coolant LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 318 of 1672

ENGINE - V8

OVERHAUL 12-2-75

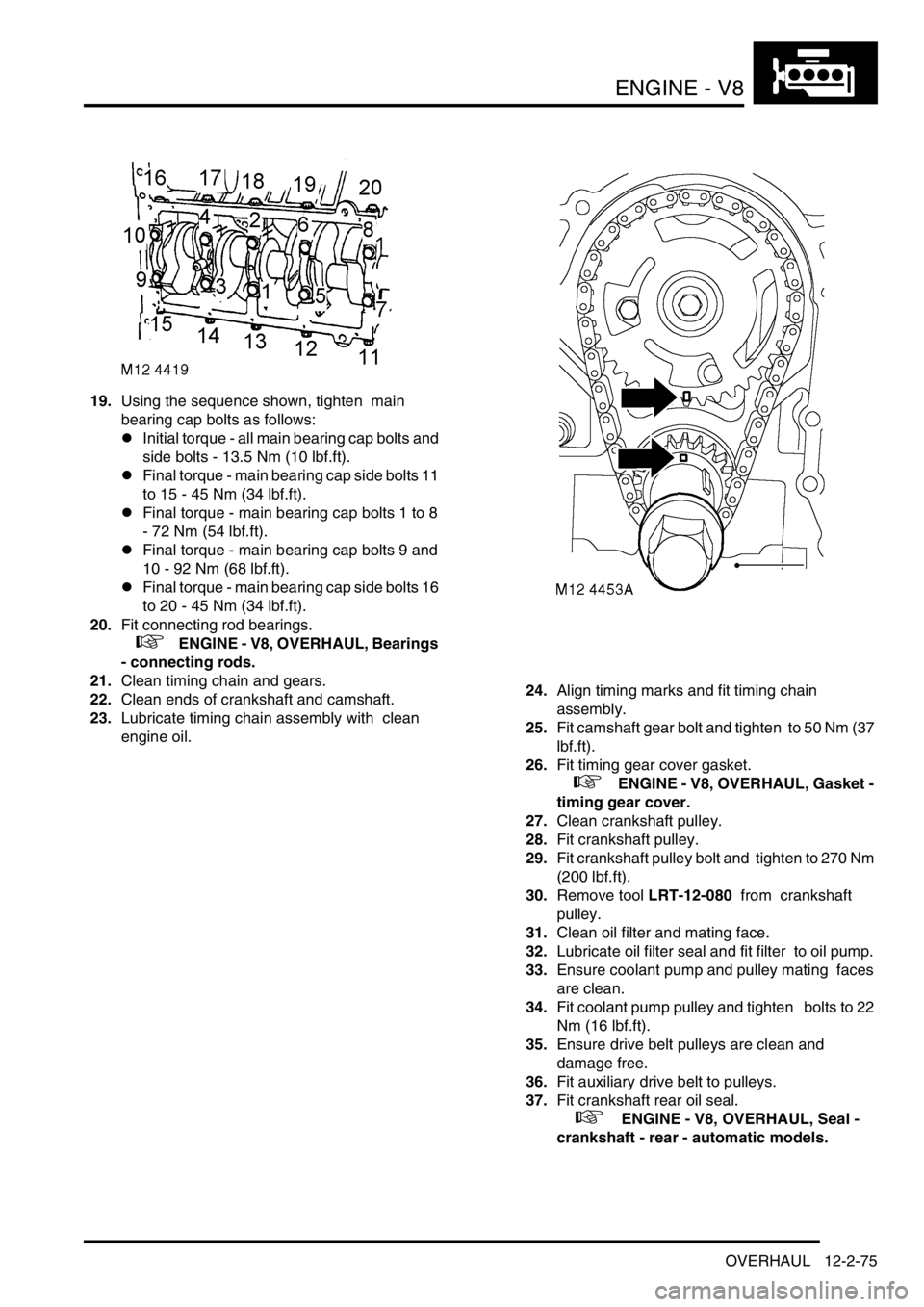

19.Using the sequence shown, tighten main

bearing cap bolts as follows:

lInitial torque - all main bearing cap bolts and

side bolts - 13.5 Nm (10 lbf.ft).

lFinal torque - main bearing cap side bolts 11

to 15 - 45 Nm (34 lbf.ft).

lFinal torque - main bearing cap bolts 1 to 8

- 72 Nm (54 lbf.ft).

lFinal torque - main bearing cap bolts 9 and

10 - 92 Nm (68 lbf.ft).

lFinal torque - main bearing cap side bolts 16

to 20 - 45 Nm (34 lbf.ft).

20.Fit connecting rod bearings.

+ ENGINE - V8, OVERHAUL, Bearings

- connecting rods.

21.Clean timing chain and gears.

22.Clean ends of crankshaft and camshaft.

23.Lubricate timing chain assembly with clean

engine oil. 24.Align timing marks and fit timing chain

assembly.

25.Fit camshaft gear bolt and tighten to 50 Nm (37

lbf.ft).

26.Fit timing gear cover gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

timing gear cover.

27.Clean crankshaft pulley.

28.Fit crankshaft pulley.

29.Fit crankshaft pulley bolt and tighten to 270 Nm

(200 lbf.ft).

30.Remove tool LRT-12-080 from crankshaft

pulley.

31.Clean oil filter and mating face.

