battery LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 473 of 1007

DRIVESHAFTS

47-6 REPAIRS

Gaiter - inner joint

$% 47.10.16

Remove

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove outer gaiter.

+ DRIVESHAFTS, REPAIRS, Gaiter -

bell & joint - outer - front.

5.Release both gaiter clips and discard.

6.Slide gaiter from shaft.

Refit

1.Clean drive shaft and gaiter.

2.Apply grease from the sachet to the joint.

3.Fit new gaiter to shaft.

4.Position gaiter to joint and use a 'Band-it

thriftool' LRT-99-019 to secure the 2 new clips.

5.Fit outer gaiter.

+ DRIVESHAFTS, REPAIRS, Gaiter -

bell & joint - outer - front.

6.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

7.Remove stands and lower vehicle.

8.Connect battery earth lead.

Shaft with both joints - rear

$% 47.11.01

Remove

1.Disconnect battery earth lead.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Release stake from drive shaft nut.

5.With assistant depressing the brake pedal,

remove and discard drive shaft nut.

6.Remove nut and bolt securing trailing link to

rear hub, collect spacer from under bolt head.

7.Remove nut and bolt securing fixed transverse

link to subframe. Collect dynamic damper.

8.Remove nut and bolt securing adjustable

transverse link to subframe.

9.Position container to catch oil spillage

Page 474 of 1007

DRIVESHAFTS

REPAIRS 47-7

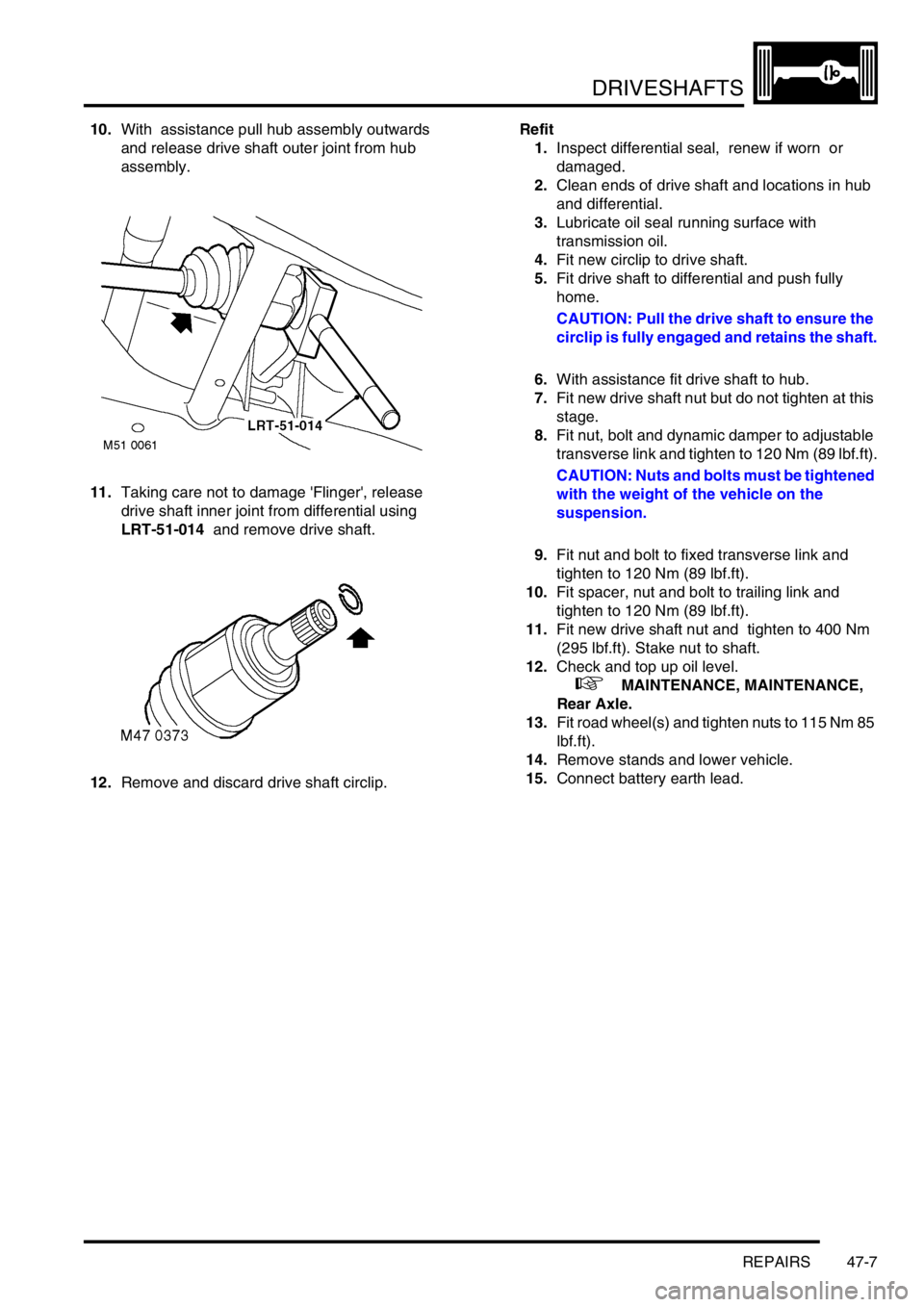

10.With assistance pull hub assembly outwards

and release drive shaft outer joint from hub

assembly.

