fuel pressure LAND ROVER DISCOVERY 2002 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 363 of 1672

EMISSION CONTROL - V8

17-2-26 DESCRIPTION AND OPERATION

Secondary air injection system

The secondary air injection (SAI) system comprises the following components:

lSecondary air injection pump

lSAI vacuum solenoid valve

lSAI control valves (2 off, 1 for each bank of cylinders)

lSAI pump relay

lVacuum reservoir

lVacuum harness and pipes

The secondary air injection system is used to limit the emission of carbon monoxide (CO) and hydrocarbons (HCs)

that are prevalent in the exhaust during cold starting of a spark ignition engine. The concentration of hydrocarbons

experienced during cold starting at low temperatures are particularly high until the engine and catalytic converter

reach normal operating temperature. The lower the cold start temperature, the greater the prevalence of

hydrocarbons emitted from the engine.

There are several reasons for the increase of HC emissions at low cold start temperatures, including the tendency for

fuel to be deposited on the cylinder walls, which is then displaced during the piston cycle and expunged during the

exhaust stroke. As the engine warms up through operation, the cylinder walls no longer retain a film of fuel and most

of the hydrocarbons will be burnt off during the combustion process.

The SAI pump is used to provide a supply of air into the exhaust ports in the cylinder head, onto the back of the

exhaust valves, during the cold start period. The hot unburnt fuel particles leaving the combustion chamber mix with

the air injected into the exhaust ports and immediately combust. This subsequent combustion of the unburnt and

partially burnt CO and HC particles help to reduce the emission of these pollutants from the exhaust system. The

additional heat generated in the exhaust manifold also provides rapid heating of the exhaust system catalytic

converters. The additional oxygen which is delivered to the catalytic converters also generate an exothermic reaction

which causes the catalytic converters to 'light off' quickly.

The catalytic converters only start to provide effective treatment of emission pollutants when they reach an operating

temperature of approximately 250

°C (482°F) and need to be between temperatures of 400°C (752°F) and 800°C

(1472

°F) for optimum efficiency. Consequently, the heat produced by the secondary air injection “afterburning”,

reduces the time delay before the catalysts reach an efficient operating temperature.

The engine control module (ECM) checks the engine coolant temperature when the engine is started, and if it is below

60º C (131

°F), the SAI pump is started. Secondary air injection will remain operational for a period controlled by the

ECM (76 seconds for NAS vehicles, 64 seconds for EU-3 vehicles). The SAI pump operation can be cut short due to

excessive engine speed or load.

Air from the SAI pump is supplied to the SAI control valves via pipework and an intermediate T-piece which splits the

air flow evenly to each bank.

At the same time the secondary air pump is started, the ECM operates a SAI vacuum solenoid valve, which opens to

allow vacuum from the reservoir to be applied to the vacuum operated SAI control valves on each side of the engine.

When the vacuum is applied to the SAI control valves, they open simultaneously to allow the air from the SAI pump

through to the exhaust ports. Secondary air is injected into the inner most exhaust ports on each bank.

When the ECM breaks the ground circuit to de-energise the SAI vacuum solenoid valve, the vacuum supply to the

SAI control valves is cut off and the valves close to prevent further air being injected into the exhaust manifold. At the

same time as the SAI vacuum solenoid valve is closed, the ECM opens the ground circuit to the SAI pump relay, to

stop the SAI pump.

A vacuum reservoir is included in the vacuum line between the intake manifold and the SAI vacuum solenoid valve.

This prevents changes in vacuum pressure from the intake manifold being passed on to cause fluctuations of the

secondary air injection solenoid valve. The vacuum reservoir contains a one way valve and ensures a constant

vacuum is available for the SAI vacuum solenoid valve operation. This is particularly important when the vehicle is at

high altitude.

Page 372 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-35

Failure of the closed loop control of the exhaust emission system may be attributable to one of the failure modes

indicated below:

lMechanical fitting & integrity of the sensor.

lSensor open circuit / disconnected.

lShort circuit to vehicle supply or ground.

lLambda ratio outside operating band.

lCrossed sensors.

lContamination from leaded fuel or other sources.

lChange in sensor characteristic.

lHarness damage.

lAir leak into exhaust system (cracked pipe / weld or loose fixings).

