coolant LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 400 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-7

Engine Control Module (ECM)

The ECM is made from aluminium alloy and is located in the engine compartment on the RH side inner wing. The

ECM has an interface of 72 pins via two connectors providing both input information and output control. The ECM

receives information from the sensors to inform it of the current state of the engine. The ECM then refers this

information to stored values in its memory and makes any changes to the operation of the engine as necessary via

the actuators. This is a rolling process and is called adaptive strategy. By using this adaptive strategy the ECM is

able to control the engine to give optimum driveability throughout all operating conditions. There is no ECM self test,

although the ECM saves driveability data from the last journey. Power down of the ECM can take between 10 seconds

and 10 minutes dependent on coolant temperature.

Page 407 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-14 DESCRIPTION AND OPERATION

Engine Coolant Temperature (ECT) sensor

The ECT sensor is located in the coolant outlet elbow on the top of the engine. It provides the ECM with engine coolant

temperature information. The ECM uses this ECT information for the following functions:

lFuelling calculations.

lTemperature gauge.

lTo limit engine operation if coolant temperature is too high.

lCooling fan operation.

lGlow plug operating time.

The ECT works as an NTC sensor. As temperature rises, the resistance in the sensor decreases, as temperature

decreases, the resistance in the sensor increases. The ECM compares the voltage signal to stored values and

compensates fuel delivery to ensure optimum driveability at all times.

Input/Output

The inputs and outputs for the ECT are earth and signal out.

The ECT signal is measured at pin 7 of the ECM connector C0158. The earth path is via pin 18 of ECM connector

C0158.

ECT sensor temperature to resistance table.

Temperature, °C Temperature, °F Resistance, ohms

nominal)

-10 14 9397

0325896

10 50 3792

30 86 1707

50 122 834.0

70 158 435.7

90 194 243.2

110 230 144.2

130 266 89.3

Page 408 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-15

The ECT sensor can fail the following ways or supply incorrect signal:

lSensor open circuit.

lShort circuit to vehicle supply.

lShort circuit to earth.

lIncorrect mechanical fitting.

lSignal fixed above 40

°C (104 °F) not detected.

lSignal fixed below 40

°C (104 °F) not detected.

In the event of an ECT sensor signal failure any of the following symptoms may be observed:

lDifficult cold start.

lDifficult hot start.

lDriveability concerns.

lInstrument pack temperature warning illuminated.

lTemperature gauge reads excessively hot.

lTemperature gauge reads excessively cold.

In the event of component failure the ECM calculates coolant temperature from the fuel temperature sensor signal. If

this occurs, the limit engine operation if coolant temperature is too high becomes inoperative.

The MIL will not illuminate in an ECT sensor failure.

Page 424 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-31

The purpose of the glow plugs is:

lAssist cold engine start.

lReduce exhaust emissions at low engine load/speed.

The main part of the glow plug is a tubular heating element that protrudes into the combustion chamber of the engine.

The heating element contains a spiral filament that is encased in magnesium oxide powder. At the tip of the tubular

heating element is the heater coil. Behind the heater coil and connected in series is a control coil. The control coil

regulates the heater coil to ensure that it does not overheat and cause a possible failure. The glow plug circuit has its

own control relay located in the engine compartment fuse box.

Pre-heat is the length of time the glow plugs operate prior to engine cranking. The ECM controls the pre-heat time of

the glow plugs based on battery voltage and coolant temperature information via the glow plug relay.

Post-heat is the length of time the glow plugs operate after the engine starts. The ECM controls the post-heat time

based on ECT information. If the ECT fails the ECM will operate pre/post-heat time strategies with default values from

its memory. The engine will be difficult to start.

Input/Output

The glow plugs receive voltage from the glow plug relay that is controlled by the ECM. The ECM provides the earth

path for the relay coil closing the relay contacts and supplying the glow plugs with battery voltage. The supply voltage

heats the coils to approximately 1000

°C (1832 °F). The glow plug circuit is wired in parallel, the body of each glow

plug is screwed directly into the engine block which provides each glow plug with an earth path.

