ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 618 of 1672

COOLING SYSTEM - V8

REPAIRS 26-2-17

16.Remove radiator assembly.

17.Release clip and remove bottom hose from

radiator.

18.Remove 2 bolts and remove extension

brackets from radiator.

19.Remove 2 captive nuts from radiator.

20.Remove 2 screws and remove gearbox oil

cooler from radiator.

21. If fitted: Remove 2 screws and remove engine

oil cooler from radiator.

22.Remove 2 rubber mountings from radiator.

23.Remove sealing strip from bottom of radiator.

24.Remove 2 cowl retaining clips from radiator. Refit

1.Fit cowl retaining clips to radiator.

2.Fit sealing strip to radiator.

3.Fit rubber mountings to radiator.

4.Fit gearbox oil cooler to radiator and secure

with screws.

5. If fitted: Fit engine oil cooler to radiator and

secure with screws.

6.Fit captive nuts to radiator.

7.Fit extension brackets to radiator and secure

with bolts.

8.Fit bottom hose to radiator and secure with clip.

9.Fit radiator and engage lower mountings in

chassis.

10.Ensure connections are clean, then secure

hoses to oil coolers.

11.Fit air conditioning condenser brackets and

secure with screws.

12.Fit radiator upper mounting brackets and

secure with bolts.

13.Fit LH horn and secure with nut.

14.Fit air deflectors and secure with scrivets.

15.Connect multiplug of gearbox oil temperature

sensor.

16.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

17.Connect bottom hose to thermostat housing

and secure with clip.

18.Connect top hose to radiator and secure with

clip.

19.Connect bleed hose to radiator and fit clip.

20.Fit lower fan cowl and secure with screws.

21.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

22.Top up gearbox oil.

23.Top up engine oil.

