oil LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 308 of 1672

ENGINE - V8

OVERHAUL 12-2-65

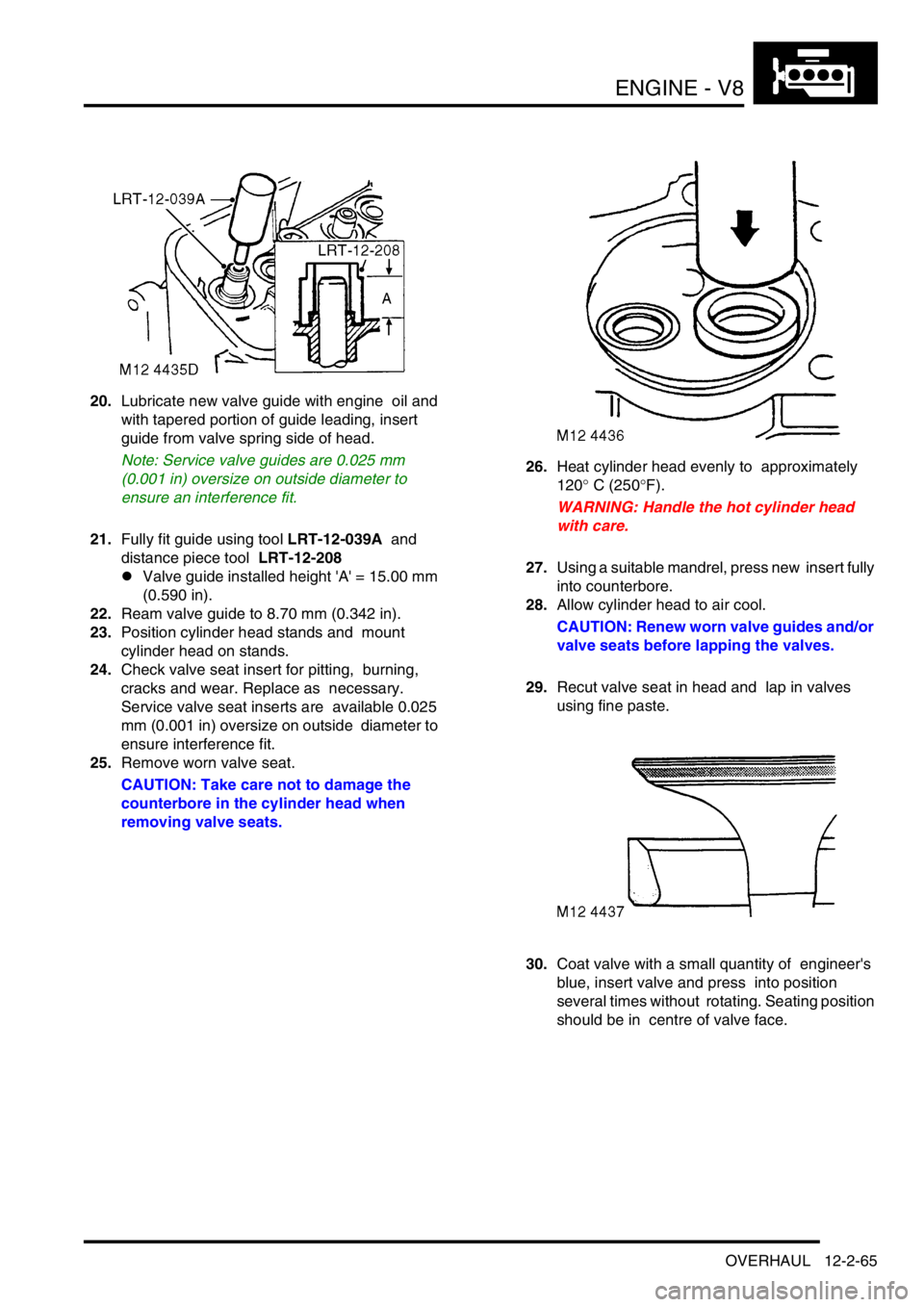

20.Lubricate new valve guide with engine oil and

with tapered portion of guide leading, insert

guide from valve spring side of head.

Note: Service valve guides are 0.025 mm

(0.001 in) oversize on outside diameter to

ensure an interference fit.

21.Fully fit guide using tool LRT-12-039A and

distance piece tool LRT-12-208

lValve guide installed height 'A' = 15.00 mm

(0.590 in).

22.Ream valve guide to 8.70 mm (0.342 in).

23.Position cylinder head stands and mount

cylinder head on stands.

24.Check valve seat insert for pitting, burning,

cracks and wear. Replace as necessary.

Service valve seat inserts are available 0.025

mm (0.001 in) oversize on outside diameter to

ensure interference fit.

25.Remove worn valve seat.

CAUTION: Take care not to damage the

counterbore in the cylinder head when

removing valve seats.26.Heat cylinder head evenly to approximately

120

° C (250°F).

WARNING: Handle the hot cylinder head

with care.

27.Using a suitable mandrel, press new insert fully

into counterbore.

28.Allow cylinder head to air cool.

CAUTION: Renew worn valve guides and/or

valve seats before lapping the valves.

29.Recut valve seat in head and lap in valves

using fine paste.

30.Coat valve with a small quantity of engineer's

blue, insert valve and press into position

several times without rotating. Seating position

should be in centre of valve face.