11.Taking care not to damage 'Flinger', release

drive shaft inner joint from differential using

LRT-51-014 and remove drive shaft.

12.Remove and discard drive shaft circlip.Refit

1.Inspect differential seal, renew if worn or

damaged.

2.Clean ends of drive shaft and locations in hub

and differential.

3.Lubricate oil seal running surface with

transmission oil.

4.Fit new circlip to drive shaft.

5.Fit drive shaft to differential and push fully

home.

CAUTION: Pull the drive shaft to ensure the

circlip is fully engaged and retains the shaft.

6.With assistance fit drive shaft to hub.

7.Fit new drive shaft nut but do not tighten at this

stage.

8.Fit nut, bolt and dynamic damper to adjustable

transverse link and tighten to 120 Nm (89 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.

9.Fit nut and bolt to fixed transverse link and

tighten to 120 Nm (89 lbf.ft).

10.Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

11.Fit new drive shaft nut and tighten to 400 Nm

(295 lbf.ft). Stake nut to shaft.

12.Check and top up oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

13.Fit road wheel(s) and tighten nuts to 115 Nm 85

lbf.ft).

14.Remove stands and lower vehicle.

15.Connect battery earth lead.

Page 475 of 1007

DRIVESHAFTS

47-8 REPAIRS

Gaiter - outer - rear

$% 47.11.03

Remove

1.Disconnect battery earth lead.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove drive shaft outer joint.

+ DRIVESHAFTS, REPAIRS, Bell &

joint - outer - rear.

5.Slide gaiter from shaft.

Refit

1.Clean drive shaft and gaiter.

2.Apply grease from the sachet to the joint.

3.Fit new gaiter to shaft.

4.Fit drive shaft outer joint.

+ DRIVESHAFTS, REPAIRS, Bell &

joint - outer - rear.

5.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

6.Remove stands and lower vehicle.

7.Connect battery earth lead.

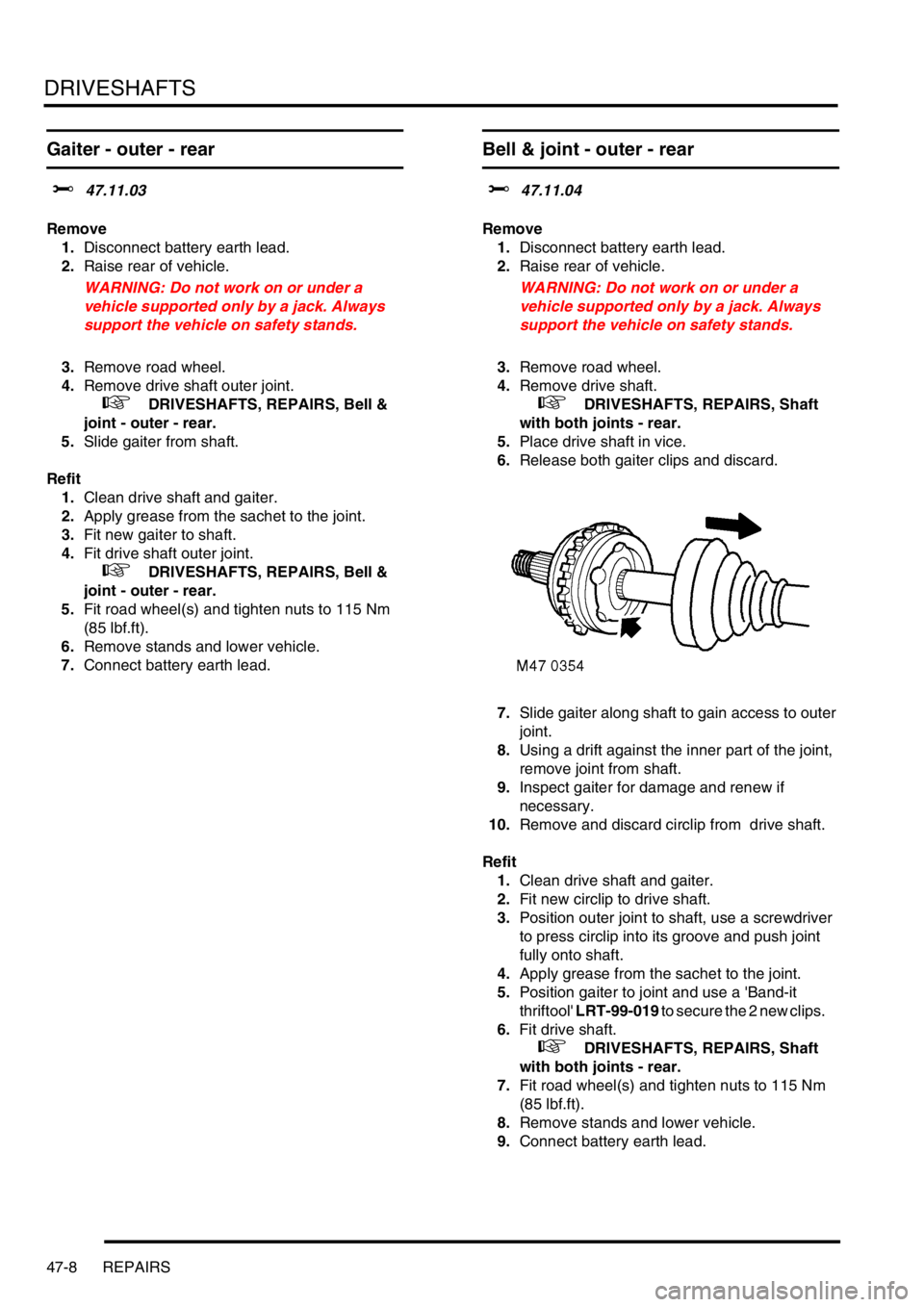

Bell & joint - outer - rear

$% 47.11.04

Remove

1.Disconnect battery earth lead.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - rear.

