oil level LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 126 of 1672

MAINTENANCE

PROCEDURES 10-17

Automatic gearbox

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil filter

1.Replace oil filter.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Filter - oil.

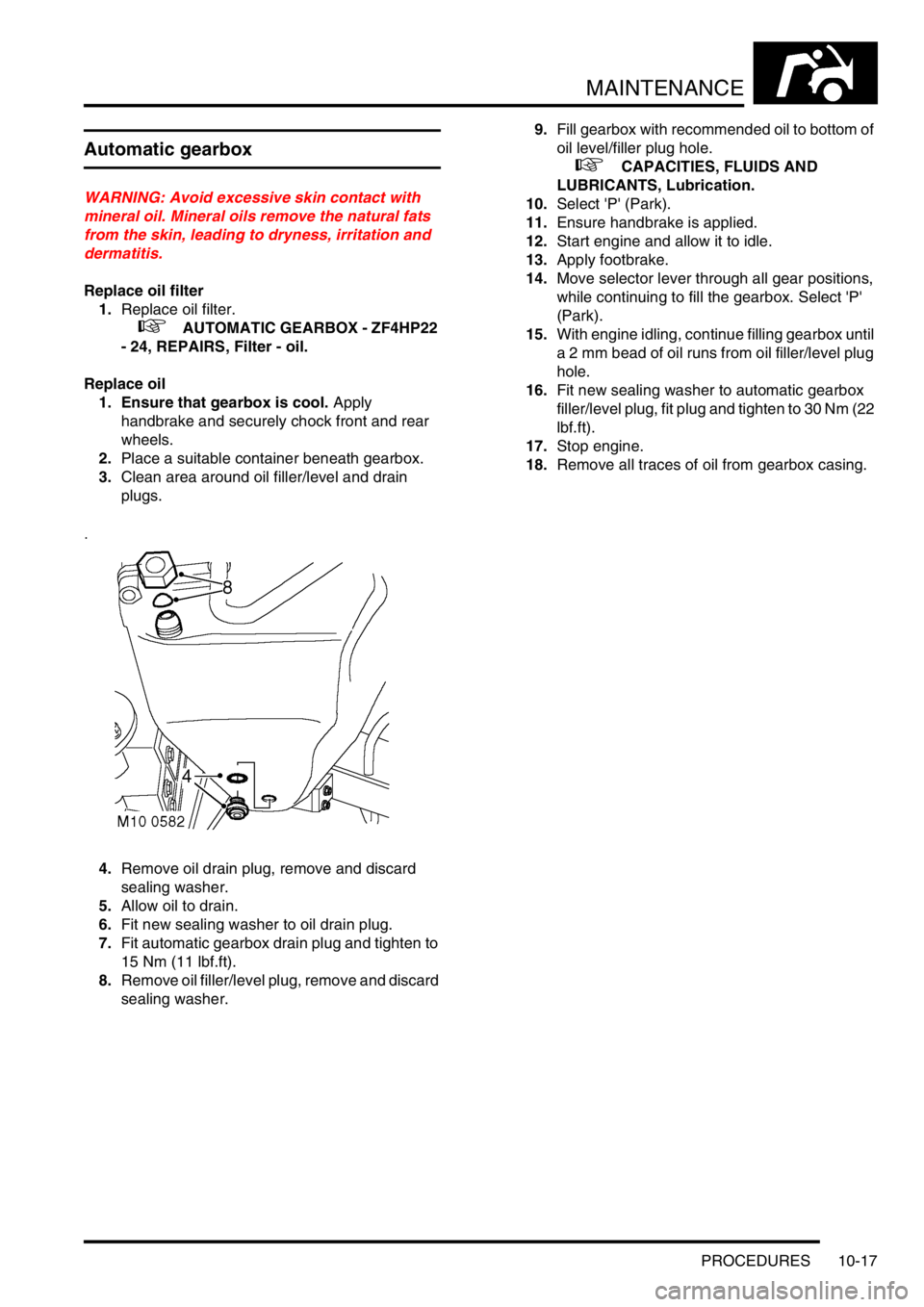

Replace oil

1. Ensure that gearbox is cool. Apply

handbrake and securely chock front and rear

wheels.

