of the tubular

heating element is the heater coil. Behind the heater coil and connected in series is a control coil. The control coil

regulates the heater coil to ensure that it does not overheat and cause a possible failure. The glow plug circuit has its

own control relay located in the engine compartment fuse box.

Pre-heat is the length of time the glow plugs operate prior to engine cranking. The ECM controls the pre-heat time of

the glow plugs based on battery voltage and coolant temperature information via the glow plug relay.

Post-heat is the length of time the glow plugs operate after the engine starts. The ECM controls the post-heat time

based on ECT information. If the ECT fails the ECM will operate pre/post-heat time strategies with default values from

its memory. The engine will be difficult to start.

Input/Output

The glow plugs receive voltage from the glow plug relay that is controlled by the ECM. The ECM provides the earth

path for the relay coil closing the relay contacts and supplying the glow plugs with battery voltage. The supply voltage

heats the coils to approximately 1000

°C (1832 °F). The glow plug circuit is wired in parallel, the body of each glow

plug is screwed directly into the engine block which provides each glow plug with an earth path.

The glow plugs can fail in the following ways:

lHeater coil open circuit.

lControl coil open circuit.

lPoor earth quality.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lWiring loom fault.

lRelay windings open circuit.

lIncorrect relay fitted.

In the event of a glow plug failure any of the following symptoms may be observed:

lDifficult starting.

lExcessive smoke emissions after engine start.

Page 426 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-33

The turbocharger is exposed to extremely high operating temperatures (up to 1,000 °C (1832 °F)) because of the hot

exhaust gases and the high speed revolution of the turbine (up to 150,000 rev/min). In order to resist wear of the

turbine bearings a flow of lubrication oil is supplied from the engine lubrication system to keep the bearings cool. Oil

is supplied from a tapping at the front of the full-flow filter adaptor housing via a metal pipe with banjo connections.

Oil is returned to the sump via a metal pipe which connects to the cylinder block at a port below the turbocharger

assembly.

A heatshield is attached to the left hand side of the engine to protect adjacent components from the heat generated

at the turbocharger. The heatshield is attached to the engine by two bolts an additional bolt attaches the heatshield

to the turbocharger casting.

The engine control module controls the amount of boost pressure the engine receives by way of the turbocharger.

When full boost is reached a control signal is sent to the wastegate modulator, and a vacuum is applied to the

wastegate valve. The wastegate valve opens, bypassing some of the exhaust gas away from the turbine to be output

to the exhaust system.

The engine should be allowed to idle for 15 seconds following engine start up and before the engine is switched off

to protect the turbocharger by maintaining oil supply to the turbine bearings.

Intercooler

The intercooler is an air-to-air heat exchanger which lowers the intake air temperature to obtain a higher air density

for better combustion efficiency. The intercooler receives compressed air from the turbocharger via a metal pipe; it

cools the intake air via the intercooler matrix and delivers it to the intake manifold by means of a rubber hose which

connects between the intercooler outlet and the intake manifold outlet. The rubber hose is connected to ports at each

end by metal band clips.

+ COOLING SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

The intercooler is located at the front of the engine bay, forward of the radiator.

Page 448 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-55

Turbocharger

$% 19.42.01

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Release fixings and remove battery cover.

3.Disconnect battery earth lead.

4.Remove cooling fan cover.

5.Remove 3 bolts and remove exhaust manifold

heat shield.

6.Release clip and disconnect breather hose

from camshaft cover.

7.Release clip and disconnect vacuum hose from

turbocharger wastegate.

8.Loosen clips and release air intake and outlet

hoses from turbocharger. 9.Remove turbocharger oil feed banjo bolt and

discard sealing washers.

10.Remove 2 bolts and release turbocharger oil

drain pipe and discard gasket.

11.Remove 3 nuts and release exhaust front pipe

from turbocharger and discard gasket.

12.Remove 3 nuts securing turbocharger to

exhaust manifold.

13. Remove turbocharger and discard gasket.

Refit

1.Clean turbocharger and exhaust manifold

mating faces.

2.Using a new gasket, fit turbocharger to exhaust

manifold and tighten nuts to 30 Nm (22 lbf.ft).

3.Using new gasket, align exhaust front pipe and

tighten nuts to 30 Nm (22 lbf.ft).

4.Using new gasket, align turbocharger drain

pipe and tighten bolts to 9 Nm (7 lbf.ft).

5.Fit banjo bolt to oil feed pipe using new sealing

washers and tighten to 25 Nm (18 lbf.ft)..

6.Position air hoses to turbocharger and tighten

clips.

7.Position and secure breather hose to camshaft

cover.

8.Position and secure vacuum hose to

turbocharger wastegate.

9.Position exhaust manifold heat shield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolt to

25 Nm (18 lbf.ft).

10.Fit fan cowl and secure fixings.

11.Fit acoustic cover and secure the fixings.

12.Connect battery earth lead.

13.Fit battery cover and secure fixings.