32.Lubricate oil filter seal and fit filter to oil pump.

33.Ensure coolant pump and pulley mating faces

are clean.

34.Fit coolant pump pulley and tighten bolts to 22

Nm (16 lbf.ft).

35.Ensure drive belt pulleys are clean and

damage free.

36.Fit auxiliary drive belt to pulleys.

37.Fit crankshaft rear oil seal.

+ ENGINE - V8, OVERHAUL, Seal -

crankshaft - rear - automatic models.

Page 326 of 1672

EMISSION CONTROL - TD5

DESCRIPTION AND OPERATION 17-1-5

Exhaust gas recirculation

The exhaust gas recirculation (EGR) valve permits a controlled amount of exhaust gas to combine with the fresh air

entering the engine. The exhaust gas reduces the combustion temperature by delaying the fuel burning rate, which

assists in reducing the quantity of oxides of nitrogen.

On EU3 models, an EGR cooler is employed to further reduce the combustion temperature. By passing the exhaust

gas through a bundle of pipes flooded by coolant, the density of the exhaust gas going into the engine is increased.

This process further reduces the amount of oxygen, which in turn, further reduces the amount of NO

2 in the exhaust.

Recirculating too much exhaust gas can result in higher emissions of soot, HC and CO due to insufficient air. The

recirculated exhaust gas must be limited so that there is sufficient oxygen available for combustion of the injected fuel

in the combustion chamber, to do this the Engine Control Module (ECM) is used to control the precise quantity of

exhaust gas to be recirculated in accordance with the prevailing operating conditions. Influencing factors include:

lthe mass of air flow detected by the mass air flow sensor.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

lthe ambient air pressure, determined by the ambient air pressure sensor which is used to initiate adjustments

to reduce the amount of smoke produced at high altitudes.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

Other factors which are taken into consideration by the engine management system for determining the optimum

operating condition include:

lManifold inlet air temperature

lCoolant temperature

lEngine speed

lFuel delivered

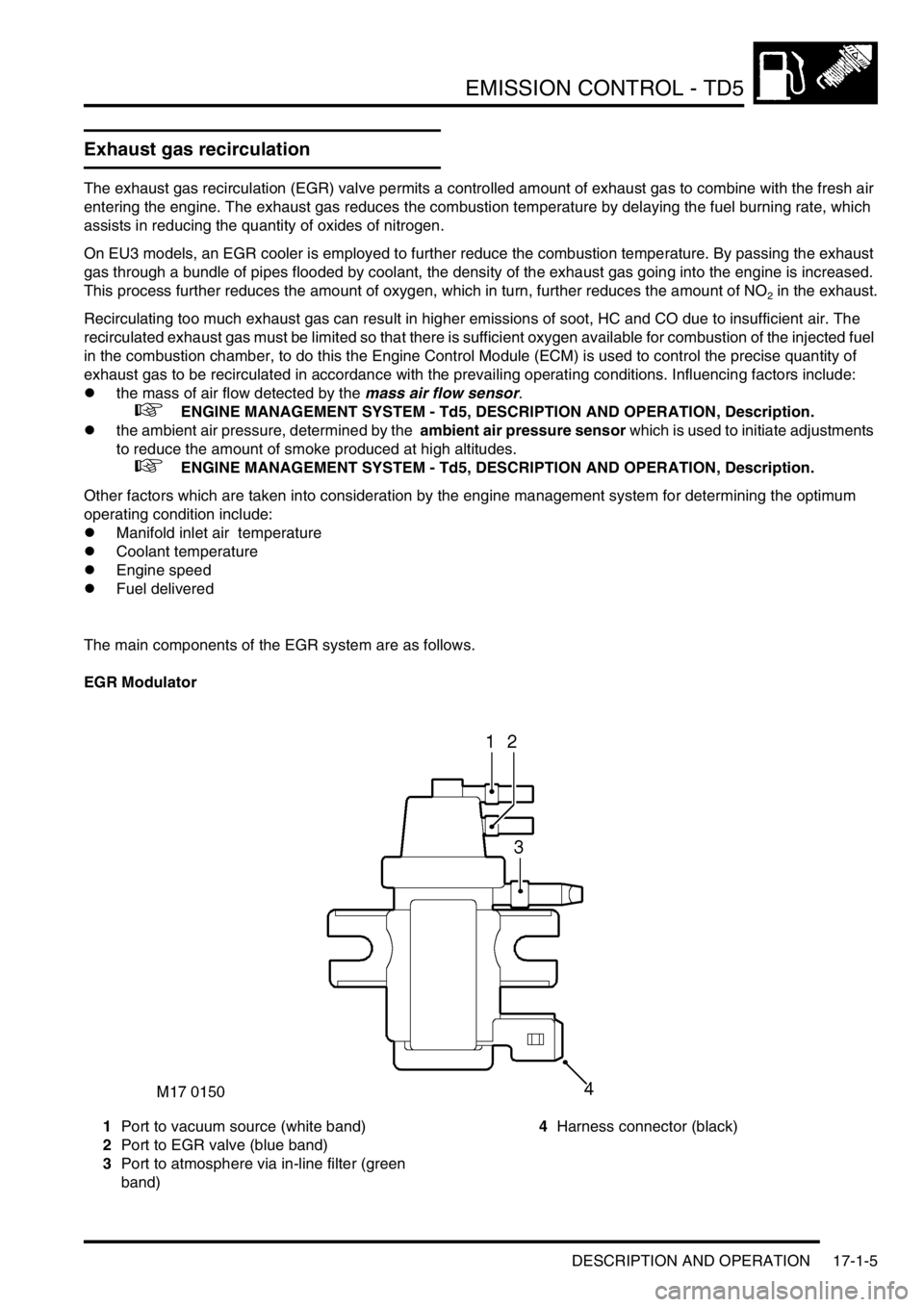

The main components of the EGR system are as follows.