The glow plugs can fail in the following ways:

lHeater coil open circuit.

lControl coil open circuit.

lPoor earth quality.

lShort circuit to vehicle supply.

lShort circuit to vehicle earth.

lWiring loom fault.

lRelay windings open circuit.

lIncorrect relay fitted.

In the event of a glow plug failure any of the following symptoms may be observed:

lDifficult starting.

lExcessive smoke emissions after engine start.

Page 432 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-39

With the ECM in a 'Secure' state, it will not function unless an alarm system is fitted to the vehicle. A 'Secure' ECM

cannot be configured into a 'No Code' ECM.

With the ECM in a 'No Code' state, it does not require an alarm system to be fitted to allow the engine to operate. If

the ECM senses that an alarm system is fitted it will not start. A 'No Code' ECM can be configured to a 'Secure' ECM

using TestBook. A 'Secure' ECM can not be configured to a 'No Code' state.

Setting up of the ECM immobilisation configurations can only be performed using TestBook.

If a vehicle stalls immediately after starting it is possible that it has been immobilised. This means either:

lThe ECM was configured as 'No Code' but the ECM is receiving a code at its alarm input pin.

lThe ECM received an incorrect code.

lThe ECM was expecting a security code but did not receive one at its alarm input pin.

Fuel delivery/injection control

The fuel delivery/injection control delivers a precise amount of finely atomised fuel to mix with the air in the

combustion chamber to create a controlled explosion.

To precisely control fuel delivery and control fuel injection, the following input conditions must be met:

lCKP information.

lInjection timing map information.

lFT information.

lECT information.

The ECM monitors the conditions required for optimum combustion of fuel in the cylinder from the various sensors

around the engine and then compares it against stored information. From this calculation the ECM can adjust the

quantity and timing of the fuel being delivered to the cylinder.

The ECM uses CKP information as follows:

lTo calculate engine speed.

lTo determine engine crankshaft position.

Engine speed and crankshaft position allows the ECM to determine fuel injection timing.

The ECM also uses ECT information and FT sensor information to allow optimum fuel delivery and injection control

for all engine coolant and fuel temperatures.

Turbocharger control

Turbocharger control is vital to ensure the turbocharger does not over boost the engine. Within the turbocharger is a

wastegate, which when operated by the turbocharger wastegate modulator will open and close a bypass valve

regulating boost pressure.

The turbocharger wastegate modulator, via the ECM, controls boost pressure under the following conditions:

lAcceleration.

lWide open throttle.

lIdle.

lOverrun.

The turbocharger wastegate modulator receives a battery voltage supply from the main relay. The ECM supplies the

earth path in the form of a pulse width modulation (PWM) signal. This signal allows the turbocharger wastegate

modulator to open and close the wastegate. A proportion of the exhaust gas can bypass the turbocharger through

the wastegate, regulating boost pressure.

