engine LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1530 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-21

Emergency key access

If the handset fails to operate, the engine can be remobilised by using the key to enter a unique four digit Emergency

Key Access (EKA) code.

There are three configurations for emergency key access:

lEKA not active (no immobiliser fitted).

lEKA active.

lEKA with super locking on receiving good passive remobilisation exciter coil signal.

The code is recorded on the security information card and is entered as follows:

1Using the key, turn the driver's door lock to the UNLOCK position and hold in this position for at least 5 seconds.

An audible warning is then emitted to indicate that the body control unit is ready to accept the code. Return the

key to the centre position. It is now possible to use the key to enter the separate numerical values of the four

digits that make up the EKA code.

2Enter the first digit of the code. If the first digit is 4, turn the key to the UNLOCK position 4 times. Ensure the

key is fully returned to the centre position after each turn of the key.

3Enter the second digit of the code. If the second digit is 3, turn the key to the LOCK position 3 times. Ensure

the key is fully returned to the centre position after each turn of the key.

4Enter the third digit of the code. If the third digit is 2, turn the key to the UNLOCK position twice. Ensure the key

is fully returned to the centre position after each turn of the key.

5Enter the fourth digit of the code. If the fourth digit is 1, turn the key to the LOCK position once. Ensure the key

is fully returned to the centre position after each turn of the key.

6Finally, turn the key to the UNLOCK position and back to the centre position, a double bleep will indicate that

the code has been entered correctly. A single bleep indicates that the code has been entered incorrectly.

Then, before opening the door, wait 5 minutes for the alarm and immobiliser to be de-activated. During the 5

minute wait for the alarm and immobiliser to be de-activated, the alarm indicator LED in the instrument pack

continues to flash (one flash every 2 seconds). DO NOT OPEN THE DOOR OR ATTEMPT TO ENTER THE

CAR until the full delay period has elapsed.

When the 5 minute wait has elapsed, the alarm indicator LED stops flashing. Immediately open the door, insert

the key in the ignition switch and turn the switch to position II. If the ignition switch is not turned to position II

within 30 seconds of the end of the 5 minute wait, the engine is automatically immobilised again.

The EKA code will not be recognised if there is an interval of 10 seconds or more between key turns or if the key is

held turned for 5 seconds or more during the procedure.

In some system configurations a successful EKA code entry is indicated by the audible warning device pulsing twice

for a period of 50 ms on, 200 ms off. The theft deterrent LED is switched on for 1 second, all doors unlock, the alarm

disarms and the vehicle is remobilised allowing the engine to start.

If an incorrect code is entered, an audible warning is emitted and the procedure must be repeated. Up to a maximum

of 10 attempts to enter the code is possible. After 10 attempts, the BCU will not allow any further codes to be entered

for a period of 10 minutes.

Single point entry

Single point entry (SPE) allows the driver to unlock the driver's door while leaving all other doors locked.

There are two configurations for single point entry:

lSPE not active.

lSPE active.

To use SPE, press the unlock button on the handset once. Depressing the unlock button a second time in the space

of one minute unlocks the remaining doors. SPE is also possible by turning the key in the driver's door lock to the

unlock position once. Turning the key to the unlock position again within one minute unlocks the remaining doors.

In order for SPE to operate, the following conditions must be met:

lThe ignition is off.

lAll doors are locked.

Page 1531 of 1672

ALARM SYSTEM AND HORN

86-4-22 DESCRIPTION AND OPERATION

Speed related locking

For added protection the vehicle doors can automatically lock when the vehicle exceeds a specific road speed.

There are two configurations for speed related locking:

lSpeed related locking not active.

lSpeed related locking active.

Speed related locking causes the doors to automatically lock when the vehicle exceeds a speed of 4 mph (7 km/h).

When the ignition is switched off, the doors are automatically unlocked. Depressing the instrument panel mounted

central door unlocking switch disables the speed related locking for the duration of the journey.

Speed related locking only activates once per ignition cycle. If speed related locking activates and a door is then

unlocked, the door does not automatically re-lock.