EGR Modulator

1Port to vacuum source (white band)

2Port to EGR valve (blue band)

3Port to atmosphere via in-line filter (green

band)4Harness connector (black)

Page 363 of 1672

EMISSION CONTROL - V8

17-2-26 DESCRIPTION AND OPERATION

Secondary air injection system

The secondary air injection (SAI) system comprises the following components:

lSecondary air injection pump

lSAI vacuum solenoid valve

lSAI control valves (2 off, 1 for each bank of cylinders)

lSAI pump relay

lVacuum reservoir

lVacuum harness and pipes

The secondary air injection system is used to limit the emission of carbon monoxide (CO) and hydrocarbons (HCs)

that are prevalent in the exhaust during cold starting of a spark ignition engine. The concentration of hydrocarbons

experienced during cold starting at low temperatures are particularly high until the engine and catalytic converter

reach normal operating temperature. The lower the cold start temperature, the greater the prevalence of

hydrocarbons emitted from the engine.

There are several reasons for the increase of HC emissions at low cold start temperatures, including the tendency for

fuel to be deposited on the cylinder walls, which is then displaced during the piston cycle and expunged during the

exhaust stroke. As the engine warms up through operation, the cylinder walls no longer retain a film of fuel and most

of the hydrocarbons will be burnt off during the combustion process.

The SAI pump is used to provide a supply of air into the exhaust ports in the cylinder head, onto the back of the

exhaust valves, during the cold start period. The hot unburnt fuel particles leaving the combustion chamber mix with

the air injected into the exhaust ports and immediately combust. This subsequent combustion of the unburnt and

partially burnt CO and HC particles help to reduce the emission of these pollutants from the exhaust system. The

additional heat generated in the exhaust manifold also provides rapid heating of the exhaust system catalytic

converters. The additional oxygen which is delivered to the catalytic converters also generate an exothermic reaction

which causes the catalytic converters to 'light off' quickly.

The catalytic converters only start to provide effective treatment of emission pollutants when they reach an operating

temperature of approximately 250

°C (482°F) and need to be between temperatures of 400°C (752°F) and 800°C

(1472

°F) for optimum efficiency. Consequently, the heat produced by the secondary air injection “afterburning”,

reduces the time delay before the catalysts reach an efficient operating temperature.

The engine control module (ECM) checks the engine coolant temperature when the engine is started, and if it is below

60º C (131

°F), the SAI pump is started. Secondary air injection will remain operational for a period controlled by the

ECM (76 seconds for NAS vehicles, 64 seconds for EU-3 vehicles). The SAI pump operation can be cut short due to

excessive engine speed or load.

Air from the SAI pump is supplied to the SAI control valves via pipework and an intermediate T-piece which splits the

air flow evenly to each bank.

At the same time the secondary air pump is started, the ECM operates a SAI vacuum solenoid valve, which opens to

allow vacuum from the reservoir to be applied to the vacuum operated SAI control valves on each side of the engine.

When the vacuum is applied to the SAI control valves, they open simultaneously to allow the air from the SAI pump

through to the exhaust ports. Secondary air is injected into the inner most exhaust ports on each bank.

When the ECM breaks the ground circuit to de-energise the SAI vacuum solenoid valve, the vacuum supply to the

SAI control valves is cut off and the valves close to prevent further air being injected into the exhaust manifold. At the

same time as the SAI vacuum solenoid valve is closed, the ECM opens the ground circuit to the SAI pump relay, to

stop the SAI pump.

A vacuum reservoir is included in the vacuum line between the intake manifold and the SAI vacuum solenoid valve.

This prevents changes in vacuum pressure from the intake manifold being passed on to cause fluctuations of the

secondary air injection solenoid valve. The vacuum reservoir contains a one way valve and ensures a constant

vacuum is available for the SAI vacuum solenoid valve operation. This is particularly important when the vehicle is at

high altitude.

