ECO mode LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1388 of 1672

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-15

Distribution switch. Enabled only while the system is on. Provides manual control of air distribution:

lEach press changes the air distribution, in sequence, through footwells only, footwells and windscreen/side

windows demist, windscreen/side windows demist only, face level only, face level and footwells.

lIf the switch is kept depressed, after 1 second subsequent distribution changes occur every 0.4 seconds until

distribution reaches face level and footwells. Releasing and then pressing the switch again changes distribution

back to footwells only.

External air temperature (EXT) switch. Enabled while the system is on or off. Switches the external temperature output

on and off:

lIf the system is already on, the temperature output overrides the system outputs for approximately 7 seconds,

then the display reverts to system outputs.

lIf the system is switched on while the external temperature output is on, the system outputs override the external

temperature output.

Fresh/Recirculated air switch. Enabled only while the system is on. Provides manual control of inlet air selection.

Defrost mode switch. Starts the system in, or switches the system to and from, defrost mode.

Automatic mode (AUTO) switch. Starts the system in, or switches the system to and from, the automatic mode.

Economy mode (ECON) switch. Enabled only while the system is on. Provides manual on/off control of the refrigerant

system compressor, to reduce fuel consumption when there is no requirement for cool or dehumidified air, e.g. when

the ambient temperature is lower than the LH and RH temperature settings.

Temperature settings: The LH and RH temperature settings are reference inputs used by the control system and give

an approximation of the temperatures that will be established in the cabin. They are not necessarily actual distribution

outlet temperatures, or the temperatures at specific points in the cabin.

Audible warning: A 'beep' is emitted from the ATC ECU each time it receives a control switch input. This audible

warning can be switched off and on by pressing and holding the AUTO switch, then pressing and holding the A/C on/

off switch until the audible warning sounds (approximately 3 seconds). While switched off, the audible warning still

sounds when:

lSwitching between

°F and °C on the display.

lSwitching the audible warning from off to on.

lSwitching the timed feet function on and off.

lSwitching the timed recirculated inlet air on and off.

lSwitching the latched recirculated inlet air on and off.

lWhen there is a fault warning.

lRunning the self diagnostic routine.