In order for speed related locking to activate the following conditions must be met:

lAll doors unlocked.

lEngine running.

lVehicle speed greater than 4 mph (7 km/h).

Acclimatisation related locking

Acclimatisation related locking allows the engine to be started and then the vehicle locked with a spare key and left

unattended to allow the vehicle interior to reach the desired temperature.

There are two configurations for acclimatisation related locking:

lAcclimatisation related locking not active.

lAcclimatisation related locking active.

Once the engine is started, the vehicle is locked with a spare key at the driver's door while the engine is running.

During these conditions the alarm is not armed.

In order to activate acclimatisation related locking the following conditions must be met:

lEngine running.

lAll doors closed.

Visual warnings

The direction indicators serve as a visual indication when the alarm is triggered. The direction indicators are also used

as a visual indication during lock/unlock procedures.

There are three configurations of alarm armed/disarmed indication:

lNo direction indicators on, alarm armed/disarmed/trigger.

lDirection indicators on, alarm trigger only.

lDirection indicators on, alarm armed/disarmed/trigger.

Dependent on system configuration the direction indicators flash one short pulse to confirm that the alarm is armed

and flash two short pulses to confirm that the vehicle is super locked. If the alarm is triggered the direction indicators

operate in phase with the audible warning. When the alarm is disarmed, the direction indicators flash one long pulse.

Audible warning

An audible warning device is used to indicate that the alarm has been triggered, or a mislock has occurred, or an EKA

request has occurred, or the EKA code has been entered.

There are six audible warning configurations:

lNo sound (audible warnings disabled).

lAlarm sounder only.

lVehicle horn only.

lAlarm sounder and vehicle horn.

lBBUS only.

lAlarm sounder, vehicle horn and BBUS.

Page 1532 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-23

Depending on which market the vehicle is sold, either the vehicle horn, a specific alarm sounder, or a BBUS operates

in phase with the direction indicators when the alarm is triggered. The audible warning device operates for

approximately 30 seconds at 0.25 second on, and 0.25 second off. The BCU allows the alarm to be triggered up to 3

times in any armed period.

Theft deterrent LED

An LED located in the instrument pack indicates the status of the alarm system.

There are eight theft deterrent alarm configurations:

lNo handset low battery warning.

lHandset low battery warning.

lNo passive immobilisation.

lPassive immobilisation.

lEngine immobilised (ignition off, LED off).

lEngine immobilised (ignition off, LED flashes).

lNo alarm tampered indication.

lAlarm tampered indication.

The theft deterrent LED utilises a particular flash to show the status of the following:

lAlarm armed.

lEngine immobilised.

lAlarm tampered.

lHandset low battery warning.

Transit mode

To prevent excessive battery drain during transportation to overseas markets, the vehicle is placed in a transit mode

at the end of line test.

The following functions are disabled when the vehicle is in transit mode:

lVolumetric sensors.

lPassive immobilisation.

lMobilisation of the vehicle by use of door lock.

lIgnition key interlock.

lElectric seat enable time-out with drivers door open.

To exit this mode, switch on the ignition and simultaneously hold down the heated rear window and the rear fog lamp

switch for 2 seconds.

Transit mode can be entered using Testbook.

Page 1563 of 1672

IN CAR ENTERTAINMENT

86-6-10 DESCRIPTION AND OPERATION

Remote radio steering wheel controls (midline and high line systems)

The remote radio control switch is located on the LH side of the steering wheel and is secured with two screws. The

wiring from the remote radio control switch plugs in to a connector that is part of the steering wheel rotary coupler.

Operation of the remote radio control switches allow the driver to control the ICE without releasing the steering wheel.

Volume, mode and selection functions can be carried out using the steering wheel mounted control switches. Control

inputs from the remote radio control switches are sent to the radio cassette player.

Aerial

On base and midline ICE systems an AM/FM aerial is built-in to the side window glass on the RH side of the vehicle.

An amplifier is located on the frame above the rear side widow behind the rear quarter trim, and is secured (and

earthed) with one bolt. Coaxial leads connect the aerial to the aerial amplifier and radio cassette. Power is supplied

from the auxilary relay in the engine compartment fuse box, through a fuse in the passenger compartment fusebox to

the amplifier.

