fuel pump LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 91 of 1672

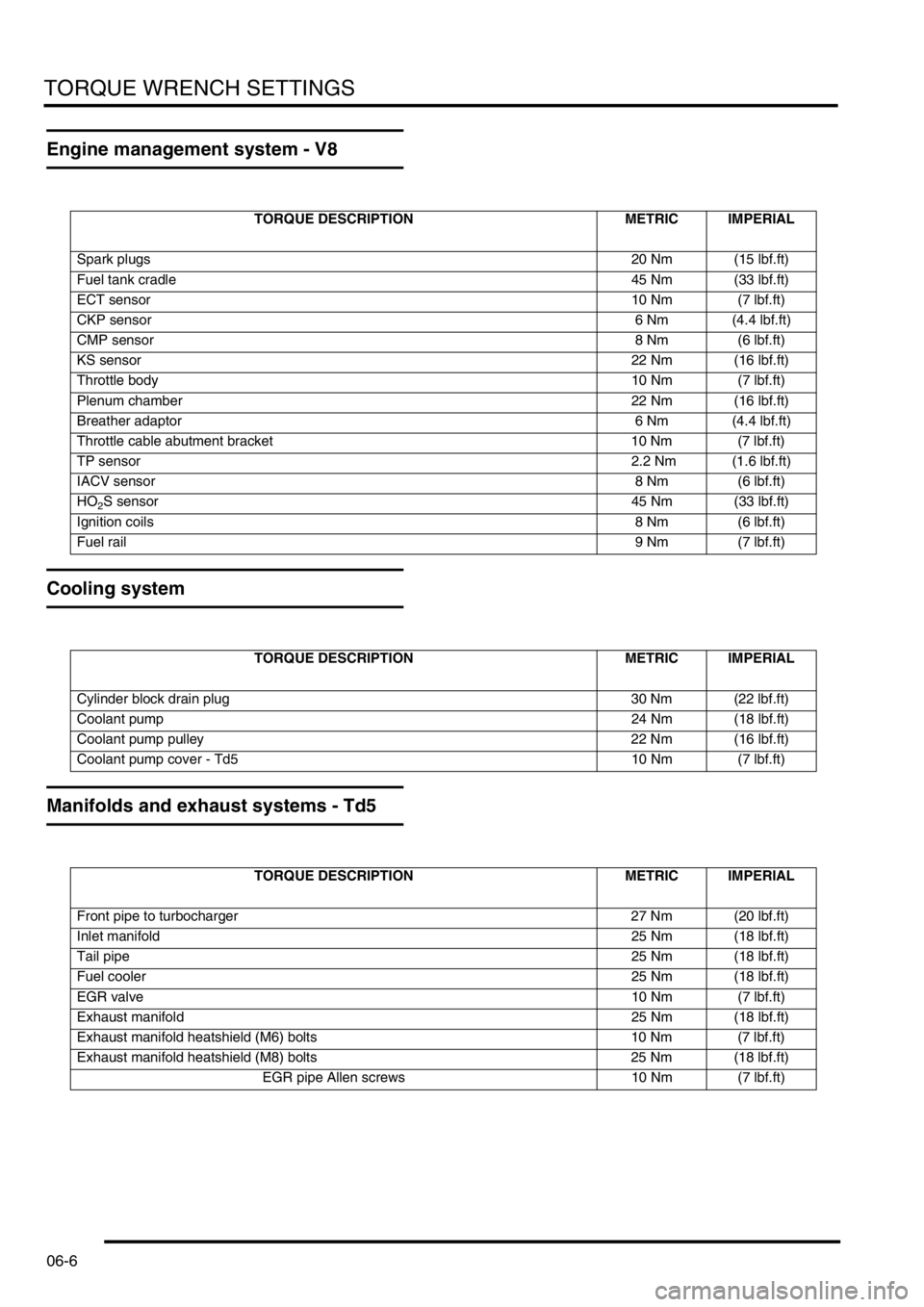

TORQUE WRENCH SETTINGS

06-6

Engine management system - V8

Cooling system

Manifolds and exhaust systems - Td5

TORQUE DESCRIPTION METRIC IMPERIAL

Spark plugs20 Nm (15 lbf.ft)

Fuel tank cradle45 Nm (33 lbf.ft)

ECT sensor10 Nm (7 lbf.ft)

CKP sensor6 Nm (4.4 lbf.ft)

CMP sensor8 Nm (6 lbf.ft)

KS sensor22 Nm (16 lbf.ft)

Throttle body10 Nm (7 lbf.ft)

Plenum chamber22 Nm (16 lbf.ft)

Breather adaptor6 Nm (4.4 lbf.ft)

Throttle cable abutment bracket 10 Nm (7 lbf.ft)

TP sensor 2.2 Nm (1.6 lbf.ft)

IACV sensor8 Nm (6 lbf.ft)

HO

2S sensor45 Nm (33 lbf.ft)

Ignition coils8 Nm (6 lbf.ft)

Fuel rail9 Nm (7 lbf.ft)

TORQUE DESCRIPTION METRIC IMPERIAL

Cylinder block drain plug 30 Nm (22 lbf.ft)

Coolant pump24 Nm (18 lbf.ft)

Coolant pump pulley 22 Nm (16 lbf.ft)

Coolant pump cover - Td5 10 Nm (7 lbf.ft)

TORQUE DESCRIPTION METRIC IMPERIAL

Front pipe to turbocharger 27 Nm (20 lbf.ft)

Inlet manifold25 Nm (18 lbf.ft)

Tail pipe25 Nm (18 lbf.ft)

Fuel cooler25 Nm (18 lbf.ft)

EGR valve10 Nm (7 lbf.ft)

Exhaust manifold25 Nm (18 lbf.ft)

Exhaust manifold heatshield (M6) bolts 10 Nm (7 lbf.ft)

Exhaust manifold heatshield (M8) bolts 25 Nm (18 lbf.ft)

EGR pipe Allen screws 10 Nm (7 lbf.ft)

Page 161 of 1672

ENGINE - TD5

12-1-22 DESCRIPTION AND OPERATION

The camshaft carrier and cylinder head assembly is attached to the cylinder block by twelve cylinder head retaining

bolts which pass through the camshaft carrier and the cylinder head to secure the assembly to the cylinder block.