Page 364 of 1672

EMISSION CONTROL - V8

DESCRIPTION AND OPERATION 17-2-27

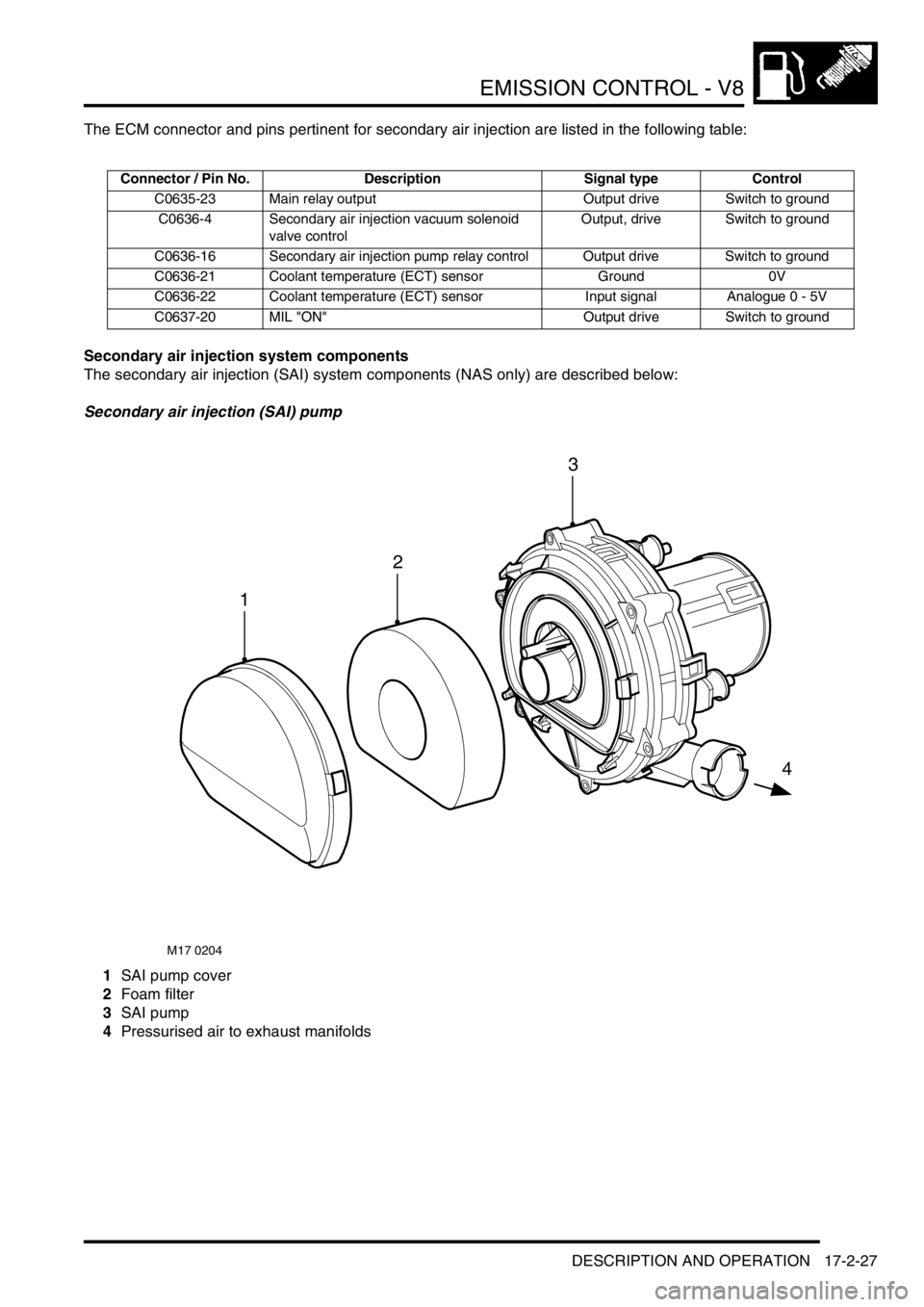

The ECM connector and pins pertinent for secondary air injection are listed in the following table:

