ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 666 of 1672

CLUTCH - TD5

REPAIRS 33-1-15

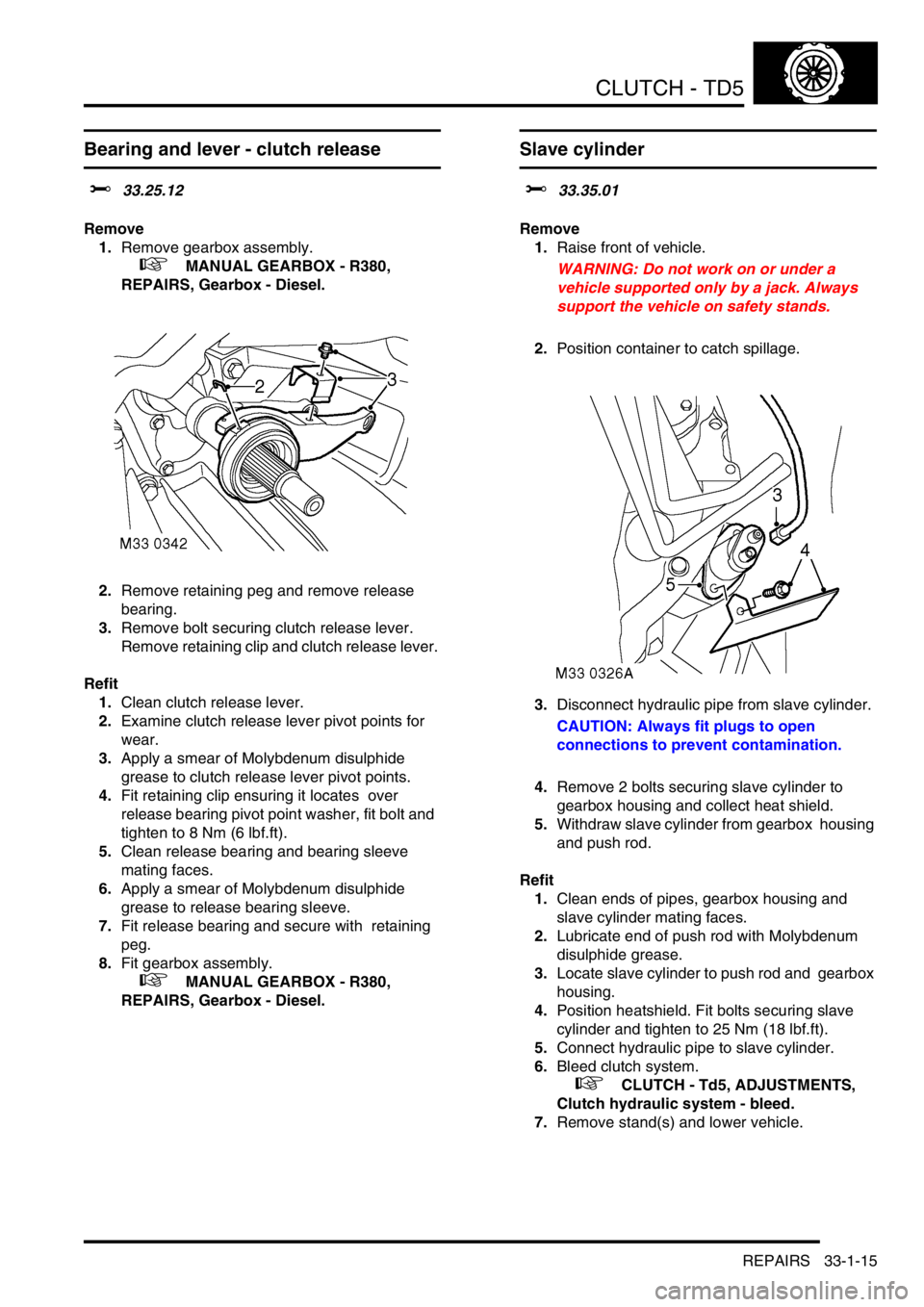

Bearing and lever - clutch release

$% 33.25.12

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - Diesel.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release lever.