System failure will be indicated by the following symptoms:

lMIL light on (NAS and EU-3 only).

lDefault to open-loop fuelling for the defective cylinder bank.

lIf sensors are crossed, engine will run normally after initial start and then become progressively unstable with

one bank going to its maximum rich clamp and the other bank going to its maximum lean clamp – the system will

then revert to open-loop fuelling.

lHigh CO reading

lStrong smell of H

2S (rotten eggs)

lExcessive emissions

Fuel metering

When the engine is cold, additional fuel has to be provided to the air:fuel mixture to assist starting. This supplementary

fuel enrichment continues until the combustion chamber has heated up sufficiently during the warm-up phase.

Under normal part-throttle operating conditions the fuel mixture is adjusted to provide minimum fuel emissions and

the air:fuel mixture is held close to the optimum ratio (

λ = 1). The engine management system monitors the changing

engine and environmental conditions and uses the data to determine the exact fuelling requirements necessary to

maintain the air:fuel ratio close to the optimum value that is needed to ensure effective exhaust emission treatment

through the three-way catalytic converters.

During full-throttle operation the air:fuel mixture needs to be made rich to provide maximum torque. During

acceleration, the mixture is enriched by an amount according to engine temperature, engine speed, change in throttle

position and change in manifold pressure, to provide good acceleration response.

When the vehicle is braking or travelling downhill the fuel supply can be interrupted to reduce fuel consumption and

eliminate exhaust emissions during this period of operation.

If the vehicle is being used at altitude, a decrease in the air density will be encountered which needs to be

compensated for to prevent a rich mixture being experienced. Without compensation for altitude, there would be an

increase in exhaust emissions and problems starting, poor driveability and black smoke from the exhaust pipe. For

open loop systems, higher fuel consumption may also occur.

Page 374 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-37

In the case of a catalytic converter failure the following failure symptoms may be apparent:

lMIL light on after 2 driving cycles (NAS market only).

lHigh exhaust back pressure if catalyst partly melted.

lExcessive emissions

lStrong smell of H

2S (rotten eggs).

Oxygen sensor voltages can be monitored using 'Testbook', the approximate output voltage from the heated oxygen

sensors with a warm engine at idle and with closed loop fuelling active are shown in the table below:

Mass air flow sensor and air temperature sensor

The engine management ECM uses the mass air flow sensor to measure the mass of air entering the intake and

interprets the data to determine the precise fuel quantity which needs to be injected to maintain the stoichiometric

air:fuel ratio for the exhaust catalysts. If the mass air flow sensor fails, lambda control and idle speed control will be

affected and the emission levels will not be maintained at the optimum level. If the device should fail and the ECM

detects a fault, it invokes a software backup strategy.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

The air temperature sensor is used by the engine management ECM to monitor the temperature of the inlet air. If the

device fails, catalyst monitoring will be affected. The air temperature sensor in integral to the mass air flow sensor.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Throttle position sensor

If the engine management ECM detects a throttle position sensor failure, it may indicate a blocked or restricted air

intake filter. Failure symptoms may include:

lPoor engine running and throttle response

lEmission control failure

lNo closed loop idle speed control

lAltitude adaption is incorrect

If a signal failure should occur, a default value is derived using data from the engine load and speed.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Atmospheric pressure will vary with altitude and have a resulting influence on the calculations performed by the ECM

in determining the optimum engine operating conditions to minimise emissions. The following are approximate

atmospheric pressures for the corresponding altitudes:

l0.96 bar at sea level

l0.70 bar at 2,750 m (9,000 ft.)