24.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 619 of 1672

COOLING SYSTEM - V8

26-2-18 REPAIRS

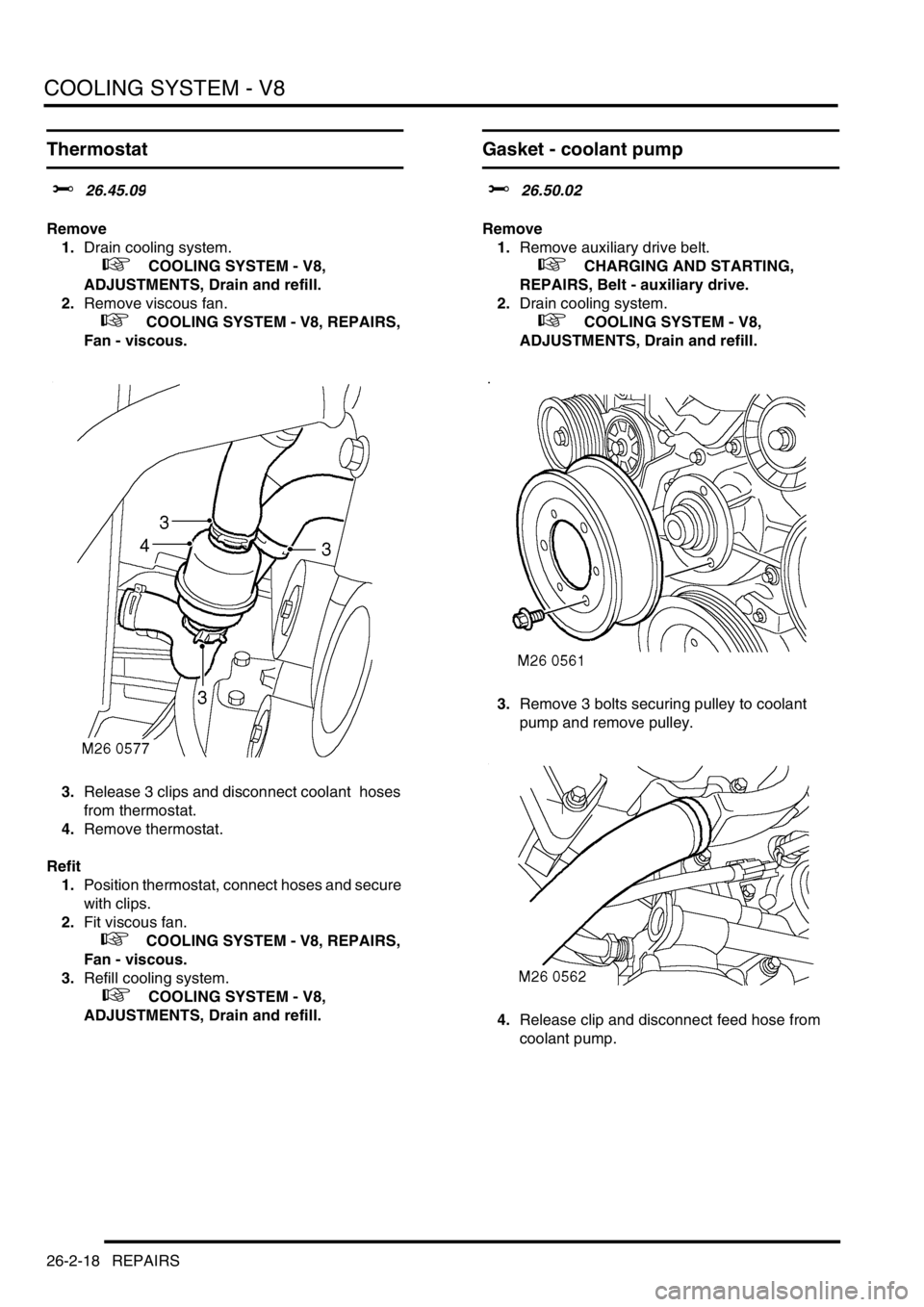

Thermostat

$% 26.45.09

Remove

1.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2.Remove viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

3.Release 3 clips and disconnect coolant hoses

from thermostat.

4.Remove thermostat.

Refit

1.Position thermostat, connect hoses and secure

with clips.