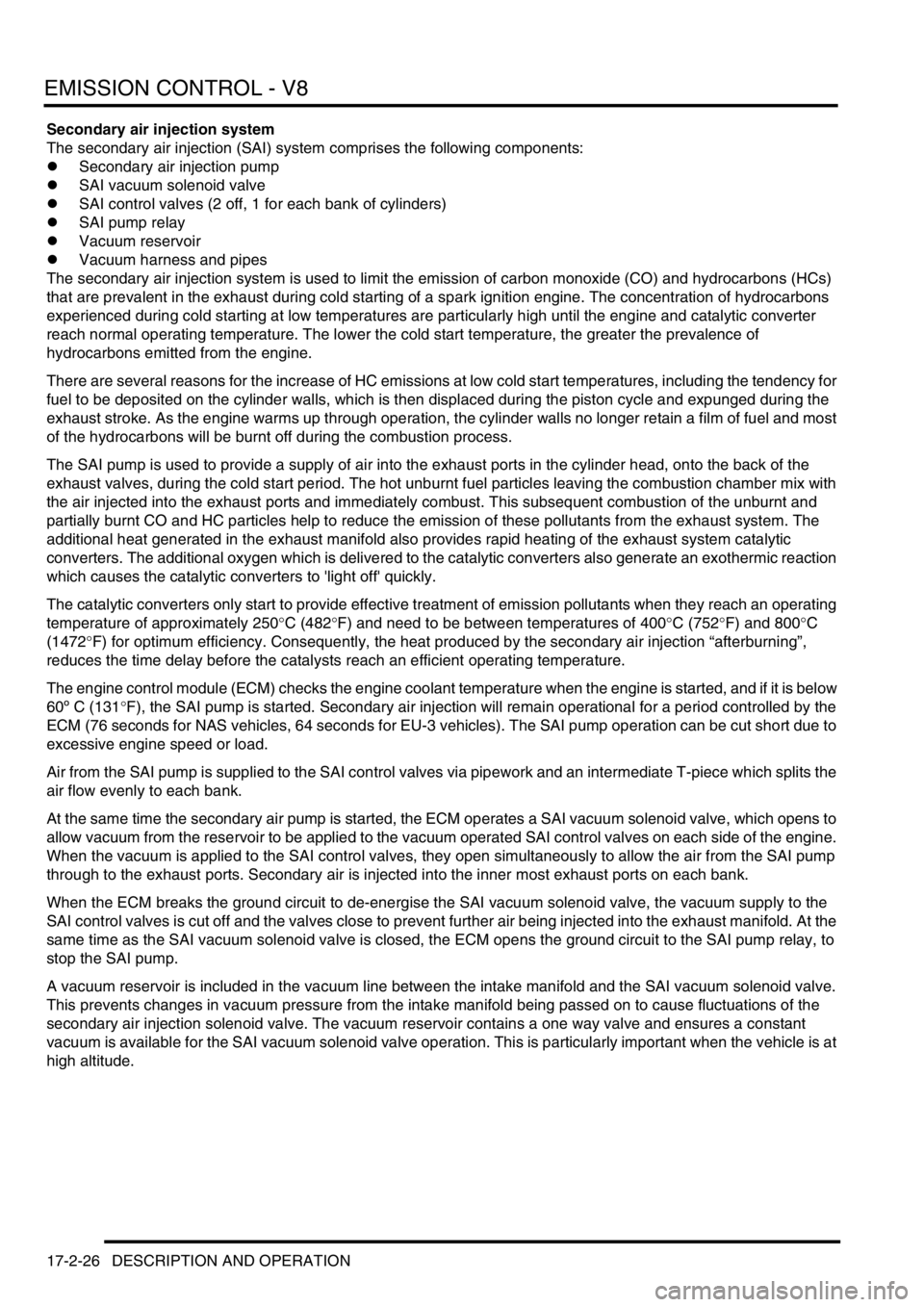

Secondary air injection system components

The secondary air injection (SAI) system components (NAS only) are described below:

Secondary air injection (SAI) pump

1SAI pump cover

2Foam filter

3SAI pump

4Pressurised air to exhaust manifolds

Connector / Pin No. Description Signal type Control

C0635-23 Main relay output Output drive Switch to ground

C0636-4 Secondary air injection vacuum solenoid

valve controlOutput, drive Switch to ground

C0636-16 Secondary air injection pump relay control Output drive Switch to ground

C0636-21 Coolant temperature (ECT) sensor Ground 0V

C0636-22 Coolant temperature (ECT) sensor Input signal Analogue 0 - 5V

C0637-20 MIL "ON" Output drive Switch to ground

M17 0204

1

4

2

3

Page 375 of 1672

EMISSION CONTROL - V8

17-2-38 DESCRIPTION AND OPERATION

Evaporative emission control operation

Fuel vapour is stored in the activated charcoal (EVAP) canister for retention when the vehicle is not operating. When

the vehicle is operating, fuel vapour is drawn from the canister into the engine via a purge control valve. The vapour

is then delivered to the intake plenum chamber to be supplied to the engine cylinders where it is burned in the

combustion process.

During fuel filling the fuel vapour displaced from the fuel tank is allowed to escape to atmosphere, valves within the

fuel filler prevent any vapour escaping through to the EVAP canister as this can adversely affect the fuel cut-off height.

Only fuel vapour generated whilst driving is prevented from escaping to atmosphere by absorption into the charcoal

canister. The fuel filler shuts off to leave the tank approximately 10% empty to ensure the ROVs are always above

the fuel level and so vapour can escape to the EVAP canister and the tank can breathe. The back pressures normally

generated during fuel filling are too low to open the pressure relief valve, but vapour pressures accumulated during

driving are higher and can open the pressure relief valve. Should the vehicle be overturned, the ROVs shut off to

prevent any fuel spillage.

Fuel vapour generated from within the fuel tank as the fuel heats up is stored in the tank until the pressure exceeds

the operating pressure of the two-way valve. When the two-way valve opens, the fuel vapour passes along the vent

line from the fuel tank (via the fuel tank vapour separator) to the evaporation inlet port of the EVAP canister. The fuel

tank vents between 5.17 and 6.9 kPa.

Fuel vapour evaporating from the fuel tank is routed to the EVAP canister through the fuel vapour separator and vent

line. Liquid fuel must not be allowed to contaminate the charcoal in the EVAP canister. To prevent this, the fuel vapour

separator fitted to the fuel neck allows fuel to drain back into the tank. As the fuel vapour cools, it condenses and is

allowed to flow back into the fuel tank from the vent line by way of the two-way valve.

The EVAP canister contains charcoal which absorbs and stores fuel vapour from the fuel tank while the engine is not

running. When the canister is not being purged, the fuel vapour remains in the canister and clean air exits the canister

via the air inlet port.

The engine management ECM controls the electrical output signal to the purge valve. The system will not work

properly if there is leakage or clogging within the system or if the purge valve cannot be controlled.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

When the engine is running, the ECM decides when conditions are correct for vapour to be purged from the EVAP

canister and opens the canister purge valve. This connects a manifold vacuum line to the canister and fuel vapour

containing the hydrocarbons is drawn from the canister's charcoal element to be burned in the engine. Clean air is

drawn into the canister through the atmosphere vent port to fill the displaced volume of vapour.