5.Place drive shaft in vice.

6.Release both gaiter clips and discard.

7.Slide gaiter along shaft to gain access to outer

joint.

8.Using a drift against the inner part of the joint,

remove joint from shaft.

9.Inspect gaiter for damage and renew if

necessary.

10.Remove and discard circlip from drive shaft.

Refit

1.Clean drive shaft and gaiter.

2.Fit new circlip to drive shaft.

3.Position outer joint to shaft, use a screwdriver

to press circlip into its groove and push joint

fully onto shaft.

4.Apply grease from the sachet to the joint.

5.Position gaiter to joint and use a 'Band-it

thriftool' LRT-99-019 to secure the 2 new clips.

6.Fit drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - rear.

7.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

8.Remove stands and lower vehicle.

9.Connect battery earth lead.

Page 476 of 1007

DRIVESHAFTS

REPAIRS 47-9

Gaiter - inner joint - rear

$% 47.11.16

Remove

1.Disconnect battery earth lead.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove outer gaiter.

+ DRIVESHAFTS, REPAIRS, Gaiter -

outer - rear.

5.Release both gaiter clips and discard.

6.Slide gaiter from shaft.

Refit

1.Clean drive shaft and gaiter.

2.Apply grease from the sachet to the joint.

3.Fit new gaiter to shaft.

4.Apply grease from the sachet to the joint.

5.Position gaiter to joint and use a 'Band-it

thriftool' LRT-99-019 to secure the 2 new clips.

6.Fit outer gaiter.

+ DRIVESHAFTS, REPAIRS, Gaiter -

outer - rear.

7.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

8.Remove stands and lower vehicle.

9.Connect battery earth lead.