Page 1389 of 1672

AIR CONDITIONING

82-16DESCRIPTION AND OPERATION

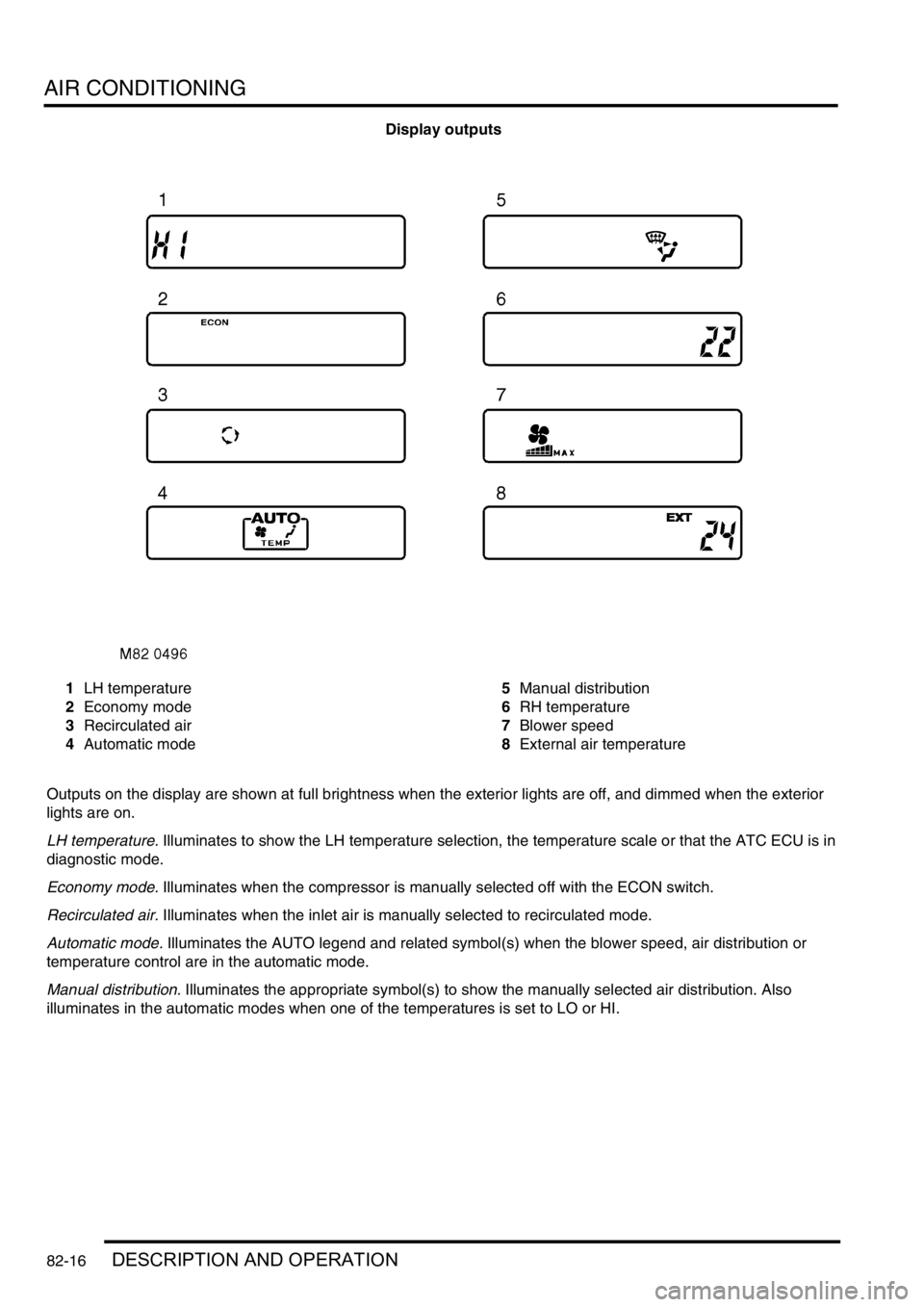

Display outputs

1LH temperature

2Economy mode

3Recirculated air

4Automatic mode5Manual distribution

6RH temperature

7Blower speed

8External air temperature

Outputs on the display are shown at full brightness when the exterior lights are off, and dimmed when the exterior

lights are on.

LH temperature. Illuminates to show the LH temperature selection, the temperature scale or that the ATC ECU is in

diagnostic mode.

Economy mode. Illuminates when the compressor is manually selected off with the ECON switch.

Recirculated air. Illuminates when the inlet air is manually selected to recirculated mode.

Automatic mode. Illuminates the AUTO legend and related symbol(s) when the blower speed, air distribution or

temperature control are in the automatic mode.

Manual distribution. Illuminates the appropriate symbol(s) to show the manually selected air distribution. Also

illuminates in the automatic modes when one of the temperatures is set to LO or HI.

Page 1390 of 1672

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-17

RH temperature. Illuminates to show the RH temperature selection, external air temperature or diagnostic fault code.

Blower speed. Illuminates when the blower speed is manually selected. Also illuminates in the automatic modes when

one of the temperatures is set to LO or HI.

External air temperature. EXT illuminates to show that external air temperature is selected on.

All temperature indications on the display are in either

°C or °F. For 1 second after the system is first switched on, the

display shows only

°C or °F, in the LH temperature window, to indicate which temperature scale is in use. After 1

second, the

°C or °F indication goes off and the display shows all relevant outputs.

Temperature conversion: While the system is on, the temperature indications on the display can be switched between

the two scales by pressing and holding the fresh/recirculated air switch, then pressing and holding the A/C on/off

switch until the audible warning sounds (approximately 3 seconds).

Dual pressure switch

The dual pressure switch protects the refrigerant system from extremes of pressure. The normally closed switch is

installed in the top of the receiver drier. If minimum or maximum pressure limits are exceeded the switch contacts

open, causing the compressor clutch to be disengaged. The minimum pressure limit protects the compressor, by

preventing operation of the system unless there is a minimum refrigerant pressure (and thus refrigerant and

lubricating oil) in the system. The maximum pressure limit keeps the refrigerant system within a safe operating

pressure.

