oil change LAND ROVER DISCOVERY 2002 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 690 of 1672

MANUAL GEARBOX - R380

DESCRIPTION AND OPERATION 37-7

Description

General

The R380 all synchromesh gearbox has five forward speeds and reverse and is mounted in line with the engine. The

clutch bell housing is bolted to the front of the gearbox and the transfer box is mounted at the rear.

Gearbox casings

Gearbox casings consist of a front cover, gearcase, centre plate and extension housing. All casings with the exception

of the front cover are located to each other by dowels and sealed. Gearbox filler/level and drain plugs are located in

the gearcase.

Reverse lamp switch

A reverse lamp switch is inserted into the extension housing. Selection of reverse gear will close the switch allowing

current from fuse 25 to flow through the switch to illuminate the reverse lamps. The switch also provides a feed to the

BCU and the automatic interior mirror - if fitted; the mirror moving to the dimming position.

Gearchange assembly

The gearchange assembly is bolted to the top of the gearcase, the upper gear lever being attached to the lower gear

lever by means of a clamp bolt. The lower gear lever ball is housed in a Railko bush inserted in the gear change

housing, the end of the lever locating in the selector yoke which is attached to the end of the selector shaft. Bias

springs provide a positive return of the gear lever to the neutral position with selection of 1st/2nd and 5th/reverse gears

being against bias spring pressure. Spring loaded detent balls fitted in the centre plate locate in grooves in the selector

shaft to provide positive gear and neutral selection.

Lubrication

Lubrication is by an oil pump located in the extension housing and driven by the layshaft with additional lubrication

being provided by splash. The pump directs oil via a filter and internal drillings in the output shaft to lubricate the

components. On non UK and non European models, provision for oil cooling is by means of a thermostat housed in

a cover bolted to the side of the extension housing. The cover incorporates tappings for connections to an oil cooler.

On UK and European models, the thermostat and cover are replaced by an oil by-pass block.

Internal pressures produced within the gearbox are vented to atmosphere via a plastic breather pipe. The pipe is

attached to the extension housing and is routed across the top of the gearcase and secured at the open end by a clip

attached to the engine cylinder block.

Selector shaft and forks

Selector forks for 1st/2nd, 3rd/4th and 5th/reverse gears are located on a single selector shaft; the 1st/2nd and 3rd/

4th selector forks are inside the main gearcase whilst the 5th/reverse selector fork is inside the extension housing.

Each of the selector forks locates inside its corresponding synchromesh hub.

Synchromesh assemblies

Each synchromesh assembly is located on the output shaft adjacent to its corresponding gears and comprises a

synchromesh ring, hub, slippers and sleeve. The hubs and slippers are retained in the sleeves by means of spring

clips. 1st/2nd and 3rd synchromesh assemblies are fitted with double synchromesh rings whilst 4th, 5th and reverse

assemblies are fitted with single rings.