On high line ICE systems two amplified aerials are built-in to the side window glass of the vehicle. The two aerials are

an AM/FM aerial on the RH side, and an FM aerial on the LH side. The amplifier for each aerial are located on the

frame above each rear side widow behind the rear quarter trim, and are each secured (and earthed) with one bolt.

Amplified aerials improve the reception quality, the FM aerial gives improved reception in areas of poor signal

(diversity) conditions in urban areas. A Power feed from the radio cassette player is connected to the amplified aerials,

power is available when the cassette player is operating. The aerials are connected to the radio cassette player by

two coaxial cables, a small plug connects the FM only aerial, a larger plug connects the AM/FM aerial.

Power amplifier (high line system)

The amplifier is located on a bracket under the LH front seat and is secured with three screws and washers. The

amplifier receives inputs from the radio, radio cassette player or (via the radio cassette player) the CD-autochanger.

Power for the amplifier is supplied from the passenger compartment fuse box. The amplifier will power up when an

enable logic signal is sent from the radio cassette, this signal is sent by the radio cassette when it is turned on.

CD-autochanger (high line system)

A CD-autochanger is located under the RH front seat, the unit is secured to brackets in the floor with four screws and

washers. A tray is used to hold each compact disk (CD), the loaded tray is then inserted in a magazine, the magazine

holds six trays and is then inserted into the CD-autochanger. A sliding cover protects the internal components of the

CD-autochanger from dirt entry through the magazine opening. An eject button located on the front of the CD-

autochanger can be used to release the magazine from the CD-autochanger. The sliding cover has to be opened

manually before the magazine eject button is pressed. The operation of the CD-autochanger is controlled by inputs

from the radio cassette, the control inputs can be from the radio cassette buttons, the remote radio controls or the rear

radio headphone amplifiers if they are fitted. The output from the CD-autochanger are connected to the radio cassette

player. The radio cassette player sends the outputs to the power amplifier. Power is supplied to the CD-autochanger

by a feed from the radio cassette player.

Radio headphone amplifiers (high line system)

The rear mounted radio headphone amplifiers are located in the lower rear quarter trim casing and are held in position

by a clip on the side of the headphone amplifier. Mode and function buttons are located on a control panel, the mode

button allows each of the rear seat passengers to independently select from the radio, tape or CD-autochanger. The

driver and the rear seat passengers can each listen to any of the audio devices they select. However the radio

cassette setting has overall priority e.g:

lIf the radio cassette is using a radio wave band (AM or FM), the headphone user will be able to select the cassette

tracks or CD-autochanger. The user will be able to listen to same radio band that is selected on the radio

cassette, but will not be able to change the station selected.

lIf the radio cassette has CD-autochanger selected, the headphone amplifiers will allow listening to the compact

disk but will not allow track changes. The headphone user will be able to select on all of the radio bands or

cassette tracks.

lIf the radio cassette has tape selected, the headphone amplifiers will allow listening to the tape but will not allow

track changes. The headphone user will be able to select all radio bands or CD's on the CD-autochanger.