CAUTION: The valve heads, tips of the injectors and glow plugs protrude below the face of the cylinder head

and will be damaged if the cylinder head is stored face down.

The camshaft is located between the cylinder head and the camshaft carrier, and the bearing journals are line bored

between the two components to form a matched pair.

CAUTION: Always fit plugs to open connections to prevent contamination.

The valve guides and valve seat inserts are sintered components which are interference fit to the cylinder head. The

cylinder head machining also provide the locations for the electronic unit injectors, glow plugs, hydraulic lash

adjusters, finger followers and low pressure fuel rail.

Cooling to the cylinder head is provided by coolant flow through a water jacket machined into the cylinder head.

Drillings through the block provide lubrication channels for pressurised oil supply to cylinder head components such

as the lash adjusters, finger followers, rocker arms and camshaft bearings.

A coolant outlet elbow is fitted to the front LH side of the cylinder head to allow flow of coolant from the cylinder head

back to the radiator. A metal gasket is used to seal the joint between the water outlet elbow and the cylinder head. A

coolant temperature sensor is located in a port in the side of the water outlet elbow for monitoring coolant temperature.

A stub pipe is connected at the front RH side of the cylinder block above the timing cover which connects a pipe to

supply oil to the vacuum pump. The timing chain tensioner adjuster is screwed in a thread in the cylinder head at a

location on the front RH side of the engine below the oil feed port for the vacuum pump.

An access hole for the camshaft gear is included at the front of the cylinder head which is sealed with a plastic plug

and rubber 'O'-ring. A press-fit core plug for the chain chest is located on the front face of the cylinder head.

A press-fit core plug for the cylinder head water jacket is located at the rear of the cylinder head and a threaded brass

plug for the water jacket is located on the LH side of the cylinder head beneath the exhaust manifold assembly.

Page 179 of 1672

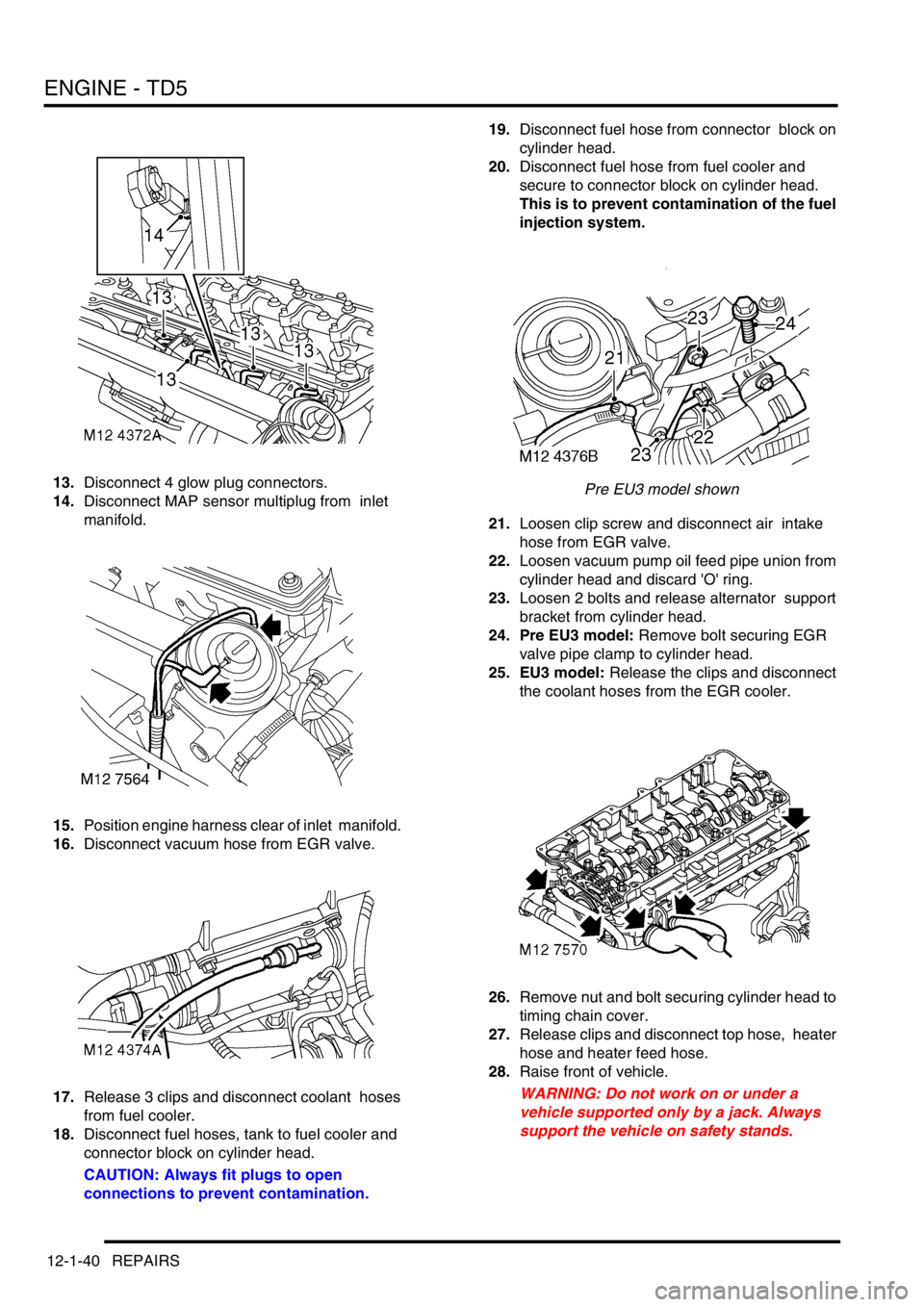

ENGINE - TD5

12-1-40 REPAIRS

13.Disconnect 4 glow plug connectors.