Remove retaining clip and clutch release lever.

Refit

1.Clean clutch release lever.

2.Examine clutch release lever pivot points for

wear.

3.Apply a smear of Molybdenum disulphide

grease to clutch release lever pivot points.

4.Fit retaining clip ensuring it locates over

release bearing pivot point washer, fit bolt and

tighten to 8 Nm (6 lbf.ft).

5.Clean release bearing and bearing sleeve

mating faces.

6.Apply a smear of Molybdenum disulphide

grease to release bearing sleeve.

7.Fit release bearing and secure with retaining

peg.

8.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - Diesel.

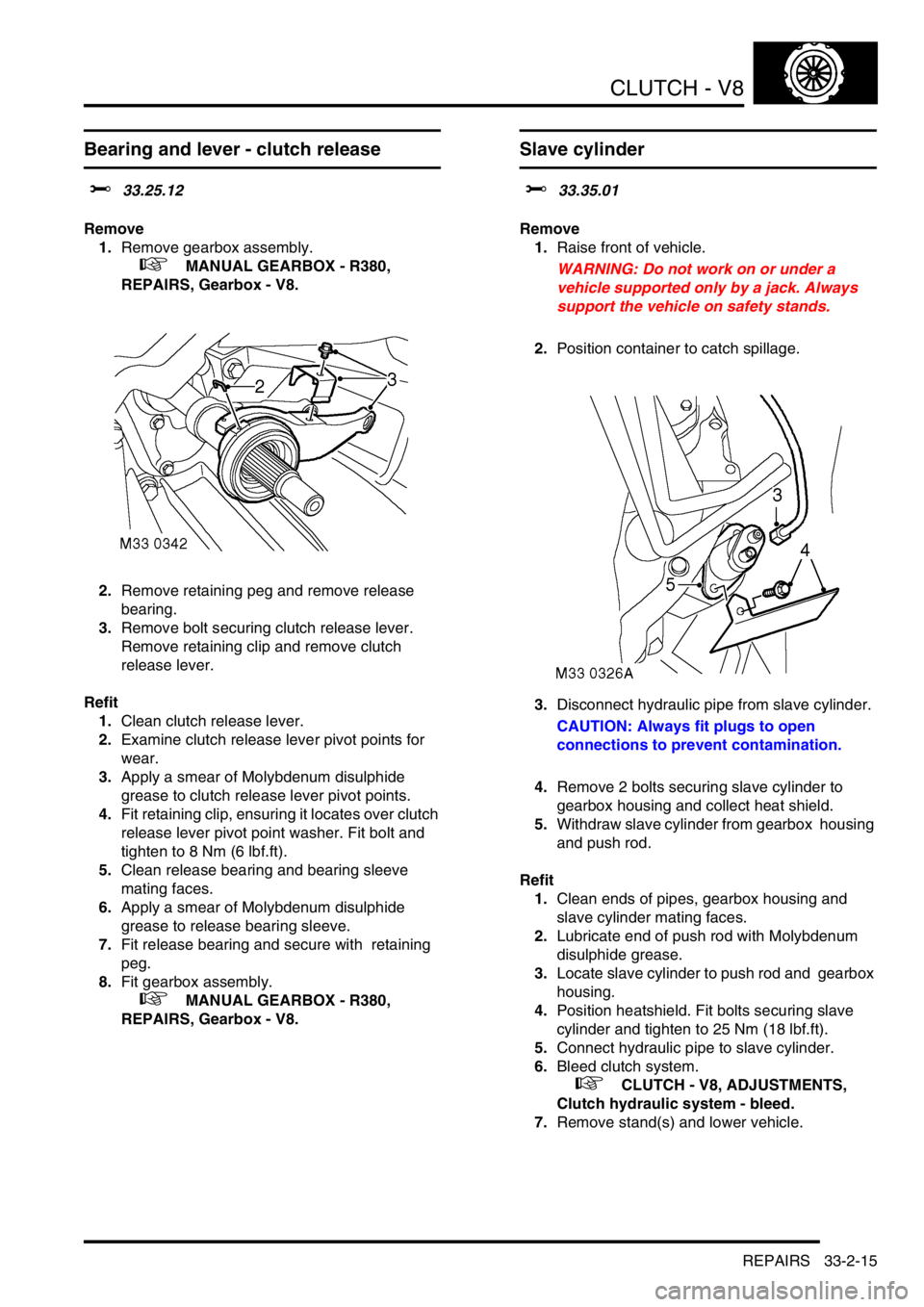

Slave cylinder

$% 33.35.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Position container to catch spillage.

3.Disconnect hydraulic pipe from slave cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove 2 bolts securing slave cylinder to

gearbox housing and collect heat shield.

5.Withdraw slave cylinder from gearbox housing

and push rod.

Refit

1.Clean ends of pipes, gearbox housing and

slave cylinder mating faces.

2.Lubricate end of push rod with Molybdenum

disulphide grease.

3.Locate slave cylinder to push rod and gearbox

housing.

4.Position heatshield. Fit bolts securing slave

cylinder and tighten to 25 Nm (18 lbf.ft).

5.Connect hydraulic pipe to slave cylinder.

6.Bleed clutch system.

+ CLUTCH - Td5, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 673 of 1672

CLUTCH - V8

33-2-6 DESCRIPTION AND OPERATION

Description

General

The clutch system is a conventional diaphragm type clutch operated by a hydraulic cylinder. The clutch requires no

adjustment to compensate for wear.

Hydraulic clutch

The hydraulic clutch comprises a master cylinder, slave cylinder and a hydraulic reservoir, which is also shared with

the braking system. The master and slave cylinders are connected to each other hydraulically by plastic and metal

pipes. The plastic section of the pipe allows ease of pipe routing and also absorbs engine movements and vibrations.