Page 698 of 1672

MANUAL GEARBOX - R380

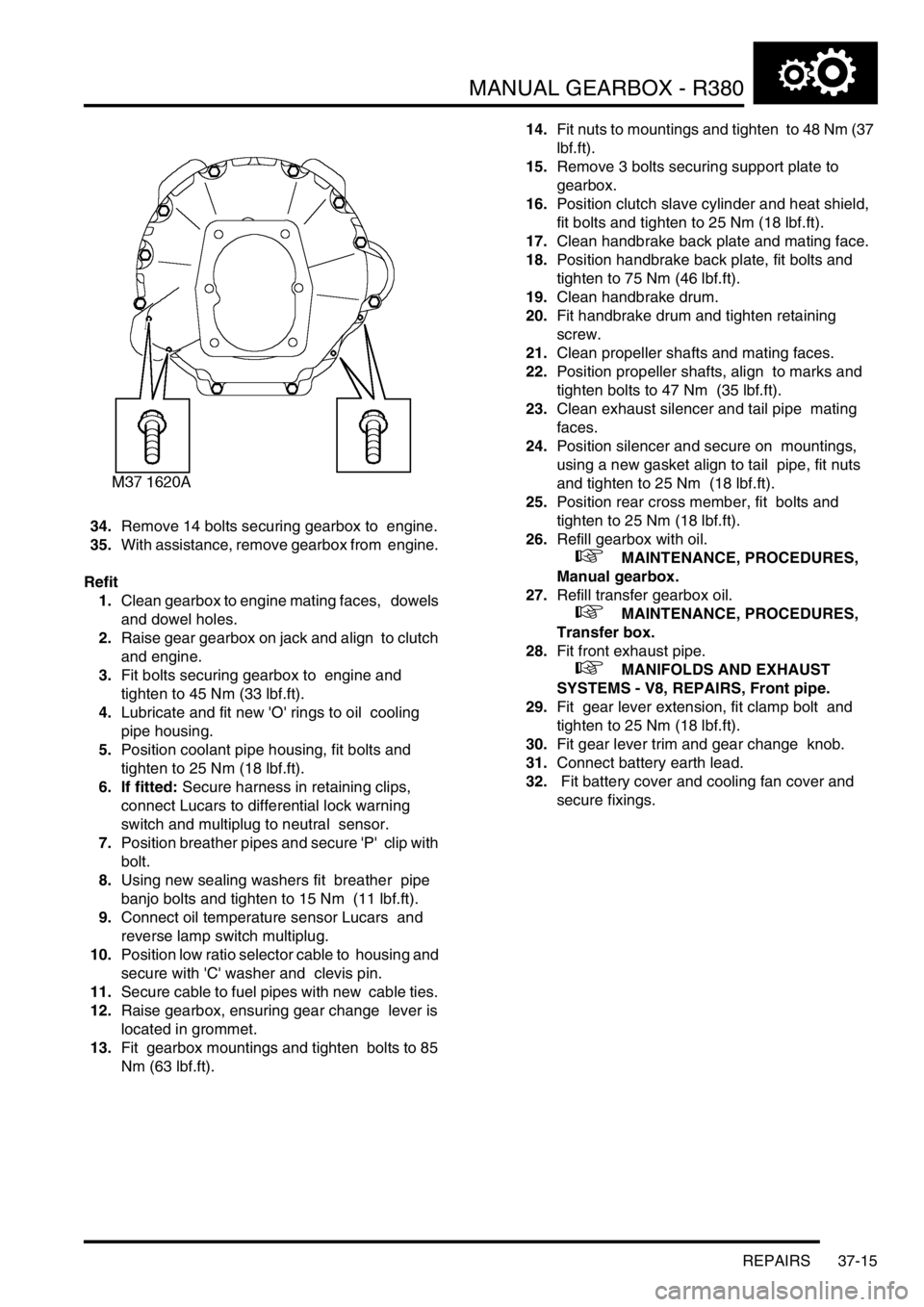

REPAIRS 37-15

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft). 14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 702 of 1672