14.Disconnect MAP sensor multiplug from inlet

manifold.

15.Position engine harness clear of inlet manifold.

16.Disconnect vacuum hose from EGR valve.

17.Release 3 clips and disconnect coolant hoses

from fuel cooler.

18.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Always fit plugs to open

connections to prevent contamination.19.Disconnect fuel hose from connector block on

cylinder head.

20.Disconnect fuel hose from fuel cooler and

secure to connector block on cylinder head.

This is to prevent contamination of the fuel

injection system.

Pre EU3 model shown

21.Loosen clip screw and disconnect air intake

hose from EGR valve.

22.Loosen vacuum pump oil feed pipe union from

cylinder head and discard 'O' ring.

23.Loosen 2 bolts and release alternator support

bracket from cylinder head.

24. Pre EU3 model: Remove bolt securing EGR

valve pipe clamp to cylinder head.

25. EU3 model: Release the clips and disconnect

the coolant hoses from the EGR cooler.

26.Remove nut and bolt securing cylinder head to

timing chain cover.

27.Release clips and disconnect top hose, heater

hose and heater feed hose.

28.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

Page 182 of 1672

ENGINE - TD5

REPAIRS 12-1-43

11.Clean camshaft sprocket and mating face on

camshaft.

12.Ensure engine is set to TDC No. 1 cylinder and

mark on camshaft sprocket is positioned

between the 2 coloured links.

13.Position camshaft sprocket to camshaft; fit and

lightly tighten new bolts, then loosen bolts half

a turn.

14.Clean timing chain fixed guide retaining pin and

apply Loctite 242 to threads.

15.Fit timing chain fixed guide retaining pin and

tighten to 25 Nm (18 lbf.ft) .

16.Clean timing chain tensioner and fit new

sealing washer.

17.Fit timing chain tensioner and tighten to 45 Nm

(22 lbf.ft).

18.Tighten bolts securing camshaft sprocket to

camshaft to 37 Nm (27 lbf.ft).

19.Remove tool LRT-12-058 from camshaft.

20.Remove tool LRT-12-158 from gearbox bell

housing.

21.Fit new camshaft bore blanking plug and 'O'-

ring seal in recess in cylinder head.

22.Clean vacuum pump union.

23.Tighten union securing vacuum pump oil feed

pipe to cylinder head to 10 Nm (7 lbf.ft) .

24.Fit bolts securing alternator support bracket to

cylinder head and tighten to 25 Nm (18 lbf.ft) .

25.Connect top hose and heater hoses and secure

with clips.

26. Pre EU3 model:Fit bolt securing EGR pipe

clamp to cylinder head bolt and tighten to 10

Nm (7 lbf.ft) .

27. EU3 model: Connect coolant hoses to EGR

cooler and secure with the clips.

28.Position air intake hose to EGR valve and

tighten clip screw.

29.Disconnect fuel hose from connector block and

connect to fuel cooler.

30.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

31.Connect coolant hoses to fuel cooler and

secure clips.

32.Connect vacuum hose to EGR valve.

33.Position engine harness and connect multi

plugs and glow plug connectors.

34.Fit and tighten bolts, engine harness to

camshaft carrier.

35.Clean exhaust manifold and turbocharger

interface.

36.Fit new gasket to exhaust manifold, position

turbocharger and tighten – nuts securing

turbocharger to manifold to 30 Nm (22 lbf.ft).

37.Clean turbocharger oil feed hose bolt.

38.Position turbocharger oil feed hose using new

sealing washers. Fit banjo bolt securing

turbocharger oil feed hose and tighten to 25 Nm

(18 lbf.ft) . 39.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolt to

25 Nm (18 lbf.ft).

40.Fit cooling fan coupling.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

41.Fit camshaft cover with new seal.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

42.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

43.Connect battery earth lead.

44.Fit battery cover and secure fixings.