The master cylinder comprises a body with a central bore. Two ports in the body connect the bore to the hydraulic

feed pipe to the slave cylinder and the brake/clutch fluid reservoir. A piston is fitted in the bore and has an external

rod which is attached to the clutch pedal with a pin. Two coiled springs on the clutch pedal reduce the effort required

to depress the pedal.

The master cylinder is mounted on the bulkhead in the engine compartment and secured with two bolts. The cylinder

is connected to the shared brake/clutch reservoir on the brake servo by a braided connecting hose.

The slave cylinder is located on the left hand side of the gearbox housing and secured with two bolts. A heat shield

protects the underside of the cylinder from heat generated from the exhaust system. The slave cylinder comprises a

cylinder with a piston and a rod. A port in the cylinder body provides the attachment for the hydraulic feed pipe from

the master cylinder. A second port is fitted with a bleed nipple for removing air from the hydraulic system after

servicing. The piston rod locates on a clutch release lever located in the gearbox housing. The rod is positively

retained on the release lever with a clip.

Clutch mechanism

The clutch mechanism comprises a flywheel, drive plate, pressure plate, release lever and a release bearing. The

clutch mechanism is fully enclosed at the rear of the engine by the gearbox housing.

A clutch release bearing sleeve is attached in the gearbox housing with two bolts and located on two dowels. A spigot

with a ball end is formed on the release bearing sleeve and provides a mounting and pivot point for the clutch release

lever. A dished pivot washer is located on the ball of the spigot. When the release lever is located on the ball, the pivot

washer seats against the rear face of the release lever. A spring clip is located on the lever and the pivot washer and

secures the lever on the spigot. A small bolt retains the spring clip in position.