Measurement Normal catalyst Defective catalyst

Pre-catalytic heated oxygen sensors ~ 100 to 900 mV switching @ ~ 0.5

Hz~ 100 to 900 mV switching @ ~ 0.5 Hz

Post-catalytic heated oxygen sensors ~ 200 to 650 mV, static or slowly

changing~ 200 to 850 mV, changing up to same

frequency as pre-catalytic heated oxygen

sensors

Amplitude ratio (LH HO

2 sensors & RH

HO

2 sensors)<0.3 seconds >0.6 seconds (needs to be approximately

0.75 seconds for single catalyst fault)

Number of speed/load monitoring areas

exceeded (LH & RH)0 >1 (needs to be 3 for fault storage)

Page 375 of 1672

EMISSION CONTROL - V8

17-2-38 DESCRIPTION AND OPERATION

Evaporative emission control operation

Fuel vapour is stored in the activated charcoal (EVAP) canister for retention when the vehicle is not operating. When

the vehicle is operating, fuel vapour is drawn from the canister into the engine via a purge control valve. The vapour

is then delivered to the intake plenum chamber to be supplied to the engine cylinders where it is burned in the

combustion process.

During fuel filling the fuel vapour displaced from the fuel tank is allowed to escape to atmosphere, valves within the

fuel filler prevent any vapour escaping through to the EVAP canister as this can adversely affect the fuel cut-off height.

Only fuel vapour generated whilst driving is prevented from escaping to atmosphere by absorption into the charcoal

canister. The fuel filler shuts off to leave the tank approximately 10% empty to ensure the ROVs are always above

the fuel level and so vapour can escape to the EVAP canister and the tank can breathe. The back pressures normally

generated during fuel filling are too low to open the pressure relief valve, but vapour pressures accumulated during

driving are higher and can open the pressure relief valve. Should the vehicle be overturned, the ROVs shut off to

prevent any fuel spillage.

Fuel vapour generated from within the fuel tank as the fuel heats up is stored in the tank until the pressure exceeds

the operating pressure of the two-way valve. When the two-way valve opens, the fuel vapour passes along the vent

line from the fuel tank (via the fuel tank vapour separator) to the evaporation inlet port of the EVAP canister. The fuel

tank vents between 5.17 and 6.9 kPa.

Fuel vapour evaporating from the fuel tank is routed to the EVAP canister through the fuel vapour separator and vent

line. Liquid fuel must not be allowed to contaminate the charcoal in the EVAP canister. To prevent this, the fuel vapour

separator fitted to the fuel neck allows fuel to drain back into the tank. As the fuel vapour cools, it condenses and is

allowed to flow back into the fuel tank from the vent line by way of the two-way valve.

The EVAP canister contains charcoal which absorbs and stores fuel vapour from the fuel tank while the engine is not

running. When the canister is not being purged, the fuel vapour remains in the canister and clean air exits the canister

via the air inlet port.

The engine management ECM controls the electrical output signal to the purge valve. The system will not work

properly if there is leakage or clogging within the system or if the purge valve cannot be controlled.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

When the engine is running, the ECM decides when conditions are correct for vapour to be purged from the EVAP

canister and opens the canister purge valve. This connects a manifold vacuum line to the canister and fuel vapour

containing the hydrocarbons is drawn from the canister's charcoal element to be burned in the engine. Clean air is

drawn into the canister through the atmosphere vent port to fill the displaced volume of vapour.

The purge valve remains closed below preset coolant and engine speed values to protect the engine tune and

catalytic converter performance. If the EVAP canister was purged during cold running or at idling speed, the additional

enrichment in the fuel mixture would delay the catalytic converter light off time and cause erratic idle. When the purge

valve is opened, fuel vapour from the EVAP canister is drawn into the plenum chamber downside of the throttle

housing, to be delivered to the combustion chambers for burning.

The purge valve is opened and closed in accordance with a pulse width modulated (PWM) signal supplied from the

engine management ECM. The system will not work properly if the purge valve cannot be controlled. Possible failure

modes associated with the purge valve are listed below:

lValve drive open circuit.

lShort circuit to vehicle supply or ground.

lPurge valve or pipework blocked or restricted.

lPurge valve stuck open.

lPipework joints leaking or disconnected.

Page 376 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-39

Possible symptoms associated with a purge valve or associated pipework failure is listed below:

lEngine may stall on return to idle if purge valve is stuck open.

lPoor idling quality if the purge valve is stuck open

lFuelling adaptions forced excessively lean if the EVAP canister is clear and the purge valve is stuck open.

lFuelling adaptions forced excessively rich if the EVAP canister is saturated and the purge valve is stuck open.

lSaturation of the EVAP canister if the purge valve is stuck closed.

