ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1296 of 1672

PANEL REPAIRS

REPAIRS 77-2-47

Cross member outer rear panel (centre

section)

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

4.Remove rear bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - rear - up to 03MY.

5.Remove rear folding step.

+ EXTERIOR FITTINGS, REPAIRS,

Rear folding step.

6.Remove exhaust tailpipe heatshield.

7.Remove tail door tread plate.

8.Remove head lining rear trim finisher.

9.Remove tail door aperture seal.

10.Remove relevant wiring.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.Refit

1.Fit and secure wiring.

2.Fit tail door aperture seal.

3.Fit head lining rear trim finisher.

4.Fit tail door tread plate.

5.Fit exhaust tailpipe heatshield.

6.Fit rear folding step.

+ EXTERIOR FITTINGS, REPAIRS,

Rear folding step.

7.Fit rear bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - rear - up to 03MY.

8.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

9.Connect leads/multiplug to alternator.

10.Connect battery leads, negative lead last.

Page 1297 of 1672

PANEL REPAIRS

77-2-48 REPAIRS

Cross member outer rear panel (RH/LH

section)

In this procedure, the panel body side assembly and

the 'E' post assembly are replaced in conjunction

with either the RH or LH section of the cross member

outer rear panel.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove 'E' post assembly.

+ PANEL REPAIRS, REPAIRS, 'E' post

assembly.

4.Remove rear folding step.

+ EXTERIOR FITTINGS, REPAIRS,

Rear folding step.

5. LH side: Remove exhaust tailpipe heatshield.

6.Remove relevant wiring.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit and secure wiring.

2. LH side: Fit exhaust tailpipe heatshield.

3.Fit rear folding step.

+ EXTERIOR FITTINGS, REPAIRS,

Rear folding step.

4.Fit 'E' post assembly.

+ PANEL REPAIRS, REPAIRS, 'E' post

assembly.

5.Connect leads/multiplug to alternator.

6.Connect battery leads, negative lead last.

Cross member closing rear panel

In this procedure, the cross member outer rear panel

is replaced in conjunction with the cross member

closing rear panel. The cross member rear assembly

can also be replaced, if required.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove cross member outer rear panel.

+ PANEL REPAIRS, REPAIRS, Cross

member outer rear panel.

4.Remove fuel tank.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Tank - fuel.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Tank - fuel.

5.Remove 2 rear bolts securing body rear to

chassis.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit 2 rear bolts securing body rear to chassis

and tighten to 45 Nm (33 lbf.ft).

2.Fit fuel tank.

+ FUEL DELIVERY SYSTEM - V8,

REPAIRS, Tank - fuel.

+ FUEL DELIVERY SYSTEM - Td5,

REPAIRS, Tank - fuel.

3.Fit cross member rear outer panel.

+ PANEL REPAIRS, REPAIRS, Cross

member outer rear panel.

4.Connect leads/multiplug to alternator.

5.Connect battery leads, negative lead last.

Page 1299 of 1672

PANEL REPAIRS

77-2-50 REPAIRS

Rear floor complete assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

4.Remove rear seats.

+ SEATS, REPAIRS, Seat - rear.

5.Remove rear carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - rear.

6.Remove rear bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - rear - up to 03MY.

7.Remove RH and LH mud flap and brackets.

8.Remove exhaust tail pipe heatshields.

9.Remove tread plates from rear door apertures.

10.Remove rear door aperture seal.

11.Remove tail door tread plate.

12.Remove loadspace carpet retainer.

13.Remove head lining rear trim finisher.

14.Remove tail door aperture seal.

15.Remove bolts securing body to chassis.

16.Remove relevant wiring from floor area.Repair

M77 1712A

M77 1721A

Page 1300 of 1672

PANEL REPAIRS

REPAIRS 77-2-51

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Position and secure wiring.

2.Fit and tighten bolts securing body to chassis to

45 Nm (33 lbf.ft).

3.Fit tail door aperture seal.

4.Fit head lining rear trim finisher.

5.Fit loadspace carpet retainer.

6.Fit tail door tread plate.

7.Fit rear door aperture seals.

8.Fit tread plate to rear door apertures.

9.Fit exhaust tail pipe heatshields.