Page 309 of 1672

ENGINE - V8

12-2-66 OVERHAUL

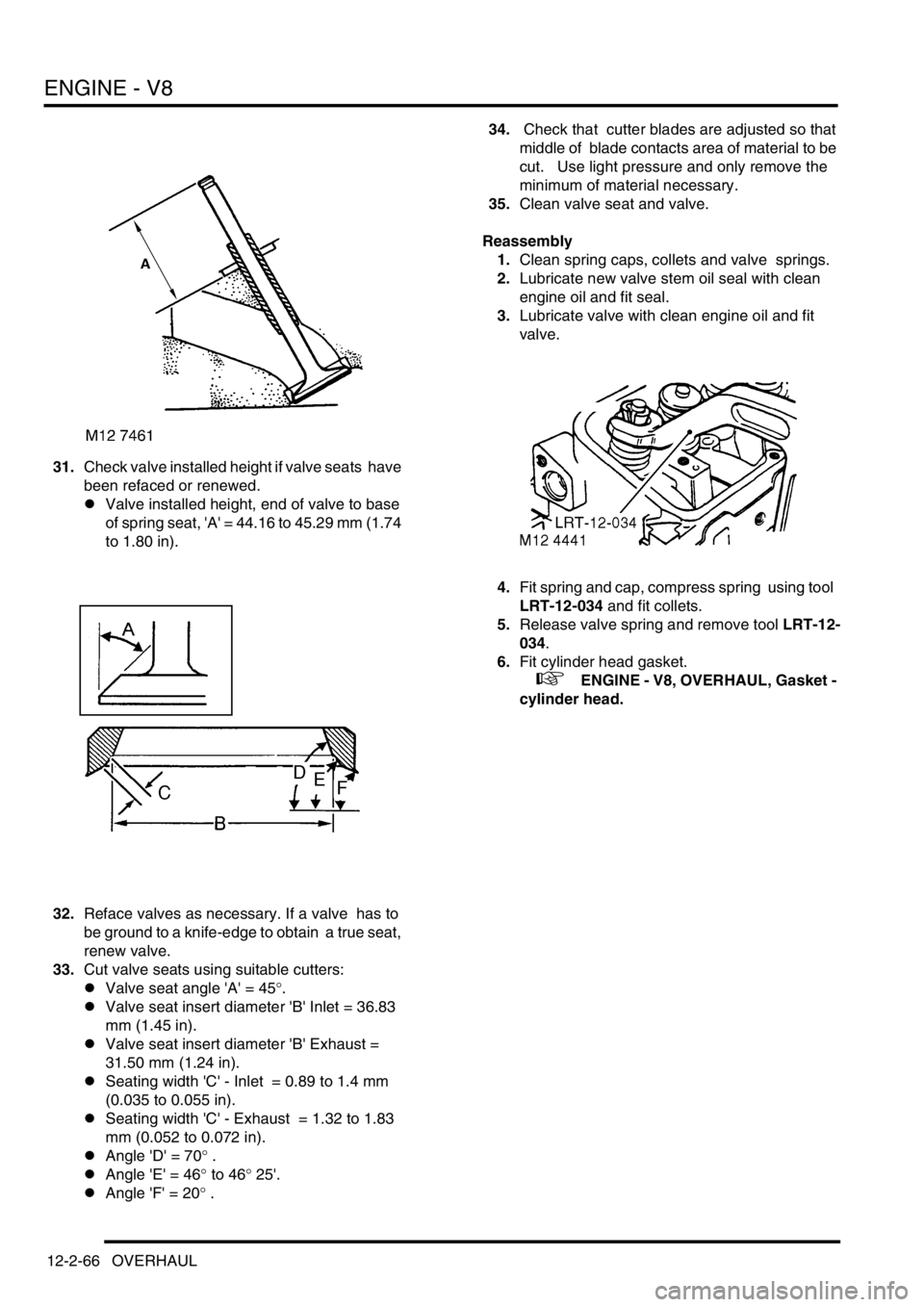

31.Check valve installed height if valve seats have

been refaced or renewed.

lValve installed height, end of valve to base

of spring seat, 'A' = 44.16 to 45.29 mm (1.74

to 1.80 in).

32.Reface valves as necessary. If a valve has to

be ground to a knife-edge to obtain a true seat,

renew valve.

33.Cut valve seats using suitable cutters:

lValve seat angle 'A' = 45

°.

lValve seat insert diameter 'B' Inlet = 36.83

mm (1.45 in).

lValve seat insert diameter 'B' Exhaust =

31.50 mm (1.24 in).

lSeating width 'C' - Inlet = 0.89 to 1.4 mm

(0.035 to 0.055 in).

lSeating width 'C' - Exhaust = 1.32 to 1.83

mm (0.052 to 0.072 in).

lAngle 'D' = 70

° .

lAngle 'E' = 46

° to 46° 25'.

lAngle 'F' = 20

° .34. Check that cutter blades are adjusted so that

middle of blade contacts area of material to be

cut. Use light pressure and only remove the

minimum of material necessary.

35.Clean valve seat and valve.

Reassembly

1.Clean spring caps, collets and valve springs.

2.Lubricate new valve stem oil seal with clean

engine oil and fit seal.

3.Lubricate valve with clean engine oil and fit

valve.

4.Fit spring and cap, compress spring using tool

LRT-12-034 and fit collets.

5.Release valve spring and remove tool LRT-12-

034.

6.Fit cylinder head gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

cylinder head.

Page 310 of 1672

ENGINE - V8

OVERHAUL 12-2-67

Piston assemblies

$% 12.17.02.01

Disassembly

1.Remove cylinder head.

+ ENGINE - V8, OVERHAUL, Gasket -

cylinder head.

2.Remove oil pick-up strainer

+ ENGINE - V8, OVERHAUL, Strainer

- oil pick-up.

