oil LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 251 of 1672

ENGINE - V8

12-2-8 DESCRIPTION AND OPERATION

Lubrication

A - To oil cooler, B - From oil cooler

NOTE: The oil cooler is only fitted to vehicles up to VIN 756821.

1Rocker shaft assembly

2Hydraulic tappet

3Oil pump

4Oil filter element

5Oil pick-up pipe and strainer

6Oil pressure switch

Oil is drawn from the sump through a strainer and into the oil pump via the oil pick-up pipe. Pressurised oil from the

pump passes through the oil cooler (if fitted) mounted in front of the radiator and returns to the full flow oil filter

Page 252 of 1672

ENGINE - V8

DESCRIPTION AND OPERATION 12-2-9

element. Oil from the filter passes into the main oil gallery and through internal drillings to the crankshaft where it is

directed to each main bearing and to the big-end bearings via numbers 1, 3 and 5 main bearings. An internal drilling

in the cylinder block directs oil to the camshaft where it passes through further internal drillings to the hydraulic

tappets, camshaft bearing journals and rocker shafts. Lubrication to the pistons, small ends and cylinder bores is by

oil grooves machined in the connecting rods and by splash.

Oil pressure switch

The oil pressure warning light switch registers low oil pressure in the main oil gallery on the outflow side of the filter.

Whilst the engine is running and oil pressure is correct, the switch is open. When the ignition is switched on or if oil

pressure drops below the pressure setting of the switch, the switch closes and the low oil pressure warning lamp

located in the instrument pack will illuminate.

Hydraulic tappets

1Clip

2Pushrod seat

3Inner sleeve

4Upper chamber5Non-return ball valve

6Spring

7Outer sleeve

8Lower chamber

The hydraulic tappet provides maintenance free, quiet operation of the valves. This is achieved by utilizing engine oil

pressure to eliminate the clearance between the rocker arms and valve stems. When the valve is closed, engine oil

pressure present in the upper chamber, passes through the non-return ball valve and into the lower chamber. When

the cam begins to lift the outer sleeve, the resistance of the valve spring, felt through the push rod and seat, causes

the tappet inner sleeve to move downwards inside the outer sleeve. This downwards movement closes the non-return

ball valve and increases the pressure in the lower chamber sufficiently to ensure that the valve is fully opened by the

push rod. As the tappet moves off the peak of the cam, the non-return ball valve opens thereby allowing the pressure

in both chambers to equalize. This ensures that the valve will be fully closed when the tappet is on the back of the

cam.

Crankcase ventilation

A positive crankcase ventilation system is used to vent crankcase gases to the air induction system. Gases are drawn

from the left hand rocker cover to a tapping in the throttle body. An oil separator is incorporated in the hose connection

stub pipe in the right hand rocker cover, gases from this connection are drawn to a tapping in the inlet manifold.

+ EMISSION CONTROL - V8, DESCRIPTION AND OPERATION, Crankcase emission control system.

Page 254 of 1672

ENGINE - V8

ADJUSTMENTS 12-2-11

ADJUST ME NTS

Engine oil pressure check

$% 12.90.09.01

Check

1.Remove oil pressure switch.

+ ENGINE - V8, REPAIRS, Switch - oil

pressure.

2.Connect pressure check kit LRT-12-052C

adaptor and gauge to oil pressure switch

position on timing gear cover.

3.Check and if necessary top up engine oil.

4.Run engine at idle speed and check that oil

pressure is within limits given.

+ GENERAL DATA, Engine - V8.

5.Switch off ignition.

6.Remove pressure check kit LRT-12-052C.

7.Clean oil spillage.

8.Fit oil pressure switch.

+ ENGINE - V8, REPAIRS, Switch - oil

pressure.

Adjust

1.If engine oil pressure is below figures given,

check condition of oil pump and/or main and

big end bearings.

Page 256 of 1672

ENGINE - V8

REPAIRS 12-2-13

REPAIRS

Seal - crankshaft - rear

$% 12.21.20

Remove

1. Automatic gearbox models:Remove

converter drive plate.

+ ENGINE - V8, REPAIRS, Plate - drive

- automatic.