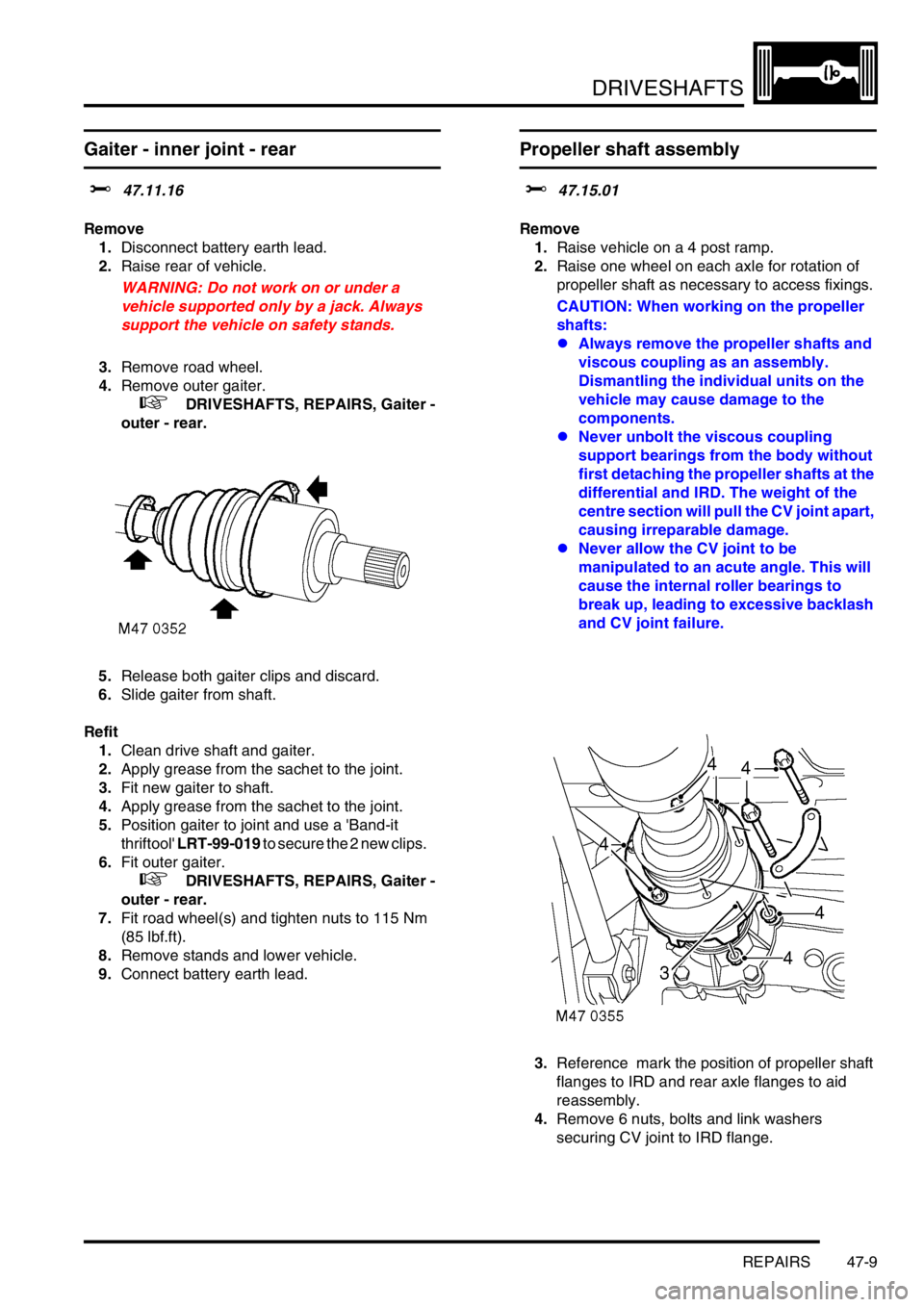

Propeller shaft assembly

$% 47.15.01

Remove

1.Raise vehicle on a 4 post ramp.

2.Raise one wheel on each axle for rotation of

propeller shaft as necessary to access fixings.

CAUTION: When working on the propeller

shafts:

lAlways remove the propeller shafts and

viscous coupling as an assembly.

Dismantling the individual units on the

vehicle may cause damage to the

components.

lNever unbolt the viscous coupling

support bearings from the body without

first detaching the propeller shafts at the

differential and IRD. The weight of the

centre section will pull the CV joint apart,

causing irreparable damage.

lNever allow the CV joint to be

manipulated to an acute angle. This will

cause the internal roller bearings to

break up, leading to excessive backlash

and CV joint failure.

3.Reference mark the position of propeller shaft

flanges to IRD and rear axle flanges to aid

reassembly.

4.Remove 6 nuts, bolts and link washers

securing CV joint to IRD flange.

Page 502 of 1007

STEERING

REPAIRS 57-9

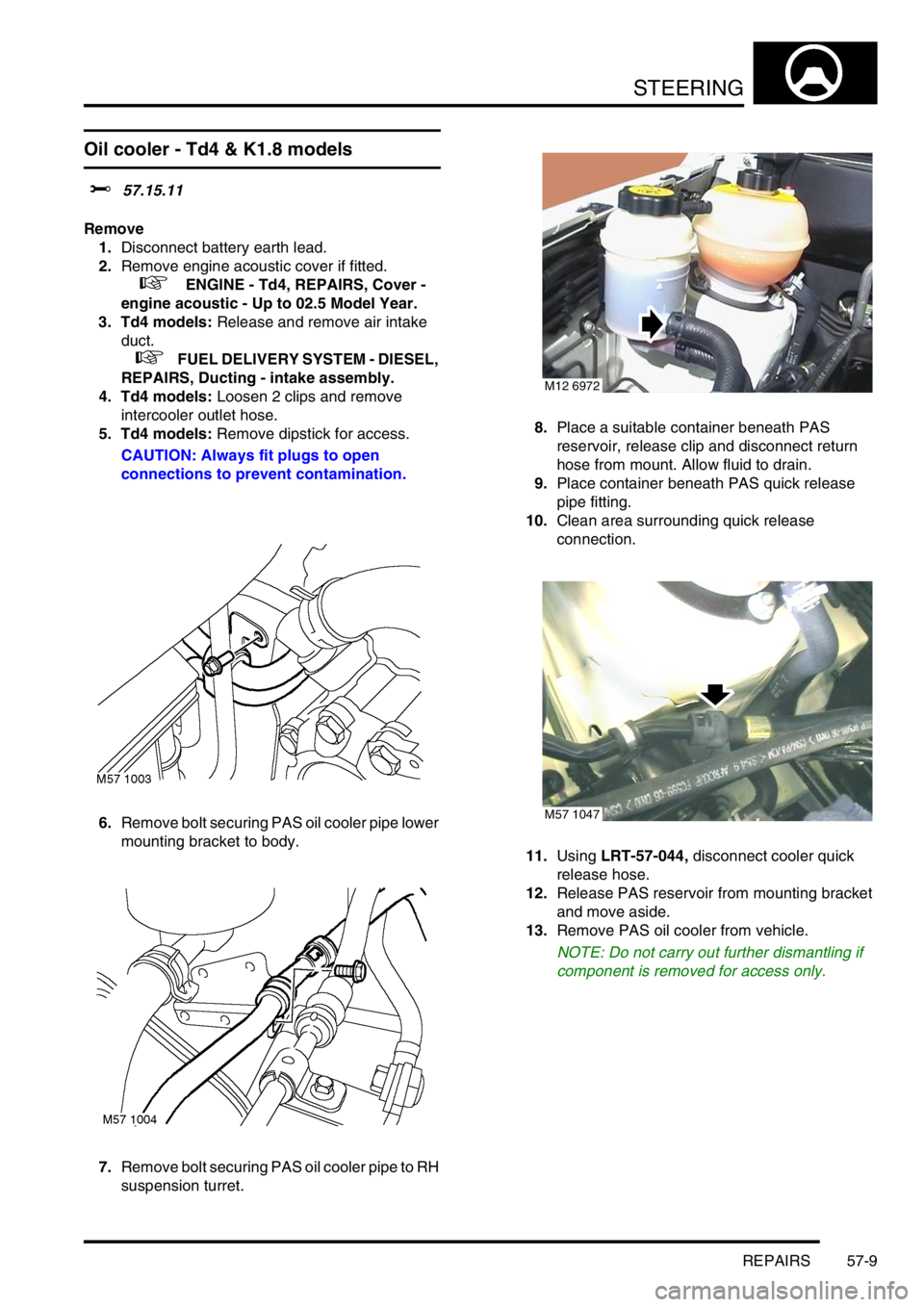

Oil cooler - Td4 & K1.8 models

$% 57.15.11

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

3. Td4 models: Release and remove air intake

duct.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

4. Td4 models: Loosen 2 clips and remove

intercooler outlet hose.