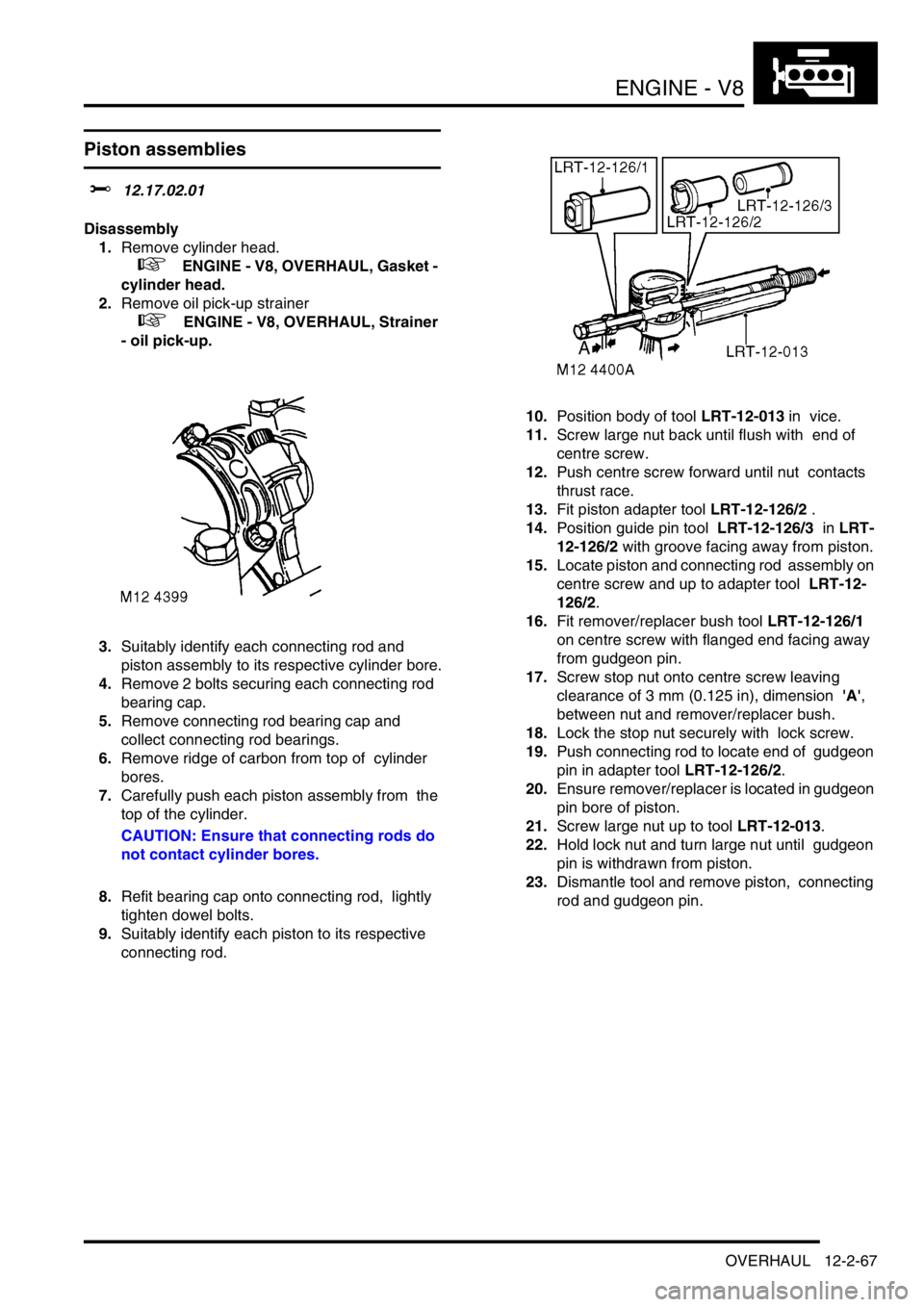

3.Suitably identify each connecting rod and

piston assembly to its respective cylinder bore.

4.Remove 2 bolts securing each connecting rod

bearing cap.

5.Remove connecting rod bearing cap and

collect connecting rod bearings.

6.Remove ridge of carbon from top of cylinder

bores.

7.Carefully push each piston assembly from the

top of the cylinder.

CAUTION: Ensure that connecting rods do

not contact cylinder bores.

8.Refit bearing cap onto connecting rod, lightly

tighten dowel bolts.

9.Suitably identify each piston to its respective

connecting rod.10.Position body of tool LRT-12-013 in vice.

11.Screw large nut back until flush with end of

centre screw.

12.Push centre screw forward until nut contacts

thrust race.

13.Fit piston adapter tool LRT-12-126/2 .

14.Position guide pin tool LRT-12-126/3 in LRT-

12-126/2 with groove facing away from piston.

15.Locate piston and connecting rod assembly on

centre screw and up to adapter tool LRT-12-

126/2.

16.Fit remover/replacer bush tool LRT-12-126/1

on centre screw with flanged end facing away

from gudgeon pin.

17.Screw stop nut onto centre screw leaving

clearance of 3 mm (0.125 in), dimension 'A',

between nut and remover/replacer bush.

18.Lock the stop nut securely with lock screw.

19.Push connecting rod to locate end of gudgeon

pin in adapter tool LRT-12-126/2.

20.Ensure remover/replacer is located in gudgeon

pin bore of piston.

21.Screw large nut up to tool LRT-12-013.

22.Hold lock nut and turn large nut until gudgeon

pin is withdrawn from piston.

23.Dismantle tool and remove piston, connecting

rod and gudgeon pin.

Page 312 of 1672

ENGINE - V8

OVERHAUL 12-2-69

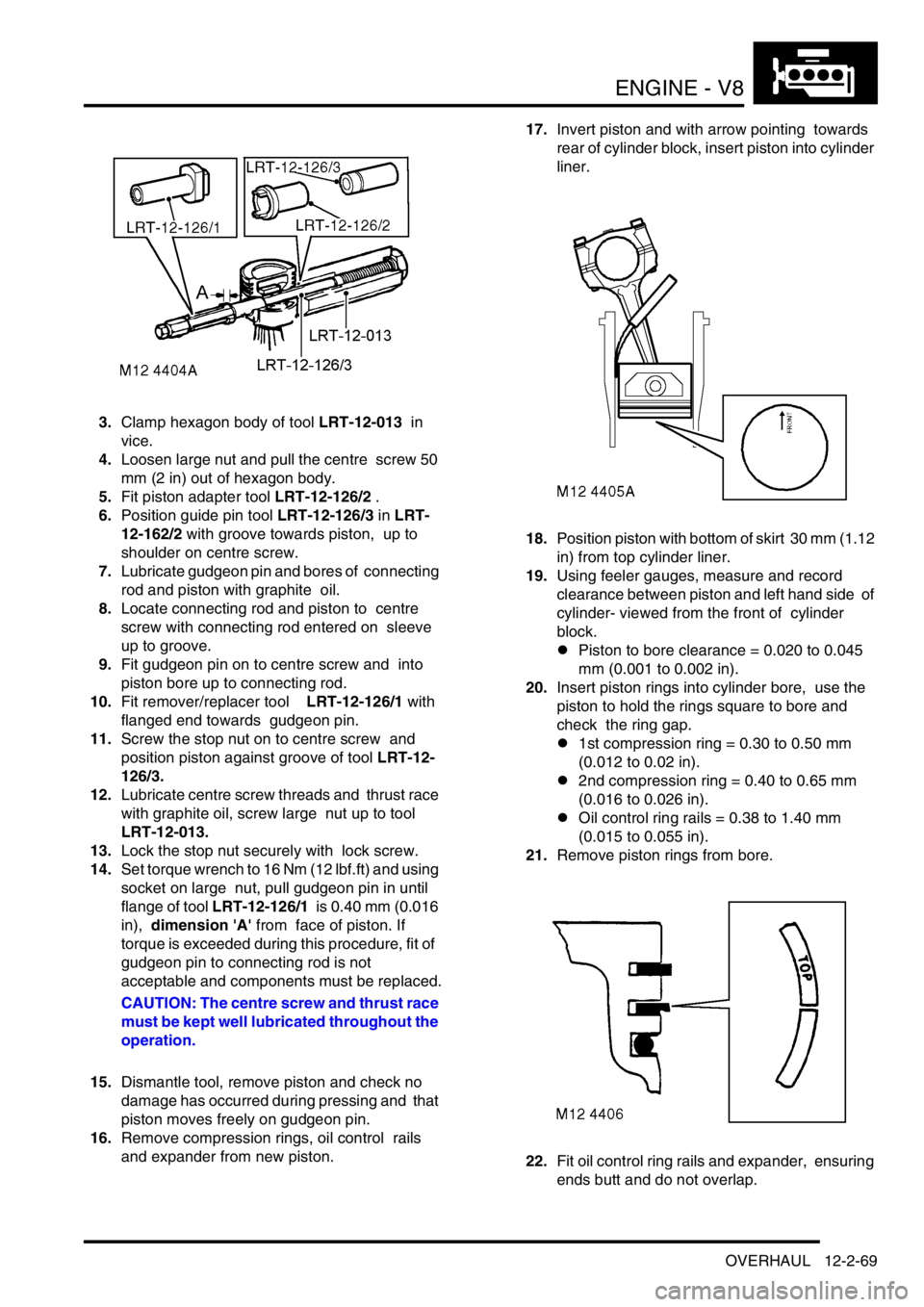

3.Clamp hexagon body of tool LRT-12-013 in

vice.