2. Manual gearbox models:Remove flywheel.

+ ENGINE - V8, REPAIRS, Flywheel.

3.Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft. Discard seal.

Refit

1.Ensure both seal location and running surface

on crankshaft are clean. 2.Fit seal guide LRT-12-095 to crankshaft.

CAUTION: Oil seal must be fitted dry.

3.Fit new oil seal squarely onto crankshaft and

remove guide.

4.Fit seal into location using tools LRT-12-091

and LRT-99-003.

5. Automatic gearbox models:Fit converter

drive plate.

+ ENGINE - V8, REPAIRS, Plate - drive

- automatic.

6. Manual gearbox models:Fit flywheel.

+ ENGINE - V8, REPAIRS, Flywheel.

Page 258 of 1672

ENGINE - V8

REPAIRS 12-2-15

10.Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

11.Remove cylinder head gasket.

Refit

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry. Clean mating faces of

cylinder head and exhaust manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Check head and block faces for warping and

pitting. If out of specification, renew head.

3.Fit cylinder head gasket with the word 'TOP'

uppermost.

CAUTION: Gaskets must be fitted dry.

4.Carefully fit cylinder head and locate on

dowels.

5.Lightly lubricate new cylinder head bolt threads

with clean engine oil. 6.Noting that bolts 1, 3 and 5 are longer than the

remainder, fit cylinder head bolts and tighten in

the sequence shown to 20 Nm (15 lbf.ft) then

90

° , and finally a further 90° .

CAUTION: Do not tighten bolts 180

° in one

operation.

7. Models with SAI: Fit new air injection adapters

and tighten to 33 Nm (24 lbf.ft).

8.Clean push rods.

9.Lubricate ends of push rods with clean engine

oil.

10.Fit push rods in their removed order.

11.Clean bases of rocker pillars and mating faces

on cylinder head.

12.Clean contact surfaces on rockers, valves and

push rods.

13.Lubricate contact surfaces and rocker shaft

with clean engine oil.

14.Fit rocker shaft assembly and engage push

rods.

15.Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft).

16.Using new gaskets, position exhaust manifold

to cylinder head, fit bolts and using sequence

shown, tighten initially to 15 Nm (11 lbf.ft), then

finally to 36 Nm (28 lbf.ft).

Page 261 of 1672

ENGINE - V8

12-2-18 REPAIRS

Refit

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry. Clean mating faces of

cylinder head and exhaust manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Check head and block faces for warping and

pitting. If out of specification, renew head.

3.Fit cylinder head gasket with the word 'TOP'

uppermost.

CAUTION: Gaskets must be fitted dry.

4.Carefully fit cylinder head and locate on

dowels.

5.Lightly lubricate new cylinder head bolt threads

with clean engine oil.

6.Noting that bolts 1, 3 and 5 are longer than the

remainder, fit bolts and tighten in the sequence

shown to 20 Nm (15 lbf.ft) then 90

°, and finally

a further 90

°.

CAUTION: Do not tighten bolts 180

° in one

operation.

7. Models with SAI: Fit new air injection adapters

and tighten to 33 Nm (24 lbf.ft).

8.Clean push rods.

9.Lubricate ends of push rods with clean engine

oil.

10.Fit push rods in their removed order.

11.Clean bases of rocker pillars and mating faces

on cylinder head.

12.Clean contact surfaces on rockers, valves and

push rods.

13.Lubricate contact surfaces and rocker shaft

with clean engine oil.

14.Fit rocker shaft assembly and engage push

rods.

15.Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft). 16.Position alternator mounting bracket, fit bolts

and tighten to 40 Nm (30 lbf.ft).

17.Position auxiliary drive belt tensioner, fit bolt

and tighten to 45 Nm (33 lbf.ft).

18.Connect ht leads to spark plugs in their fitted

order.

19. Using new gaskets, fit exhaust manifold to

cylinder head. Fit bolts and using sequence

shown, tighten initially to 15 Nm (11 lbf.ft), then

finally tighten to 36 Nm (28 lbf.ft).