10.Fit mud flap bracklets and mud flaps.

11.Fit rear bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - rear - up to 03MY.

12.Fit rear carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - rear.

13.Fit rear seats.

+ SEATS, REPAIRS, Seat - rear.

14.Fit loadspace carpet.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Carpet - loadspace.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Rear floor (rear section)

In this procedure, the cross member rear assembly,

cross member outer rear panel, cross member

closing rear panel, 'E' post assembly, 'E' post closing

assembly and the panel body side assembly are

replaced in conjunction with the rear floor (rear

section).

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove cross member rear assembly.

+ PANEL REPAIRS, REPAIRS, Cross

member rear assembly.

4.Remove mud flap mounting brackets.

5. LH side: Remove exhaust heatshield from rear

floor.

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown. Welds for RH side are symmetrically

opposite to those shown.

Refit

1. LH side: Fit exhaust heatshield to rear floor.

2.Fit mud flap mounting brackets.

3.Fit cross member rear assembly.

+ PANEL REPAIRS, REPAIRS, Cross

member rear assembly.

4.Connect leads/multiplug to alternator.

5.Connect battery leads, negative lead last.

Page 1302 of 1672

PANEL REPAIRS

REPAIRS 77-2-53

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

2. During welding operations, apply 'Heat

shrink paste' to roof and body side panel to

avoid heat damage to paintwork.Refit

1.Fit and secure wiring.

2.Fit side and rear drip rail finishers.

3.Fit alpine light glass.

+ SCREENS, REPAIRS, Glass - alpine

light.

4.Fit windscreen.

+ SCREENS, REPAIRS, Windscreen.

5.Fit 'D' post outer trim finishers.

6.Fit rear door aperture seals.

7.Fit tread plates to rear door apertures.

8.Fit front door aperture seals.

9.Fit 'A' post lower trim panels.

10.Fit tread plates to front door apertures.

11.Fit roof bars.

+ EXTERIOR FITTINGS, REPAIRS,

Roof bars.

12.Fit rear headrests.

13.Fit rear seats.

+ SEATS, REPAIRS, Seat - rear.

14.Fit front seats.

+ SEATS, REPAIRS, Seat - front.

15. Models with fixed roof: Fit head lining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining.

16. Models with sunroof: Fit sunroof drain tubes.

17. Models with sunroof: Fit rear sunroof.

+ SUNROOF, REPAIRS, Sunroof -

rear.

18. Models with sunroof: Fit front sunroof.

+ SUNROOF, REPAIRS, Sunroof -

front.

19.Connect leads/multiplug to alternator.

20.Connect battery leads, negative lead last.

M77 1715A

Page 1349 of 1672

HEATING AND VENTILATION

80-8DESCRIPTION AND OPERATION

Control panel

The controls for heating and ventilation are installed on a control panel in the centre of the fascia, below the radio.

Three rotary knobs control the LH and RH outlet temperatures and distribution. A slider switch controls blower speed.

A latching pushswitch controls the selection of fresh/recirculated air; an amber LED in the switch illuminates when

recirculated air is selected.

Graphics on the panel and the controls indicate the function and operating positions of the controls.

Outlet vent

The outlet vent promotes the free flow of heating and ventilation air through the cabin. The outlet vent is installed in

the RH rear quarter body panel and vents cabin air into the sheltered area between the rear quarter body panel and

the outer body side panel. The vent consists of a grille covered by soft rubber flaps and is effectively a non-return

valve. The flap opens and closes automatically depending on the differential between cabin and outside air pressures.

FBH system (diesel models only)

The FBH system is an auxiliary heating system that compensates for the relatively low coolant temperatures inherent

in the diesel engine. At low ambient temperatures, the FBH system heats the coolant supply to the heater assembly,

and maintains it within the temperature range required for good in-car heating performance. Operation is fully

automatic, with no intervention required by the driver.