To maintain driveability and effective emission control, EVAP canister purging must be closely controlled by the

engine management ECM, as a 1% concentration of fuel vapour from the EVAP canister in the air intake may shift

the air:fuel ratio by as much as 20%. The ECM must purge the fuel vapour from the EVAP canister at regular intervals

as its storage capacity is limited and an excessive build up of evaporated fuel pressure in the system could increase

the likelihood of vapour leaks. Canister purging is cycled with the fuelling adaptation as both cannot be active at the

same time. The ECM alters the PWM signal to the purge valve to control the rate of purging of the canister to maintain

the correct stoichiometric air:fuel mixture for the engine.

Fuel leak detection system (vacuum type) – NAS only

The advanced evaporative loss control system used on NAS vehicles is similar to the standard system, but also

includes a CVS valve and fuel tank pressure sensor and is capable of detecting holes in the fuel evaporative system

down to 1 mm (0.04 in.). The test is carried out in three parts. First the purge valve and the canister vent solenoid

valve closes off the storage system and the vent pressure increases due to the fuel vapour pressure level in the tank.

If the pressure level is greater than the acceptable limit, the test will abort because a false leak test response will

result. In part two of the test, the purge valve is opened and the fuel tank pressure will decrease due to the depression

from the intake manifold, evident at the purge port of the EVAP canister during purge operation. In part three of the

test, the leak measurement test is performed. The pressure response of the tests determines the level of leak, and if

this is greater than the acceptable limit on two consecutive tests, the ECM stores the fault in diagnostic memory and

the MIL light on the instrument pack is illuminated. The test is only carried out at engine idle with the vehicle stationary,

and a delay of 15 minutes after engine start is imposed before diagnosis is allowed to commence.

Page 377 of 1672

EMISSION CONTROL - V8

17-2-40 DESCRIPTION AND OPERATION

EVAP system, leak detection diagnostic (vacuum type)

The EVAP system leak detection is performed as follows:

1The ECM checks that the signal from the fuel tank pressure sensor is within the expected range. If the signal is

not within range, the leakage test will be cancelled.

2Next the purge valve is held closed and the canister vent solenoid (CVS) valve is opened to atmosphere. If the

ECM detects a rise in pressure with the valves in this condition, it indicates there is a blockage in the fuel

evaporation line between the CVS valve and the EVAP canister, or that the CVS valve is stuck in the closed

position and thus preventing normalisation of pressure in the fuel evaporation system. In this instance, the

leakage test will be cancelled.

3The CVS valve and the purge valve are both held in the closed position while the ECM checks the fuel tank

pressure sensor. If the fuel tank pressure sensor detects a decline in pressure, it indicates that the purge valve

is not closing properly and vapour is leaking past the valve seat face under the influence of the intake manifold

depression. In this instance, the leakage test will be cancelled.

4If the preliminary checks are satisfactory, a compensation measurement is determined next. Variations in fuel

level occur within the fuel tank, which will influence the pressure signal detected by the fuel tank pressure

sensor. The pressure detected will also be influenced by the rate of change in the fuel tank pressure, caused by

the rate of fuel evaporation which itself is dependent on the ambient temperature conditions. Because of these

variations, it is necessary for the ECM to evaluate the conditions prevailing at a particular instance when testing,

to ensure that the corresponding compensation factor is included in its calculations.

The CVS valve and purge valves are both closed while the ECM checks the signal from the fuel tank pressure

sensor. The rise in fuel pressure detected over a defined period is used to determine the rate of fuel evaporation

and the consequent compensation factor necessary.

5With the CVS valve still closed, the purge valve is opened. The inlet manifold depression present while the purge

valve is open, decreases EVAP system pressure and sets up a small vacuum in the fuel tank. The fuel tank

pressure sensor is monitored by the ECM and if the vacuum gradient does not increase as expected, a large

system leak is assumed by the ECM (e.g. missing or leaking fuel filler cap) and the diagnostic test is terminated.