MANUAL GEARBOX - R380

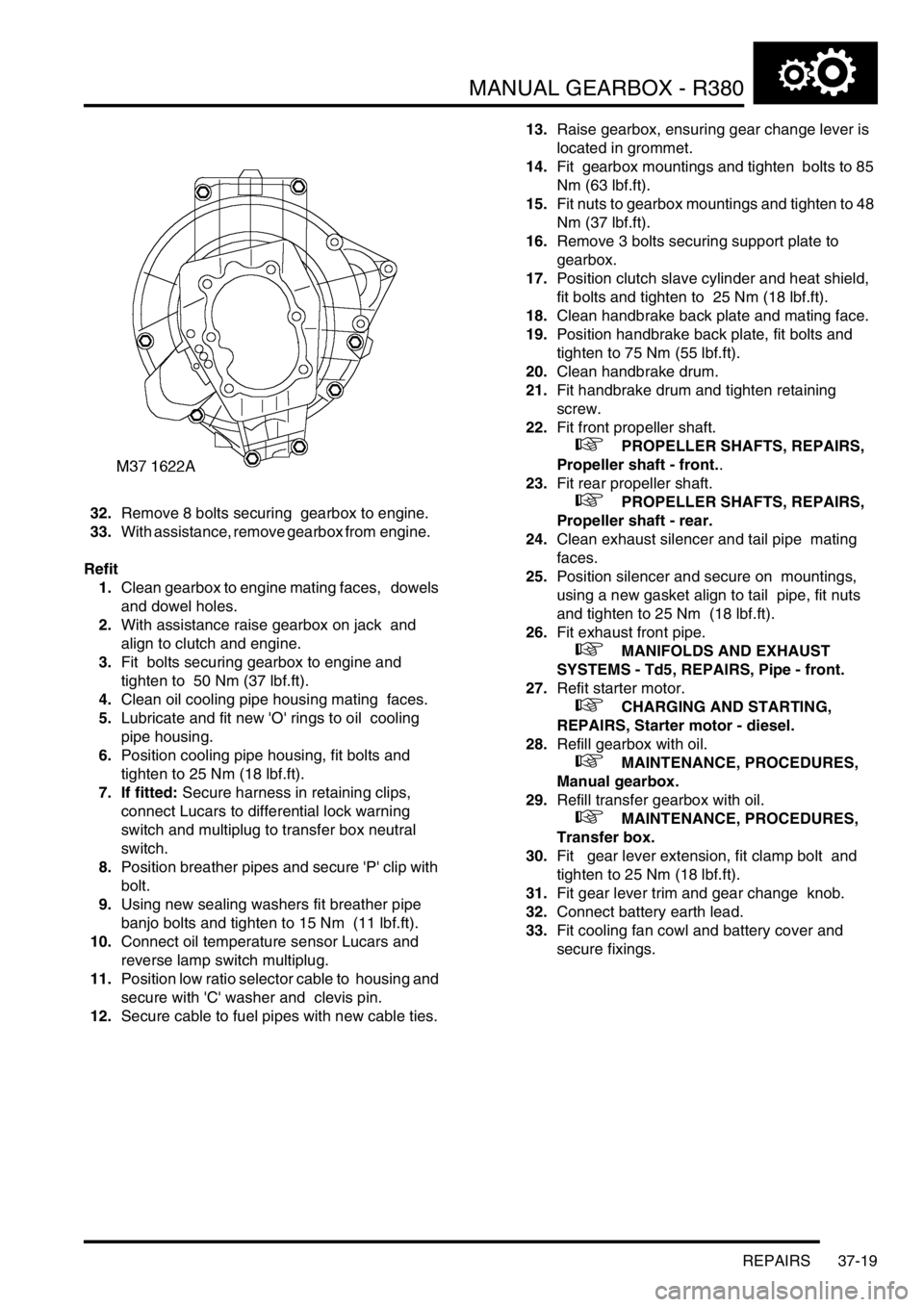

REPAIRS 37-19

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties. 13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox.

17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.