Page 440 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-47

REPAIRS

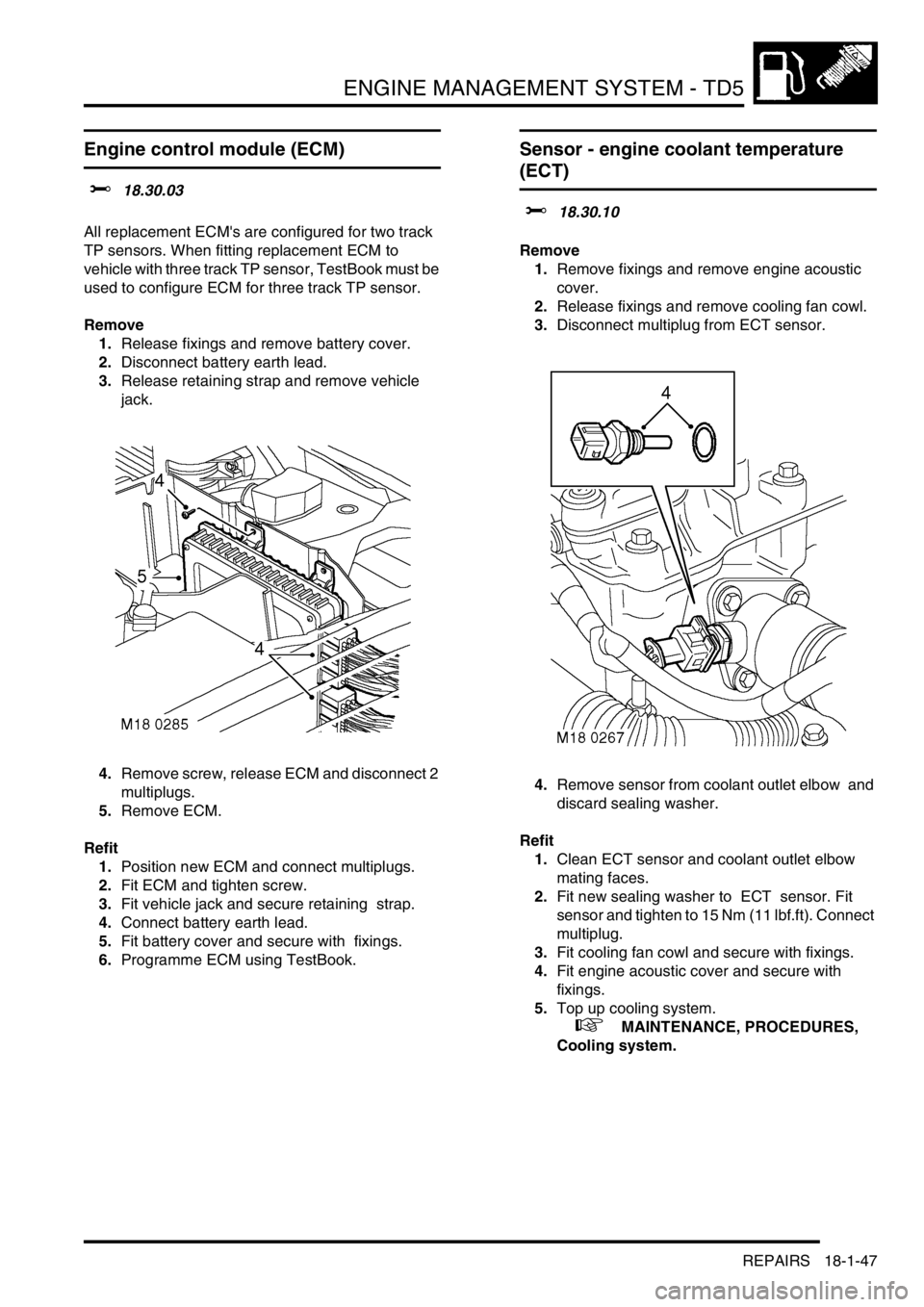

Engine control module (ECM)

$% 18.30.03

All replacement ECM's are configured for two track

TP sensors. When fitting replacement ECM to

vehicle with three track TP sensor, TestBook must be

used to configure ECM for three track TP sensor.

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Release retaining strap and remove vehicle

jack.

4.Remove screw, release ECM and disconnect 2

multiplugs.

5.Remove ECM.

Refit

1.Position new ECM and connect multiplugs.

2.Fit ECM and tighten screw.

3.Fit vehicle jack and secure retaining strap.

4.Connect battery earth lead.

5.Fit battery cover and secure with fixings.

6.Programme ECM using TestBook.

Sensor - engine coolant temperature

(ECT)

$% 18.30.10

Remove

1.Remove fixings and remove engine acoustic

cover.

2.Release fixings and remove cooling fan cowl.

3.Disconnect multiplug from ECT sensor.

4.Remove sensor from coolant outlet elbow and

discard sealing washer.

Refit

1.Clean ECT sensor and coolant outlet elbow

mating faces.

2.Fit new sealing washer to ECT sensor. Fit

sensor and tighten to 15 Nm (11 lbf.ft). Connect

multiplug.

3.Fit cooling fan cowl and secure with fixings.

4.Fit engine acoustic cover and secure with

fixings.

5.Top up cooling system.

+ MAINTENANCE, PROCEDURES,

Cooling system.