Dual pressure switch nominal operating pressures

Evaporator temperature sensor

The evaporator temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of the

evaporator air outlet temperature. The evaporator temperature sensor is installed in a clip which locates in the

evaporator matrix in the heater assembly. The ATC ECU uses the input to prevent the formation of ice on the

evaporator.

In-car temperature sensor

The in-car temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of cabin air

temperature. The sensor is integrated into the inlet of an electric fan, which is installed behind a grille in the fascia

outboard of the steering column. The fan runs continuously, while the ignition is on, to draw air through the grille and

across the sensor.

Sunlight sensor

The sunlight sensor consists of two diodes that provide the ATC ECU with inputs of light intensity, one as sensed

coming from the left of the vehicle and one as sensed coming from the right. The inputs are used as a measure of the

solar heating effect on vehicle occupants. The sensor is installed in the centre of the fascia upper surface.

Heater coolant temperature sensor

The heater coolant temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input related

to heater matrix coolant temperature. The sensor is installed in the casing of the heater assembly and presses against

the end tank of the heater matrix.

Ambient temperature sensor

The ambient temperature sensor is an encapsulated thermistor that provides the ATC ECU with an input of external

air temperature. The sensor is attached to the cooling fan mounting bracket in front of the condenser.

Limit Opening pressure, bar (lbf.in2) Closing pressure, bar (lbf.in2)

Minimum 2.0 (29.0), pressure decreasing 2.3 (33.4), pressure increasing

Maximum 32 (464), pressure increasing 26 (377), pressure decreasing

Page 1391 of 1672

AIR CONDITIONING

82-18DESCRIPTION AND OPERATION

Operation

General

While the system is on, the ATC ECU operates the refrigerant system and the inlet air, blower speed, air temperature

and air distribution functions to produce the conditions requested on the control panel. When the system is first

switched on, the ATC ECU resumes the control outputs in use when the system was last switched off. If conditions

have changed, or a different mode is selected to switch the system on, the control outputs are then changed to

produce the required new settings.

The system operates in automatic, economy and defrost modes, with manual overrides of the inlet air source, blower

speed and air distribution. The air temperature is automatically controlled in all operating modes.

In the automatic mode, the ATC ECU operates the system to warm-up or cool down the cabin to establish and

maintain the temperature selections on the control panel, while directing the air to those outlets most comfortable for

the occupant(s). If a difference between the LH and RH temperature selections causes a conflict of the required inlet

air source, blower speed or air distribution settings, priority is given to achieving the temperature requested on the

driver's side of the control panel.

The ATC ECU enters the economy mode when the refrigerant compressor is selected off while the system is in the

automatic mode, which reduces the load on the engine. Economy mode operation is similar to the automatic mode,

but without the ability to cool the cabin if the ambient temperature is higher than the temperature selections made on

the control panel, or to dehumidify the air in the cabin.

In the defrost mode, the ATC ECU sets the inlet air source to fresh air, the blower to maximum speed, the air

distribution to windscreen and side windows, and outputs signals to the BCU to operate the rear window heater and

(where fitted) the windscreen heater. The BCU starts or, if the heaters are already on, resets the heater timers and

energises the rear window and windscreen heaters for a complete on cycle.

Air temperature control

To determine the amount of heat or cooling required by the cabin, the ATC ECU uses the sensor inputs and the

temperatures selected on the control panel to calculate target air outlet temperatures for the driver's and the front

passenger's side of the heater assembly. The ATC ECU then signals the servo motors controlling the respective blend

flaps in the heater assembly to move to the flaps to the appropriate position. The target temperatures are constantly

updated and, in the automatic mode, also used in further calculations to determine the inlet air source, the blower

speed and the air distribution.

Inlet air control

The inlet air source is automatically controlled while the system is off or on. While the system is on, the inlet air source

can also be manually controlled to give timed recirculated air or latched recirculated air.

While the system is off, the ATC ECU uses vehicle speed to determine the inlet air source. With the vehicle at rest,

the inlet air source is set to recirculated air. When vehicle speed reaches 17.5 mph (28 km/h), the inlet air source

changes to fresh air. The inlet air source then remains at fresh air until the vehicle speed decreases to 5 mph (8 km/

h), when it returns to recirculated air.