Page 1572 of 1672

HARNESSES

REPAIRS 86-7-1

HARNESSES REPAIRS

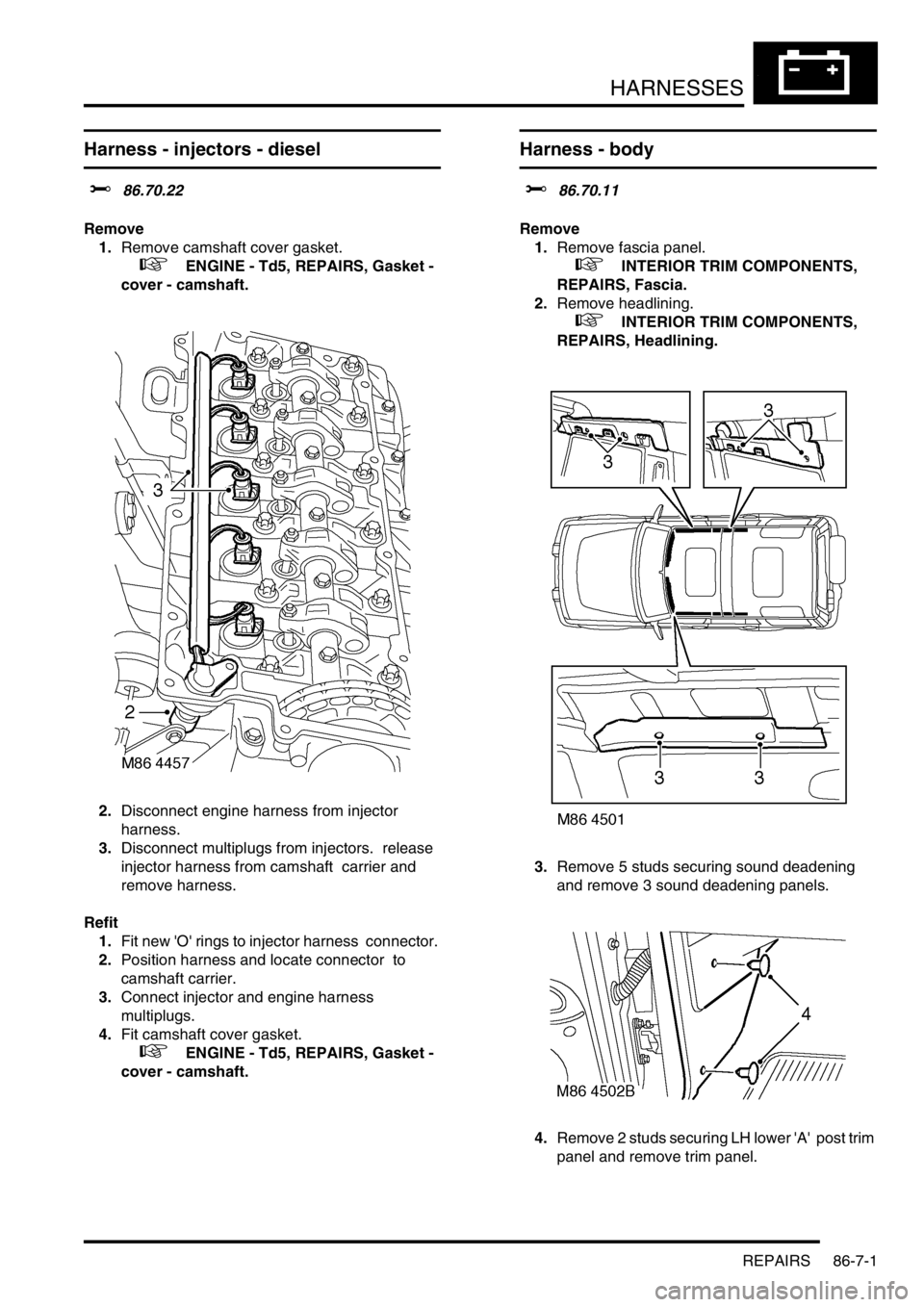

Harness - injectors - diesel

$% 86.70.22

Remove

1.Remove camshaft cover gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

2.Disconnect engine harness from injector

harness.

3.Disconnect multiplugs from injectors. release

injector harness from camshaft carrier and

remove harness.

Refit

1.Fit new 'O' rings to injector harness connector.

2.Position harness and locate connector to

camshaft carrier.

3.Connect injector and engine harness

multiplugs.

4.Fit camshaft cover gasket.

+ ENGINE - Td5, REPAIRS, Gasket -

cover - camshaft.

Harness - body

$% 86.70.11

Remove

1.Remove fascia panel.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.

2.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

3.Remove 5 studs securing sound deadening

and remove 3 sound deadening panels.

4.Remove 2 studs securing LH lower 'A' post trim

panel and remove trim panel.

Page 1579 of 1672

HARNESSES

86-7-8 REPAIRS

35.Secure harness to LH side of body with cable

tie clips and retainers.