Page 446 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

REPAIRS 18-1-53

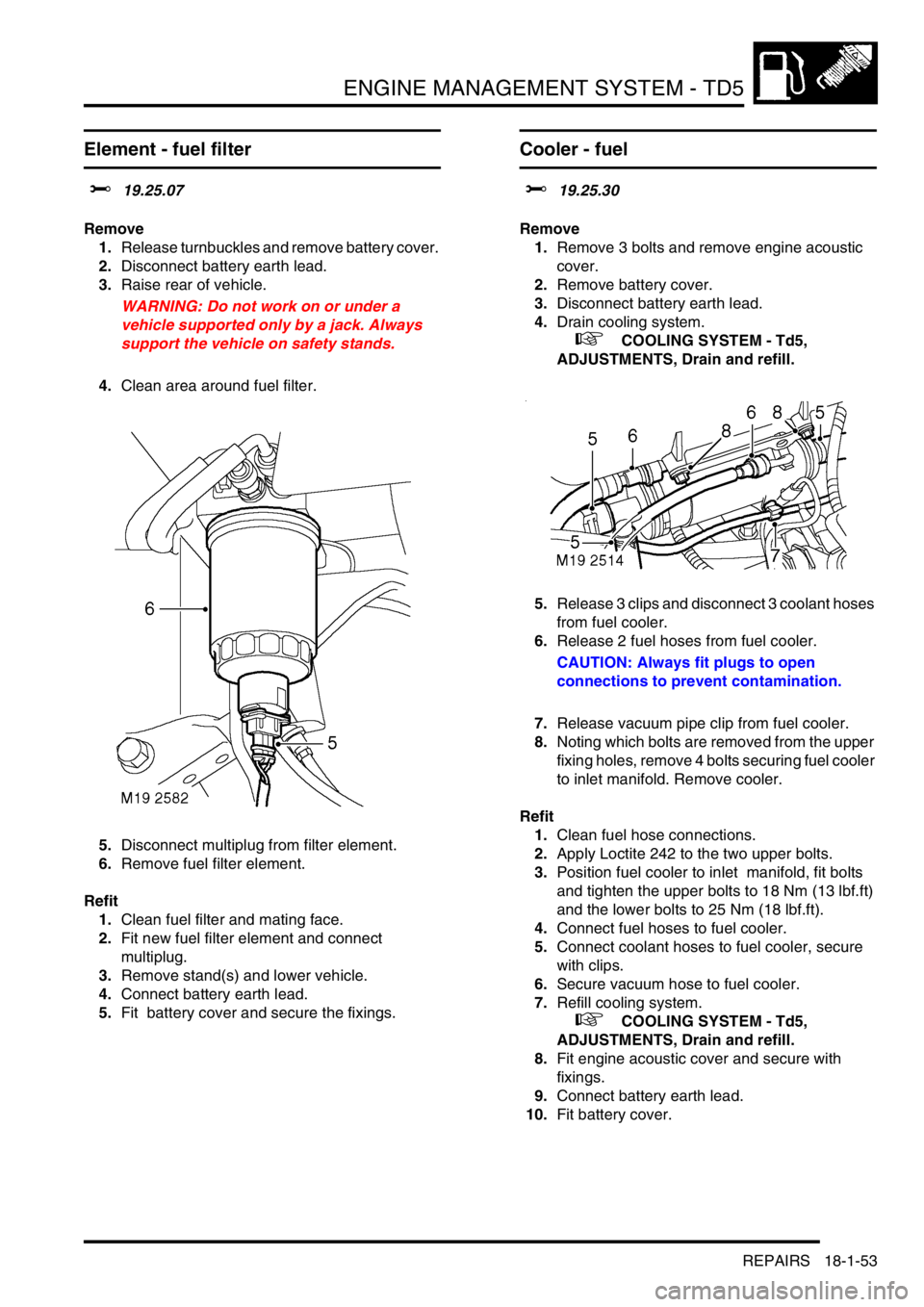

Element - fuel filter

$% 19.25.07

Remove

1.Release turnbuckles and remove battery cover.

2.Disconnect battery earth lead.

3.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Clean area around fuel filter.

5.Disconnect multiplug from filter element.

6.Remove fuel filter element.

Refit

1.Clean fuel filter and mating face.

2.Fit new fuel filter element and connect

multiplug.

3.Remove stand(s) and lower vehicle.

4.Connect battery earth lead.

5.Fit battery cover and secure the fixings.