2.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

3.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

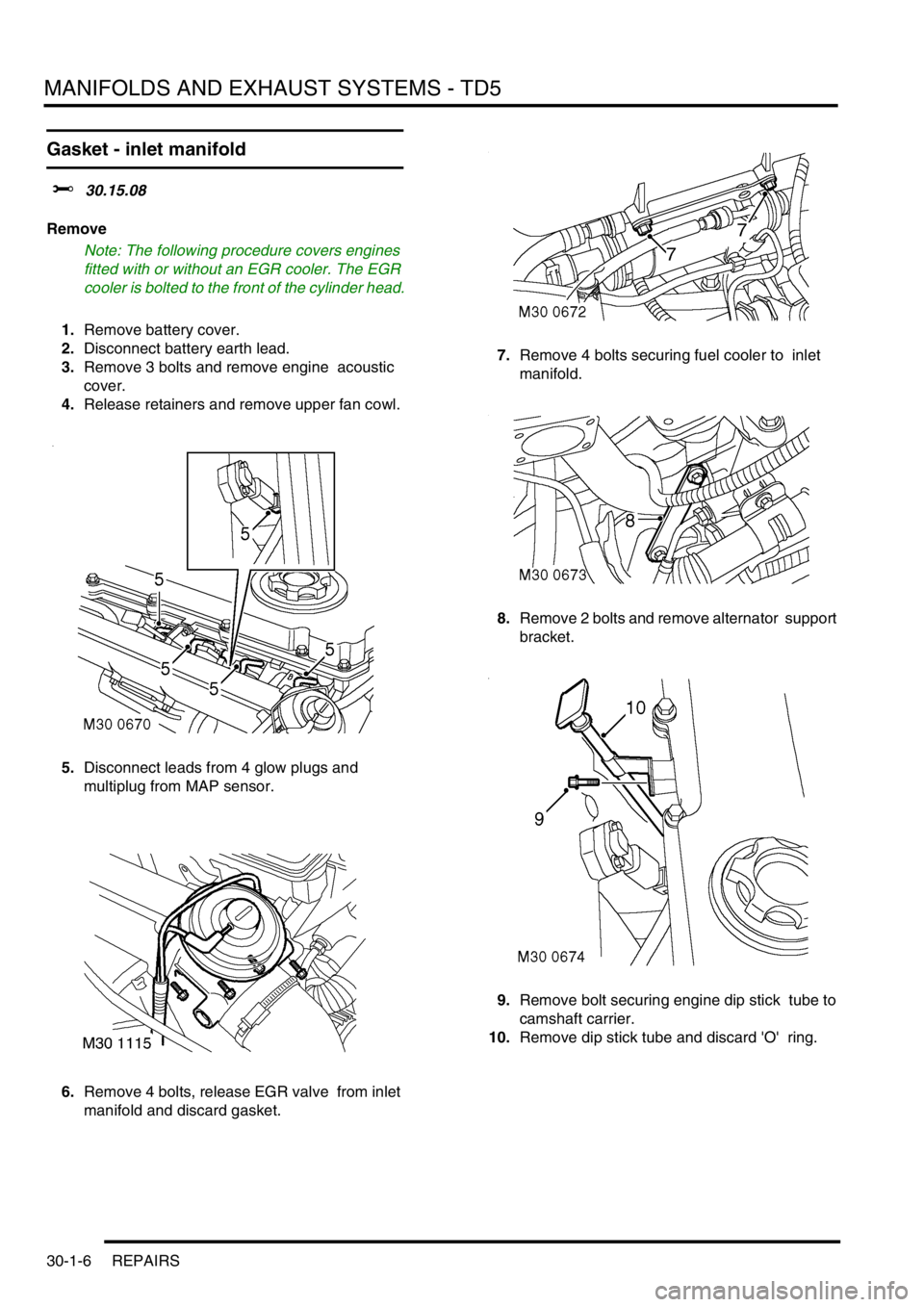

Gasket - coolant pump

$% 26.50.02

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

3.Remove 3 bolts securing pulley to coolant

pump and remove pulley.

4.Release clip and disconnect feed hose from

coolant pump.

Page 620 of 1672

COOLING SYSTEM - V8

REPAIRS 26-2-19

5.Remove 9 bolts securing coolant pump,

remove pump and discard gasket. Refit

1.Clean coolant pump and mating face.

2.Fit new gasket and coolant pump to cylinder

block. Fit bolts and tighten to 24 Nm (18 lbf.ft).

3.Connect feed hose to coolant pump and secure

with clip.

4.Ensure mating faces of coolant pump pulley

and flange are clean. Fit pulley and tighten

bolts to 22 Nm (16 lbf.ft).

5.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

6.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 624 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

DESCRIPTION AND OPERATION 30-1-3

Description

General

The diesel engine has the inlet manifold attached to the right hand side of the engine and the exhaust manifold

attached to the left hand side of the engine. The inlet manifold directs cooled compressed air from the turbocharger

and intercooler into the cylinders, where it is mixed with fuel from the injectors. Exhaust gases from the exhaust

manifold can also be directed into the inlet manifold via a pipe from the exhaust manifold and an Exhaust Gas

Recirculation (EGR) valve on the inlet manifold. The exhaust manifold allows combustion gases from the cylinders to

leave the engine where they are directed into the exhaust system and turbocharger.

The exhaust system is attached to the turbocharger and is directed along the underside of the vehicle to emit exhaust

gases from a tail pipe at the rear of the vehicle. A silencer is installed midway along the system and a second tail

silencer is located at the rear of the vehicle.