45.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 186 of 1672

ENGINE - TD5

REPAIRS 12-1-47

Engine and ancillaries

$% 12.41.01

Remove

1.Remove bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

4.Remove radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

5.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

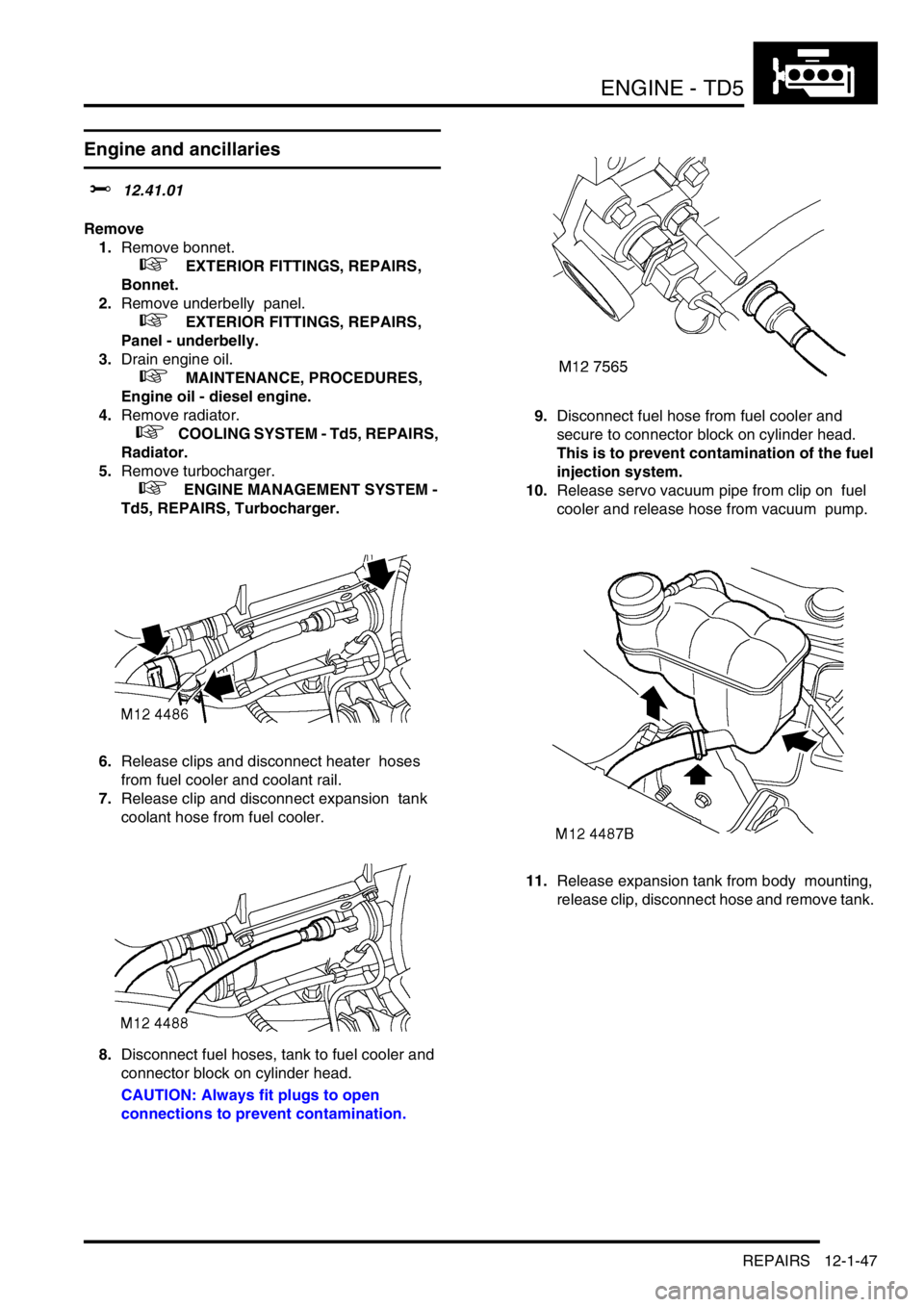

6.Release clips and disconnect heater hoses

from fuel cooler and coolant rail.

7.Release clip and disconnect expansion tank

coolant hose from fuel cooler.

8.Disconnect fuel hoses, tank to fuel cooler and

connector block on cylinder head.