2.Place a suitable container beneath gearbox.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil drain plug, remove and discard

sealing washer.

5.Allow oil to drain.

6.Fit new sealing washer to oil drain plug.

7.Fit automatic gearbox drain plug and tighten to

15 Nm (11 lbf.ft).

8.Remove oil filler/level plug, remove and discard

sealing washer.9.Fill gearbox with recommended oil to bottom of

oil level/filler plug hole.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

10.Select 'P' (Park).

11.Ensure handbrake is applied.

12.Start engine and allow it to idle.

13.Apply footbrake.

14.Move selector lever through all gear positions,

while continuing to fill the gearbox. Select 'P'

(Park).

15.With engine idling, continue filling gearbox until

a 2 mm bead of oil runs from oil filler/level plug

hole.

16.Fit new sealing washer to automatic gearbox

filler/level plug, fit plug and tighten to 30 Nm (22

l b f . f t ) .

17.Stop engine.

18.Remove all traces of oil from gearbox casing.

Page 127 of 1672

MAINTENANCE

10-18 PROCEDURES

Transfer box

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Check/top-up oil level

1.Release fixings, remove rear underbelly panel.

2.Clean area around oil filler/level plug.

3.Remove oil filler/level plug.

4.Check that oil level is to bottom of filler/level

plug hole.

5.Top-up level (if required) with recommended oil

to bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

6.Remove all traces of sealant from threads of oil

filler/level plug.

7.Apply Loctite 290 to threads of oil filler/level

plug.

8. Fit transfer box filler/level plug and tighten to 25

Nm (18 lbf.ft).

9.Remove all traces of oil from main casing.

10.Fit rear underbelly panel (if fitted), secure

fixings.Replace oil

1. Release fixings, remove rear underbelly panel.

2.Place a suitable container beneath transfer box

drain plug.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil filler/level plug.

5.Remove oil drain plug.

6.Allow oil to drain.

7.Apply Loctite 290 to threads of oil drain plug.

8. Fit transfer box drain plug and tighten to 30

Nm (22 lbf.ft).

9.Fill transfer box with recommended oil to

bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

10.Remove all traces of sealant from threads of oil

filler/level plug.

11.Apply Loctite 290 to threads of oil filler/level

plug.

12. Fit transfer box filler/level plug and tighten to 25

Nm (18 lbf.ft).

13. Remove all traces of oil from transfer box.

14.Fit rear underbelly panel (if fitted), secure

fixings.

Page 128 of 1672

MAINTENANCE

PROCEDURES 10-19

Front and rear axle

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil

1.Place a suitable container beneath differential

housing of axle to be drained.

2.Clean area around oil filler/level and drain

plugs.

3.Remove oil filler/level plug.

4.Remove and discard 'O' ring from oil filler/level

plug.

5.Remove oil drain plug, allow oil to drain.

6.Remove all traces of Loctite from threads of oil

drain plug.

7.Apply Loctite 290 to threads of oil drain plug.

8. Fit axle drain plug and tighten to 64 Nm (47

lbf.ft).

9.Fill differential housing with recommended oil to

bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

10.Lubricate a new 'O' ring with recommended oil

and fit to oil filler/level plug.

11.Fit axle filler/level plug and tighten to 10 Nm (7

lbf.ft).

12.Remove all traces of oil from differential

housing.

Propeller shafts

Lubricate

Rear shaft

1.Clean area around front universal joint grease

nipple.

2.Apply recommended grease to the grease

nipple.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

Front shaft

3.Remove blanking plug adjacent to sliding joint

from propeller shaft.

4.Screw a 1/4in UNF grease nipple into blanking

plug hole.