The release lever is forked at its inner end and locates on the clutch release bearing carrier. The outer end of the

release lever has a nylon seat which locates the slave cylinder piston rod. A second nylon seat, positioned centrally

on the release lever, locates on the ball spigot of the release bearing sleeve and allows the release lever to pivot freely

around the ball.

The clutch release bearing locates on the clutch release lever and the release bearing sleeve. The bearing is retained

on a carrier which has two flats to prevent the carrier rotating on the release lever. A clip retains the release lever on

the carrier. The bearing and carrier are not serviceable individually.

Page 675 of 1672

CLUTCH - V8

33-2-8 DESCRIPTION AND OPERATION

The pressure plate is forged from cast iron and machined to provide a smooth surface for the drive plate to engage

on. Three lugs on the outer diameter of the pressure plate connect it via three leaf springs to the cover. The leaf

springs have two tempered steel leaves which assist in pulling the pressure plate away from the drive plate when the

clutch pedal is depressed.

The cover is made from pressed steel and houses and locates all pressure plate components. Shouldered rivets

support the diaphragm and fulcrum rings inside the cover. The cover also provides attachment for balance weights

when the pressure plate assembly is balanced. Three holes in the cover locate on the dowels on the flywheel and six

further holes provide for the attachment of the cover to the flywheel with six bolts and spring washers. Larger holes

in the cover provide ventilation for the drive plate and pressure plate and flywheel contact surfaces.

The diaphragm comprises a cast ring with eighteen fingers. The diaphragm is attached to the cover with nine

shouldered rivets. Two circular steel fulcrum rings are also secured by the shouldered rivets on each side of the

diaphragm. The fulcrum rings allow the diaphragm to pivot between them when the clutch is depressed or released.

When pressure is applied to the diaphragm fingers by the release bearing, the diaphragm pivots between the fulcrum

rings and moves away from the pressure plate. Retractor clips are secured to the pressure plate and are located on

the outer diameter of the diaphragm. The retractor clips ensure that the diaphragm remains in contact with the

pressure plate.

Drive plate

1Friction material

2Hub

3Damper spring

4Retainer plate

5Disc adaptor

6Stop pin

Page 676 of 1672

CLUTCH - V8

DESCRIPTION AND OPERATION 33-2-9

The drive plate is of the spring centred type and is sandwiched between the pressure plate and the flywheel. The drive

plate has a splined hub which engages with the splines on the primary drive shaft from the gearbox. The hub is located

in an inner plate which contains six compression damper springs. A spring retainer plate and a disc adaptor are

secured together with stop pins which limit the angular deflection of the disc adaptor. Engine power is transmitted from

the disc adaptor to the damper springs. The damper springs then transfer the power to the retainer plate and the hub.

Friction washers are located between the hub, retainer plate and disc adaptor and provide further damping.

A spring steel plate is riveted to the disc adaptor and provides the attachment surface for the drive plate friction

material. The friction material comprises discs which are secured with rivets to each side of the plate. The rivets are

installed through recessed holes in the disc and emerge in recessed holes in the opposite disc. The drive plate is 267

mm (10.5 in) diameter and has a friction material manufactured from APTEC T385.

Page 680 of 1672

CLUTCH - V8

REPAIRS 33-2-13

REPAIRS

Clutch assembly

$% 33.10.01

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

2.Restrain flywheel.

3.Working in diagonal sequence, progressively

loosen 6 bolts securing clutch cover to flywheel.

Remove bolts.

4.Remove clutch cover.

5.Remove clutch plate.

6.Renew all worn or damaged components.Refit

1.Clean clutch cover and flywheel mating faces

and spigot bush in end of crankshaft.

2.Fit LRT-12-001 to spigot bearing in crankshaft.

3.Fit clutch plate onto LRT-12-001, ensure side

marked 'flywheel side' is against flywheel.

4.Fit clutch cover and locate on dowels.

5.Fit clutch cover bolts and progressively tighten,

in diagonal sequence shown, to 40 Nm. (30

lbf.ft).