CAUTION: Always fit plugs to open

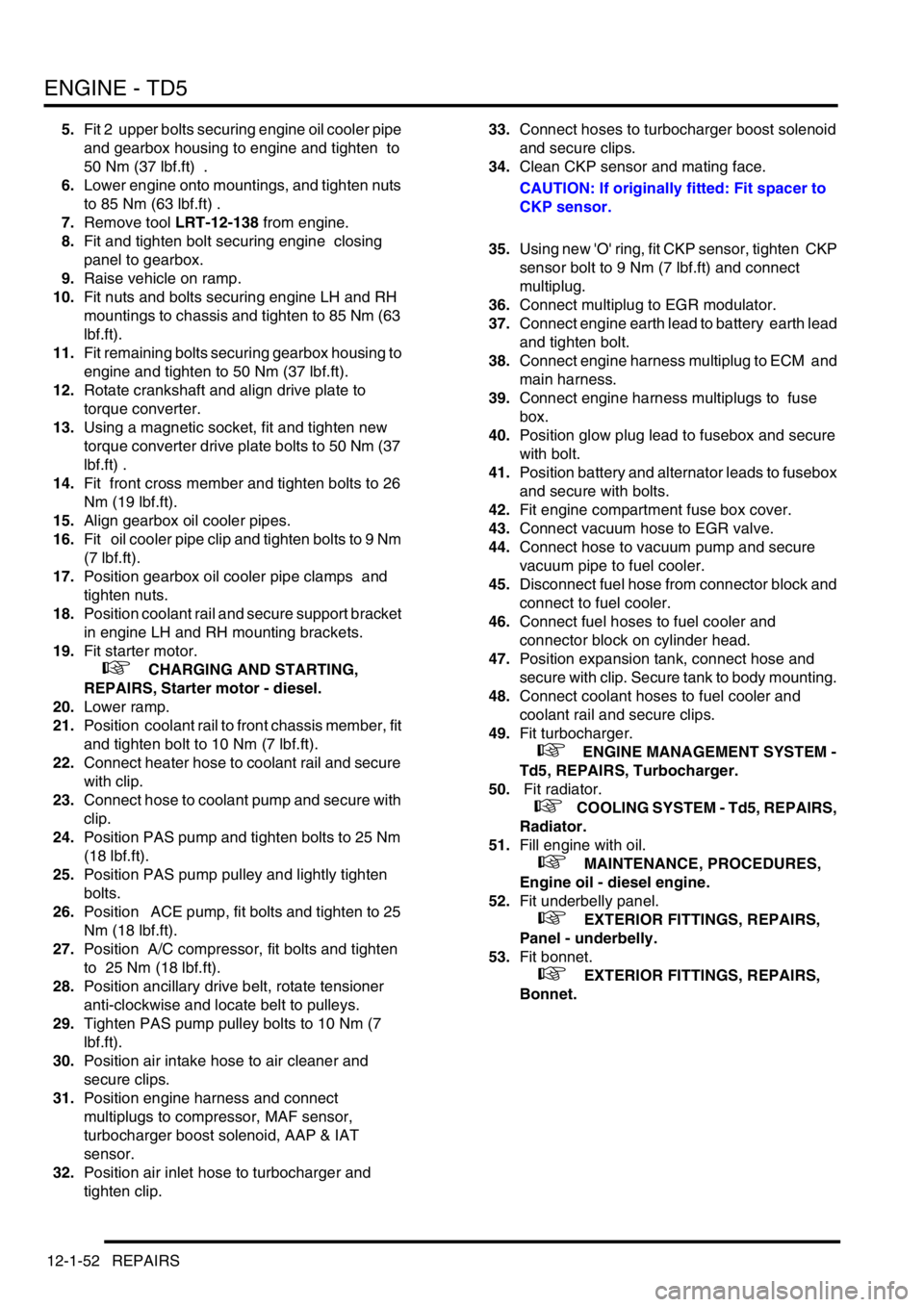

connections to prevent contamination.9.Disconnect fuel hose from fuel cooler and

secure to connector block on cylinder head.

This is to prevent contamination of the fuel

injection system.

10.Release servo vacuum pipe from clip on fuel

cooler and release hose from vacuum pump.

11.Release expansion tank from body mounting,

release clip, disconnect hose and remove tank.

Page 191 of 1672

ENGINE - TD5

12-1-52 REPAIRS

5.Fit 2 upper bolts securing engine oil cooler pipe

and gearbox housing to engine and tighten to

50 Nm (37 lbf.ft) .

6.Lower engine onto mountings, and tighten nuts

to 85 Nm (63 lbf.ft) .

7.Remove tool LRT-12-138 from engine.

8.Fit and tighten bolt securing engine closing

panel to gearbox.

9.Raise vehicle on ramp.

10.Fit nuts and bolts securing engine LH and RH

mountings to chassis and tighten to 85 Nm (63

lbf.ft).

11.Fit remaining bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

12.Rotate crankshaft and align drive plate to

torque converter.

13.Using a magnetic socket, fit and tighten new

torque converter drive plate bolts to 50 Nm (37

lbf.ft) .

14.Fit front cross member and tighten bolts to 26

Nm (19 lbf.ft).

15.Align gearbox oil cooler pipes.

16.Fit oil cooler pipe clip and tighten bolts to 9 Nm

(7 lbf.ft).

17.Position gearbox oil cooler pipe clamps and

tighten nuts.

18.Position coolant rail and secure support bracket

in engine LH and RH mounting brackets.

19.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

20.Lower ramp.

21.Position coolant rail to front chassis member, fit

and tighten bolt to 10 Nm (7 lbf.ft).

22.Connect heater hose to coolant rail and secure

with clip.

23.Connect hose to coolant pump and secure with

clip.

24.Position PAS pump and tighten bolts to 25 Nm

(18 lbf.ft).

25.Position PAS pump pulley and lightly tighten

bolts.

26.Position ACE pump, fit bolts and tighten to 25

Nm (18 lbf.ft).

27.Position A/C compressor, fit bolts and tighten

to 25 Nm (18 lbf.ft).

28.Position ancillary drive belt, rotate tensioner

anti-clockwise and locate belt to pulleys.

29.Tighten PAS pump pulley bolts to 10 Nm (7

lbf.ft).

30.Position air intake hose to air cleaner and

secure clips.

31.Position engine harness and connect

multiplugs to compressor, MAF sensor,

turbocharger boost solenoid, AAP & IAT

sensor.

32.Position air inlet hose to turbocharger and

tighten clip. 33.Connect hoses to turbocharger boost solenoid

and secure clips.

34.Clean CKP sensor and mating face.

CAUTION: If originally fitted: Fit spacer to

CKP sensor.

35.Using new 'O' ring, fit CKP sensor, tighten CKP

sensor bolt to 9 Nm (7 lbf.ft) and connect

multiplug.

36.Connect multiplug to EGR modulator.

37.Connect engine earth lead to battery earth lead

and tighten bolt.

38.Connect engine harness multiplug to ECM and

main harness.

39.Connect engine harness multiplugs to fuse

box.

40.Position glow plug lead to fusebox and secure

with bolt.

41.Position battery and alternator leads to fusebox

and secure with bolts.

42.Fit engine compartment fuse box cover.

43.Connect vacuum hose to EGR valve.

44.Connect hose to vacuum pump and secure

vacuum pipe to fuel cooler.

45.Disconnect fuel hose from connector block and

connect to fuel cooler.

46.Connect fuel hoses to fuel cooler and

connector block on cylinder head.

47.Position expansion tank, connect hose and

secure with clip. Secure tank to body mounting.

48.Connect coolant hoses to fuel cooler and

coolant rail and secure clips.

49.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

50. Fit radiator.

+ COOLING SYSTEM - Td5, REPAIRS,

Radiator.

51.Fill engine with oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

52.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

53.Fit bonnet.

+ EXTERIOR FITTINGS, REPAIRS,

Bonnet.