Page 730 of 1672

MANUAL GEARBOX - R380

OVERHAUL 37-47

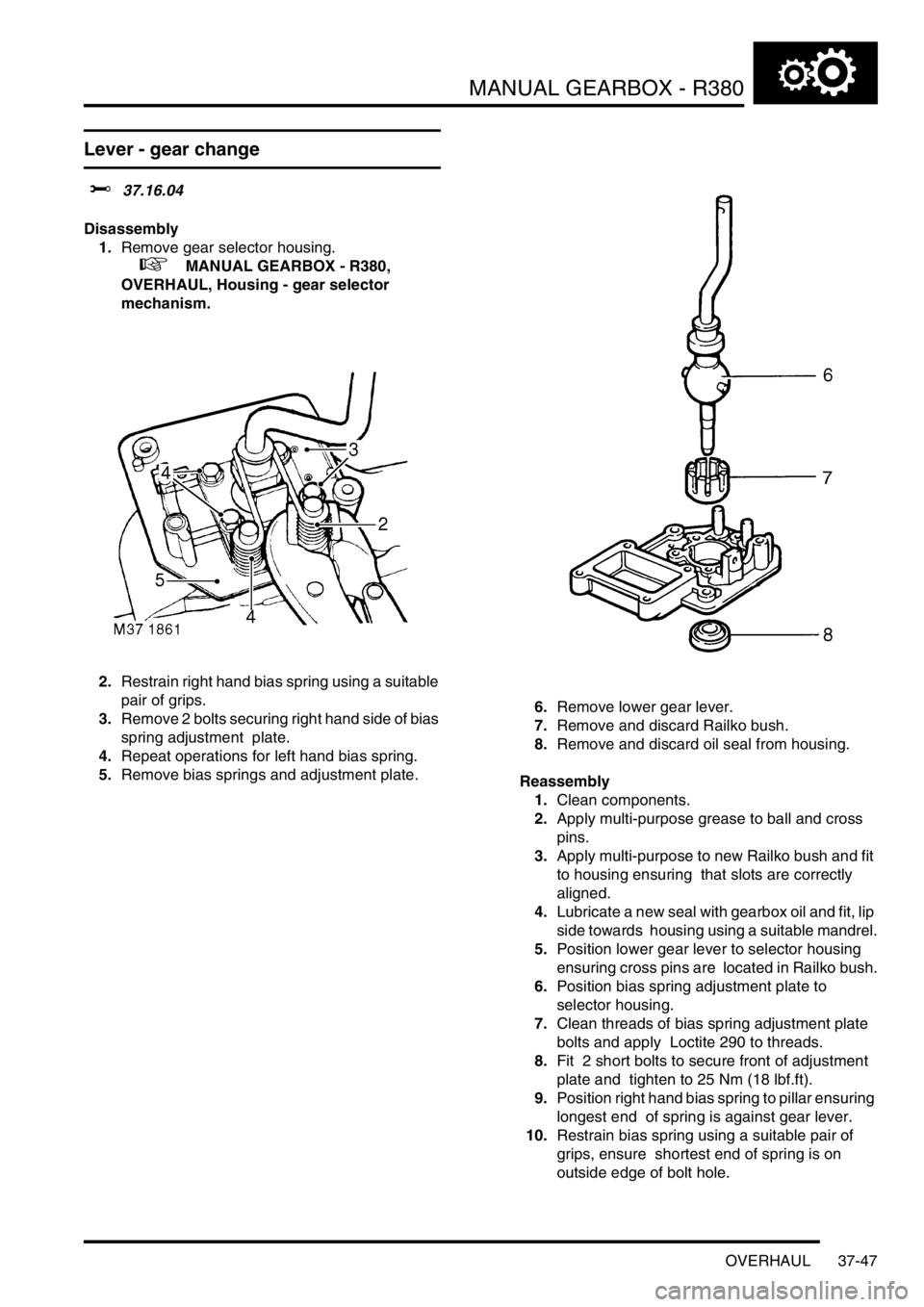

Lever - gear change

$% 37.16.04

Disassembly

1.Remove gear selector housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Housing - gear selector

mechanism.

2.Restrain right hand bias spring using a suitable

pair of grips.

3.Remove 2 bolts securing right hand side of bias

spring adjustment plate.

4.Repeat operations for left hand bias spring.

5.Remove bias springs and adjustment plate.6.Remove lower gear lever.

7.Remove and discard Railko bush.

8.Remove and discard oil seal from housing.

Reassembly

1.Clean components.

2.Apply multi-purpose grease to ball and cross

pins.

3.Apply multi-purpose to new Railko bush and fit

to housing ensuring that slots are correctly

aligned.

4.Lubricate a new seal with gearbox oil and fit, lip

side towards housing using a suitable mandrel.

5.Position lower gear lever to selector housing

ensuring cross pins are located in Railko bush.

6.Position bias spring adjustment plate to

selector housing.

7.Clean threads of bias spring adjustment plate

bolts and apply Loctite 290 to threads.

8.Fit 2 short bolts to secure front of adjustment

plate and tighten to 25 Nm (18 lbf.ft).

9.Position right hand bias spring to pillar ensuring

longest end of spring is against gear lever.

10.Restrain bias spring using a suitable pair of

grips, ensure shortest end of spring is on

outside edge of bolt hole.

Page 765 of 1672

TRANSFER BOX - LT230SE

41-32 REPAIRS

6.Remove bolt securing outer cable clip to cross

shaft housing, remove cable.

Refit

1.Clean change levers, abutment bracket and

clevis pins.

2.Apply Mobilith SHC 100 grease to inner cable

ends and clevis pins.

3.Position cable and secure to high/low lever

abutment bracket with 'C' clip.

4.Secure inner cable to high/low lever with clevis

pin.

5.Position outer cable clip to cross shaft housing,

tighten bolt to 15 Nm (11 lbf.ft).

6.Adjust high/low selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - high/low selector.

Oil seal - input shaft

$% 41.20.50

Remove

1.Remove transfer box.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

2.Lever input shaft oil seal from transfer box.

Refit

1.Clean oil seal recess in transfer gearbox.

2.Lubricate new input shaft oil seal with gearbox

oil.

3.Using tool LRT-37-014 fit input shaft seal to

transfer box.

4.Fit transfer box.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

Page 801 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-4 DESCRIPTION AND OPERATION