5. Td4 models: Remove dipstick for access.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove bolt securing PAS oil cooler pipe lower

mounting bracket to body.

7.Remove bolt securing PAS oil cooler pipe to RH

suspension turret.8.Place a suitable container beneath PAS

reservoir, release clip and disconnect return

hose from mount. Allow fluid to drain.

9.Place container beneath PAS quick release

pipe fitting.

10.Clean area surrounding quick release

connection.

11.Using LRT-57-044, disconnect cooler quick

release hose.

12.Release PAS reservoir from mounting bracket

and move aside.

13.Remove PAS oil cooler from vehicle.

NOTE: Do not carry out further dismantling if

component is removed for access only.

M12 6972

M57 1047

Page 503 of 1007

STEERING

57-10 REPAIRS

14.Remove clips from PAS oil cooler.

Refit

1.Clean cooler mounting points.

2.Fit clips to PAS cooler.

3.Fit PAS oil cooler to vehicle.

4.Connect quick release pipe fitting.

5.Align PAS pipe bracket, fit bolt and tighten to 10

Nm (7 lbf.ft).

6.Fit bolt to clip securing PAS pipe to RH turret,

tighten to 10 Nm (7 lbf.ft).

7.Fit PAS reservoir to mounting bracket.

8.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

9.Fit PAS return hose to reservoir and secure

clip.

10. Td4 models: Fit intercooler outlet hose and

tighten clips.

11. Td4 models: Fit intake duct to body and duct

assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

12. Td4 models: Fit engine oil dipstick.

13. Fit engine acoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

14.Connect battery earth lead.