20. RH drive models: Fit brake servo heat shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

21.Position engine earth lead, fit bolt and tighten to

22 Nm (16 lbf.ft).

22.Fit inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

Page 269 of 1672

ENGINE - V8

12-2-26 REPAIRS

Engine assembly

$% 12.41.01.99

Remove

1.Drain engine oil and remove oil filter.

2.Remove radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

3.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

4.Remove ignition coil assemblies.

5.Position absorbent material to catch spillage

and disconnect fuel pipe from fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Release 2 hose clips and remove top hose.

7.Using a 15 mm spanner, release auxiliary drive

belt tension and remove drive belt. 8.Remove 3 bolts securing ACE pump, release

pump and tie aside.

9.Disconnect multiplug from A/C compressor.

10.Remove 4 bolts securing A/C compressor,

release compressor and tie aside.

Page 270 of 1672

ENGINE - V8

REPAIRS 12-2-27

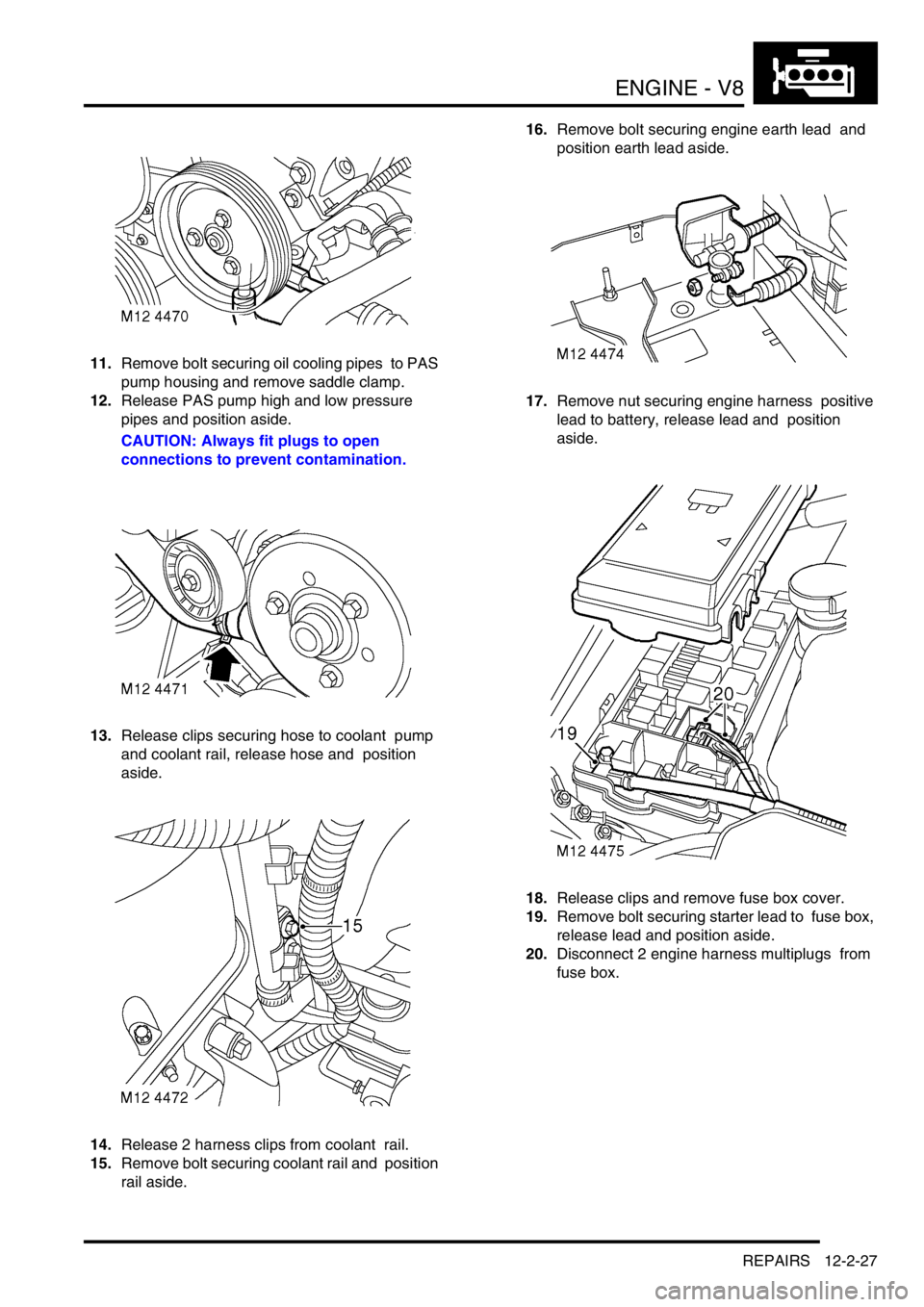

11.Remove bolt securing oil cooling pipes to PAS

pump housing and remove saddle clamp.