Page 169 of 1672

ENGINE - TD5

12-1-30 DESCRIPTION AND OPERATION

Oil from the sump is drawn up through a two-piece plastic pick-up which contains a mesh to siphon any relatively large

pieces of material which could cause damage to the pump. The head of the pick-up is centrally immersed in the sump

oil and oil is delivered to the inlet side of the eccentric rotor pump through a gallery in the stiffener plate.

Pressurised oil from the pump is passed through to the cylinder block where it is delivered to the centrifuge filter and

full-flow filter via a port in the RH cylinder block which interfaces with a port in the centre gallery of the oil cooler

housing. The oil pump contains an oil pressure relief valve which opens to allow oil to be recirculated back around the

pump if the oil pressure increases to a high enough level.

10% of the oil flow from the pump is diverted through the centrifuge filter and returned to the sump via the centrifuge

filter drain tube. The remaining 90% of the oil passes through the standard full-flow filter to the main oil gallery in the

cylinder block.

Page 171 of 1672

ENGINE - TD5

12-1-32 DESCRIPTION AND OPERATION

When the engine temperature is below 74° C, the thermostat in the full-flow filter housing is closed and a proportion

of the oil flow to the main oil gallery is diverted to the oil cooler to supply an oil feed to the turbocharger bearings. Oil

passes through the oil cooler to the front gallery in the oil cooler housing where there is a tapping to connect the feed

pipe to the turbocharger. Oil used by the turbocharger bearings is returned to the sump through an oil drain pipe which

connects to a port in the LH side of the cylinder block.

The remainder of the oil flow leaving the full-flow filter outlet is passed into the cylinder block via a port at the rear of

oil cooler rear gallery.

When the oil temperature rises above 74

° C the thermostat in the full-flow filter adaptor housing begins to open to

allow a proportion of the oil from the full-flow filter to pass through the oil cooler before it reaches the main oil gallery

in the cylinder block. In this instance, oil supply to the turbocharger bearings is fed directly from the full-flow filter

without first passing through the oil cooler. Between 74

° C and 88° C the thermostat valve plunger opens by about

9mm to allow proportionally more oil to flow through the oil cooler before being passed to the cylinder block main oil

delivery gallery. Above 88

°C the thermostat valve continues to open by about 1mm for every 10° C increase in

temperature until the valve is fully open, when all the oil flow to the cylinder block is forced to pass to the cylinder block

via the oil cooler.

An oil pressure switch is located in a port in the rear gallery of the oil cooler housing to sense the oil pressure level

before flow enters the main oil gallery in the engine block. A warning lamp in the instrument cluster is switched on if

the oil pressure is detected as being too low.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Drillings from the cylinder block main oil gallery direct oil to the crankshaft main bearings and cross drillings in the

crankshaft direct oil to the big-end bearings. An additional five drillings in the cylinder block supply oil at reduced

pressure to the oil squirt jets for piston cooling and gudgeon pin lubrication.

Oil supply from the cylinder block is then passed to the cylinder head galleries through a non-return valve which is

included as an integral item in the lower face of the cylinder head.