Cooler - fuel

$% 19.25.30

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Remove battery cover.

3.Disconnect battery earth lead.

4.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

5.Release 3 clips and disconnect 3 coolant hoses

from fuel cooler.

6.Release 2 fuel hoses from fuel cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

7.Release vacuum pipe clip from fuel cooler.

8.Noting which bolts are removed from the upper

fixing holes, remove 4 bolts securing fuel cooler

to inlet manifold. Remove cooler.

Refit

1.Clean fuel hose connections.

2.Apply Loctite 242 to the two upper bolts.

3.Position fuel cooler to inlet manifold, fit bolts

and tighten the upper bolts to 18 Nm (13 lbf.ft)

and the lower bolts to 25 Nm (18 lbf.ft).

4.Connect fuel hoses to fuel cooler.

5.Connect coolant hoses to fuel cooler, secure

with clips.

6.Secure vacuum hose to fuel cooler.

7.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

8.Fit engine acoustic cover and secure with

fixings.

9.Connect battery earth lead.

10.Fit battery cover.

Page 460 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-3

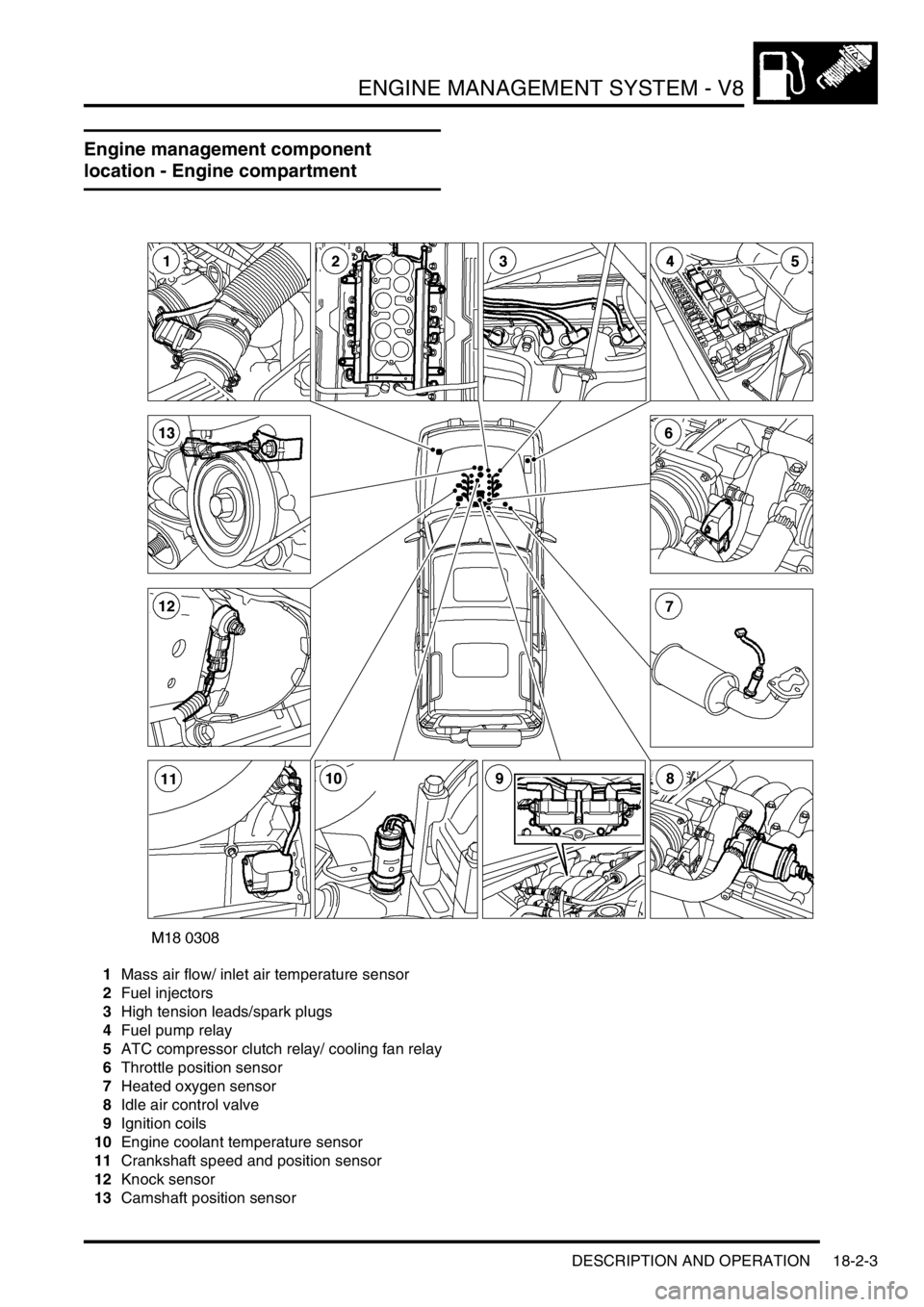

Engine management component

location - Engine compartment

1Mass air flow/ inlet air temperature sensor

2Fuel injectors

3High tension leads/spark plugs

4Fuel pump relay

5ATC compressor clutch relay/ cooling fan relay

6Throttle position sensor

7Heated oxygen sensor

8Idle air control valve

9Ignition coils

10Engine coolant temperature sensor

11Crankshaft speed and position sensor

12Knock sensor

13Camshaft position sensor

Page 462 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-5

1Engine control module

2Crankshaft speed and position sensor

3Camshaft position sensor

4Engine coolant temperature sensor

5Mass air flow/ inlet air temperature sensor

6Throttle position sensor

7Heated oxygen sensors

8Fuel injectors

9Idle air control valve

10Fuel pump relay

11EVAP canister

12EVAP canister vent valve

13EVAP canister purge valve

14Fuel tank pressure sensor

15Ignition coils

16Knock sensor

17Spark plugs

18High/ Low ratio switch

19Malfunction indication lamp

20Diagnostic connector

21Air temperature control clutch relay

22Air temperature control cooling fan relay

23ATC ECU

24CAN link to EAT

25SLABS ECU

26BCU

27Instrument cluster