Inlet manifold

The inlet manifold is a one piece aluminium casting. The manifold is secured to the cylinder head with two studs and

flanged nuts and eight flanged bolts. A one piece laminated gasket seals the manifold to the cylinder head.

Four threaded bosses on the manifold provide for the attachment of the fuel cooler. The fuel cooler is secured to the

manifold with four bolts. A boss with two threaded holes allows for the attachment of the combined intake air

temperature/pressure sensor. The sensor is secured to the manifold with two screws and sealed with a gasket.

At the forward end of the manifold, a machined face and four threaded holes provide for the attachment of the EGR

valve. The valve is sealed to the manifold with a gasket.

+ EMISSION CONTROL - Td5, DESCRIPTION AND OPERATION, Emission Control Systems.

Exhaust manifold

The exhaust manifold is made from cast iron. The manifold has five ports, one from each cylinder, which merge into

one flanged outlet connection positioned centrally on the manifold.

The manifold is attached to the cylinder head with ten studs and flanged nuts. A laminated metal gasket seals the

manifold to the cylinder head. The flanged outlet on the manifold provides the attachment for the turbocharger, which

is attached with three studs and flanged nuts and sealed with a metal laminated gasket.

A second flanged outlet, located at the forward end of the manifold, provides attachment for the EGR pipe. The EGR

pipe is secured to the manifold with two cap screws and connected to the EGR valve mounted on the inlet manifold.

There is no gasket used between the pipe and the exhaust manifold.

+ EMISSION CONTROL - Td5, DESCRIPTION AND OPERATION, Emission Control Systems.

Exhaust system

The exhaust system comprises a front pipe, an intermediate pipe which incorporates a silencer and a tail pipe

assembly which also has a silencer. The exhaust system is constructed mainly of 63 mm (2.48 in) diameter extruded

pipe with a 1.5 mm (0.06 in) wall thickness. All pipes are aluminized to resist corrosion and the silencers are fabricated

from stainless steel sheet.

Page 625 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

30-1-4 DESCRIPTION AND OPERATION

Front pipe assembly

The front pipe is of welded and fabricated tubular construction. The front pipe is connected to a flange on the

turbocharger and secured with three flanged nuts and sealed with a metal laminated gasket. The front pipe

incorporates a flexible pipe near the connection with the turbocharger and terminates in a flanged connection with the

intermediate pipe.

The flexible pipe is formed into a concertina shape with woven metal strands around its outer diameter. The flexible

pipe allows for ease of exhaust system alignment and also absorbs engine vibration. The woven metal strands also

increase the longevity of the flexible pipe.

The front pipe is attached via a bracket and a mounting rubber to the chassis. The mounting rubber allows ease of

alignment and vibration absorption.

Intermediate pipe and silencer

The intermediate pipe is of welded and fabricated tubular construction. It connects at its forward end to the front pipe

flange. Two captive studs on the intermediate pipe flange allow for attachment to the front pipe with locknuts. The rear

section of intermediate pipe connects to the tail pipe assembly via a flanged joint, sealed with a metal gasket and

secured with locknuts and studs.

The forward and rear sections are joined by a silencer. The silencer is fabricated from stainless steel sheet to form

the body of the silencer. An end plate closes each end of the silencer and is attached to the body with seam joints.

Perforated baffle tubes, inside the silencer, are connected to the inlet and outlet pipes on each end plate. Internal

baffle plates support the baffle tubes and, together with a stainless steel fibre packing, absorb combustion noise as

the exhaust gases pass through the silencer.

The intermediate pipe is attached by two brackets, positioned at each end of the silencer, and two mounting rubbers

to the chassis. The mounting rubber allows for ease of alignment and vibration absorption.

Tail pipe assembly

The tail pipe is of welded and fabricated construction. The tail pipe connects to the intermediate pipe with a flanged

joint secured with locknuts and sealed with a metal gasket. The pipe is shaped to locate above the rear axle allowing

clearance for axle articulation. The pipe is also curved to clear the left hand side of the fuel tank which has a reflective

shield to protect the tank from heat generated from the pipe.