12.Release PAS pump high and low pressure

pipes and position aside.

CAUTION: Always fit plugs to open

connections to prevent contamination.

13.Release clips securing hose to coolant pump

and coolant rail, release hose and position

aside.

14.Release 2 harness clips from coolant rail.

15.Remove bolt securing coolant rail and position

rail aside. 16.Remove bolt securing engine earth lead and

position earth lead aside.

17.Remove nut securing engine harness positive

lead to battery, release lead and position

aside.

18.Release clips and remove fuse box cover.

19.Remove bolt securing starter lead to fuse box,

release lead and position aside.

20.Disconnect 2 engine harness multiplugs from

fuse box.

Page 271 of 1672

ENGINE - V8

12-2-28 REPAIRS

21.Disconnect multiplug from EVAP purge valve.

22.Remove nut securing engine harness earth to

body and disconnect engine harness to main

harness multiplug.

23.Remove trim fixings securing toe board and

remove toe board. 24.Disconnect 5 multiplugs connecting engine

harness to ECM.

25.Release engine harness, pull into engine bay

and coil on top of engine.

26.Raise vehicle on ramp.

27.Remove 3 bolts securing oil cooling pipes to

sump and remove saddle clamps.

28.Tie oil cooling pipes aside.

29.Remove exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

Page 273 of 1672

ENGINE - V8

12-2-30 REPAIRS

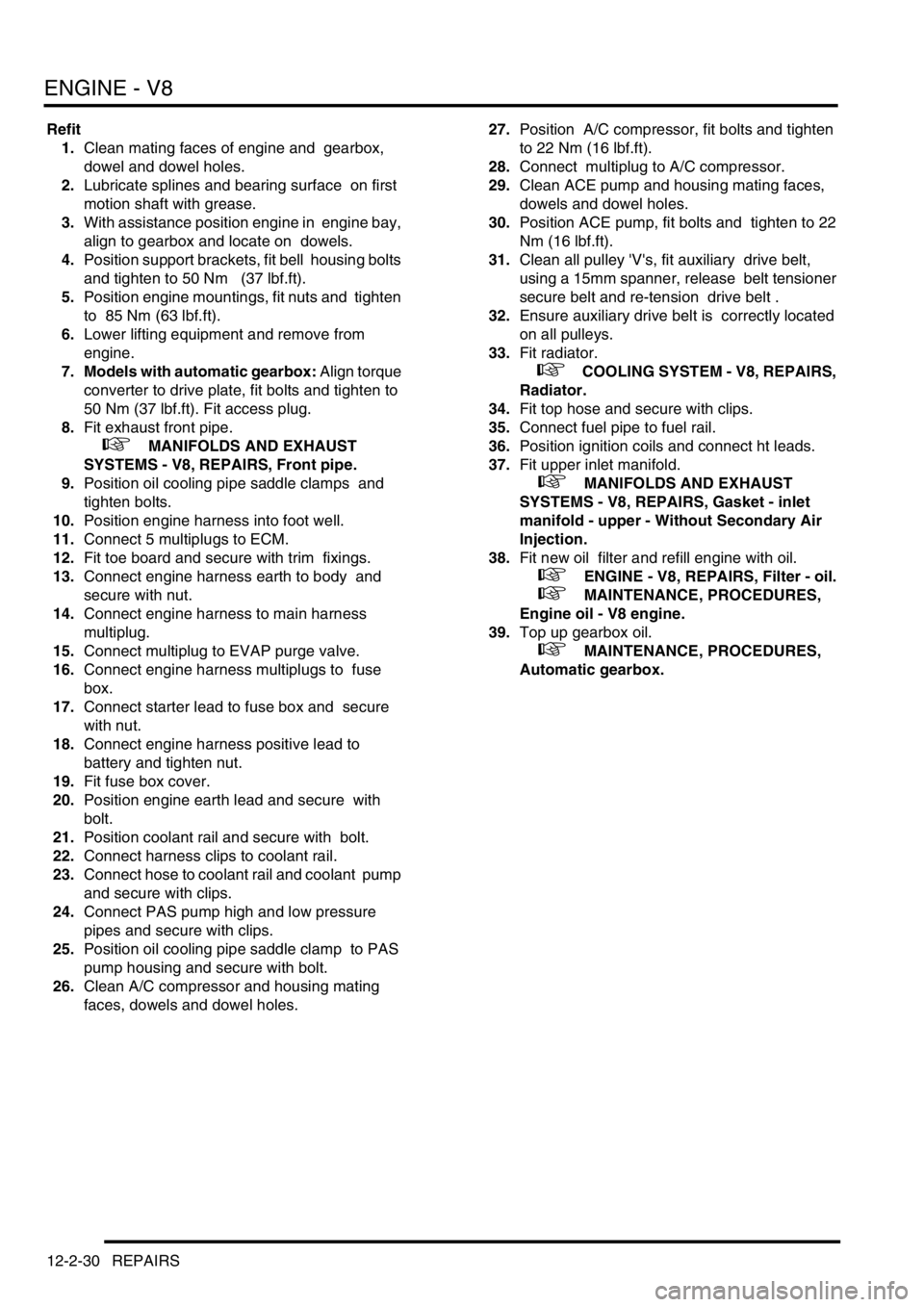

Refit

1.Clean mating faces of engine and gearbox,

dowel and dowel holes.

2.Lubricate splines and bearing surface on first

motion shaft with grease.

3.With assistance position engine in engine bay,

align to gearbox and locate on dowels.

4.Position support brackets, fit bell housing bolts

and tighten to 50 Nm (37 lbf.ft).

5.Position engine mountings, fit nuts and tighten

to 85 Nm (63 lbf.ft).

6.Lower lifting equipment and remove from

engine.

7. Models with automatic gearbox: Align torque

converter to drive plate, fit bolts and tighten to