Description

General

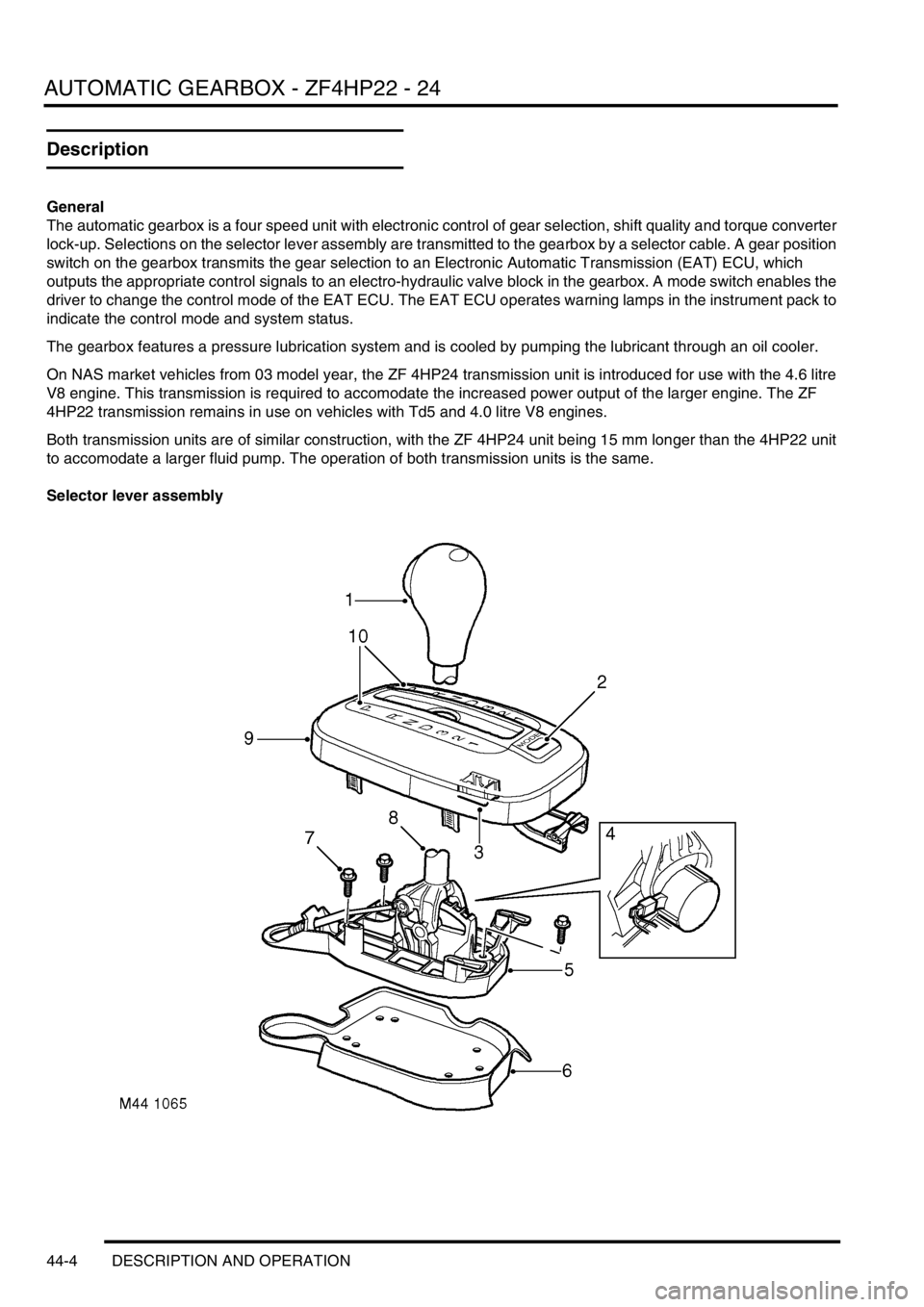

The automatic gearbox is a four speed unit with electronic control of gear selection, shift quality and torque converter

lock-up. Selections on the selector lever assembly are transmitted to the gearbox by a selector cable. A gear position

switch on the gearbox transmits the gear selection to an Electronic Automatic Transmission (EAT) ECU, which

outputs the appropriate control signals to an electro-hydraulic valve block in the gearbox. A mode switch enables the

driver to change the control mode of the EAT ECU. The EAT ECU operates warning lamps in the instrument pack to

indicate the control mode and system status.

The gearbox features a pressure lubrication system and is cooled by pumping the lubricant through an oil cooler.

On NAS market vehicles from 03 model year, the ZF 4HP24 transmission unit is introduced for use with the 4.6 litre

V8 engine. This transmission is required to accomodate the increased power output of the larger engine. The ZF

4HP22 transmission remains in use on vehicles with Td5 and 4.0 litre V8 engines.

Both transmission units are of similar construction, with the ZF 4HP24 unit being 15 mm longer than the 4HP22 unit

to accomodate a larger fluid pump. The operation of both transmission units is the same.