15.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

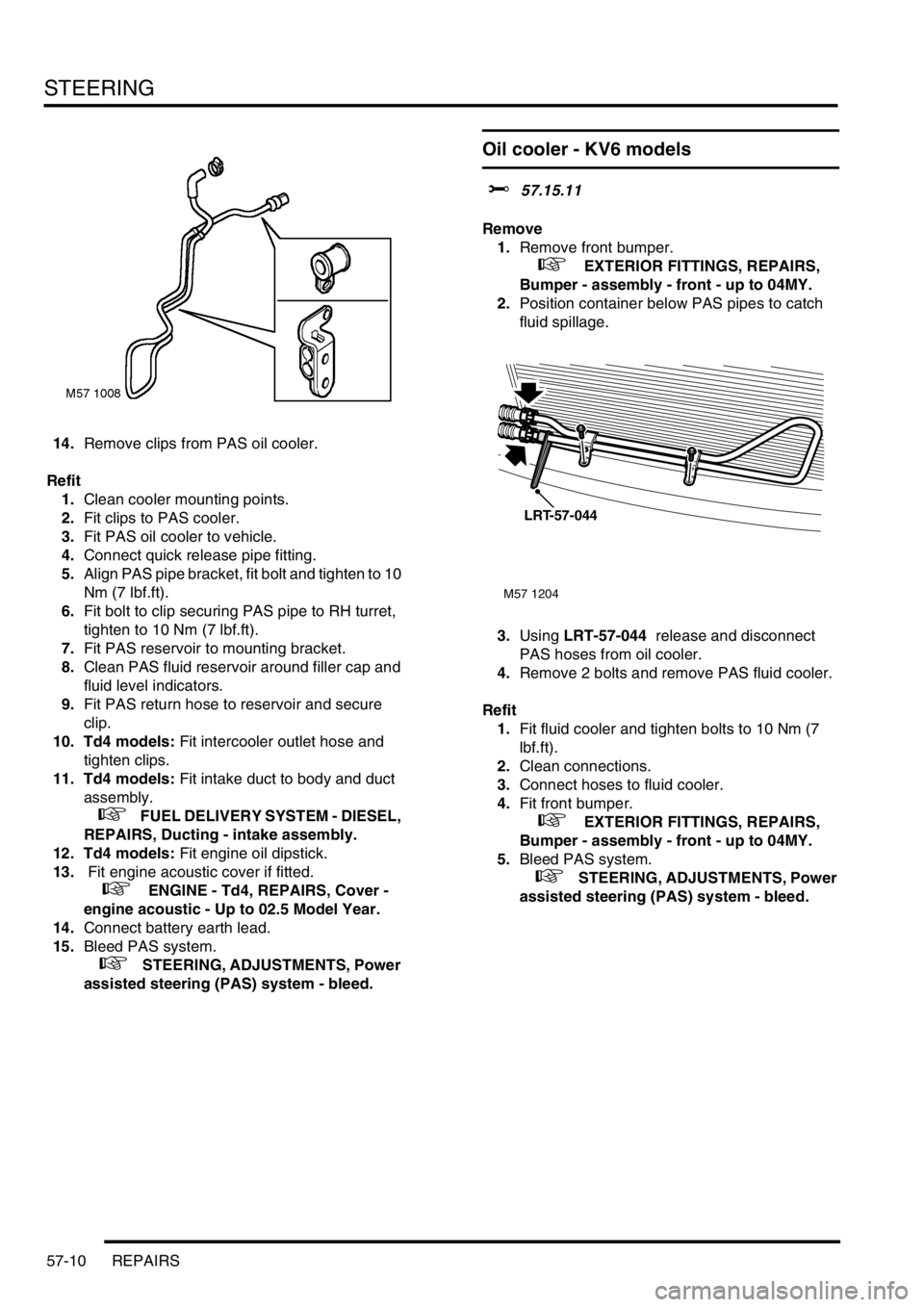

Oil cooler - KV6 models

$% 57.15.11

Remove

1.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

2.Position container below PAS pipes to catch

fluid spillage.

3.Using LRT-57-044 release and disconnect

PAS hoses from oil cooler.

4.Remove 2 bolts and remove PAS fluid cooler.

Refit

1.Fit fluid cooler and tighten bolts to 10 Nm (7

lbf.ft).

2.Clean connections.

3.Connect hoses to fluid cooler.

4.Fit front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

M57 1204

LRT-57-044

Page 504 of 1007

STEERING

REPAIRS 57-11

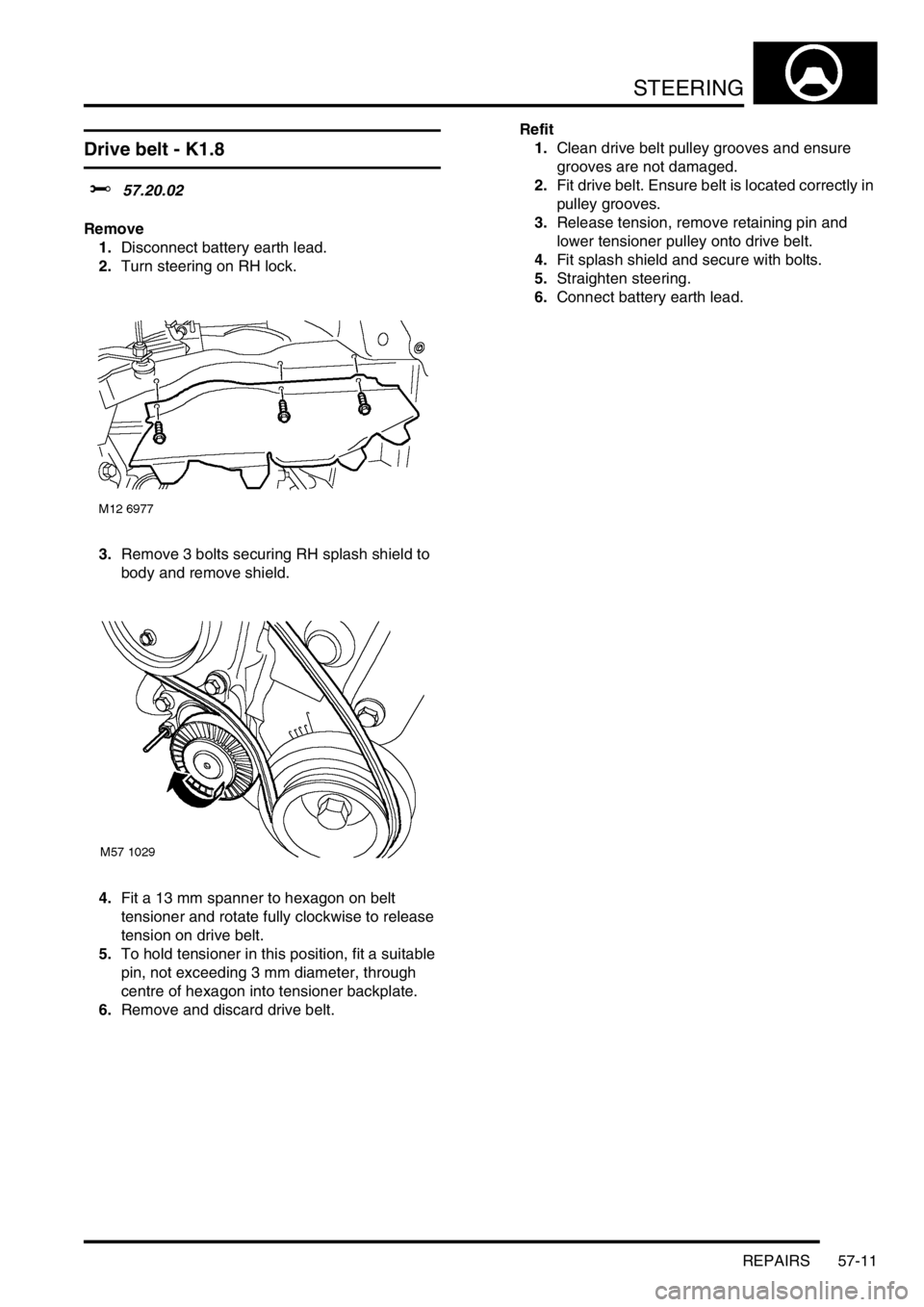

Drive belt - K1.8

$% 57.20.02

Remove

1.Disconnect battery earth lead.

2.Turn steering on RH lock.

3.Remove 3 bolts securing RH splash shield to

body and remove shield.