36.Connect and secure multiplugs to lower LH 'A'

post.

37.Feed harness through roof to centre.

38.Secure harness behind bonnet release cable.

39.Connect rear washer pipe at lower 'A' post and

secure with clip.

40.Secure harness to roof with clips.

41.Connect multiplug to interior mirror, ARC

accelerometer.

42.Position sound deadening panels and secure

with clips.

43.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

44.Fit fascia panel.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.

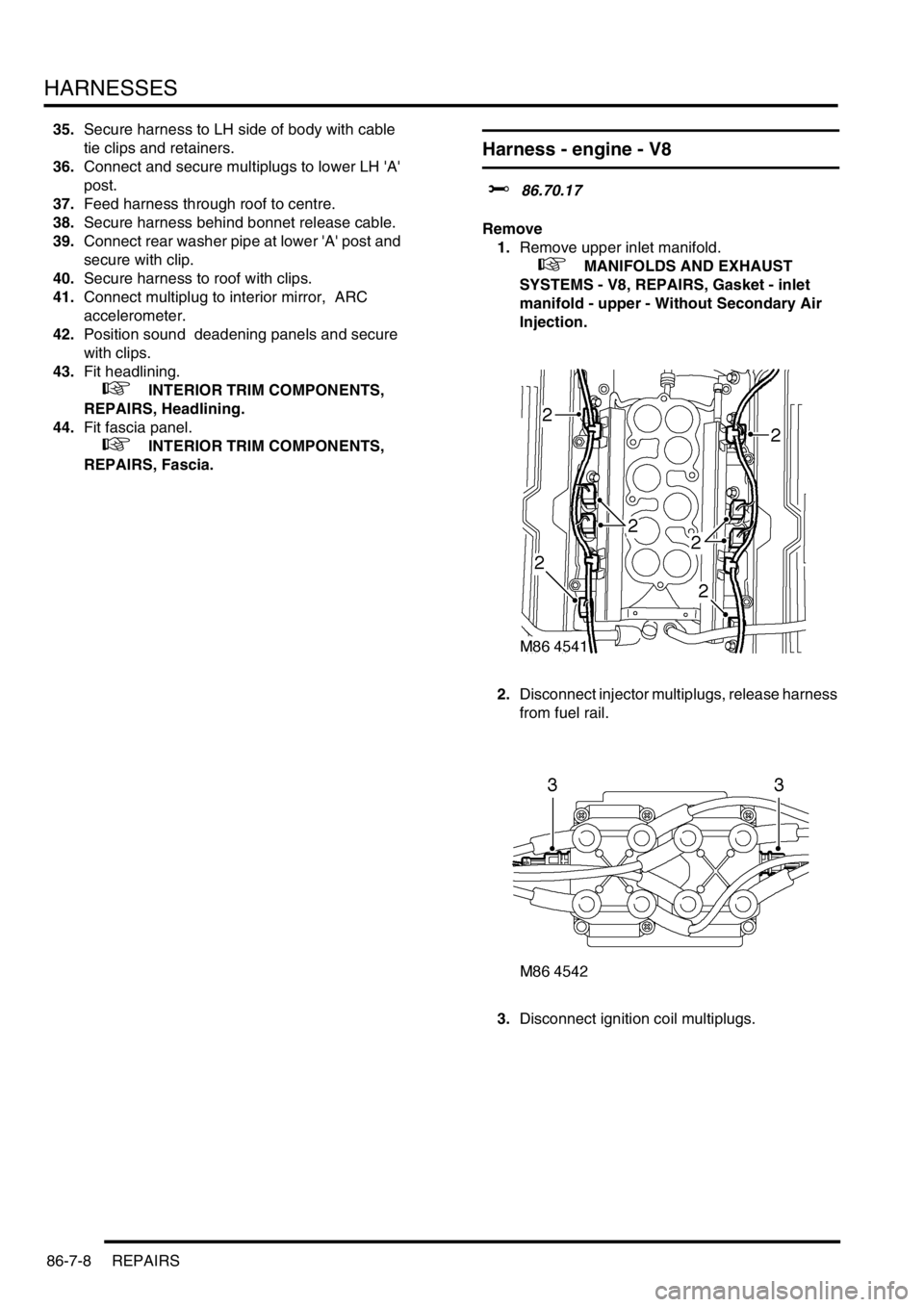

Harness - engine - V8

$% 86.70.17

Remove

1.Remove upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

2.Disconnect injector multiplugs, release harness

from fuel rail.