6.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Page 681 of 1672

CLUTCH - V8

33-2-14 REPAIRS

Master cylinder

$% 33.20.01

CAUTION: Brake fluid will damage paint finished

surfaces. If spilled, immediately remove fluid and

clean area with water.

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Release spring clip securing clutch pedal

clevis pin and remove pin from push rod and

clutch pedal.

3.Position container to catch spillage. Disconnect

hydraulic pipe from clutch master cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.4.Release clip and remove connecting hose from

clutch master cylinder.

5.Remove 2 bolts securing clutch master

cylinder to pedal box and remove clutch master

cylinder.

Refit

1.Clean master cylinder and pedal box mating

faces.

2.Position clutch master cylinder to pedal box, fit

bolts and tighten to 25 Nm (18 lbf.ft).

3.Position clevis pin to push-rod and clutch pedal

and secure with spring clip.

4.Fit connecting hose to brake master cylinder

and tighten clip.

5.Position hydraulic pipe and tighten union to 18

Nm (13 lbf.ft).

6.Bleed clutch.

+ CLUTCH - V8, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 682 of 1672

CLUTCH - V8

REPAIRS 33-2-15

Bearing and lever - clutch release

$% 33.25.12

Remove

1.Remove gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

2.Remove retaining peg and remove release

bearing.

3.Remove bolt securing clutch release lever.

Remove retaining clip and remove clutch

release lever.

Refit

1.Clean clutch release lever.

2.Examine clutch release lever pivot points for

wear.

3.Apply a smear of Molybdenum disulphide

grease to clutch release lever pivot points.

4.Fit retaining clip, ensuring it locates over clutch

release lever pivot point washer. Fit bolt and

tighten to 8 Nm (6 lbf.ft).

5.Clean release bearing and bearing sleeve

mating faces.

6.Apply a smear of Molybdenum disulphide

grease to release bearing sleeve.

7.Fit release bearing and secure with retaining

peg.

8.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Slave cylinder

$% 33.35.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Position container to catch spillage.

3.Disconnect hydraulic pipe from slave cylinder.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove 2 bolts securing slave cylinder to

gearbox housing and collect heat shield.

5.Withdraw slave cylinder from gearbox housing

and push rod.

Refit

1.Clean ends of pipes, gearbox housing and

slave cylinder mating faces.

2.Lubricate end of push rod with Molybdenum

disulphide grease.

3.Locate slave cylinder to push rod and gearbox

housing.

4.Position heatshield. Fit bolts securing slave

cylinder and tighten to 25 Nm (18 lbf.ft).

5.Connect hydraulic pipe to slave cylinder.

6.Bleed clutch system.

+ CLUTCH - V8, ADJUSTMENTS,

Clutch hydraulic system - bleed.

7.Remove stand(s) and lower vehicle.

Page 690 of 1672

MANUAL GEARBOX - R380

DESCRIPTION AND OPERATION 37-7

Description

General

The R380 all synchromesh gearbox has five forward speeds and reverse and is mounted in line with the engine. The

clutch bell housing is bolted to the front of the gearbox and the transfer box is mounted at the rear.

Gearbox casings

Gearbox casings consist of a front cover, gearcase, centre plate and extension housing. All casings with the exception

of the front cover are located to each other by dowels and sealed. Gearbox filler/level and drain plugs are located in

the gearcase.

Reverse lamp switch

A reverse lamp switch is inserted into the extension housing. Selection of reverse gear will close the switch allowing

current from fuse 25 to flow through the switch to illuminate the reverse lamps. The switch also provides a feed to the

BCU and the automatic interior mirror - if fitted; the mirror moving to the dimming position.