While the system is on, the ATC ECU uses the LH and RH temperature selections, vehicle speed, ambient air

temperature and coolant temperature to determine the inlet air source. In the automatic mode:

lIf one temperature selection is set to LO and one is set to a specific temperature or HI, the inlet air is set to

recirculated air.

lIf one temperature selection is set to HI and one is set to a specific temperature or HI, the inlet air is set to fresh

air.

lWhen specific LH and RH temperature selections are set, the inlet air source remains at fresh air except when

the air distribution function is set to face level only or face level and footwell outlets. If the air distribution function

is set to face level only or face level and footwell outlets, at 56 mph (90 km/h) the inlet air source changes to

recirculated air (to exclude ram effect, which becomes excessive at speed). When the vehicle speed decreases

to 37.5 mph (60 km/h), the inlet air source returns to fresh air.

Page 1392 of 1672

AIR CONDITIONING

DESCRIPTION AND OPERATION 82-19

In the defrost mode, the inlet air source is set to fresh air except at low ambient air and coolant temperatures. If, within

5 minutes of the ignition being switched on, the vehicle speed is less than 5 mph (8 km/h) while the external air

temperature is

−16 °C (3 °F) or less and the heater coolant temperature is −10 °C (14 °F) or less, then the inlet air

source is automatically set to the timed recirculated air mode. The timed recirculated air mode is cancelled

immediately the vehicle speed reaches 8 km/h or more .

Timed recirculated air

The timed recirculated air mode sets the inlet air source to recirculated air for 5

± 1 minutes, after which it automatically

reverts to fresh air. Timed recirculated air can be manually selected:

lIn the automatic mode, by pressing the fresh/recirculated air switch for 1.5 seconds or more; the audible warning

sounds twice.

lIn the economy or defrost modes, by pressing the fresh/recirculated air switch for less than 1.5 seconds; the

audible warning sounds once.

Latched recirculated air

The inlet air source can be latched to recirculated air:

lIn the automatic mode, by pressing the fresh/recirculated air switch for less than 1.5 seconds; the audible

warning sounds once.

lIn the economy or defrost modes, by pressing the fresh/recirculated air switch for 1.5 seconds or more; the

audible warning sounds twice.

Blower control

The ATC ECU operates a blower relay, power transistor and power relay to run the blower at one of 31 stepped

speeds. All speed steps are available in the automatic modes of blower control. In the manual mode, speed steps 3,

10, 16, 22 and 31 are used to provide slow, three intermediate and fast blower speeds. The ATC ECU energises the

blower relay and modulates the power transistor to operate the blower for speed steps 1 to 30. For speed step 31, the

ATC ECU energises the power relay, which switches the earth side of the blower motor direct to earth, bypassing the

power transistor.

In the automatic, economy and defrost modes, blower speed is corrected for vehicle speed to compensate for the

increase in ram effect on the inlet air as the vehicle speed increases. Correction begins at approximately 50 km/h,

when blower speed is progressively decreased as vehicle speed increases, until a maximum decrease of 13 steps

occurs at 123 km/h. Similarly, blower speed increases as vehicle speed decreases down to approximately 50 km/h.

In the automatic and economy modes, if the LH or RH temperature is set to LO or HI, the blower runs at maximum

speed with correction only for vehicle speed. If both the LH and RH outlet air temperatures are set to a specific

temperature, blower speed corrections are added to compensate for the heater coolant temperature, external air

temperature, and the solar load acting on the vehicle:

lDuring warm-up, the blower speed is set to 3 while the heater coolant temperature is below approximately 20

°C

(68

°F). From approximately 20 °C (68 °F), the blower speed is progressively increased as the coolant

temperature increases, until maximum speed is set at approximately 50

°C (122 °F).

lDuring cool down, blower speed is set to 3, for 5 seconds after the system is switched on. Over the following 6

seconds, the blower speed is progressively increased up to maximum speed.

lAs the temperature in the cabin approaches the selected temperatures, blower speed is progressively reduced

until, once the selected temperatures have been established, blower speed stabilises at approximately 6.

lSolar heating correction is employed when air distribution is set to face level or to face and footwells. The

correction progressively increases the blower speed, up to a maximum of 9 steps, with increasing values of solar

heating.

Page 1393 of 1672

AIR CONDITIONING

82-20DESCRIPTION AND OPERATION

Air distribution control

To control the air distribution within the cabin the ATC ECU signals the servo motor controlling the distribution flaps

in the heater assembly to move to the flaps to the appropriate position.