4.Fit a 13 mm spanner to hexagon on belt

tensioner and rotate fully clockwise to release

tension on drive belt.

5.To hold tensioner in this position, fit a suitable

pin, not exceeding 3 mm diameter, through

centre of hexagon into tensioner backplate.

6.Remove and discard drive belt.Refit

1.Clean drive belt pulley grooves and ensure

grooves are not damaged.

2.Fit drive belt. Ensure belt is located correctly in

pulley grooves.

3.Release tension, remove retaining pin and

lower tensioner pulley onto drive belt.

4.Fit splash shield and secure with bolts.

5.Straighten steering.

6.Connect battery earth lead.

Page 505 of 1007

STEERING

57-12 REPAIRS

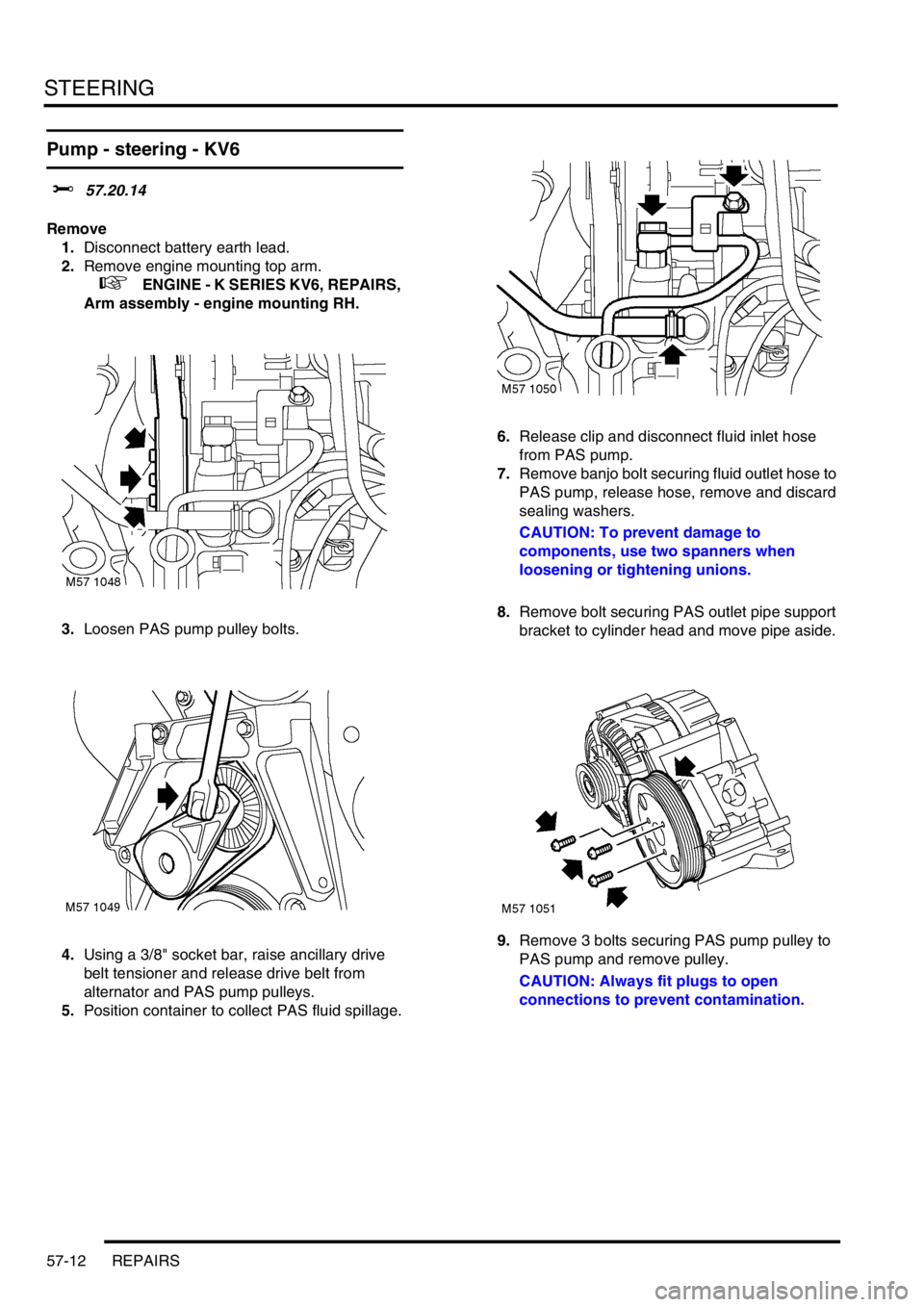

Pump - steering - KV6

$% 57.20.14

Remove

1.Disconnect battery earth lead.

2.Remove engine mounting top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

3.Loosen PAS pump pulley bolts.

4.Using a 3/8" socket bar, raise ancillary drive

belt tensioner and release drive belt from

alternator and PAS pump pulleys.

5.Position container to collect PAS fluid spillage.6.Release clip and disconnect fluid inlet hose

from PAS pump.

7.Remove banjo bolt securing fluid outlet hose to

PAS pump, release hose, remove and discard

sealing washers.

CAUTION: To prevent damage to

components, use two spanners when

loosening or tightening unions.

8.Remove bolt securing PAS outlet pipe support

bracket to cylinder head and move pipe aside.