50 Nm (37 lbf.ft). Fit access plug.

8.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

9.Position oil cooling pipe saddle clamps and

tighten bolts.

10.Position engine harness into foot well.

11.Connect 5 multiplugs to ECM.

12.Fit toe board and secure with trim fixings.

13.Connect engine harness earth to body and

secure with nut.

14.Connect engine harness to main harness

multiplug.

15.Connect multiplug to EVAP purge valve.

16.Connect engine harness multiplugs to fuse

box.

17.Connect starter lead to fuse box and secure

with nut.

18.Connect engine harness positive lead to

battery and tighten nut.

19.Fit fuse box cover.

20.Position engine earth lead and secure with

bolt.

21.Position coolant rail and secure with bolt.

22.Connect harness clips to coolant rail.

23.Connect hose to coolant rail and coolant pump

and secure with clips.

24.Connect PAS pump high and low pressure

pipes and secure with clips.

25.Position oil cooling pipe saddle clamp to PAS

pump housing and secure with bolt.

26.Clean A/C compressor and housing mating

faces, dowels and dowel holes. 27.Position A/C compressor, fit bolts and tighten

to 22 Nm (16 lbf.ft).

28.Connect multiplug to A/C compressor.

29.Clean ACE pump and housing mating faces,

dowels and dowel holes.

30.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

31.Clean all pulley 'V's, fit auxiliary drive belt,

using a 15mm spanner, release belt tensioner

secure belt and re-tension drive belt .

32.Ensure auxiliary drive belt is correctly located

on all pulleys.

33.Fit radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

34.Fit top hose and secure with clips.

35.Connect fuel pipe to fuel rail.

36.Position ignition coils and connect ht leads.

37.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

38.Fit new oil filter and refill engine with oil.

+ ENGINE - V8, REPAIRS, Filter - oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

39.Top up gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.