4.Loosen large nut and pull the centre screw 50

mm (2 in) out of hexagon body.

5.Fit piston adapter tool LRT-12-126/2 .

6.Position guide pin tool LRT-12-126/3 in LRT-

12-162/2 with groove towards piston, up to

shoulder on centre screw.

7.Lubricate gudgeon pin and bores of connecting

rod and piston with graphite oil.

8.Locate connecting rod and piston to centre

screw with connecting rod entered on sleeve

up to groove.

9.Fit gudgeon pin on to centre screw and into

piston bore up to connecting rod.

10.Fit remover/replacer tool LRT-12-126/1 with

flanged end towards gudgeon pin.

11.Screw the stop nut on to centre screw and

position piston against groove of tool LRT-12-

126/3.

12.Lubricate centre screw threads and thrust race

with graphite oil, screw large nut up to tool

LRT-12-013.

13.Lock the stop nut securely with lock screw.

14.Set torque wrench to 16 Nm (12 lbf.ft) and using

socket on large nut, pull gudgeon pin in until

flange of tool LRT-12-126/1 is 0.40 mm (0.016

in), dimension 'A' from face of piston. If

torque is exceeded during this procedure, fit of

gudgeon pin to connecting rod is not

acceptable and components must be replaced.

CAUTION: The centre screw and thrust race

must be kept well lubricated throughout the

operation.

15.Dismantle tool, remove piston and check no

damage has occurred during pressing and that

piston moves freely on gudgeon pin.

16.Remove compression rings, oil control rails

and expander from new piston. 17.Invert piston and with arrow pointing towards

rear of cylinder block, insert piston into cylinder

liner.

18.Position piston with bottom of skirt 30 mm (1.12

in) from top cylinder liner.

19.Using feeler gauges, measure and record

clearance between piston and left hand side of

cylinder- viewed from the front of cylinder

block.

lPiston to bore clearance = 0.020 to 0.045

mm (0.001 to 0.002 in).

20.Insert piston rings into cylinder bore, use the

piston to hold the rings square to bore and

check the ring gap.

l1st compression ring = 0.30 to 0.50 mm

(0.012 to 0.02 in).

l2nd compression ring = 0.40 to 0.65 mm

(0.016 to 0.026 in).

lOil control ring rails = 0.38 to 1.40 mm

(0.015 to 0.055 in).

21.Remove piston rings from bore.

22.Fit oil control ring rails and expander, ensuring

ends butt and do not overlap.

Page 313 of 1672

ENGINE - V8

12-2-70 OVERHAUL

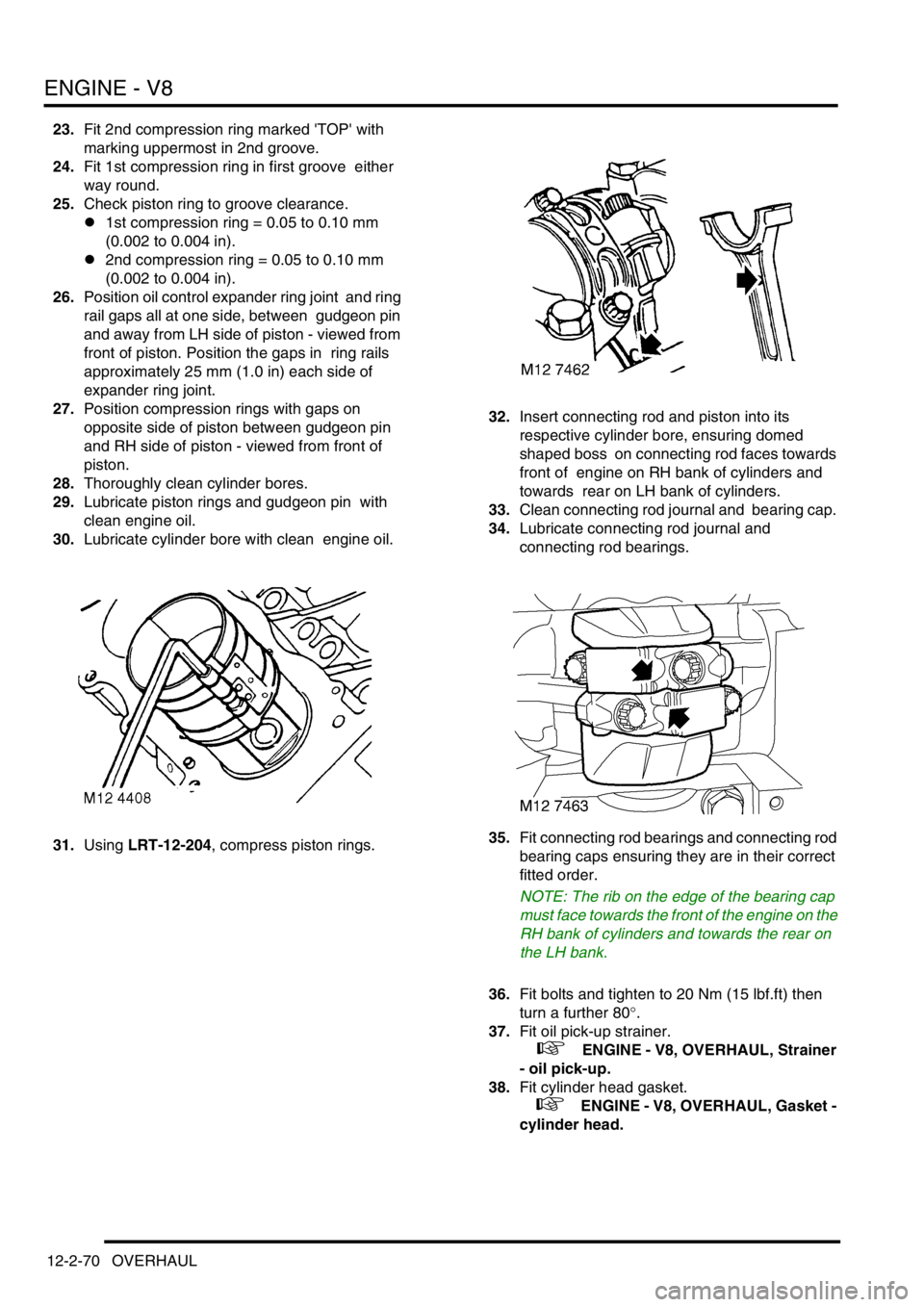

23.Fit 2nd compression ring marked 'TOP' with

marking uppermost in 2nd groove.