If the EVAP canister is heavily loaded with hydrocarbons, purging may cause the air:fuel mixture to become

excessively rich, resulting in the upstream oxygen sensors requesting a leaner mix from the ECM to bring the

mixture back to the stoichiometric ideal. This may cause instability in the engine idle speed and consequently

the diagnostic test will have to be abandoned. The ECM checks the status of the upstream oxygen sensors

during the remainder of the diagnostic, to ensure the air:fuel mixture does not adversely affect the engine idle

speed.

6When the fuel tank pressure sensor detects that the required vacuum has been reached (-800 Pa), the purge

valve is closed and the EVAP system is sealed. The ECM then checks the change in the fuel tank pressure

sensor signal (diminishing vacuum) over a period of time, and if it is greater than expected (after taking into

consideration the compensation factor due to fuel evaporation within the tank, determined earlier in the

diagnostic), a leak in the EVAP system is assumed. If the condition remains, the MIL warning light will be turned

on after two drive cycles.

The decrease in vacuum pressure over the defined period must be large enough to correspond to a hole

equivalent to 1 mm (0.04 in.) diameter or greater, to be considered significant enough to warrant the activation

of an emissions system failure warning.

The diagnostic test is repeated at regular intervals during the drive cycle, when the engine is at idle condition. The

diagnostic test will not be able to be performed under the following conditions:

lDuring EVAP canister purging

lDuring fuelling adaption

lIf excess slosh in the fuel tank is detected (excess fuel vapour will be generated, invalidating the result)

Page 378 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-41

Following the test, the system returns to normal purge operation after the canister vent solenoid opens. Possible

reasons for an EVAP system leak test failure are listed below:

lFuel filler not tightened or cap missing.

lSensor or actuator open circuit.

lShort circuit to vehicle supply or ground.

lEither purge or CVS valve stuck open.

lEither purge or CVS valve stuck shut or blocked pipe.

lPiping broken or not connected.

lLoose or leaking connection.

If the piping is broken forward of the purge valve or is not connected, the engine may run rough and fuelling adaptions

will drift. The fault will not be detected by the leak detection diagnostic, but it will be determined by the engine

management ECM through the fuelling adaption diagnostics.

The evaluation of leakage is dependent on the differential pressure between the fuel tank and ambient atmospheric

pressure, the diagnostic is disabled above altitudes of 9500 ft. (2800 m) to avoid false detection of fuel leaks due to

the change in atmospheric pressure at altitude.

Fuel leak detection system (positive pressure leak detection type) – NAS only

The EVAP system with positive pressure leak detection capability used on NAS vehicles is similar to the standard

system, but also includes a fuel evaporation leak detection pump with integral solenoid valve. It is capable of detecting

holes in the EVAP system down to 0.5 mm (0.02 in.). The test is carried out at the end of a drive cycle, when the

vehicle is stationary and the ignition switch has been turned off. The ECM maintains an earth supply to the Main relay

to hold it on, so that power can be supplied to the leak detection pump.

First a reference measurement is established by passing the pressurised air through a by-pass circuit containing a

fixed sized restriction. The restriction assimilates a 0.5 mm (0.02 in) hole and the current drawn by the pump motor

during this procedure is recorded for comparison against the value to be obtained in the system test. The purge valve

is held closed, and the reversing valve in the leak detection pump module is not energised while the leak detection

pump is switched on. The pressurised air from the leak detection pump is forced through an orifice while the current

drawn by the pump motor is monitored.

Next the EVAP system diagnostic is performed; the solenoid valve is energised so that it closes off the EVAP system's

vent line to atmosphere, and opens a path for the pressurised air from the leak detection pump to be applied to the

closed EVAP system.

The current drawn by the leak detection pump is monitored and checked against that obtained during the reference

measurement. If the current is less than the reference value, this infers there is a hole in the EVAP system greater

than 0.5 mm (0.02 in) which is allowing the positive air pressure to leak out. If the current drawn by the pump motor

is greater than the value obtained during the reference check, the system is sealed and free from leaks. If an EVAP

system leak is detected, the ECM stores the fault in diagnostic memory and the MIL light on the instrument pack is

illuminated.