Selector lever assembly

Page 810 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-13

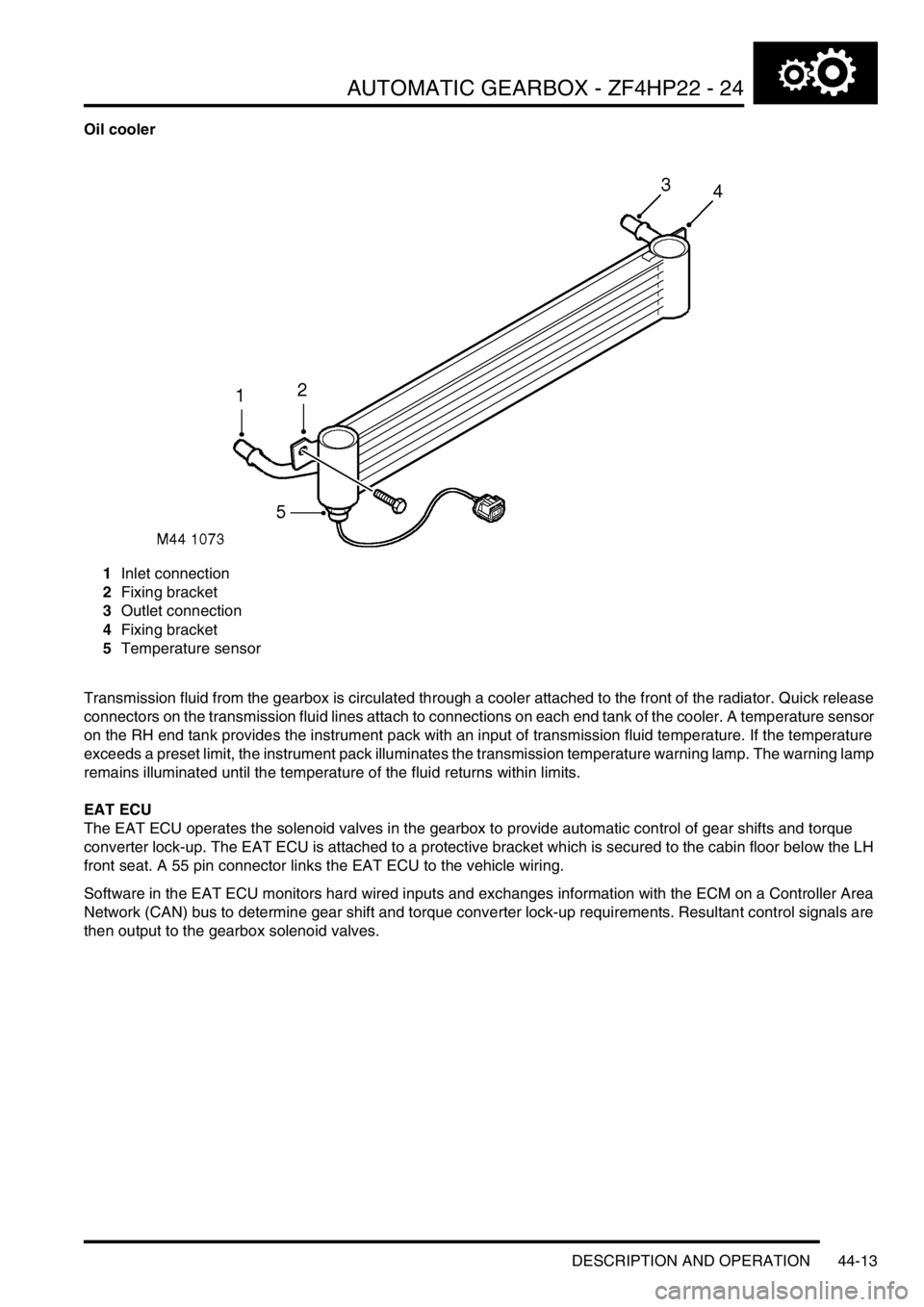

Oil cooler

1Inlet connection

2Fixing bracket

3Outlet connection

4Fixing bracket

5Temperature sensor

Transmission fluid from the gearbox is circulated through a cooler attached to the front of the radiator. Quick release

connectors on the transmission fluid lines attach to connections on each end tank of the cooler. A temperature sensor

on the RH end tank provides the instrument pack with an input of transmission fluid temperature. If the temperature

exceeds a preset limit, the instrument pack illuminates the transmission temperature warning lamp. The warning lamp

remains illuminated until the temperature of the fluid returns within limits.

EAT ECU

The EAT ECU operates the solenoid valves in the gearbox to provide automatic control of gear shifts and torque

converter lock-up. The EAT ECU is attached to a protective bracket which is secured to the cabin floor below the LH

front seat. A 55 pin connector links the EAT ECU to the vehicle wiring.

Software in the EAT ECU monitors hard wired inputs and exchanges information with the ECM on a Controller Area

Network (CAN) bus to determine gear shift and torque converter lock-up requirements. Resultant control signals are

then output to the gearbox solenoid valves.