24.Fit 1st compression ring in first groove either

way round.

25.Check piston ring to groove clearance.

l1st compression ring = 0.05 to 0.10 mm

(0.002 to 0.004 in).

l2nd compression ring = 0.05 to 0.10 mm

(0.002 to 0.004 in).

26.Position oil control expander ring joint and ring

rail gaps all at one side, between gudgeon pin

and away from LH side of piston - viewed from

front of piston. Position the gaps in ring rails

approximately 25 mm (1.0 in) each side of

expander ring joint.

27.Position compression rings with gaps on

opposite side of piston between gudgeon pin

and RH side of piston - viewed from front of

piston.

28.Thoroughly clean cylinder bores.

29.Lubricate piston rings and gudgeon pin with

clean engine oil.

30.Lubricate cylinder bore with clean engine oil.

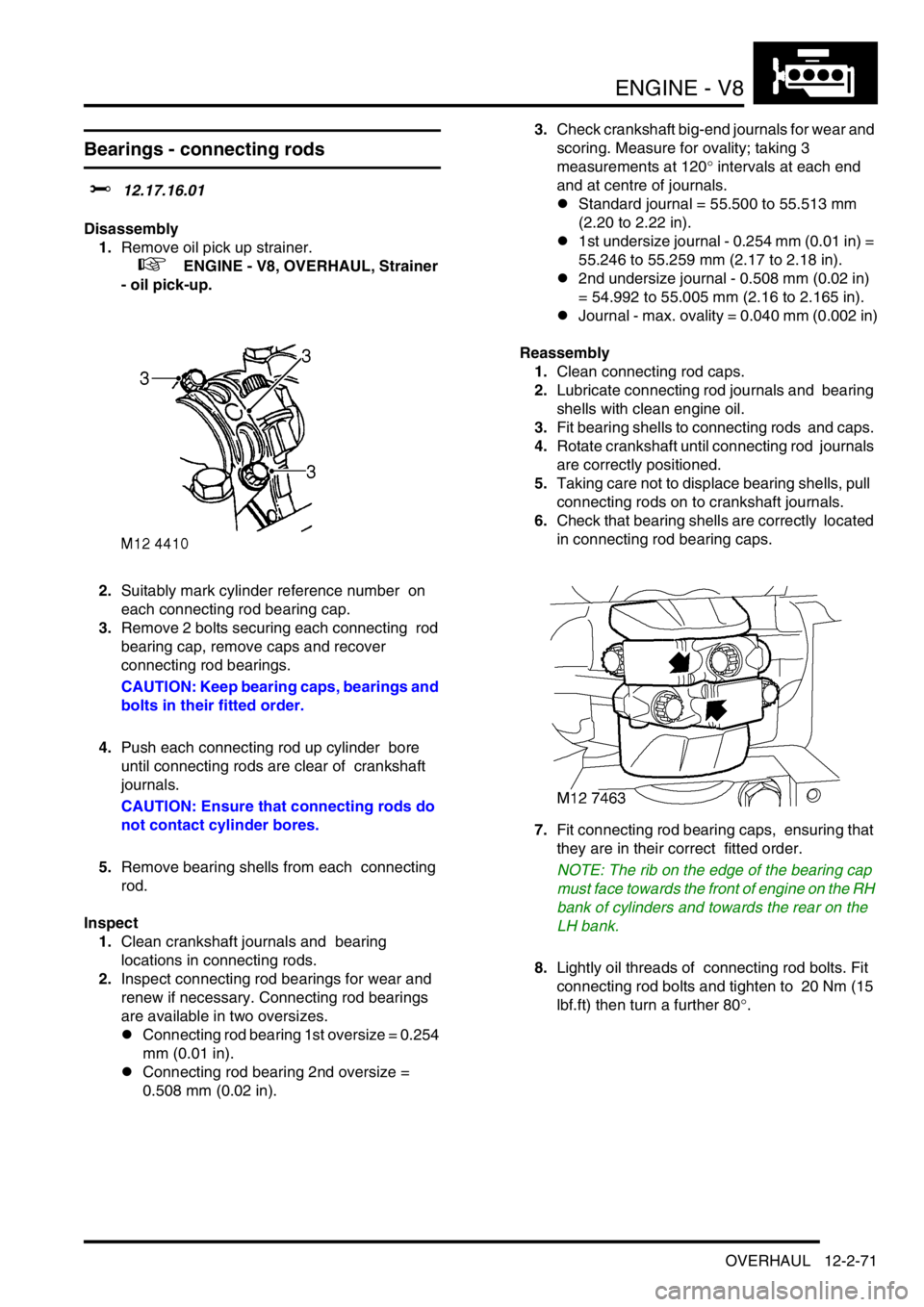

31.Using LRT-12-204, compress piston rings. 32.Insert connecting rod and piston into its

respective cylinder bore, ensuring domed

shaped boss on connecting rod faces towards

front of engine on RH bank of cylinders and

towards rear on LH bank of cylinders.

33.Clean connecting rod journal and bearing cap.

34.Lubricate connecting rod journal and

connecting rod bearings.

35.Fit connecting rod bearings and connecting rod

bearing caps ensuring they are in their correct

fitted order.

NOTE: The rib on the edge of the bearing cap

must face towards the front of the engine on the

RH bank of cylinders and towards the rear on

the LH bank.

36.Fit bolts and tighten to 20 Nm (15 lbf.ft) then

turn a further 80

°.

37.Fit oil pick-up strainer.

+ ENGINE - V8, OVERHAUL, Strainer

- oil pick-up.

38.Fit cylinder head gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

cylinder head.

Page 314 of 1672

ENGINE - V8

OVERHAUL 12-2-71

Bearings - connecting rods

$% 12.17.16.01

Disassembly

1.Remove oil pick up strainer.

+ ENGINE - V8, OVERHAUL, Strainer

- oil pick-up.