Page 212 of 1672

ENGINE - TD5

OVERHAUL 12-1-73

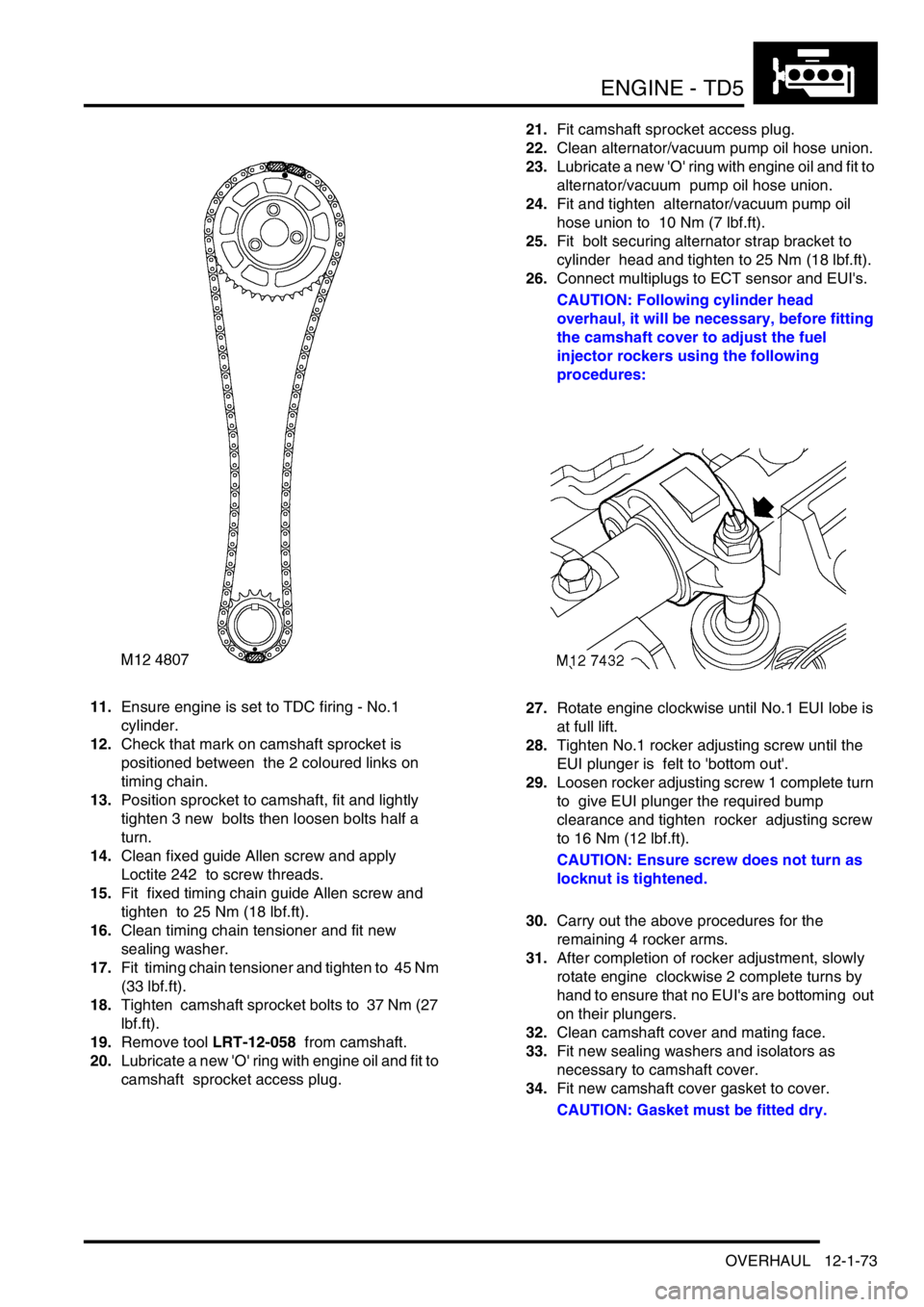

11.Ensure engine is set to TDC firing - No.1

cylinder.

12.Check that mark on camshaft sprocket is

positioned between the 2 coloured links on

timing chain.

13.Position sprocket to camshaft, fit and lightly

tighten 3 new bolts then loosen bolts half a

turn.

14.Clean fixed guide Allen screw and apply

Loctite 242 to screw threads.

15.Fit fixed timing chain guide Allen screw and

tighten to 25 Nm (18 lbf.ft).

16.Clean timing chain tensioner and fit new

sealing washer.

17.Fit timing chain tensioner and tighten to 45 Nm

(33 lbf.ft).

18.Tighten camshaft sprocket bolts to 37 Nm (27

lbf.ft).

19.Remove tool LRT-12-058 from camshaft.

20.Lubricate a new 'O' ring with engine oil and fit to

camshaft sprocket access plug.21.Fit camshaft sprocket access plug.

22.Clean alternator/vacuum pump oil hose union.

23.Lubricate a new 'O' ring with engine oil and fit to

alternator/vacuum pump oil hose union.

24.Fit and tighten alternator/vacuum pump oil

hose union to 10 Nm (7 lbf.ft).

25.Fit bolt securing alternator strap bracket to

cylinder head and tighten to 25 Nm (18 lbf.ft).

26.Connect multiplugs to ECT sensor and EUI's.

CAUTION: Following cylinder head

overhaul, it will be necessary, before fitting

the camshaft cover to adjust the fuel

injector rockers using the following

procedures:

27.Rotate engine clockwise until No.1 EUI lobe is

at full lift.

28.Tighten No.1 rocker adjusting screw until the

EUI plunger is felt to 'bottom out'.

29.Loosen rocker adjusting screw 1 complete turn

to give EUI plunger the required bump

clearance and tighten rocker adjusting screw

to 16 Nm (12 lbf.ft).

CAUTION: Ensure screw does not turn as

locknut is tightened.

30.Carry out the above procedures for the

remaining 4 rocker arms.

31.After completion of rocker adjustment, slowly

rotate engine clockwise 2 complete turns by

hand to ensure that no EUI's are bottoming out

on their plungers.

32.Clean camshaft cover and mating face.

33.Fit new sealing washers and isolators as

necessary to camshaft cover.

34.Fit new camshaft cover gasket to cover.

CAUTION: Gasket must be fitted dry.

Page 269 of 1672

ENGINE - V8

12-2-26 REPAIRS

Engine assembly

$% 12.41.01.99

Remove

1.Drain engine oil and remove oil filter.

2.Remove radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

3.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

4.Remove ignition coil assemblies.