The system consists of an air temperature sensor, a FBH fuel pump and a FBH unit. Fuel for the FBH system is taken

from the fuel tank, through a line attached to the fuel tank's fuel pump, and supplied via the FBH fuel pump to the FBH

unit. The connection on the fuel tank's fuel pump incorporates a tube which extends down into the tank. At the FBH

unit connection, the fuel line incorporates a self-sealing, quick disconnect coupling. In the FBH unit, the fuel delivered

by the FBH fuel pump is burned and the resultant heat output is used to heat the coolant. An ECU integrated into the

FBH unit controls the operation of the system at one of two heat output levels, 2.5 kW at part load and 5 kW at full load

Ambient temperature sensor

The ambient temperature sensor controls a power supply from the alternator to the FBH unit. The sensor is installed

on the RH support strut of the bonnet closing panel and contains a temperature sensitive switch that is closed at

temperatures below 5

°C (41 °F) and open at temperatures of 5 °C (41 °F) and above.

Page 1350 of 1672

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-9

FBH fuel pump

The FBH fuel pump regulates the fuel supply to the FBH unit. The FBH fuel pump is installed in a rubber mounting on

the chassis crossmember immediately in front of the fuel tank. The pump is a self priming, solenoid operated plunger

pump, with a fixed displacement of 0.063 ml/Hz. The ECU in the FBH unit outputs a pulse width modulated signal to

control the operation of the pump. When the pump is de-energised, it provides a positive shut-off of the fuel supply to

the FBH unit.

FBH fuel pump nominal operating speeds/outputs

Sectioned view of FBH fuel pump

1Solenoid coil

2Plunger

3Filter insert

4Fuel line connector

5'O' ring seal6Spring

7Piston

8Bush

9Fuel line connector

10Non return valve

The solenoid coil of the FBH fuel pump is installed around a housing which contains a plunger and piston. The piston

locates in a bush, and a spring is installed on the piston between the bush and the plunger. A filter insert and a fuel

line connector are installed in the inlet end of the housing. A non return valve and a fuel line connector are installed

in the fuel outlet end of the housing.

While the solenoid coil is de-energised, the spring holds the piston and plunger in the 'closed' position at the inlet end

of the housing. An 'O' ring seal on the plunger provides a fuel tight seal between the plunger and the filter insert,

preventing any flow through the pump. When the solenoid coil is energised, the piston and plunger move towards the

outlet end of the housing, until the plunger contacts the bush, and draw fuel in through the inlet connection and filter.

The initial movement of the piston also closes transverse drillings in the bush and isolates the pumping chamber at

the outlet end of the housing. Subsequent movement of the piston then forces fuel from the pumping chamber through

the non return valve and into the line to the FBH unit. When the solenoid coil de-energises, the spring moves the piston

and plunger back towards the closed position. As the piston and plunger move towards the closed position, fuel flows

passed the plunger and through the annular gaps and transverse holes in the bush to replenish the pumping chamber.

Operating phase Speed, Hz Output, l/h (US galls/h)

Start sequence 0.70 0.159 (0.042)

Part load 1.35 0.306 (0.081)

Full load 2.70 0.612 (0.163)