In the automatic and economy modes, if the LH or RH temperature selections are set to LO or HI, air distribution is

fixed as follows:

lIf one is set to LO and one is set to a specific temperature, to face level only.

lIf one is set to HI and one is set to a specific temperature, to footwells only.

lIf one is set to LO and one is set to HI, to face level and footwells.

When specific LH and RH temperature selections are set, air distribution is determined from the target air outlet

temperatures. For higher target air outlet temperatures, air distribution is set to footwells only. For lower target air

outlet temperatures, air distribution is set to face level only. For intermediate target air outlet temperatures, air

distribution is set to face level and footwells. When the air distribution is set to face level and footwells, the ATC ECU

varies the bias between the footwells and the face level outlets, in three stages, to provide a gradual transition of air

distribution from footwells only to face level only. The three stages of bias are also employed when the air distribution

is manually selected to face level and footwells.

During warm-up, the air distribution changes to face level and footwells for a period, then reverts to footwells only.

The period of air distribution at face level and footwells can be cancelled by pressing and holding the on/off and defrost

mode switches, then turning the ignition switch from off to on. Pressing and holding the AUTO and defrost switches,

then turning the ignition switch from off to on, restores the period of air distribution at face level and footwells.

Compressor control

To engage the compressor clutch, the ATC ECU outputs a compressor clutch request to the ECM, which then

energises the A/C compressor clutch relay. Compressor operation is governed by the evaporator outlet air

temperature, at one of two settings, dependent on the amount of cooling required. When more cooling is required, the

compressor clutch request is output if evaporator outlet air temperature increases to 4

°C (39 °F) and cancelled when

it decreases to 3

°C (37 °F). When less cooling is required, the compressor clutch request is output if evaporator outlet

air temperature increases to 11

°C (52 °F) and cancelled when it decreases to 10 °C (50 °F).

Engine cooling fan control

While the A/C system is on, operation of the electric engine cooling fan, to assist refrigerant condenser operation, is

determined by a combination of vehicle speed and external air temperature. When cooling fan operation is required,

the ATC ECU outputs a cooling fan request to the ECM, which then energises the cooling fan relay. The cooling fan

request is output if vehicle speed is 80 km/h or less while the external air temperature is 28

°C (82 °F) or more. The

request is cancelled, and the cooling fan switched off, if either the vehicle speed increases to 100 km/h, or the external

air temperature decreases to 25

°C (77 °F).

Default settings

If the battery power supply to the ATC ECU is disrupted for any reason, e.g. battery disconnected, the system reverts

to default settings when the battery power supply is restored. Default settings are:

lTemperature indications in

°C (in some markets a conversion connector is fitted to the ATC ECU to change the

default temperature scale to

°F).

lLH and RH outlet temperatures of 22

°C (72 °F).

laudible warning switched on.

lWarm-up air distribution (to face level and footwells) function switched on.

lIf the system is first switched on using the A/C on/off switch, the automatic mode is engaged, regardless of the

settings in use when the battery was disconnected.

Page 1415 of 1672

AIR CONDITIONING

82-42REPAIRS

13.Remove covering from TX valve, release 2

clips securing TX valve to pipe.

14.Release 2 unions securing TX valve, remove

TX valve, remove and discard 'O' rings.

15.Release pipe union, remove pipe and discard

'O' ring.

Refit

1.Using a new 'O' ring, position pipe to

evaporator and tighten union.

2.Using new 'O' rings, position TX valve. Connect

pressure pipe union and tighten to 22 Nm (16

lbf. ft). Connect evaporator pipe and tighten to

32 Nm (24 lbf.ft).

3.Position TX valve sensor to pipe and secure

with clips.

4.Fit sensor covering.

5.Fit evaporator thermistor.

6.Fit evaporator assembly.

7.Fit insulation to evaporator casing and fit

casing.

8.Secure spring clips.

9.Fit and tighten casing screws.

10.Fit heater matrix, ensuring matrix temperature

is correctly positioned.

11.Fit coolant pipe saddle, fit and tighten screws

securing saddle and pipe bracket.

12.Fit and tighten temperature servo screws.