Page 945 of 1672

FRONT SUSPENSION

60-6 DESCRIPTION AND OPERATION

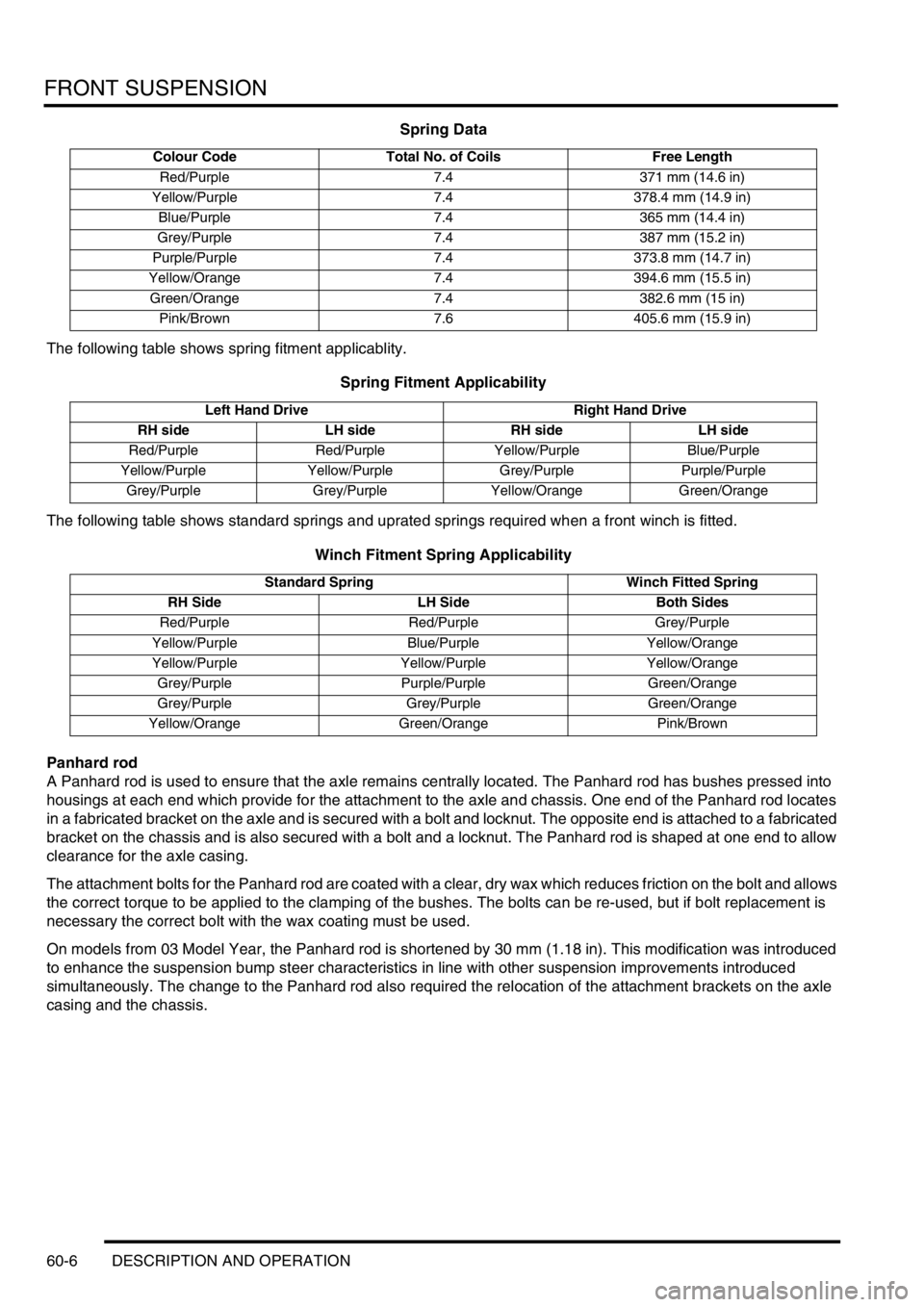

Spring Data

The following table shows spring fitment applicablity.

Spring Fitment Applicability

The following table shows standard springs and uprated springs required when a front winch is fitted.

Winch Fitment Spring Applicability

Panhard rod

A Panhard rod is used to ensure that the axle remains centrally located. The Panhard rod has bushes pressed into

housings at each end which provide for the attachment to the axle and chassis. One end of the Panhard rod locates

in a fabricated bracket on the axle and is secured with a bolt and locknut. The opposite end is attached to a fabricated

bracket on the chassis and is also secured with a bolt and a locknut. The Panhard rod is shaped at one end to allow

clearance for the axle casing.

The attachment bolts for the Panhard rod are coated with a clear, dry wax which reduces friction on the bolt and allows

the correct torque to be applied to the clamping of the bushes. The bolts can be re-used, but if bolt replacement is

necessary the correct bolt with the wax coating must be used.

On models from 03 Model Year, the Panhard rod is shortened by 30 mm (1.18 in). This modification was introduced

to enhance the suspension bump steer characteristics in line with other suspension improvements introduced

simultaneously. The change to the Panhard rod also required the relocation of the attachment brackets on the axle

casing and the chassis.