28Thermostat monitoring sensor (where fitted)

Page 463 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-6 DESCRIPTION AND OPERATION

Description - engine management

General

The V8 engine is equipped with the Bosch Motronic M5.2.1 engine management system. This system is a sequential

multiport fuel injection system controlled by an Engine Control Module (ECM).

A single ECM is used for the control of the existing 4.0 litre engine and the new 4.6 litre engine introduced with 03

model year vehicles for the NAS market only. The ECM contains the tunes for both engines variants. When the ECM

is replaced, TestBook/T4 must be used to select the correct tune to match the engine fitment.

The ECM has On Board Diagnostic (OBD) strategies as required by various market legislative bodies. To meet these

requirements the system monitors and reports on any faults that cause excessive exhaust emissions.

In markets that mandate OBD, the ECM monitors performance of the engine for misfires, catalyst efficiency, exhaust

leaks and evaporative control loss. If a fault occurs, the ECM stores the relevant fault code and warns the driver of

component failure by illuminating the Malfunction Indicator Light in the instrument pack.

In markets where OBD is not mandatory, the ECM will still monitor performance of the engine and store the fault code,

but will not illuminate the Malfunction Indicator Light.

The ECM uses input and output information from its sensors and actuators to control the following engine conditions:

lFuel quantity.

lClosed loop fuelling.

lOpen loop fuelling.

lIgnition timing.

lKnock control.

lIdle speed control.

lEmission control.

lOn-Board Diagnostic (OBD) where applicable.

lVehicle immobilisation.

lMisfire detection (where applicable).

lVehicle speed signal.

lRough road signal (where applicable).

lLow fuel level signal (where applicable).

lCoolant temperature gauge signal.

The ECM processes sensor information from the following input sources:

lIgnition switch (position II).

lCrankshaft speed and position sensor.

lCamshaft position sensor.

lEngine coolant temperature sensor.

lMass air flow sensor.

lIntake air temperature sensor.

lKnock sensor.

lThrottle position sensor.

lHeated oxygen sensors.

lHigh/ Low ratio switch.

lFuel tank pressure sensor (where fitted)

lThermostat monitoring sensor (where fitted)