Page 1352 of 1672

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-11

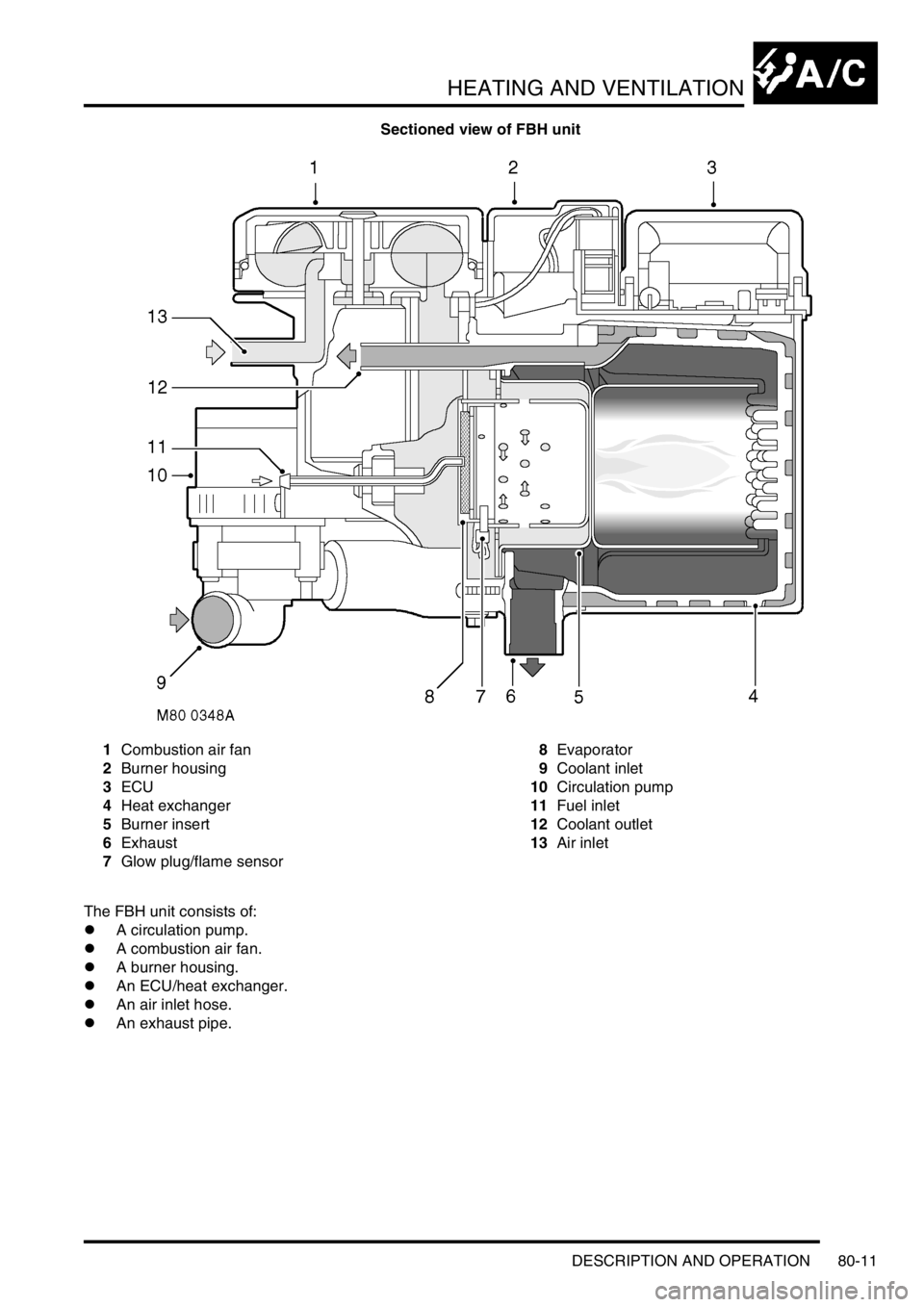

Sectioned view of FBH unit

1Combustion air fan

2Burner housing

3ECU

4Heat exchanger

5Burner insert

6Exhaust

7Glow plug/flame sensor8Evaporator

9Coolant inlet

10Circulation pump

11Fuel inlet

12Coolant outlet

13Air inlet

The FBH unit consists of:

lA circulation pump.

lA combustion air fan.

lA burner housing.

lAn ECU/heat exchanger.

lAn air inlet hose.

lAn exhaust pipe.

Page 1353 of 1672

HEATING AND VENTILATION

80-12DESCRIPTION AND OPERATION

Circulation pump. The circulation pump is installed at the coolant inlet to the FBH unit to assist the coolant flow through

the FBH unit and the heater assembly. The pump runs continuously while the FBH unit is in standby or active

operating modes. While the FBH unit is inactive, coolant flow is reliant on the engine coolant pump.

Combustion air fan. The combustion air fan regulates the flow of air into the unit to support combustion of the fuel

supplied by the FBH pump. It also supplies the air required to purge and cool the FBH unit. Ambient air is supplied to

the combustion air fan through an air inlet hose containing a sound deadening foam ring.

Burner housing. The burner housing contains the burner insert and also incorporates connections for the exhaust

pipe, the coolant inlet from the circulation pump and the coolant outlet to the heater assembly. The exhaust pipe

directs exhaust combustion gases to atmosphere at the bottom of the engine compartment.

The burner insert incorporates the fuel combustion chamber, an evaporator and a glow plug/flame sensor. Fuel from

the FBH fuel pump is supplied to the evaporator, where it evaporates and enters the combustion chamber to mix with

air from the combustion air fan. The glow plug/flame sensor provides the ignition source of the fuel:air mixture and,

once combustion is established, monitors the flame.