Page 196 of 1672

ENGINE - TD5

REPAIRS 12-1-57

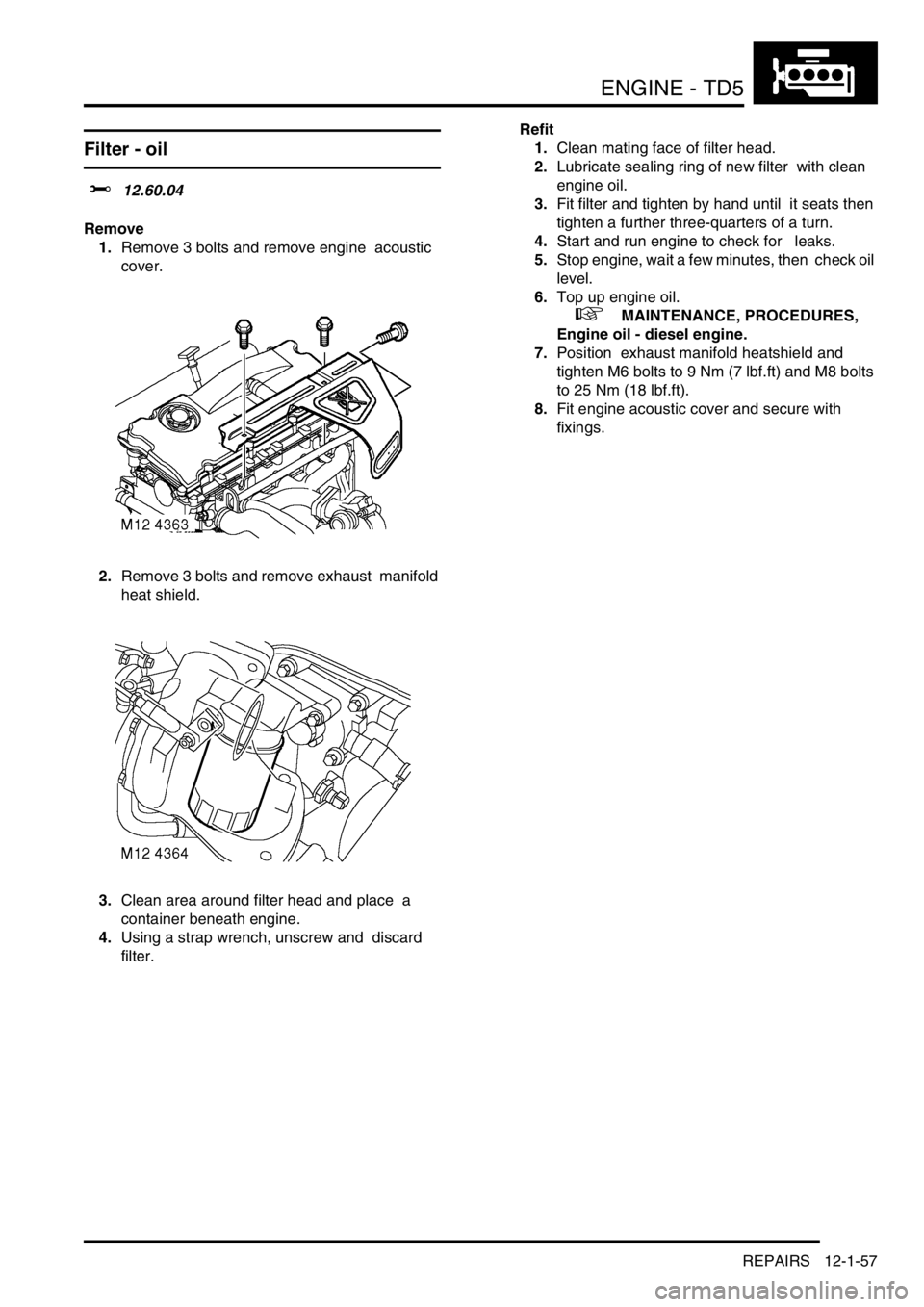

Filter - oil

$% 12.60.04

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Remove 3 bolts and remove exhaust manifold

heat shield.

3.Clean area around filter head and place a

container beneath engine.

4.Using a strap wrench, unscrew and discard

filter. Refit

1.Clean mating face of filter head.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit filter and tighten by hand until it seats then

tighten a further three-quarters of a turn.

4.Start and run engine to check for leaks.

5.Stop engine, wait a few minutes, then check oil

level.

6.Top up engine oil.

+ MAINTENANCE, PROCEDURES,

Engine oil - diesel engine.

7.Position exhaust manifold heatshield and

tighten M6 bolts to 9 Nm (7 lbf.ft) and M8 bolts

to 25 Nm (18 lbf.ft).