3.Disconnect ignition coil multiplugs.

Page 1581 of 1672

HARNESSES

86-7-10 REPAIRS

8.Disconnect coolant temperature sensor

multiplug.

9.Release 2 harness clips from coolant rail.

10.Remove nut securing engine harness positive

lead to battery, release lead and position

aside. 11.Release clips and remove fuse box cover.

12.Remove bolt securing starter lead to fuse box,

release lead and position aside.

13.Disconnect 2 engine harness multiplugs from

fuse box.

14.Disconnect EVAP solenoid multiplug.

15.Remove nut securing engine harness earth to

body and disconnect engine harness to main

harness multiplug.

Page 1582 of 1672

HARNESSES

REPAIRS 86-7-11

16.Remove trim fixings securing toe board and

remove toe board.

17.Disconnect 5 multiplugs connecting engine

harness to ECM.

18.Release engine harness, pull into engine bay.

19.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.20.Remove 3 nuts securing RH exhaust front pipe

to manifold. Remove and discard gasket.

21.Remove bolt securing starter heat shield and

remove heat shield.

22.Remove nut securing battery cable to starter

and disconnect solenoid cable.

23.Disconnect both knock sensor multiplugs.

Page 1583 of 1672

HARNESSES

86-7-12 REPAIRS

24.Remove bolt securing harness clip to LH side of

engine.

25.Disconnect camshaft sensor and oil pressure

switch multiplugs.

26.Remove engine harness. Refit

1.Position engine harness around engine.

2.Connect oil pressure switch and camshaft

sensor multiplugs.

3.Fit and tighten bolt securing harness to LH side

of engine.

4.Connect both knock sensor multiplugs.

5.Connect battery cable and solenoid cable to

starter motor.

6.Position starter heat shield and secure with

bolt.

7.Clean exhaust flange mating faces, using a

new gasket align exhaust fit nuts and tighten to

60 Nm (44 lbf.ft).

8.Remove stand(s) and lower vehicle.

9.Position harness into footwell and secure

grommet.

10.Connect ECM multiplugs.

11.Position toe board and secure with trim fixings.

12.Connect engine harness to main harness

multiplug and secure earth lead.

13.Connect EVAP solenoid multiplug.

14.Connect both fuse box multiplugs.

15.Position starter lead to fuse box and secure

screw.

16.Fit fuse box cover.

17.Position battery positive lead to battery and

secure nut.

18.Secure harness to coolant rail.

19.Position alternator cables and tighten terminal

B+ to 18 Nm (13 lbf.ft) and terminal D+ to 5 Nm

(3.7 lbf.ft)

20.Connect coolant temperature sensor multiplug.

21.Connect A/C compressor multiplug.

22.Secure harness clip to rear of LH cylinder head.

23.Connect CKP sensor multiplug.

24.Secure injector harness and connect injector

multiplugs.

25.Connect coil multiplugs.

26.Connect and secure HS

2O sensor multiplug

27.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

28.Connect battery earth lead.

Page 1584 of 1672

HARNESSES

REPAIRS 86-7-13

Harness - engine - diesel

$% 86.70.17

Remove

1.Remove engine acoustic cover.

2.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Battery carrier.

3.Remove engine compartment fuse box cover.

4.Remove bolts securing battery and alternator

leads to fuse box.

5.Remove bolt securing heater plug lead to fuse

box.

6.Disconnect 2 engine harness multiplugs from

fuse box. 7.Disconnect 2 engine harness multiplugs from

ECM and main harness.

8.Disconnect multiplug from EGR solenoid.

9.Disconnect multiplug from oil pressure switch.