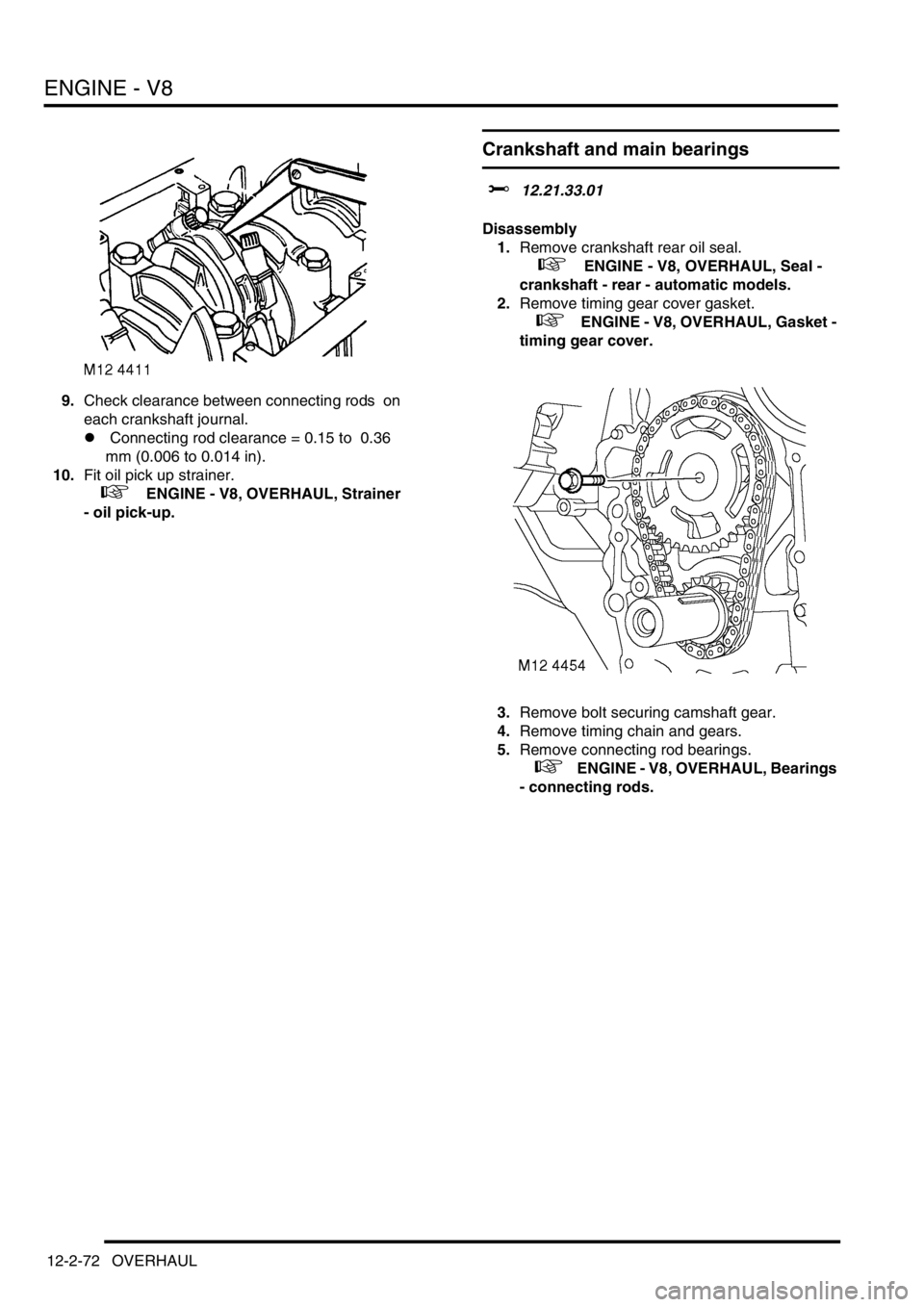

2.Suitably mark cylinder reference number on

each connecting rod bearing cap.

3.Remove 2 bolts securing each connecting rod

bearing cap, remove caps and recover

connecting rod bearings.

CAUTION: Keep bearing caps, bearings and

bolts in their fitted order.

4.Push each connecting rod up cylinder bore

until connecting rods are clear of crankshaft

journals.

CAUTION: Ensure that connecting rods do

not contact cylinder bores.

5.Remove bearing shells from each connecting

rod.

Inspect

1.Clean crankshaft journals and bearing

locations in connecting rods.

2.Inspect connecting rod bearings for wear and

renew if necessary. Connecting rod bearings

are available in two oversizes.

lConnecting rod bearing 1st oversize = 0.254

mm (0.01 in).

lConnecting rod bearing 2nd oversize =

0.508 mm (0.02 in).3.Check crankshaft big-end journals for wear and

scoring. Measure for ovality; taking 3

measurements at 120

° intervals at each end

and at centre of journals.

lStandard journal = 55.500 to 55.513 mm

(2.20 to 2.22 in).

l1st undersize journal - 0.254 mm (0.01 in) =

55.246 to 55.259 mm (2.17 to 2.18 in).

l2nd undersize journal - 0.508 mm (0.02 in)

= 54.992 to 55.005 mm (2.16 to 2.165 in).

lJournal - max. ovality = 0.040 mm (0.002 in)

Reassembly

1.Clean connecting rod caps.

2.Lubricate connecting rod journals and bearing

shells with clean engine oil.

3.Fit bearing shells to connecting rods and caps.

4.Rotate crankshaft until connecting rod journals

are correctly positioned.

5.Taking care not to displace bearing shells, pull

connecting rods on to crankshaft journals.

6.Check that bearing shells are correctly located

in connecting rod bearing caps.

7.Fit connecting rod bearing caps, ensuring that

they are in their correct fitted order.

NOTE: The rib on the edge of the bearing cap

must face towards the front of engine on the RH

bank of cylinders and towards the rear on the

LH bank.

8.Lightly oil threads of connecting rod bolts. Fit

connecting rod bolts and tighten to 20 Nm (15

lbf.ft) then turn a further 80

°.

Page 315 of 1672

ENGINE - V8

12-2-72 OVERHAUL

9.Check clearance between connecting rods on

each crankshaft journal.

l Connecting rod clearance = 0.15 to 0.36

mm (0.006 to 0.014 in).

10.Fit oil pick up strainer.

+ ENGINE - V8, OVERHAUL, Strainer

- oil pick-up.

Crankshaft and main bearings

$% 12.21.33.01

Disassembly

1.Remove crankshaft rear oil seal.

+ ENGINE - V8, OVERHAUL, Seal -

crankshaft - rear - automatic models.