Gearchange assembly

The gearchange assembly is bolted to the top of the gearcase, the upper gear lever being attached to the lower gear

lever by means of a clamp bolt. The lower gear lever ball is housed in a Railko bush inserted in the gear change

housing, the end of the lever locating in the selector yoke which is attached to the end of the selector shaft. Bias

springs provide a positive return of the gear lever to the neutral position with selection of 1st/2nd and 5th/reverse gears

being against bias spring pressure. Spring loaded detent balls fitted in the centre plate locate in grooves in the selector

shaft to provide positive gear and neutral selection.

Lubrication

Lubrication is by an oil pump located in the extension housing and driven by the layshaft with additional lubrication

being provided by splash. The pump directs oil via a filter and internal drillings in the output shaft to lubricate the

components. On non UK and non European models, provision for oil cooling is by means of a thermostat housed in

a cover bolted to the side of the extension housing. The cover incorporates tappings for connections to an oil cooler.

On UK and European models, the thermostat and cover are replaced by an oil by-pass block.

Internal pressures produced within the gearbox are vented to atmosphere via a plastic breather pipe. The pipe is

attached to the extension housing and is routed across the top of the gearcase and secured at the open end by a clip

attached to the engine cylinder block.

Selector shaft and forks

Selector forks for 1st/2nd, 3rd/4th and 5th/reverse gears are located on a single selector shaft; the 1st/2nd and 3rd/

4th selector forks are inside the main gearcase whilst the 5th/reverse selector fork is inside the extension housing.

Each of the selector forks locates inside its corresponding synchromesh hub.

Synchromesh assemblies

Each synchromesh assembly is located on the output shaft adjacent to its corresponding gears and comprises a

synchromesh ring, hub, slippers and sleeve. The hubs and slippers are retained in the sleeves by means of spring

clips. 1st/2nd and 3rd synchromesh assemblies are fitted with double synchromesh rings whilst 4th, 5th and reverse

assemblies are fitted with single rings.