13.Connect multiplug to evaporator thermistor.

14.Clean any bulk head seal from casing.

15.Fit bulkhead and evaporator pipe seals.

16.Fit heater assembly.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models with

air conditioning.

Expansion valve - (TXV) - rear

$% 82.26.01

Remove

1.Depressurise air conditioning system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Remove rear lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

3.Remove 5 bolts securing seat support bracket

and remove bracket.

4.Release insulation from TXV pipe unions and

sensor.

5.Remove clip securing sensor to pipe and

release sensor.

Page 1417 of 1672

AIR CONDITIONING

82-44REPAIRS

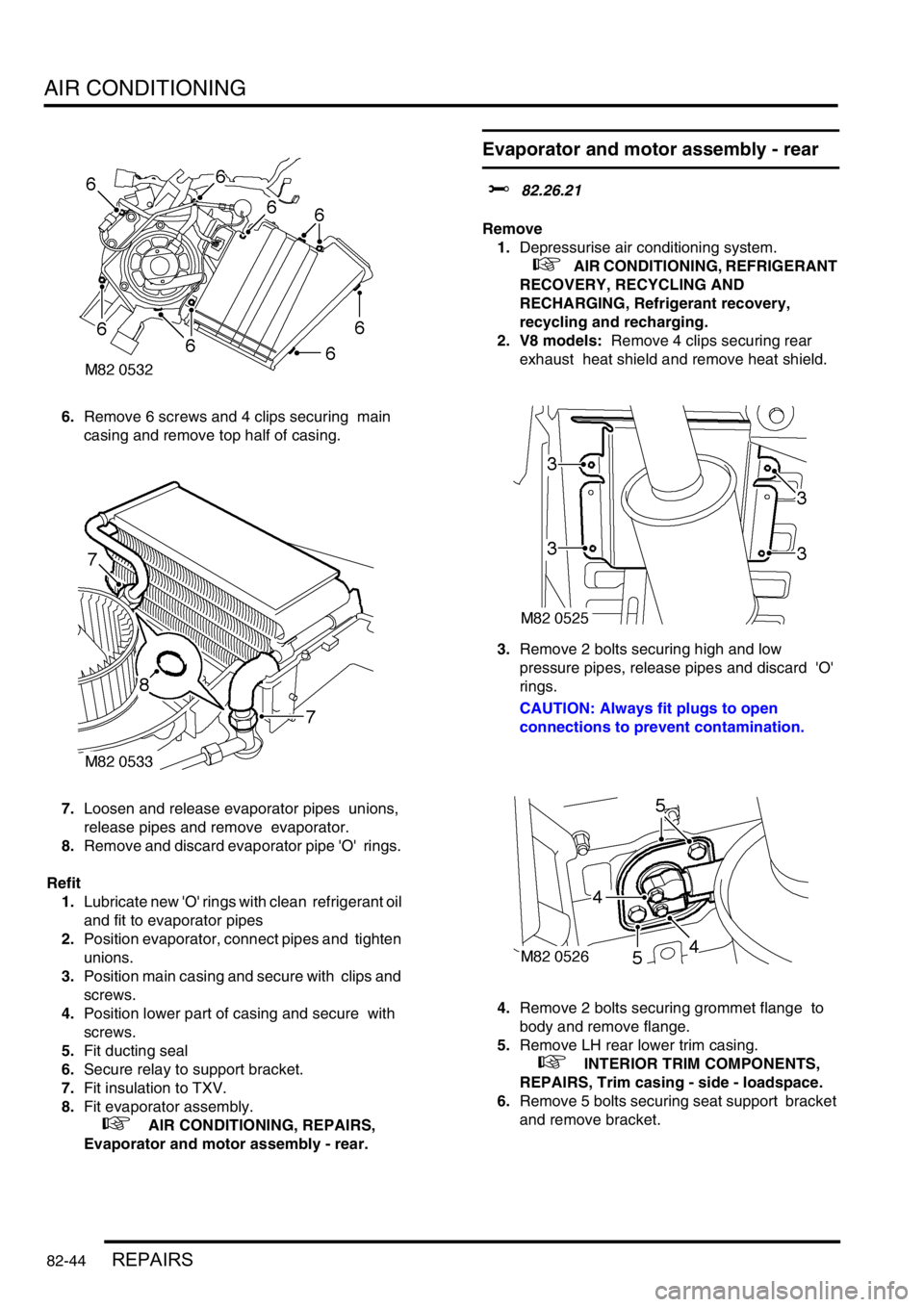

6.Remove 6 screws and 4 clips securing main

casing and remove top half of casing.