2.Remove timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

3.Remove bolt securing camshaft gear.

4.Remove timing chain and gears.

5.Remove connecting rod bearings.

+ ENGINE - V8, OVERHAUL, Bearings

- connecting rods.

Page 317 of 1672

ENGINE - V8

12-2-74 OVERHAUL

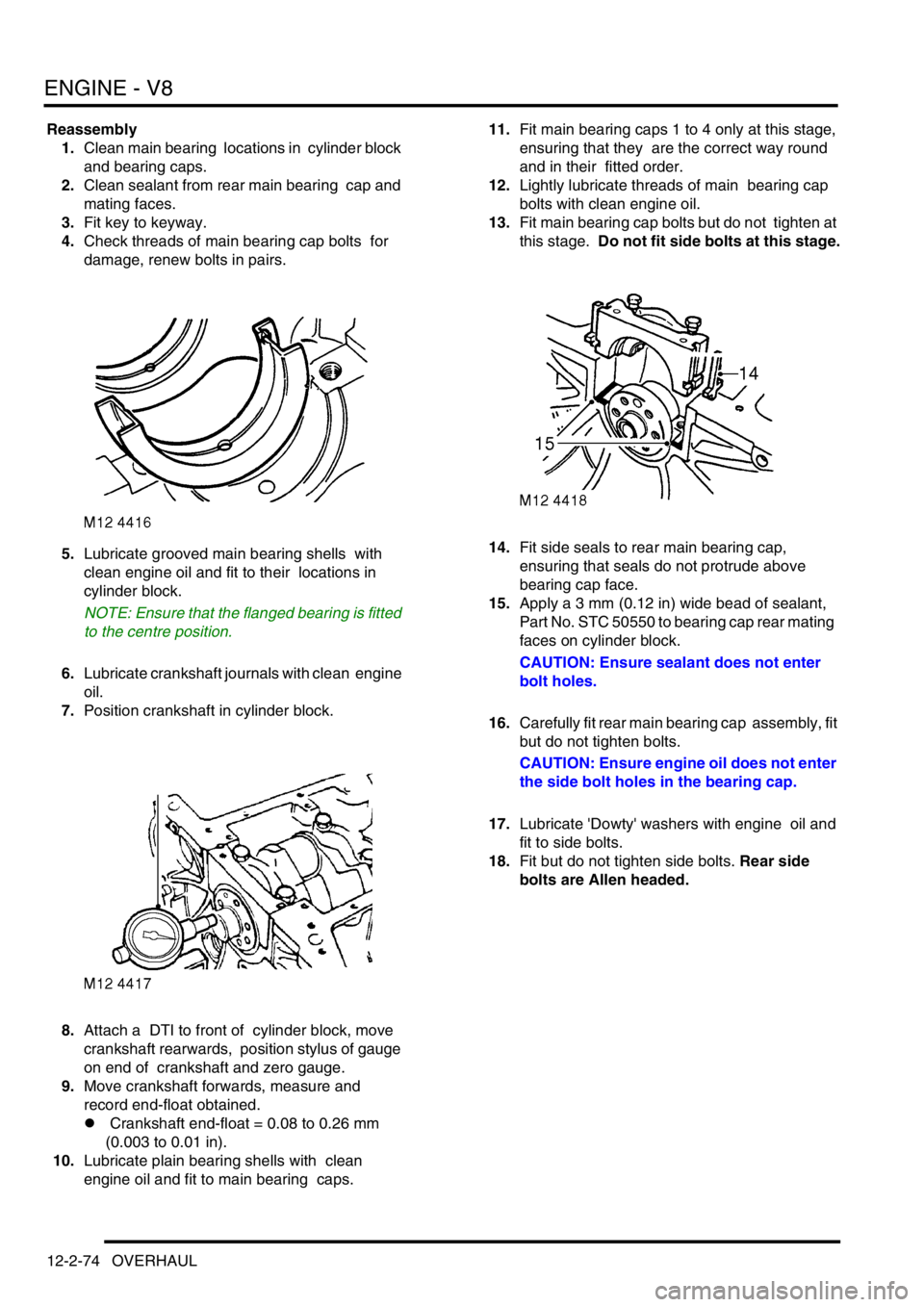

Reassembly

1.Clean main bearing locations in cylinder block

and bearing caps.

2.Clean sealant from rear main bearing cap and

mating faces.

3.Fit key to keyway.

4.Check threads of main bearing cap bolts for

damage, renew bolts in pairs.

5.Lubricate grooved main bearing shells with

clean engine oil and fit to their locations in

cylinder block.

NOTE: Ensure that the flanged bearing is fitted

to the centre position.

6.Lubricate crankshaft journals with clean engine

oil.

7.Position crankshaft in cylinder block.

8.Attach a DTI to front of cylinder block, move

crankshaft rearwards, position stylus of gauge

on end of crankshaft and zero gauge.

9.Move crankshaft forwards, measure and

record end-float obtained.

l Crankshaft end-float = 0.08 to 0.26 mm

(0.003 to 0.01 in).

10.Lubricate plain bearing shells with clean

engine oil and fit to main bearing caps. 11.Fit main bearing caps 1 to 4 only at this stage,

ensuring that they are the correct way round

and in their fitted order.

12.Lightly lubricate threads of main bearing cap

bolts with clean engine oil.

13.Fit main bearing cap bolts but do not tighten at

this stage. Do not fit side bolts at this stage.

14.Fit side seals to rear main bearing cap,

ensuring that seals do not protrude above

bearing cap face.

15.Apply a 3 mm (0.12 in) wide bead of sealant,

Part No. STC 50550 to bearing cap rear mating

faces on cylinder block.

CAUTION: Ensure sealant does not enter

bolt holes.

16.Carefully fit rear main bearing cap assembly, fit

but do not tighten bolts.

CAUTION: Ensure engine oil does not enter

the side bolt holes in the bearing cap.

17.Lubricate 'Dowty' washers with engine oil and

fit to side bolts.

18.Fit but do not tighten side bolts. Rear side

bolts are Allen headed.