ECU/heat exchanger. The ECU controls and monitors operation of the FBH system. Ventilation of the ECU is

provided by an internal flow of air from the combustion air fan. The heat exchanger transfers heat generated by

combustion to the coolant. A sensor in the heat exchanger provides the ECU with an input of heat exchanger casing

temperature, which the ECU relates to coolant temperature and uses to control system operation. The temperature

settings in the ECU are calibrated to compensate for the difference between coolant temperature and the heat

exchanger casing temperature detected by the sensor. Typically: as the coolant temperature increases, the coolant

will be approximately 7

°C (12.6 °F) hotter than the temperature detected by the sensor; as the coolant temperature

decreases, the coolant will be approximately 2

°C (3.6 °F) cooler than the temperature detected by the sensor.

Page 1354 of 1672

HEATING AND VENTILATION

DESCRIPTION AND OPERATION 80-13

Operation

Air distribution

Turning the distribution knob on the control panel turns the control flaps in the heater assembly to direct air to the

corresponding fascia and footwell outlets.

Air temperature

Turning the LH or RH temperature knob on the control panel turns the related blend flaps in the heater assembly. The

blend flaps vary the proportion of air going through the cold air bypass and the heater matrix. The proportion varies,

between full bypass no heat and no bypass full heat, to correspond with the position of the temperature knob.

Blower speed

The blower can be selected off or to run at one of four speeds. While the ignition is on, when the blower switch is set

to positions 1, 2, 3, or 4, ignition power energises the blower relay, which supplies battery power to the blower. At

switch positions 1, 2 and 3, the blower switch also connects the blower to different earth paths through the resistor

pack, to produce corresponding differences of blower operating voltage and speed. At position 4, the blower switch

connects an earth direct to the blower, bypassing the resistor pack, and full battery voltage drives the blower at

maximum speed.

Fresh/Recirculated inlet air

When the recirculated air switch is latched in, the amber indicator LED in the switch illuminates and an earth is

connected to the recirculated air side of the fresh/recirculated air servo motor. The fresh/recirculated air servo motor

then turns the control flaps in the air inlet duct to close the fresh air inlet and open the recirculated air inlets.

When the latch of the recirculated air switch is released, the amber indicator LED in the switch extinguishes and the

earth is switched from the recirculated air side to the fresh air side of the fresh/recirculated air servo motor. The fresh/

recirculated air servo motor then turns the control flaps in the air inlet duct to open the fresh air inlet and close the

recirculated air inlets.

FBH system (where fitted)

The FBH system operates only while the engine is running and the ambient temperature is less than 5

°C (41 °F).

With the engine running and the ambient temperature below 5

°C (41 °F), the air temperature sensor connects the

alternator power supply to the ECU in the FBH unit. On receipt of the alternator power supply, the ECU starts the

circulation pump and, depending on the input from the temperature sensor in the heat exchanger, enters either a

standby or active mode of operation. If the heat exchanger casing temperature is 65

°C (149 °F) or above, the ECU

enters a standby mode of operation. If the heat exchanger casing temperature is below 65

°C (149 °F), the ECU enters

an active mode of operation. In the standby mode, the ECU monitors the heat exchanger casing temperature and

enters the active mode if it drops below 65

°C (149 °F). In the active mode, the ECU initiates a start sequence and

then operates the system at full or part load combustion to provide the required heat input to the coolant.

Start sequence

At the beginning of the start sequence the ECU energises the glow plug function of the glow plug/flame sensor, to

preheat the combustion chamber, and starts the combustion air fan at slow speed. After 30 seconds, the ECU

energises the FBH fuel pump at the starting sequence speed. The fuel delivered by the FBH fuel pump evaporates in

the combustion chamber, mixes with air from the combustion air fan and is ignited by the glow plug/flame sensor. The

ECU then progressively increases the speed of the FBH fuel pump and the combustion air fan to either part or full

load speed, as required by the system. Once full or part load speed is achieved, the ECU switches the glow plug/flame

sensor from the glow plug function to the flame sensing function to monitor combustion. From the beginning of the

start sequence to stable combustion takes approximately 90 seconds for a start to part load combustion and 150

seconds for a start to full load combustion.