7.Loosen and release evaporator pipes unions,

release pipes and remove evaporator.

8.Remove and discard evaporator pipe 'O' rings.

Refit

1.Lubricate new 'O' rings with clean refrigerant oil

and fit to evaporator pipes

2.Position evaporator, connect pipes and tighten

unions.

3.Position main casing and secure with clips and

screws.

4.Position lower part of casing and secure with

screws.

5.Fit ducting seal

6.Secure relay to support bracket.

7.Fit insulation to TXV.

8.Fit evaporator assembly.

+ AIR CONDITIONING, REPAIRS,

Evaporator and motor assembly - rear.

Evaporator and motor assembly - rear

$% 82.26.21

Remove

1.Depressurise air conditioning system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2. V8 models: Remove 4 clips securing rear

exhaust heat shield and remove heat shield.

3.Remove 2 bolts securing high and low

pressure pipes, release pipes and discard 'O'

rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove 2 bolts securing grommet flange to

body and remove flange.

5.Remove LH rear lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

6.Remove 5 bolts securing seat support bracket

and remove bracket.

Page 1418 of 1672

AIR CONDITIONING

REPAIRS 82-45

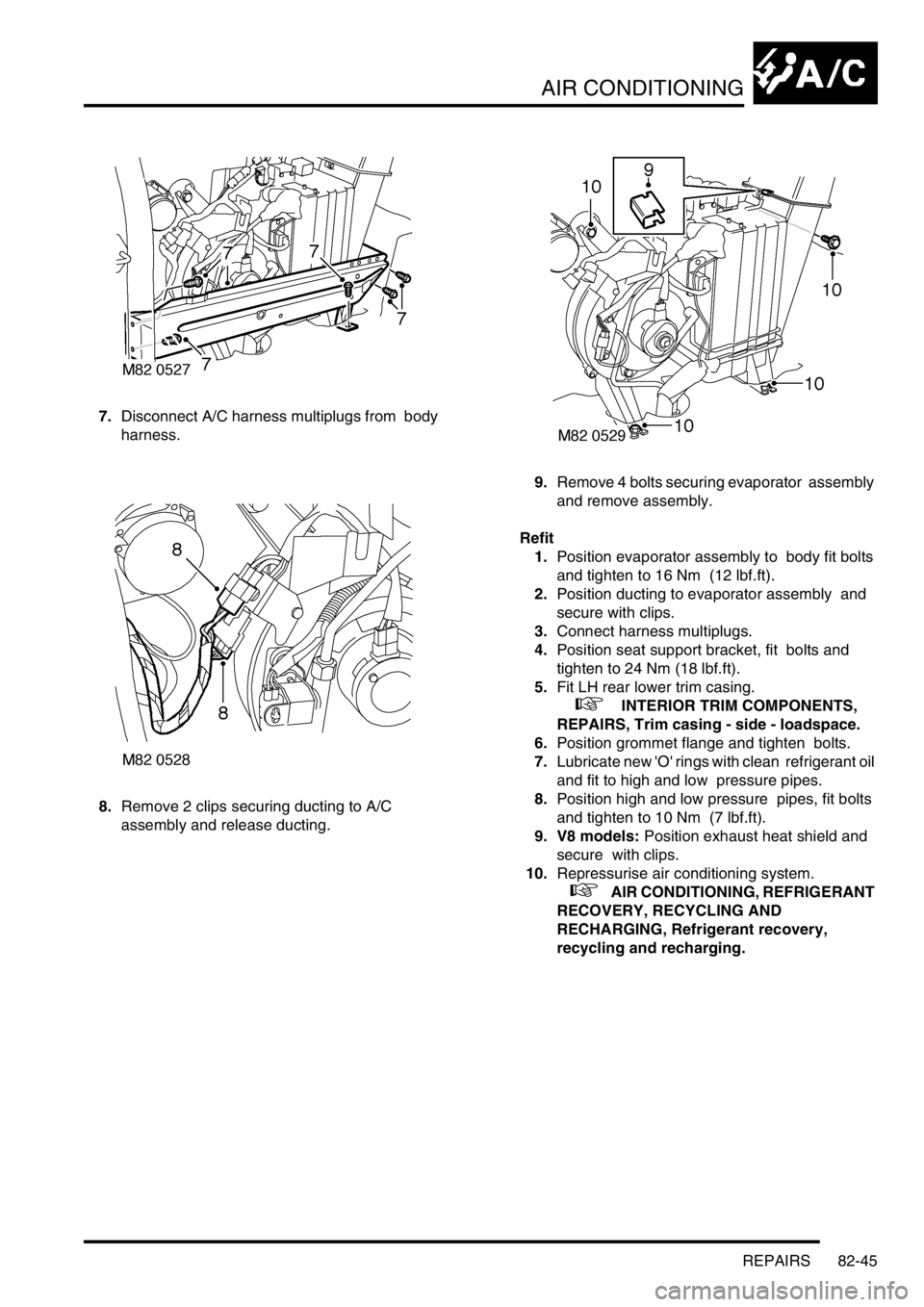

7.Disconnect A/C harness multiplugs from body

harness.

8.Remove 2 clips securing ducting to A/C

assembly and release ducting. 9.Remove 4 bolts securing evaporator assembly

and remove assembly.

Refit

1.Position evaporator assembly to body fit bolts

and tighten to 16 Nm (12 lbf.ft).

2.Position ducting to evaporator assembly and

secure with clips.

3.Connect harness multiplugs.

4.Position seat support bracket, fit bolts and

tighten to 24 Nm (18 lbf.ft).

5.Fit LH rear lower trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - side - loadspace.

6.Position grommet flange and tighten bolts.

7.Lubricate new 'O' rings with clean refrigerant oil

and fit to high and low pressure pipes.

8.Position high and low pressure pipes, fit bolts

and tighten to 10 Nm (7 lbf.ft).

9. V8 models: Position exhaust heat shield and

secure with clips.

10.Repressurise air conditioning system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

Page 1438 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-17

Front flick wipe

Flick wipe operation will only activate when the following conditions are met:

lIgnition switch is in position I or II.

lFront flick switch is operated.