Page 318 of 1672

ENGINE - V8

OVERHAUL 12-2-75

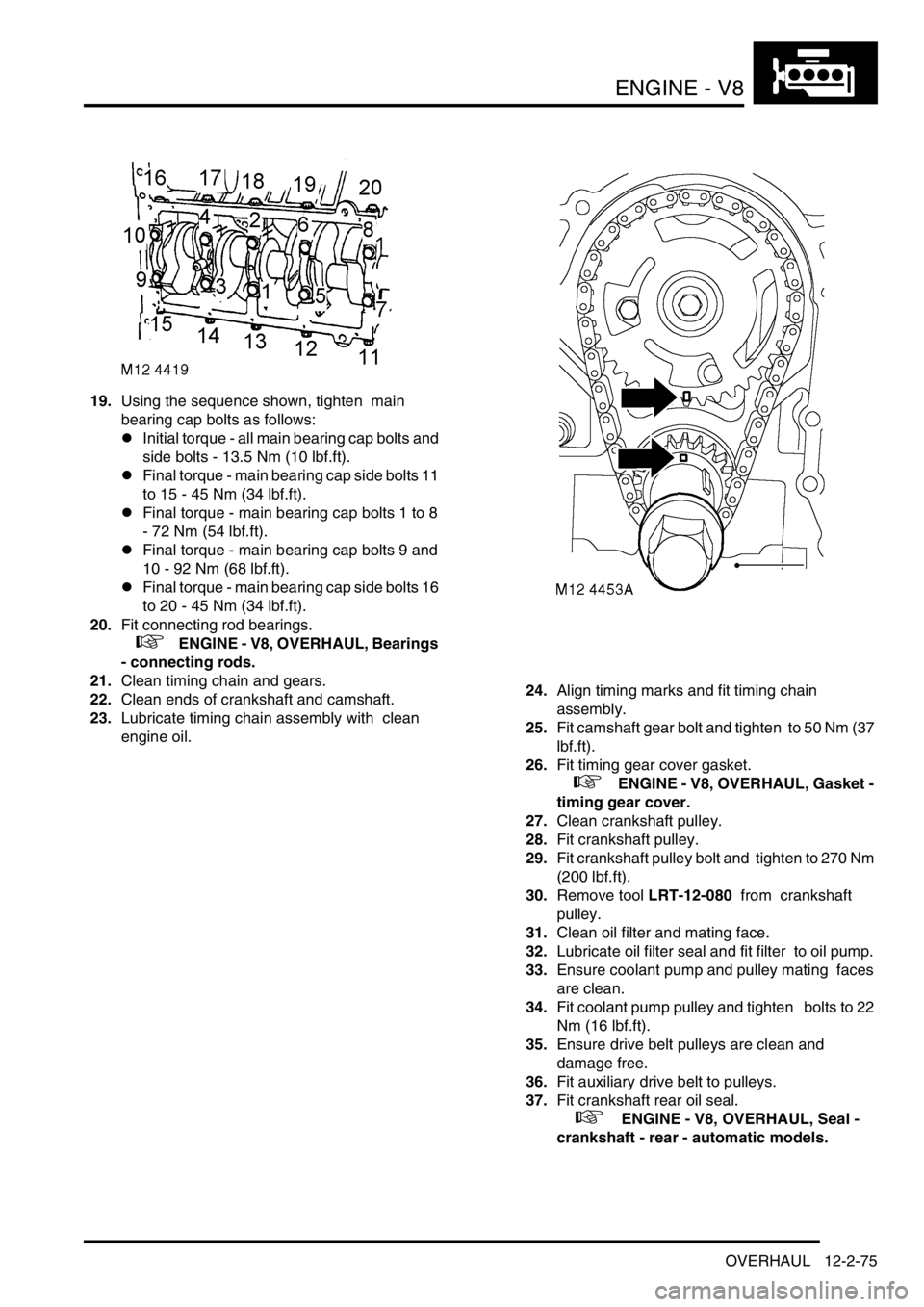

19.Using the sequence shown, tighten main

bearing cap bolts as follows:

lInitial torque - all main bearing cap bolts and

side bolts - 13.5 Nm (10 lbf.ft).

lFinal torque - main bearing cap side bolts 11

to 15 - 45 Nm (34 lbf.ft).

lFinal torque - main bearing cap bolts 1 to 8

- 72 Nm (54 lbf.ft).

lFinal torque - main bearing cap bolts 9 and

10 - 92 Nm (68 lbf.ft).

lFinal torque - main bearing cap side bolts 16

to 20 - 45 Nm (34 lbf.ft).

20.Fit connecting rod bearings.

+ ENGINE - V8, OVERHAUL, Bearings

- connecting rods.

21.Clean timing chain and gears.

22.Clean ends of crankshaft and camshaft.

23.Lubricate timing chain assembly with clean

engine oil. 24.Align timing marks and fit timing chain

assembly.

25.Fit camshaft gear bolt and tighten to 50 Nm (37

lbf.ft).

26.Fit timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

27.Clean crankshaft pulley.

28.Fit crankshaft pulley.

29.Fit crankshaft pulley bolt and tighten to 270 Nm

(200 lbf.ft).

30.Remove tool LRT-12-080 from crankshaft

pulley.

31.Clean oil filter and mating face.

32.Lubricate oil filter seal and fit filter to oil pump.

33.Ensure coolant pump and pulley mating faces

are clean.

34.Fit coolant pump pulley and tighten bolts to 22

Nm (16 lbf.ft).

35.Ensure drive belt pulleys are clean and

damage free.

36.Fit auxiliary drive belt to pulleys.

37.Fit crankshaft rear oil seal.

+ ENGINE - V8, OVERHAUL, Seal -

crankshaft - rear - automatic models.

Page 320 of 1672

ENGINE - V8

OVERHAUL 12-2-77

Reassembly

1.Clean camshaft bearings in block.

2.Clean camshaft.

3.Wipe camshaft bearing faces and lobes.

4.Clean thrust plate and mating face.

5.Lubricate camshaft bearings with clean engine

oil.

6.Fit camshaft, take care not to damage camshaft

bearings.

7.Lubricate thrust plate and mating face with

clean engine oil.

8.Position thrust plate, fit and tighten bolts to 22

Nm (17 lbf.ft).

9.Fit timing chain and gears.

+ ENGINE - V8, OVERHAUL, Timing

chain and gears.

10.Immerse tappets in engine oil. Before fitting,

pump the inner sleeve of tappet several times

using a push rod to prime the tappets.

11.Clean tappet bores.

12.Lubricate tappets and tappet bores with clean

engine oil.

13.Fit tappets.

14.Clean push rods.

15.Lubricate tappet end of push rods with clean

engine oil.

16.Fit push rods.

17.Clean bases of rocker pillars and mating faces.

18.Clean contact surfaces on rockers and valves.

19.Lubricate contact surfaces on rockers and

valves with clean engine oil.

20.Fit rocker shafts and engage push rods. Ensure

rockers shafts are fitted to the correct cylinder

head.

21.Fit and progressively tighten rocker shaft bolts

to 40 Nm (30 lbf.ft).

22.Fit inlet manifold gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

inlet manifold.