A fabricated silencer is located at the rear of the tail pipe. The silencer is circular in section and is constructed from

stainless steel sheet. A baffle tube is located inside the silencer and the space around the baffle tube is packed with

a stainless steel fibre. The holes in the baffle tube allow the packing to further reduce combustion noise from the

engine. The tail pipe from the silencer is curved downwards at the rear of the vehicle and directs exhaust gases

towards the ground. The curved pipe allows the exhaust gases to be dissipated by the airflow under the vehicle and

prevents the gases from being drawn behind the vehicle.

The tail pipe is attached by a bracket, positioned forward of the silencer, and a mounting rubber to the chassis. The

mounting rubber allows ease of alignment and vibration absorption.

Page 626 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

REPAIRS 30-1-5

REPAIRS

Pipe - front

$% 30.10.09

Remove

1.Remove 3 nuts, release front pipe from

turbocharger and discard gasket.

2.Raise vehicle on ramp.

3.Remove 2 nuts and release front pipe from

intermediate pipe/silencer.

4.Remove 16 bolts and remove chassis cross

members. 5.Release and remove front pipe from mounting.

Refit

1.Clean front pipe and mating faces.

2.Position front pipe and new front pipe to

turbocharger gasket. Align front pipe to

intermediate pipe/silencer and turbocharger.

3.Connect mounting to front pipe.

4.Fit nuts securing front pipe to turbocharger and

intermediate pipe/silencer and tighten to 27 Nm

(20 lbf.ft) .