Page 692 of 1672

MANUAL GEARBOX - R380

ADJUSTMENTS 37-9

ADJUST ME NTS

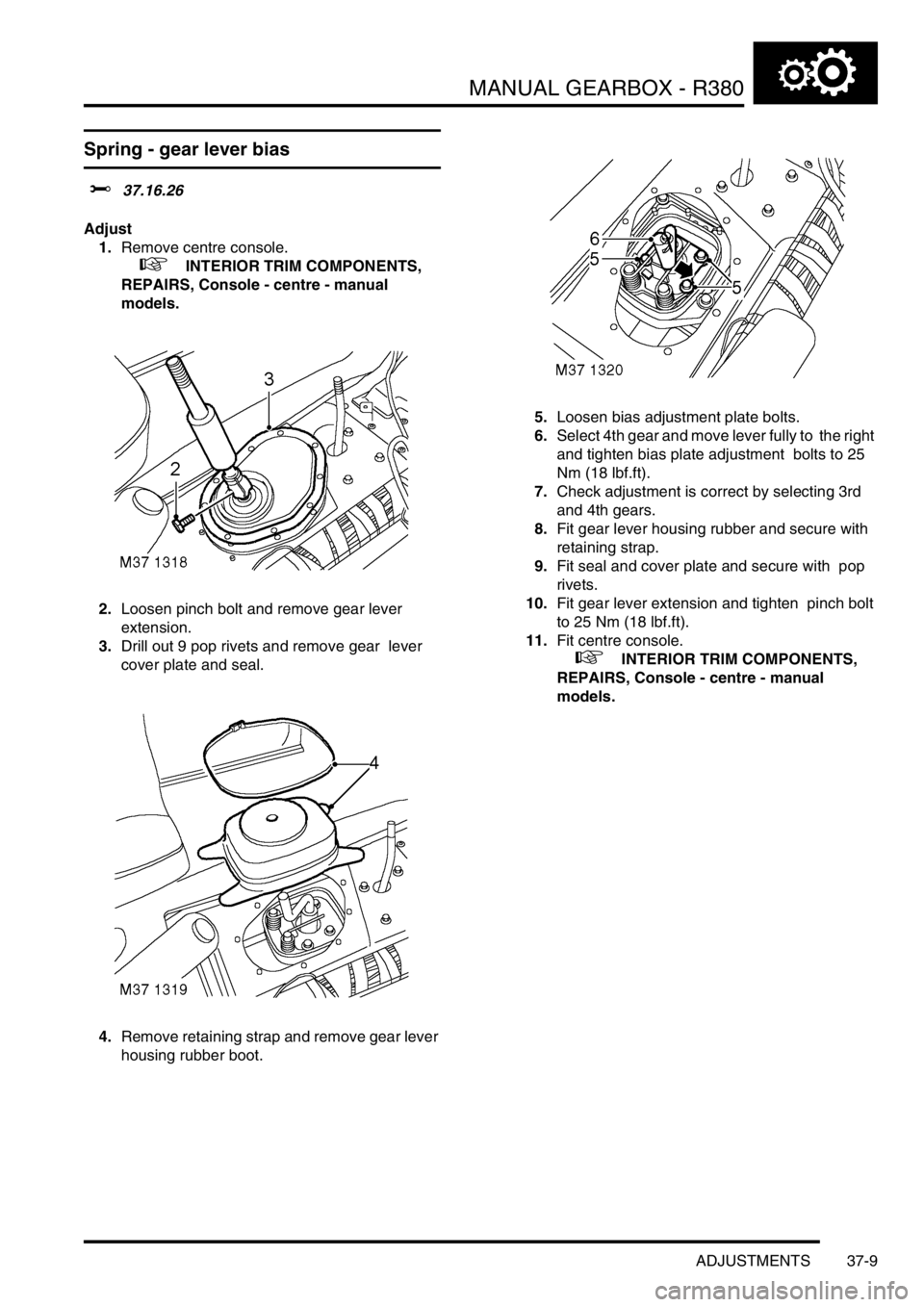

Spring - gear lever bias

$% 37.16.26

Adjust

1.Remove centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

2.Loosen pinch bolt and remove gear lever

extension.

3.Drill out 9 pop rivets and remove gear lever

cover plate and seal.

4.Remove retaining strap and remove gear lever

housing rubber boot.5.Loosen bias adjustment plate bolts.

6.Select 4th gear and move lever fully to the right

and tighten bias plate adjustment bolts to 25

Nm (18 lbf.ft).

7.Check adjustment is correct by selecting 3rd

and 4th gears.

8.Fit gear lever housing rubber and secure with

retaining strap.

9.Fit seal and cover plate and secure with pop

rivets.

10.Fit gear lever extension and tighten pinch bolt

to 25 Nm (18 lbf.ft).