8.Fit engine acoustic cover and secure with

fixings.

Page 201 of 1672

ENGINE - TD5

12-1-62 REPAIRS

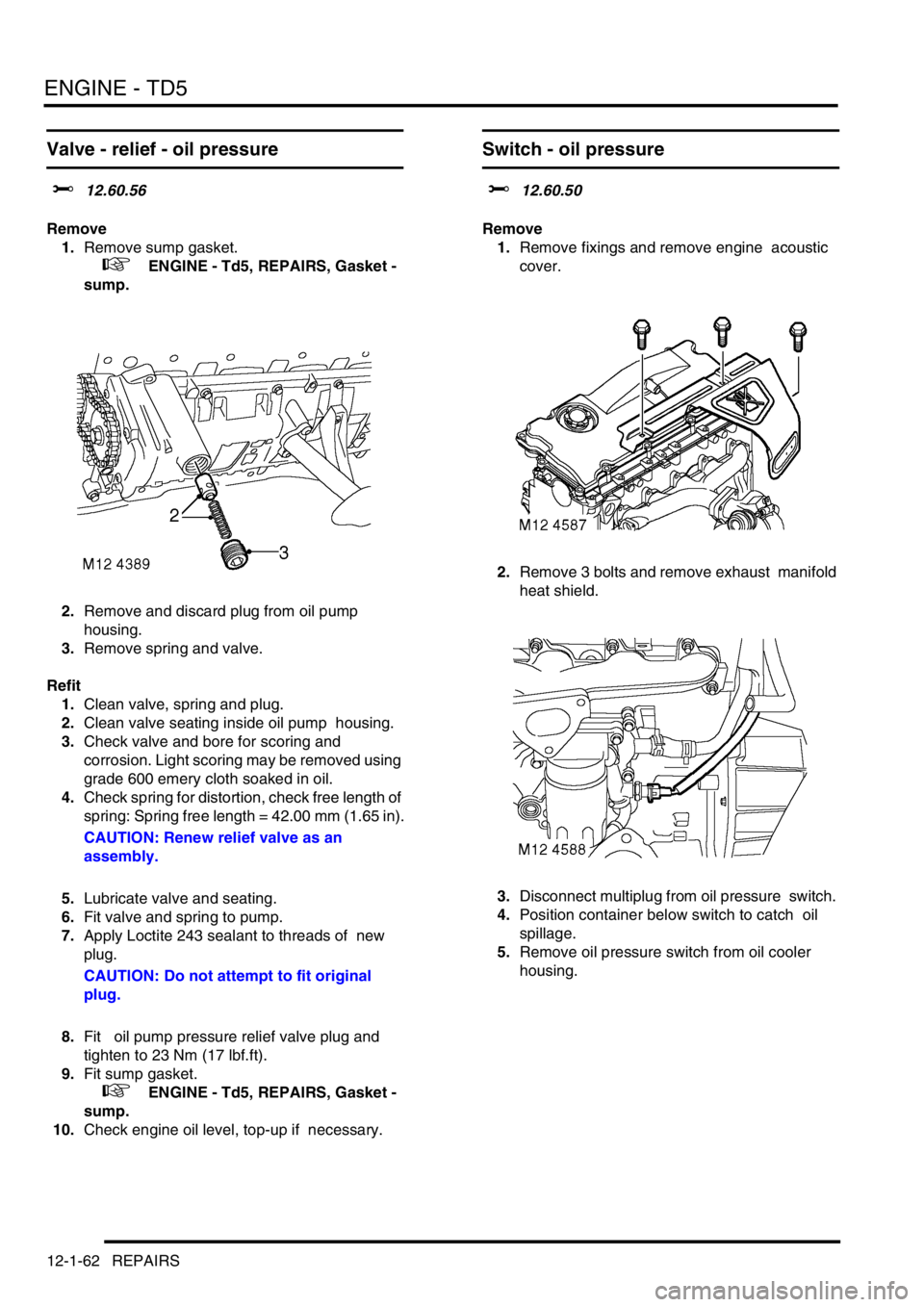

Valve - relief - oil pressure

$% 12.60.56

Remove

1.Remove sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

2.Remove and discard plug from oil pump

housing.