5.Fit chassis cross members and tighten bolts to

25 Nm (18 lbf. ft).

Page 627 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

30-1-6 REPAIRS

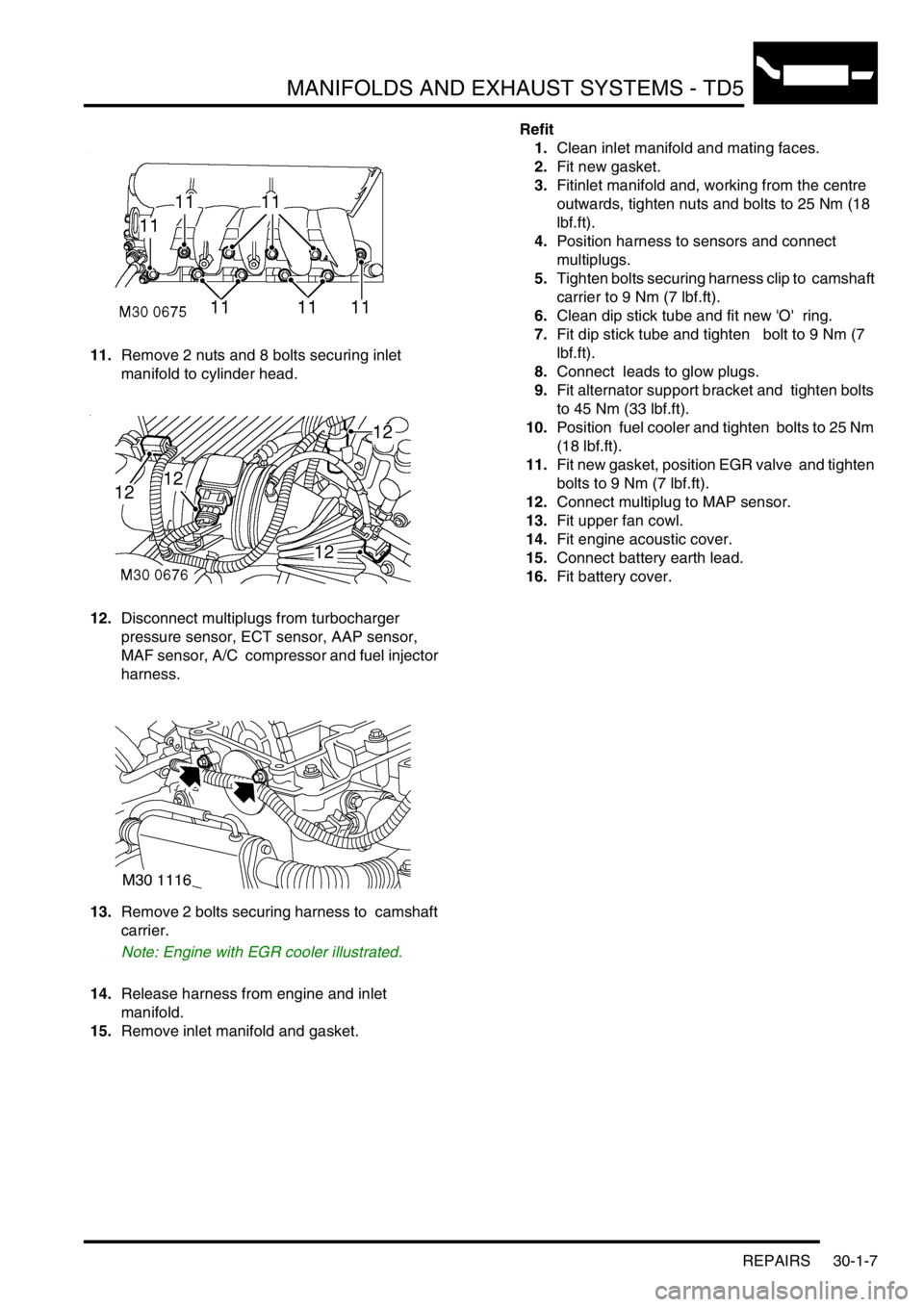

Gasket - inlet manifold

$% 30.15.08

Remove

Note: The following procedure covers engines

fitted with or without an EGR cooler. The EGR

cooler is bolted to the front of the cylinder head.

1.Remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Release retainers and remove upper fan cowl.

5.Disconnect leads from 4 glow plugs and

multiplug from MAP sensor.

6.Remove 4 bolts, release EGR valve from inlet

manifold and discard gasket. 7.Remove 4 bolts securing fuel cooler to inlet

manifold.

8.Remove 2 bolts and remove alternator support

bracket.

9.Remove bolt securing engine dip stick tube to

camshaft carrier.

10.Remove dip stick tube and discard 'O' ring.

Page 628 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

REPAIRS 30-1-7

11.Remove 2 nuts and 8 bolts securing inlet

manifold to cylinder head.

12.Disconnect multiplugs from turbocharger

pressure sensor, ECT sensor, AAP sensor,

MAF sensor, A/C compressor and fuel injector

harness.

13.Remove 2 bolts securing harness to camshaft

carrier.

Note: Engine with EGR cooler illustrated.

14.Release harness from engine and inlet

manifold.

15.Remove inlet manifold and gasket. Refit

1.Clean inlet manifold and mating faces.

2.Fit new gasket.

3.Fitinlet manifold and, working from the centre

outwards, tighten nuts and bolts to 25 Nm (18

lbf.ft).

4.Position harness to sensors and connect

multiplugs.

5.Tighten bolts securing harness clip to camshaft

carrier to 9 Nm (7 lbf.ft).

6.Clean dip stick tube and fit new 'O' ring.

7.Fit dip stick tube and tighten bolt to 9 Nm (7

lbf.ft).

8.Connect leads to glow plugs.

9.Fit alternator support bracket and tighten bolts

to 45 Nm (33 lbf.ft).

10.Position fuel cooler and tighten bolts to 25 Nm

(18 lbf.ft).

11.Fit new gasket, position EGR valve and tighten

bolts to 9 Nm (7 lbf.ft).

12.Connect multiplug to MAP sensor.

13.Fit upper fan cowl.

14.Fit engine acoustic cover.