5.Position absorbent material to catch spillage

and disconnect fuel pipe from fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Release 2 hose clips and remove top hose.

7.Using a 15 mm spanner, release auxiliary drive

belt tension and remove drive belt. 8.Remove 3 bolts securing ACE pump, release

pump and tie aside.

9.Disconnect multiplug from A/C compressor.

10.Remove 4 bolts securing A/C compressor,

release compressor and tie aside.

Page 273 of 1672

ENGINE - V8

12-2-30 REPAIRS

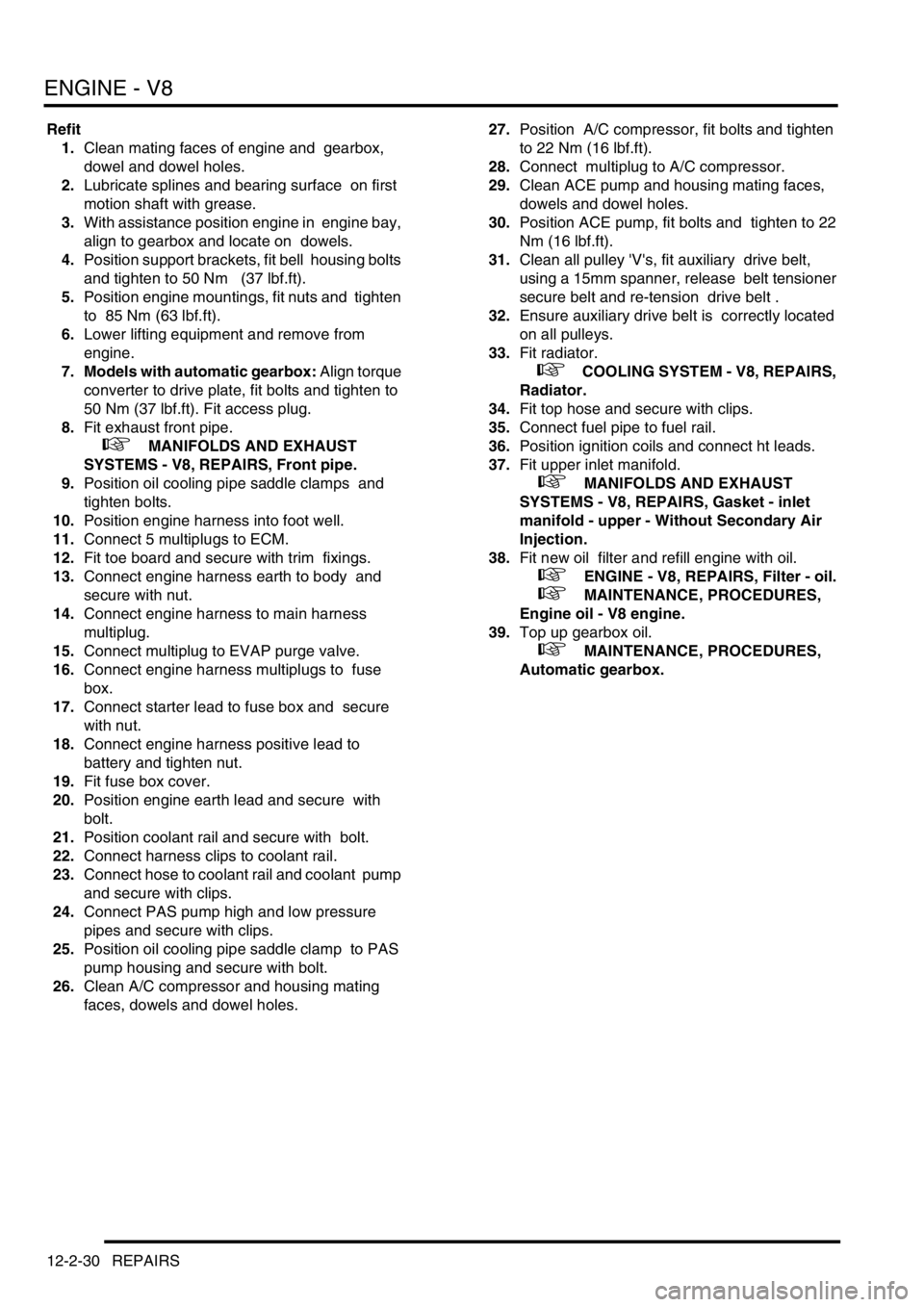

Refit

1.Clean mating faces of engine and gearbox,

dowel and dowel holes.

2.Lubricate splines and bearing surface on first

motion shaft with grease.

3.With assistance position engine in engine bay,

align to gearbox and locate on dowels.

4.Position support brackets, fit bell housing bolts

and tighten to 50 Nm (37 lbf.ft).

5.Position engine mountings, fit nuts and tighten

to 85 Nm (63 lbf.ft).

6.Lower lifting equipment and remove from

engine.

7. Models with automatic gearbox: Align torque

converter to drive plate, fit bolts and tighten to

50 Nm (37 lbf.ft). Fit access plug.

8.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

9.Position oil cooling pipe saddle clamps and

tighten bolts.

10.Position engine harness into foot well.

11.Connect 5 multiplugs to ECM.

12.Fit toe board and secure with trim fixings.

13.Connect engine harness earth to body and

secure with nut.

14.Connect engine harness to main harness

multiplug.

15.Connect multiplug to EVAP purge valve.

16.Connect engine harness multiplugs to fuse

box.

17.Connect starter lead to fuse box and secure

with nut.

18.Connect engine harness positive lead to

battery and tighten nut.

19.Fit fuse box cover.

20.Position engine earth lead and secure with

bolt.

21.Position coolant rail and secure with bolt.

22.Connect harness clips to coolant rail.

23.Connect hose to coolant rail and coolant pump

and secure with clips.

24.Connect PAS pump high and low pressure

pipes and secure with clips.