The purge valve remains closed below preset coolant and engine speed values to protect the engine tune and

catalytic converter performance. If the EVAP canister was purged during cold running or at idling speed, the additional

enrichment in the fuel mixture would delay the catalytic converter light off time and cause erratic idle. When the purge

valve is opened, fuel vapour from the EVAP canister is drawn into the plenum chamber downside of the throttle

housing, to be delivered to the combustion chambers for burning.

The purge valve is opened and closed in accordance with a pulse width modulated (PWM) signal supplied from the

engine management ECM. The system will not work properly if the purge valve cannot be controlled. Possible failure

modes associated with the purge valve are listed below:

lValve drive open circuit.

lShort circuit to vehicle supply or ground.

lPurge valve or pipework blocked or restricted.

lPurge valve stuck open.

lPipework joints leaking or disconnected.

Page 379 of 1672

EMISSION CONTROL - V8

17-2-42 DESCRIPTION AND OPERATION

Secondary air injection system

When the engine is started, the engine control module checks the engine coolant temperature and if it is below 55°

C, the ECM grounds the electrical connection to the coil of the secondary air injection (SAI) pump relay.

A 12V battery supply is fed to the inertia switch via fuse 13 in the engine compartment fusebox. When the inertia

switch contacts are closed, the feed passes through the switch and is connected to the coil of the Main relay. An earth

connection from the Main relay coil is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the Main relay.

The Main and Secondary Air Injection (SAI) pump relays are located in the engine compartment fusebox. When the

contacts of the Main relay are closed, a 12V battery supply is fed to the coil of the SAI pump relay. An earth connection

from the coil of the SAI pump relay is connected to the ECM. When the ECM completes the earth path, the coil

energises and closes the contacts of the SAI pump relay to supply 12V to the SAI pump via fusible link 2 in the engine

compartment fusebox. The SAI pump starts to operate, and will continue to do so until the ECM switches off the earth

connection to the coil of the SAI pump relay.

The SAI pump remains operational for a period determined by the ECM and depends on the starting temperature of

the engine, or for a maximum operation period determined by the ECM if the target engine coolant temperature has

not been reached in the usual time.

When the contacts of the main relay are closed, a 12V battery supply is fed to the SAI solenoid valve via Fuse 2 in

the engine compartment fusebox.

The ECM grounds the electrical connection to the SAI vacuum solenoid valve at the same time as it switches on the

SAI pump motor. When the SAI vacuum solenoid valve is energised, a vacuum is provided to the operation control

ports on both of the vacuum operated SAI control valves at the exhaust manifolds. The control vacuum is sourced

from the intake manifold depression and routed to the SAI control valves via a vacuum reservoir and the SAI vacuum

solenoid valve.

The vacuum reservoir is included in the vacuum supply circuit to prevent vacuum fluctuations caused by changes in

the intake manifold depression affecting the operation of the SAI control valves.

When a vacuum is applied to the control ports of the SAI control valves, the valves open to allow pressurised air from

the SAI pump to pass through to the exhaust ports in the cylinder heads for combustion.

When the ECM has determined that the SAI pump has operated for the desired duration, it switches off the earth paths

to the SAI pump relay and the SAI vacuum solenoid valve. With the SAI vacuum solenoid valve de-energised, the

valve closes, cutting off the vacuum supply to the SAI control valves. The SAI control valves close immediately and

completely to prevent any further pressurised air from the SAI pump entering the exhaust manifolds.

The engine coolant temperature sensor incurs a time lag in respect of detecting a change in temperature and the SAI

pump automatically enters a 'soak period' between operations to prevent the SAI pump overheating. The ECM also

compares the switch off and start up temperatures, to determine whether it is necessary to operate the SAI pump.

This prevents the pump running repeatedly and overheating on repeat starts.

Other factors which may prevent or stop SAI pump operation include the prevailing engine speed / load conditions.