Colour Code Total No. of Coils Free Length

Red/Purple 7.4 371 mm (14.6 in)

Yellow/Purple 7.4 378.4 mm (14.9 in)

Blue/Purple 7.4 365 mm (14.4 in)

Grey/Purple 7.4 387 mm (15.2 in)

Purple/Purple 7.4 373.8 mm (14.7 in)

Yellow/Orange 7.4 394.6 mm (15.5 in)

Green/Orange 7.4 382.6 mm (15 in)

Pink/Brown 7.6 405.6 mm (15.9 in)

Left Hand Drive Right Hand Drive

RH side LH side RH side LH side

Red/Purple Red/Purple Yellow/Purple Blue/Purple

Yellow/Purple Yellow/Purple Grey/Purple Purple/Purple

Grey/Purple Grey/Purple Yellow/Orange Green/Orange

Standard Spring Winch Fitted Spring

RH Side LH Side Both Sides

Red/Purple Red/Purple Grey/Purple

Yellow/Purple Blue/Purple Yellow/Orange

Yellow/Purple Yellow/Purple Yellow/Orange

Grey/Purple Purple/Purple Green/Orange

Grey/Purple Grey/Purple Green/Orange

Yellow/Orange Green/Orange Pink/Brown

Page 956 of 1672

FRONT SUSPENSION

DESCRIPTION AND OPERATION 60-17

The valve block directs hydraulic pressure to the actuators via solenoid operated directional control valves. A solenoid

operated pressure control valve regulates the required pressure to the actuators. The three valve solenoids are

controlled by signals received from the ACE ECU. A pressure transducer monitors the pressure delivered by the

pump. A replacable high pressure filter is installed into the lower face of the valve block and filters fluid before it

reaches the valves.

The valve block is located on the outside of the right hand chassis longitudinal. The valve block is secured to the

chassis with three bolts and rubber bushes. The rubber bushes isolate the valve block from the chassis, preventing

hydraulic noise from the valve block transmitting through the chassis and body.

The two solenoid operated directional control valves (DCV's) are fitted to ports in the top face of the valve block. The

DCV's are screwed into the valve block and sealed with O ring seals. Each DCV has a solenoid for electrical operation

of the valve. The solenoid is sealed to the DCV with two O ring and secured with a cap. The cap, coil and O rings are

serviceable items. The DCV's are non-serviceable and failure of a DCV requires the replacement of the valve block

assembly.

The pressure control valve is fitted to a port in the rear face of the valve block. The pressure control valve is screwed

into the valve block and sealed with O rings. The pressure control valve has a coil for electrical operation. The coil is

sealed to the pressure control valve with two O rings and secured with a cap. The cap, coil and O rings are serviceable

items. The pressure control valve is non-serviceable and failure requires replacement of the valve block assembly.

The pressure transducer is fitted to a port in the forward face of the valve block. The pressure transducer is screwed

into the valve block and sealed with an O ring seal. The pressure transducer is a serviceable item.

The high pressure filter locates in a port on the lower face of the valve block. The gauze and fibre filter is sealed in

the port with O ring seals. A threaded cap secures the filter in the valve block and is also sealed with an O ring seal.

A threaded hole on the lower face of the filter allows a bolt to be fitted to remove the filter from the port. If a system

component is replaced, the filter must be changed.

Four ports are located on the forward face of the valve block and two ports on the rear. Each port is fitted with a seal

pack which contains two O ring seals and backing rings. The ACE pipes locate and seal in the seal packs and are

secured to the valve block with the studs and nuts located on the forward and rear faces.

Actuators

Two actuators are used for the ACE system and are attached to the front and rear torsion bars. The actuators apply

hydraulically generated force to the torsion bar to oppose lateral forces caused by the vehicle cornering.

Each actuator is a conventional double-acting cylinder. A piston is attached to a rod and moves within the cylinder

when hydraulic pressure is applied. The rod is sealed at the point where it exits the cylinder. The outer end of the rod

is threaded and locates in a bush in the ACE long arm and secured with a nut. A rubber gaiter covers the rod and

prevents dirt and moisture from damaging the rod surface and cylinder seals. The cylinder has a forked attachment

which locates on the short arm bush and secured with a bolt and nut.

Two banjo connections provide for the attachment of the hydraulic hoses from the ACE valve block. The connections

provide hydraulic flow to each side of the piston to extend or retract the rod.

Page 1379 of 1672

AIR CONDITIONING

82-6DESCRIPTION AND OPERATION

Condenser

1Condenser matrix

2Outlet connection

3Inlet connection

The condenser transfers heat from the refrigerant to the surrounding air.

The condenser is installed immediately in front of the oil coolers. Rubber mounting bushes are used to mount the

condenser to the chassis sidemembers and brackets on the headlamp panels.

Ambient air, passing through the condenser matrix due to ram effect and/or the cooling fan, absorbs heat from the

refrigerant, which changes state from a vapour to a liquid.