3.Remove spring and valve.

Refit

1.Clean valve, spring and plug.

2.Clean valve seating inside oil pump housing.

3.Check valve and bore for scoring and

corrosion. Light scoring may be removed using

grade 600 emery cloth soaked in oil.

4.Check spring for distortion, check free length of

spring: Spring free length = 42.00 mm (1.65 in).

CAUTION: Renew relief valve as an

assembly.

5.Lubricate valve and seating.

6.Fit valve and spring to pump.

7.Apply Loctite 243 sealant to threads of new

plug.

CAUTION: Do not attempt to fit original

plug.

8.Fit oil pump pressure relief valve plug and

tighten to 23 Nm (17 lbf.ft).

9.Fit sump gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

sump.

10.Check engine oil level, top-up if necessary.

Switch - oil pressure

$% 12.60.50

Remove

1.Remove fixings and remove engine acoustic

cover.

2.Remove 3 bolts and remove exhaust manifold

heat shield.

3.Disconnect multiplug from oil pressure switch.

4.Position container below switch to catch oil

spillage.

5.Remove oil pressure switch from oil cooler

housing.

Page 277 of 1672

ENGINE - V8

12-2-34 REPAIRS

4.Ensure ring gear is correctly seated around the

complete circumference of flywheel and allow

to cool.

5.Fit flywheel.

+ ENGINE - V8, REPAIRS, Flywheel.