25.Position oil cooling pipe saddle clamp to PAS

pump housing and secure with bolt.

26.Clean A/C compressor and housing mating

faces, dowels and dowel holes. 27.Position A/C compressor, fit bolts and tighten

to 22 Nm (16 lbf.ft).

28.Connect multiplug to A/C compressor.

29.Clean ACE pump and housing mating faces,

dowels and dowel holes.

30.Position ACE pump, fit bolts and tighten to 22

Nm (16 lbf.ft).

31.Clean all pulley 'V's, fit auxiliary drive belt,

using a 15mm spanner, release belt tensioner

secure belt and re-tension drive belt .

32.Ensure auxiliary drive belt is correctly located

on all pulleys.

33.Fit radiator.

+ COOLING SYSTEM - V8, REPAIRS,

Radiator.

34.Fit top hose and secure with clips.

35.Connect fuel pipe to fuel rail.

36.Position ignition coils and connect ht leads.

37.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

38.Fit new oil filter and refill engine with oil.

+ ENGINE - V8, REPAIRS, Filter - oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - V8 engine.

39.Top up gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 288 of 1672

ENGINE - V8

OVERHAUL 12-2-45

OVERHAUL

Gasket - inlet manifold

$% 30.15.08.01

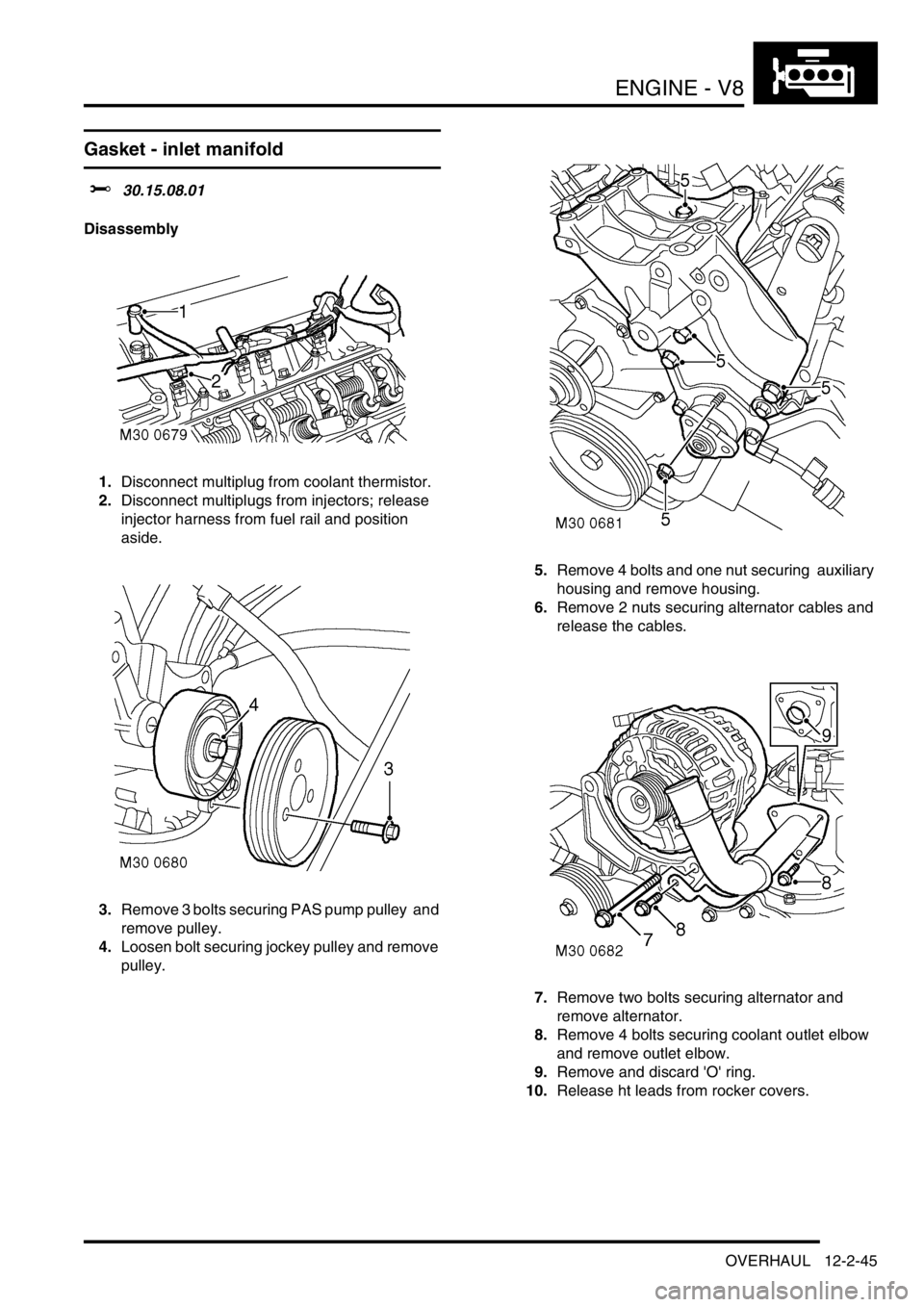

Disassembly

1.Disconnect multiplug from coolant thermistor.

2.Disconnect multiplugs from injectors; release

injector harness from fuel rail and position

aside.

3.Remove 3 bolts securing PAS pump pulley and

remove pulley.

4.Loosen bolt securing jockey pulley and remove

pulley. 5.Remove 4 bolts and one nut securing auxiliary

housing and remove housing.

6.Remove 2 nuts securing alternator cables and

release the cables.

7.Remove two bolts securing alternator and

remove alternator.

8.Remove 4 bolts securing coolant outlet elbow

and remove outlet elbow.

9.Remove and discard 'O' ring.

10.Release ht leads from rocker covers.