Page 390 of 1672

EMISSION CONTROL - V8

REPAIRS 17-2-53

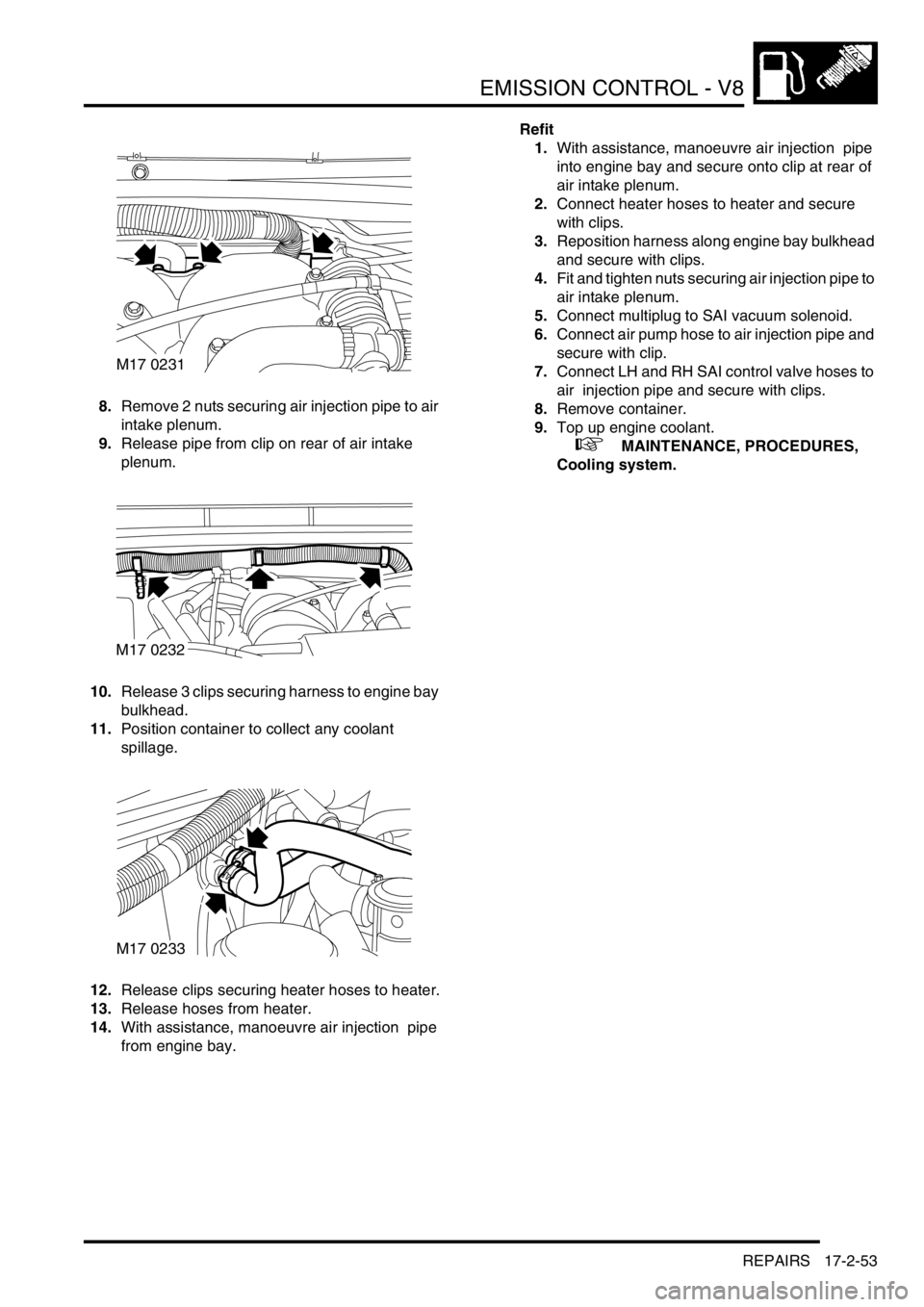

8.Remove 2 nuts securing air injection pipe to air

intake plenum.

9.Release pipe from clip on rear of air intake

plenum.

10.Release 3 clips securing harness to engine bay

bulkhead.

11.Position container to collect any coolant

spillage.

12.Release clips securing heater hoses to heater.

13.Release hoses from heater.

14.With assistance, manoeuvre air injection pipe

from engine bay.Refit

1.With assistance, manoeuvre air injection pipe

into engine bay and secure onto clip at rear of

air intake plenum.

2.Connect heater hoses to heater and secure

with clips.

3.Reposition harness along engine bay bulkhead

and secure with clips.

4.Fit and tighten nuts securing air injection pipe to

air intake plenum.

5.Connect multiplug to SAI vacuum solenoid.

6.Connect air pump hose to air injection pipe and

secure with clip.

7.Connect LH and RH SAI control valve hoses to

air injection pipe and secure with clips.

8.Remove container.

9.Top up engine coolant.

+ MAINTENANCE, PROCEDURES,

Cooling system.