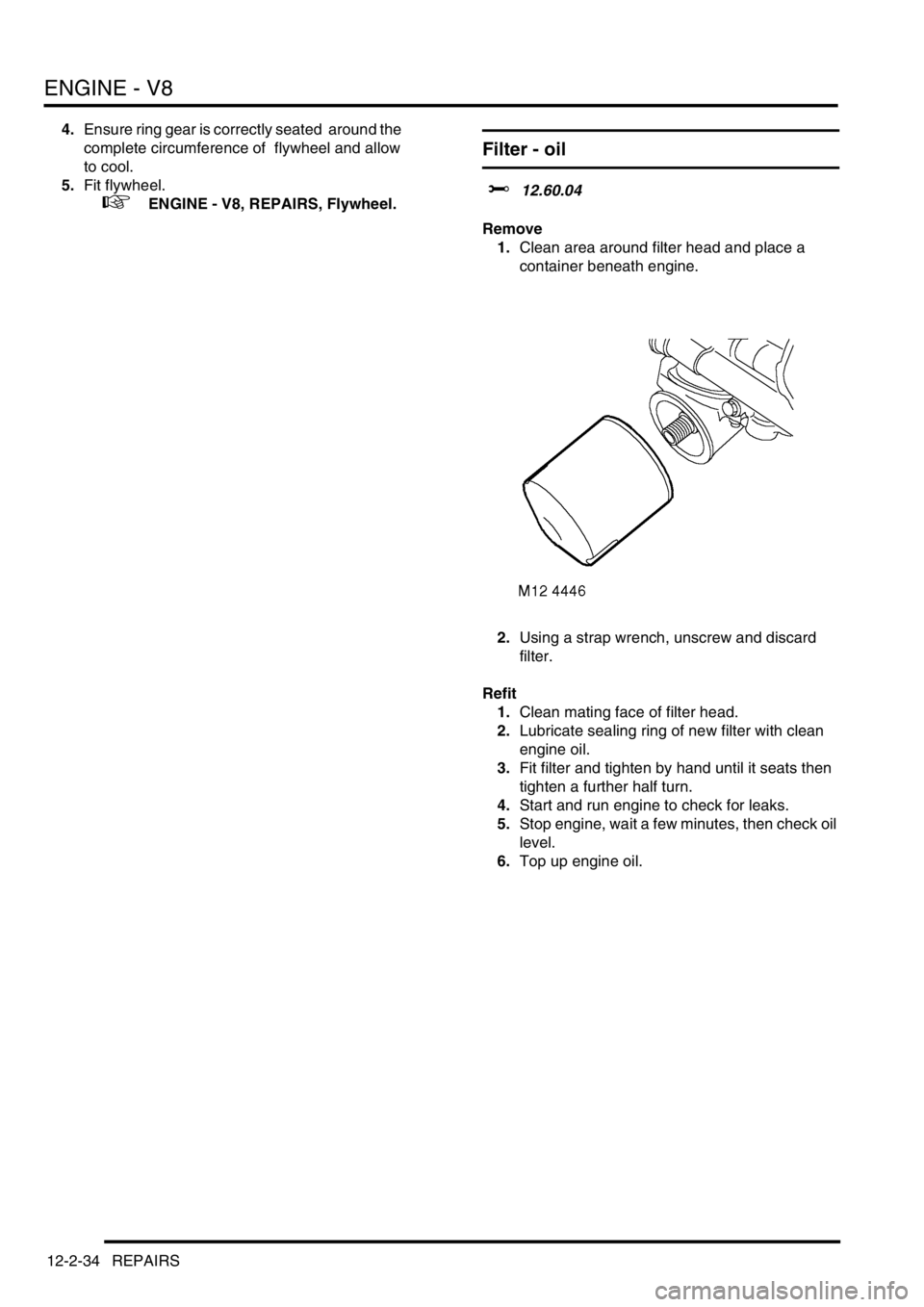

Filter - oil

$% 12.60.04

Remove

1.Clean area around filter head and place a

container beneath engine.

2.Using a strap wrench, unscrew and discard

filter.

Refit

1.Clean mating face of filter head.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit filter and tighten by hand until it seats then

tighten a further half turn.

4.Start and run engine to check for leaks.

5.Stop engine, wait a few minutes, then check oil

level.

6.Top up engine oil.

Page 325 of 1672

EMISSION CONTROL - TD5

17-1-4 DESCRIPTION AND OPERATION

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems fitted

to Land Rover vehicles are designed to maintain the emission levels within the legal limits pertaining for the specified

market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order, so that it operates at its optimum condition.

In addition to emissions improvements through engine design and the application of electronic engine management

systems, special emission control systems are used to limit the pollutant levels developed under certain conditions.

Two main types of additional emission control system are utilised with the Td5 engine to reduce the levels of harmful

emissions released into the atmosphere. These are as follows:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust gas recirculation – to reduce NO

2 emissions.

Crankcase emission control

All internal combustion engines generate oil vapour and smoke in the crankcase as a result of high crankcase

temperatures and piston ring and valve stem blow-by, a closed crankcase ventilation system is used to vent

crankcase gases back to the air induction system and so reduce the emission of hydrocarbons.

Gases from the crankcase are drawn into the inlet manifold to be burnt in the combustion chambers with the fresh air/

fuel mixture. The system provides effective emission control under all engine operating conditions.

Crankcase gases are drawn through the breather port in the top of the camshaft cover and routed through the breather

hose and breather valve on the flexible air intake duct to be drawn into the turbocharger intake for delivery to the air

inlet manifold via an intercooler.

An oil separator plate is included in the camshaft cover which removes the heavy particles of oil before the crankcase

gas leaves via the camshaft cover port. The rocker cover features circular chambers which promote swirl in the oil

mist emanating from the cylinder head and camshaft carrier. As the mist passes through the series of chambers

between the rocker cover and oil separator plate, oil particles are thrown against the separator walls where they

condense and fall back into the cylinder head via two air inlet holes located at each end of the rocker cover.