15.Connect battery earth lead.

16.Fit battery cover.

Page 629 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - TD5

30-1-8 REPAIRS

Gasket - exhaust manifold

$% 30.15.12

Remove

Note: The following procedure covers engines

fitted with or without an EGR cooler. The EGR

cooler is bolted to the front of the cylinder head.

1.Remove turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

2. Models with air conditioning: Remove

auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

3. Models with air conditioning: Remove 4 bolts

securing compressor and move to one side.

4.Remove and discard 2 Allen screws securing

EGR pipe to exhaust manifold.

Note: Engine with EGR cooler illustrated.5.Remove 10 nuts securing exhaust manifold to

cylinder head.

6.Remove exhaust manifold and gasket.

Refit

1.Clean exhaust manifold and mating faces.

2.Fit new gasket.Fit exhaust manifold and,

working from the centre outwards, tighten nuts

to 25 Nm (18 lbf.ft) .

3. Models with air conditioning:

Positioncompressor and tighten bolts to 25 Nm

(18 lbf.ft).

4.Position EGR valve pipe, fit new Allen screws

and tighten to 9 Nm (7 lbf.ft).

5.Fit turbocharger.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Turbocharger.

6. Models with air conditioning: Fit auxiliary

drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Page 634 of 1672

MANIFOLDS AND EXHAUST SYSTEMS - V8

DESCRIPTION AND OPERATION 30-2-5

Description

General

The inlet manifold on the V8 engine is located on the top of the engine, between the cylinders. The manifold directs

intake air into the cylinders. The intake air is mixed with fuel delivered by the injectors prior to ignition in the cylinders.

The inlet manifold comprises three separate aluminium castings.

Two exhaust manifolds are used, one for each bank of four cylinders. Each exhaust manifold allows combustion

gases from the cylinders to leave the engine and directs them into the exhaust system.

The exhaust system is connected to each exhaust manifold and merges into one pipe midway along the underside of

the vehicle. A catalytic converter (where fitted) is located in the front pipe from each manifold. A silencer is installed

midway along the system and a second tail silencer is located at the rear of the vehicle.

Inlet manifold

The inlet manifold comprises three aluminium castings; a lower manifold, an upper manifold and a plenum. The inlet

manifold is located on the top of the engine and feeds air into the cylinders.

Lower manifold

The lower manifold is a one piece machined aluminium casting which locates in the vee on the top of the engine and

is secured to each cylinder head with six bolts per head. A one piece coated metal gasket seals the lower manifold to

each cylinder head and also serves as a cover for the cylinder block.

Eight injectors are fitted into the lower manifold, four on each side. Each injector is sealed in the manifold with O-ring

seals and retained in position by the fuel rails. A fuel rail is attached to each side of the manifold and secured with two

bolts.

Eight air intake ports are cast and machined on the top of the manifold, each port directing intake air into one cylinder.

These ports mate with matching ports in the upper manifold and are sealed with a coated metal gasket between the

two manifolds.

A cavity at the front of the manifold collects coolant flow from the engine. A coolant outlet pipe is sealed and attached

to the front of the manifold and provides for coolant to flow through the cavity in the casting to the radiator top hose.

A smaller port in the manifold also allows coolant to flow from the cavity to the heater matrix. The lower manifold also

locates the Engine Coolant Temperature (ECT) sensor in a port in the front of the manifold.

Upper manifold

The upper manifold is a one piece machined aluminium casting. The manifold has eight ports on its lower face which

mate with the eight ports on the lower manifold. The joint between the upper and lower manifolds is sealed with a

coated metal gasket and secured with six bolts.

The manifold divides from the eight ports into eight branches, four on each side. Each set of four branches merge into

one gallery on each side of the manifold. Each gallery has an opening at its forward end which mates with the intake

plenum.

The upper manifold provides attachment for the Idle Air Control (IAC) valve and for brackets which retain pipes, plug

leads and throttle cables.