11.Fit centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

Page 694 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-11

REPAIRS

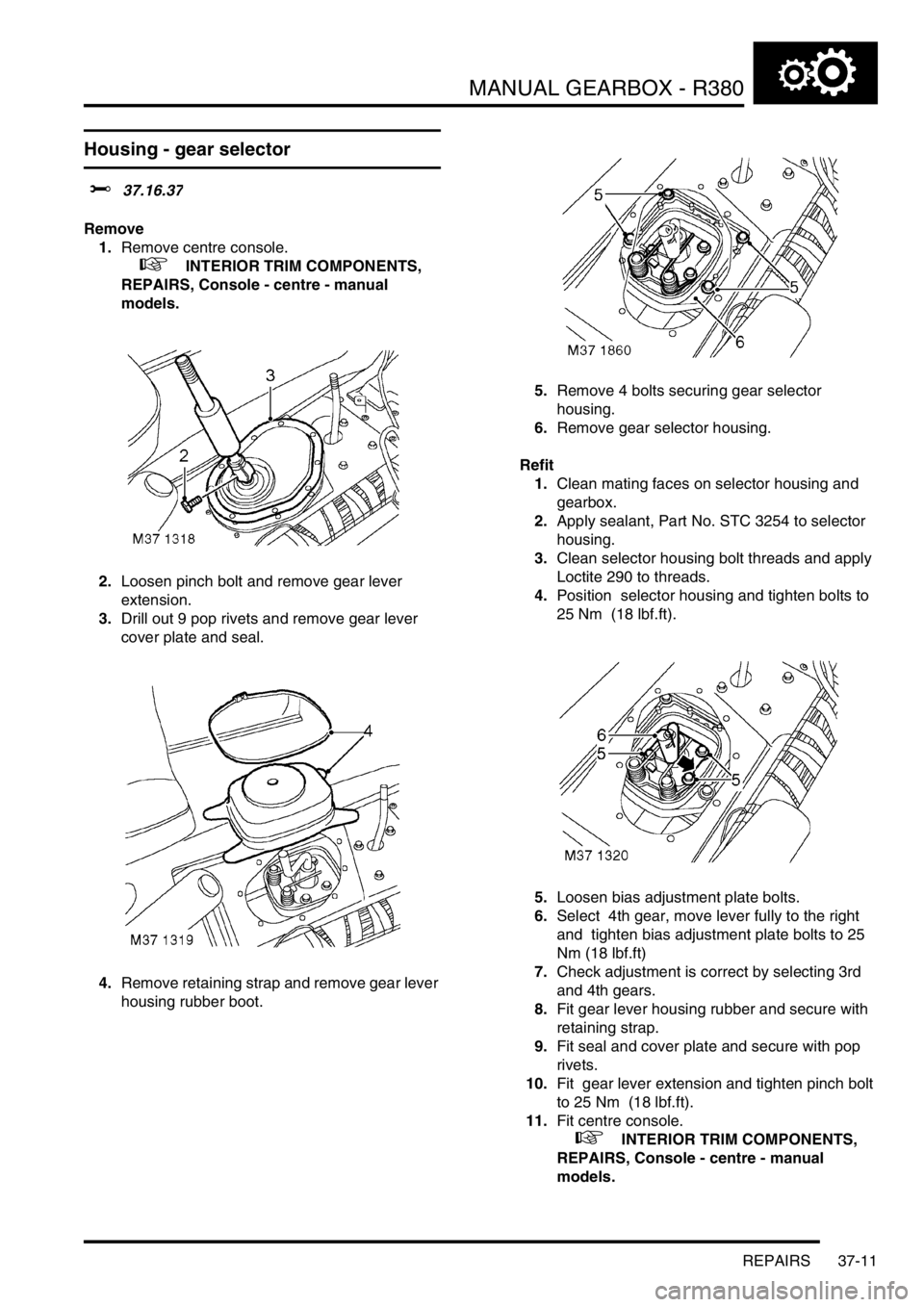

Housing - gear selector

$% 37.16.37

Remove

1.Remove centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

2.Loosen pinch bolt and remove gear lever

extension.

3.Drill out 9 pop rivets and remove gear lever

cover plate and seal.

4.Remove retaining strap and remove gear lever

housing rubber boot.5.Remove 4 bolts securing gear selector

housing.

6.Remove gear selector housing.

Refit

1.Clean mating faces on selector housing and

gearbox.

2.Apply sealant, Part No. STC 3254 to selector

housing.

3.Clean selector housing bolt threads and apply

Loctite 290 to threads.

4.Position selector housing and tighten bolts to

25 Nm (18 lbf.ft).

5.Loosen bias adjustment plate bolts.

6.Select 4th gear, move lever fully to the right

and tighten bias adjustment plate bolts to 25

Nm (18 lbf.ft)

7.Check adjustment is correct by selecting 3rd

and 4th gears.

8.Fit gear lever housing rubber and secure with

retaining strap.

9.Fit seal and cover plate and secure with pop

rivets.

10.Fit gear lever extension and tighten pinch bolt

to 25 Nm (18 lbf.ft).

11.Fit centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.