On NAS vehicles, the ECM works on a 2 trip cycle before illuminating the MIL. On EU-3 vehicles, the ECM works on

a 3 trip cycle before illuminating the MIL.

Following the test, the solenoid valve is opened to normalise the EVAP system pressure and the system returns to

normal purge operation at the start of the next drive cycle. Possible reasons for an EVAP system leak test failure are

listed below:

lFuel filler not tightened or cap missing.

lSensor or actuator open circuit.

lShort circuit to vehicle supply or ground.

lEither purge or solenoid valve stuck open.

lEither purge or solenoid valve stuck shut.

lBlocked pipe or air filter.

lPiping broken or not connected.

lLoose or leaking connection.

If the piping is broken forward of the purge valve or is not connected, the engine may run rough and fuelling adaptions

will drift. The fault will not be detected by the leak detection test, but will be determined by the engine management

ECM through the fuelling adaption diagnostics. This test can be run from TestBook.

Page 396 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-3

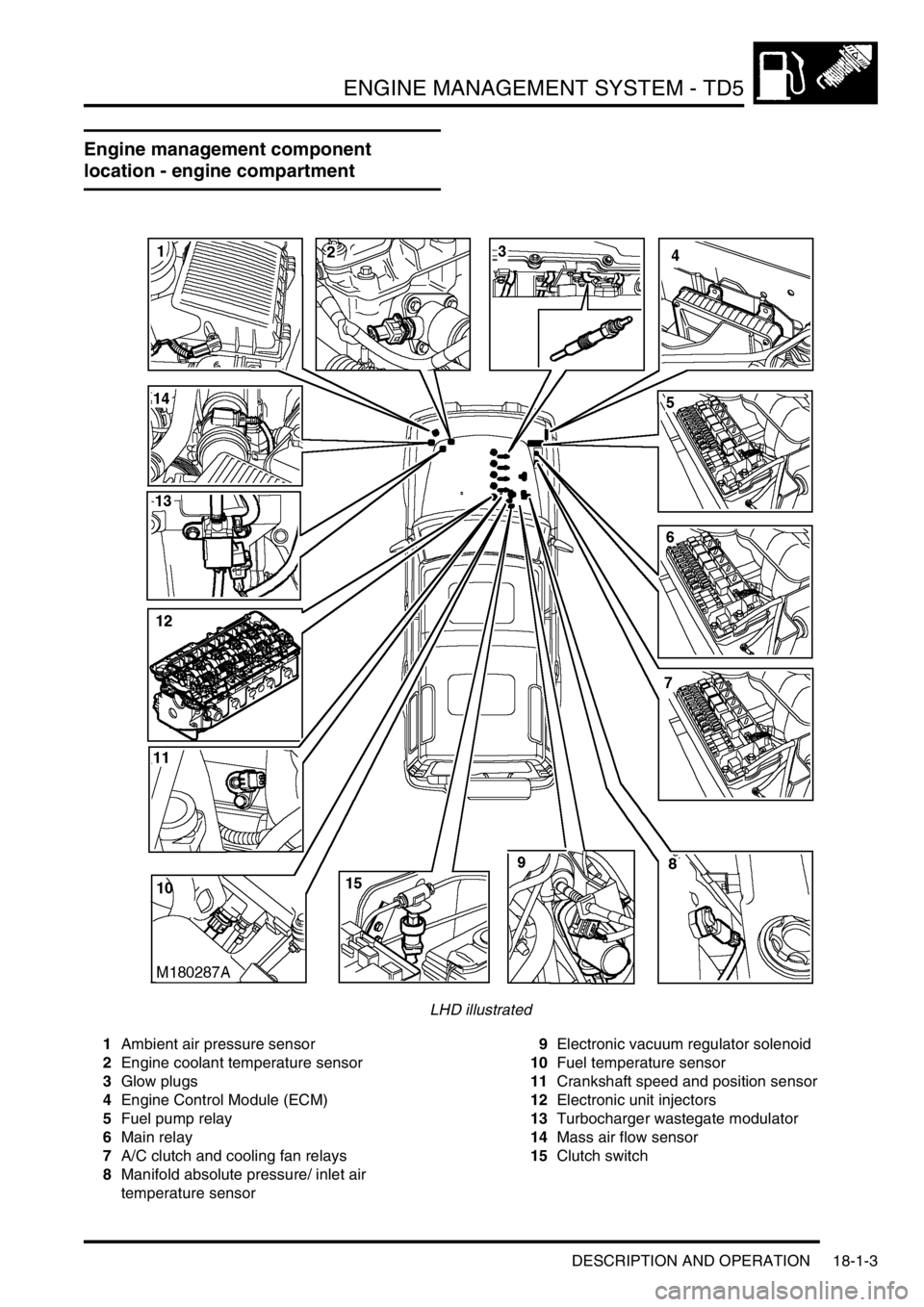

Engine management component

location - engine compartment

LHD illustrated

1Ambient air pressure sensor

2Engine coolant temperature sensor

3Glow plugs

4Engine Control Module (ECM)

5Fuel pump relay

6Main relay

7A/C clutch and cooling fan relays

8Manifold absolute pressure/ inlet air

temperature sensor9Electronic vacuum regulator solenoid

10Fuel temperature sensor

11Crankshaft speed and position sensor

12Electronic unit injectors

13Turbocharger wastegate modulator

14Mass air flow sensor

15Clutch switch

Page 398 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-5

1Mass air flow sensor

2Ambient air pressure sensor

3Manifold absolute pressure/ inlet air

temperature sensor

4Engine coolant temperature sensor

5Crankshaft speed and position sensor

6Throttle position sensor

7Fuel temperature sensor

8Brake pedal switch

9Clutch switch

10High/ Low ratio switch

11Main relay

12Malfunction indicator lamp

13Fuel pump relay

14Glow plug warning lamp

15Glow plugs16Electronic unit injectors

17Turbocharger wastegate modulator

18EGR modulator

19Diagnostic connector

20Engine control module

21Cruise control master switch

22Cruise control SET+ switch