Pressing the flick wipe switch operates the front wiper motor at high speed. The front wiper motor operates as long

as the flick switch is activated. Releasing the flick switch causes the front wiper motor to run through the park switch

circuitry. The park switch only permits low speed operation. Thus if the flick switch is pressed and immediately

released, the wipers operate at low speed.

Rear intermittent wipe variable delay

The rear intermittent wipe variable delay operation allows the driver to adjust the interval between wipes to suit local

conditions. Rear variable delay operation only activates if the following conditions are met:

lIgnition switch in position I or II.

lFront wash/ wipe switch on intermittent.

lRear wipe switch is operated.

The BCU determines the desired delay interval based on the setting of the variable delay switch. The rear wash/ wipe

delay is nominally twice as long as that of the front. This information passes from the IDM to the rear wiper relay and

activates the rear wiper motor.

If the delay duration is decreased during operation of the rear wiper, the wipers immediately operate once and the

delay cycle is reset.

If the delay duration is increased during operation of the rear wiper, the delay cycle is automatically increased by the

BCU.

Reverse wiping

Reverse wiping operates the rear wiper motor when reverse gear is selected. The transmission must be in reverse

for longer then 0.5 seconds before reversing wipe activates. Reversing wipe activates if the following conditions are

met:

lIgnition switch is in position II.

lReverse gear is selected.

lRear wiper or front wipers operating.

If the rear wiper is active in any mode when reverse gear is selected, the rear wiper activates for 4 second. After 4

seconds the rear wiper operates in a delay operation at the same delay interval set by the variable delay switch until

reverse gear is deselected.

If the front wipers are operating on either low or high speed when reverse gear is selected, the rear wiper activates

continuously until reverse gear is deselected.

In order to enable reversing wipe functions, the BCU utilises the reversing light switch located within the transmission

to determine when reverse gear has been selected.

If the front intermittent wipe is active when reverse gear is selected, the rear wiper completes 2 cycles before operating

at the same intermittent delay as the front wipers.