M17 0231

M17 0232

M17 0233

Page 396 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-3

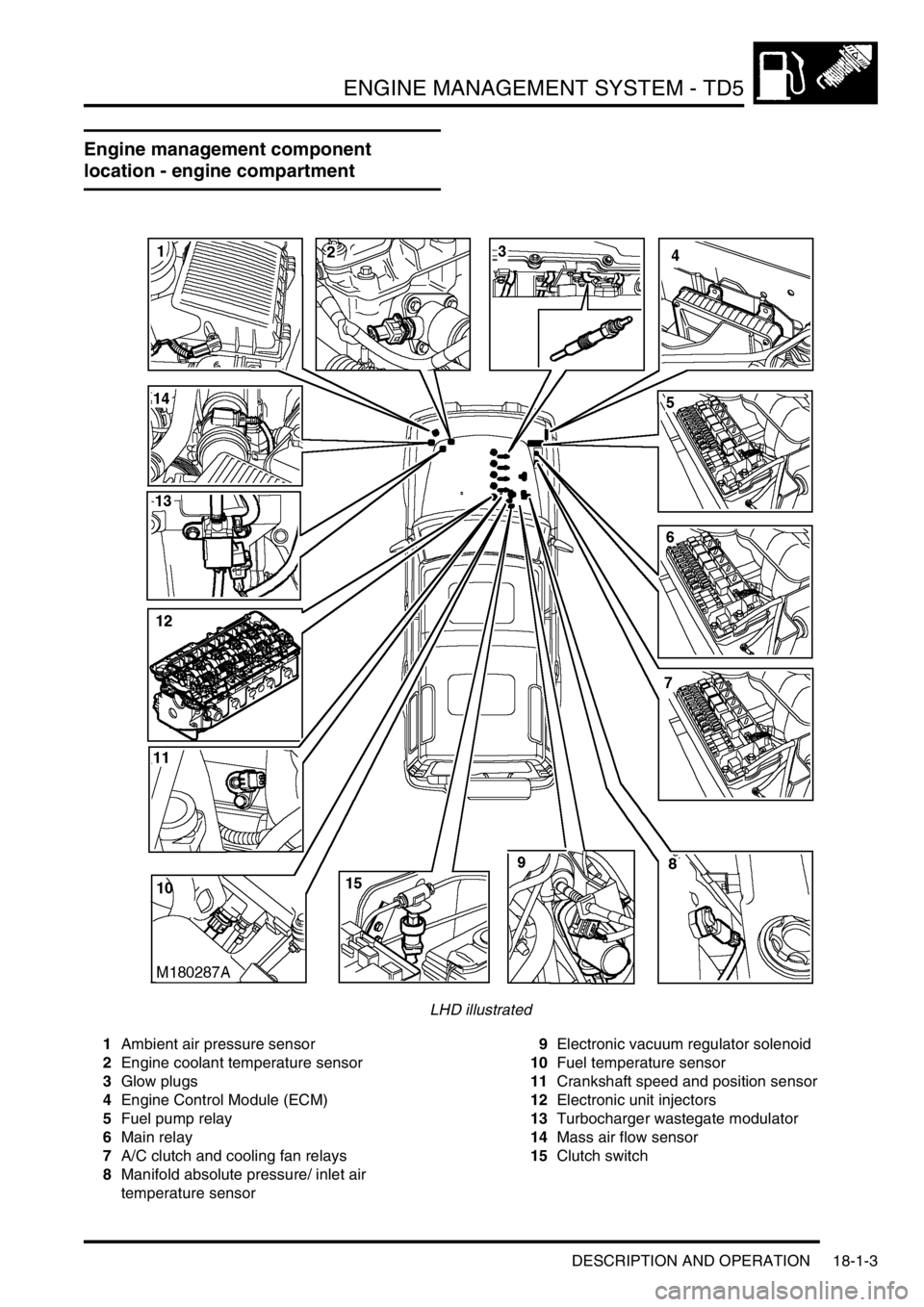

Engine management component

location - engine compartment

LHD illustrated

1Ambient air pressure sensor

2Engine coolant temperature sensor

3Glow plugs

4Engine Control Module (ECM)

5Fuel pump relay

6Main relay

7A/C clutch and cooling fan relays

8Manifold absolute pressure/ inlet air

temperature sensor9Electronic vacuum regulator solenoid

10Fuel temperature sensor

11Crankshaft speed and position sensor

12Electronic unit injectors

13Turbocharger wastegate modulator

14Mass air flow sensor

15Clutch switch

Page 398 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-5

1Mass air flow sensor

2Ambient air pressure sensor

3Manifold absolute pressure/ inlet air

temperature sensor

4Engine coolant temperature sensor

5Crankshaft speed and position sensor

6Throttle position sensor

7Fuel temperature sensor

8Brake pedal switch

9Clutch switch

10High/ Low ratio switch

11Main relay

12Malfunction indicator lamp

13Fuel pump relay

14Glow plug warning lamp

15Glow plugs16Electronic unit injectors

17Turbocharger wastegate modulator

18EGR modulator

19Diagnostic connector

20Engine control module

21Cruise control master switch

22Cruise control SET+ switch

23Cruise control RES switch

24Air conditioning clutch relay

25Air conditioning cooling fan relay

26Electronic automatic transmission ECU

27Self levelling and anti-lock brakes ECU

28Instrument cluster

29Body control unit

Page 399 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-6 DESCRIPTION AND OPERATION

Description

General

An engine control module (ECM) controls the five-cylinder direct injection diesel engine, and works on the drive by

wire principle. This means there is no throttle cable, the ECM controls the drivers needs via a signal from the Throttle

Position (TP) sensor on the throttle pedal.

The ECM is a full authoritative diesel specific microprocessor that also incorporates features for cruise control and air

conditioning control. In addition, the ECM supplies output control for the exhaust gas recirculation and turbocharger

boost pressure. The ECM has a self-diagnostic function, which is able to provide backup strategies for most sensor

failures.

The ECM processes information from the following input sources:

lMass air flow sensor.

lAmbient air pressure sensor.

lManifold absolute pressure/inlet air temperature sensor.

lEngine coolant temperature sensor.

lCrankshaft speed and position sensor.

lThrottle position sensor.

lFuel temperature sensor.

lAir conditioning request.

lAir conditioning fan request.

lBrake pedal switch.

lClutch switch.

lCruise control master switch.

lCruise control SET+ switch.

lCruise control RES switch.

lHigh/low ratio switch.

The input from the sensors constantly updates the ECM with the current operating condition of the engine. Once the

ECM has compared current information with stored information within its memory, it can make any adjustment it

requires to the operation of the engine via the following:

lAir conditioning clutch relay.

lAir conditioning cooling fan relay.

lElectronic vacuum regulator solenoid.

lMalfunction indicator lamp.

lFuel pump relay.

lGlow plug warning lamp.

lGlow plugs.

lFuel injectors.

lMain relay.

lTurbocharger wastegate modulator.

lTemperature gauge.

The ECM interfaces with the following:

lElectronic Automatic Transmission (EAT).

lSelf Levelling and Anti-lock Brakes System (SLABS).

lSerial communication link.

lInstrument cluster.

lBody Control Unit (BCU).