The breather valve is a depression limiting valve which progressively closes as engine speed increases, thereby

limiting the depression in the crankcase. The valve is of moulded plastic construction and has a port on the underside

which plugs into a port in the flexible air intake duct. A port on the side of the breather valve connects to the camshaft

cover port by means of a breather hose which is constructed from a heavy-duty braided rubber hose which is held in

place by hose clips. A corrugated plastic sleeve is used to give further protection to the breather hose. The breather

valve is orientation sensitive, and “TOP” is marked on the upper surface to ensure it is mounted correctly.

It is important that the system is airtight so hose connections to ports should be checked and the condition of the

breather hose should be periodically inspected to ensure it is in good condition.

Page 346 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-9

Emission Control Systems

Engine design has evolved in order to minimise the emission of harmful by-products. Emission control systems are

fitted to Land Rover vehicles which are designed to maintain the emission levels within the legal limits pertaining for

the specified market.

Despite the utilisation of specialised emission control equipment, it is still necessary to ensure that the engine is

correctly maintained and is in good mechanical order so that it operates at its optimal condition. In particular, ignition

timing has an effect on the production of HC and NO

x emissions, with the harmful emissions rising as the ignition

timing is advanced.

CAUTION: In many countries it is against the law for a vehicle owner or an unauthorised dealer to modify or

tamper with emission control equipment. In some cases, the vehicle owner and/or the dealer may even be

liable for prosecution.

The engine management ECM is fundamental for controlling the emission control systems. In addition to controlling

normal operation, the system complies with On Board Diagnostic (OBD) system strategies. The system monitors and

reports on faults detected with ignition, fuelling and exhaust systems which cause an excessive increase in tailpipe

emissions. This includes component failures, engine misfire, catalyst damage, catalyst efficiency, fuel evaporative

loss and exhaust leaks.

When an emission relevant fault is determined, the fault condition is stored in the ECM memory. For NAS vehicles,

the MIL warning light on the instrument pack will be illuminated when the fault is confirmed. Confirmation of a fault

condition occurs if the fault is still found to be present during the driving cycle subsequent to the one when the fault

was first detected.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The following types of supplementary control system are used to reduce harmful emissions released into the

atmosphere from the vehicle:

1Crankcase emission control – also known as blow-by gas emissions from the engine crankcase.

2Exhaust emission control – to limit the undesirable by-products of combustion.

3Fuel vapour evaporative loss control – to restrict the emission of fuel through evaporation from the fuel

system.

4Fuel leak detection system (NAS only) – there are two types of system which may be used to check the

evaporative emission system for the presence of leaks from the fuel tank to purge valve.

aVacuum leak detection test – checks for leaks down to 1 mm (0.04 in.) in diameter.

bPositive pressure leak detection test – utilises a leak detection pump to check for leaks down to 0.5 mm (0.02

in.) in diameter.

5Secondary air injection system (NAS only) – to reduce emissions experienced during cold starting.

Crankcase emission control system

The concentration of hydrocarbons in the crankcase of an engine is much greater than that in the vehicle's exhaust

system. In order to prevent the emission of these hydrocarbons into the atmosphere, crankcase emission control

systems are employed and are a standard legal requirement.

The crankcase ventilation system is an integral part of the air supply to the engine combustion chambers and it is

often overlooked when diagnosing problems associated with engine performance. A blocked ventilation pipe or filter

or excessive air leak into the inlet system through a damaged pipe or a leaking gasket can affect the air:fuel mixture,

performance and efficiency of the engine. Periodically check the ventilation hoses are not cracked and that they are

securely fitted to form airtight connections at their relevant ports.

The purpose of the crankcase ventilation system is to ensure that any noxious gas generated in the engine crankcase

is rendered harmless by complete burning of the fuel in the combustion chamber. Burning the crankcase vapours in

a controlled manner decreases the HC pollutants that could be emitted and helps to prevent the development of

sludge in the engine oil as well as increasing fuel economy.