23Cruise control RES switch

24Air conditioning clutch relay

25Air conditioning cooling fan relay

26Electronic automatic transmission ECU

27Self levelling and anti-lock brakes ECU

28Instrument cluster

29Body control unit

Page 399 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-6 DESCRIPTION AND OPERATION

Description

General

An engine control module (ECM) controls the five-cylinder direct injection diesel engine, and works on the drive by

wire principle. This means there is no throttle cable, the ECM controls the drivers needs via a signal from the Throttle

Position (TP) sensor on the throttle pedal.

The ECM is a full authoritative diesel specific microprocessor that also incorporates features for cruise control and air

conditioning control. In addition, the ECM supplies output control for the exhaust gas recirculation and turbocharger

boost pressure. The ECM has a self-diagnostic function, which is able to provide backup strategies for most sensor

failures.

The ECM processes information from the following input sources:

lMass air flow sensor.

lAmbient air pressure sensor.

lManifold absolute pressure/inlet air temperature sensor.

lEngine coolant temperature sensor.

lCrankshaft speed and position sensor.

lThrottle position sensor.

lFuel temperature sensor.

lAir conditioning request.

lAir conditioning fan request.

lBrake pedal switch.

lClutch switch.

lCruise control master switch.

lCruise control SET+ switch.

lCruise control RES switch.

lHigh/low ratio switch.

The input from the sensors constantly updates the ECM with the current operating condition of the engine. Once the

ECM has compared current information with stored information within its memory, it can make any adjustment it

requires to the operation of the engine via the following:

lAir conditioning clutch relay.

lAir conditioning cooling fan relay.

lElectronic vacuum regulator solenoid.

lMalfunction indicator lamp.

lFuel pump relay.

lGlow plug warning lamp.

lGlow plugs.

lFuel injectors.

lMain relay.

lTurbocharger wastegate modulator.

lTemperature gauge.

The ECM interfaces with the following:

lElectronic Automatic Transmission (EAT).

lSelf Levelling and Anti-lock Brakes System (SLABS).

lSerial communication link.

lInstrument cluster.

lBody Control Unit (BCU).