9.Remove 3 bolts securing PAS pump pulley to

PAS pump and remove pulley.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 506 of 1007

STEERING

REPAIRS 57-13

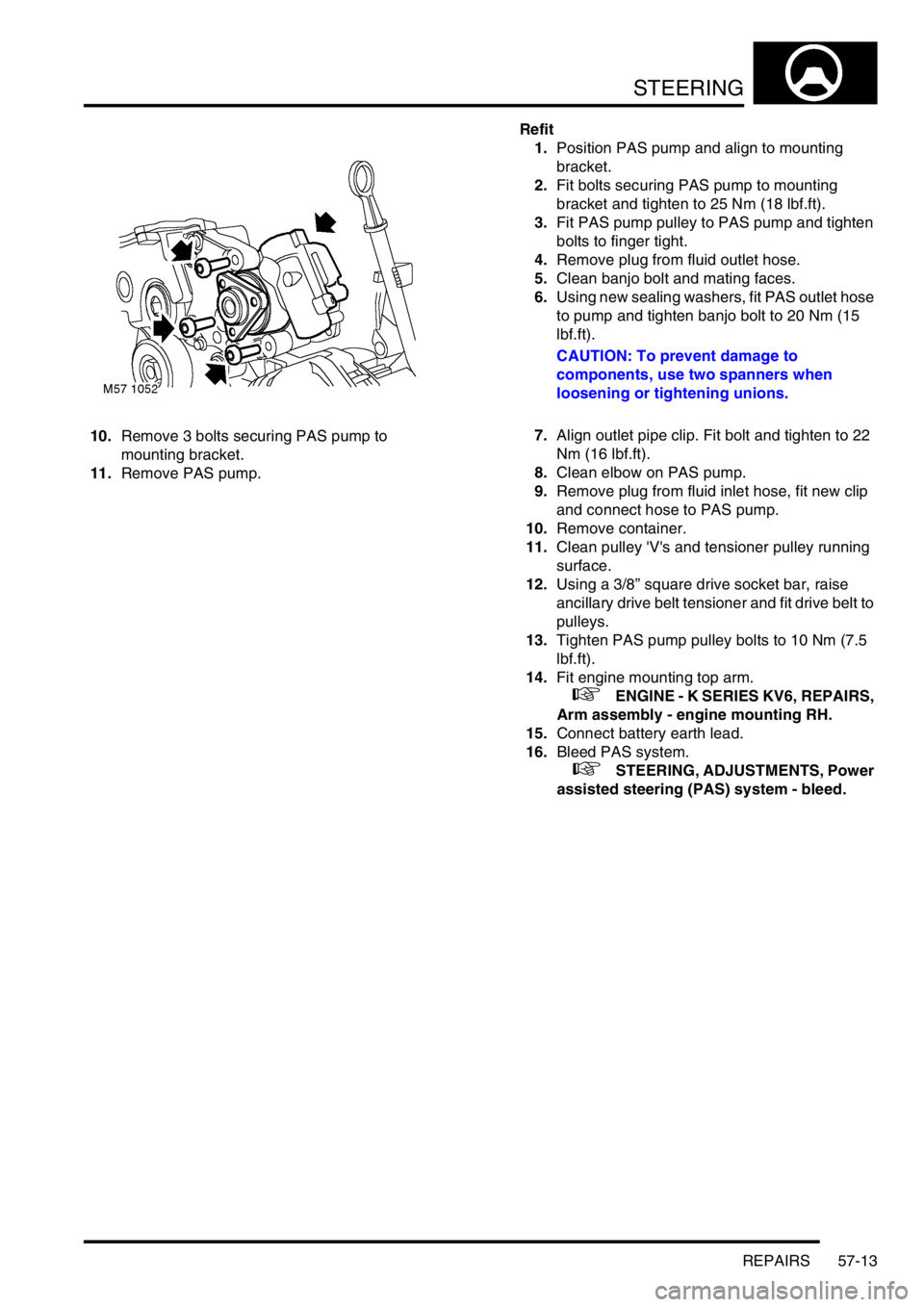

10.Remove 3 bolts securing PAS pump to

mounting bracket.

11.Remove PAS pump.Refit

1.Position PAS pump and align to mounting

bracket.

2.Fit bolts securing PAS pump to mounting

bracket and tighten to 25 Nm (18 lbf.ft).

3.Fit PAS pump pulley to PAS pump and tighten

bolts to finger tight.

4.Remove plug from fluid outlet hose.

5.Clean banjo bolt and mating faces.

6.Using new sealing washers, fit PAS outlet hose

to pump and tighten banjo bolt to 20 Nm (15

lbf.ft).

CAUTION: To prevent damage to

components, use two spanners when

loosening or tightening unions.

7.Align outlet pipe clip. Fit bolt and tighten to 22

Nm (16 lbf.ft).

8.Clean elbow on PAS pump.

9.Remove plug from fluid inlet hose, fit new clip

and connect hose to PAS pump.

10.Remove container.

11.Clean pulley 'V's and tensioner pulley running

surface.

12.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

13.Tighten PAS pump pulley bolts to 10 Nm (7.5

lbf.ft).

14.Fit engine mounting top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

15.Connect battery earth lead.

16.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

Page 507 of 1007

STEERING

57-14 REPAIRS

Pump - steering - K1.8

$% 57.20.14

Remove

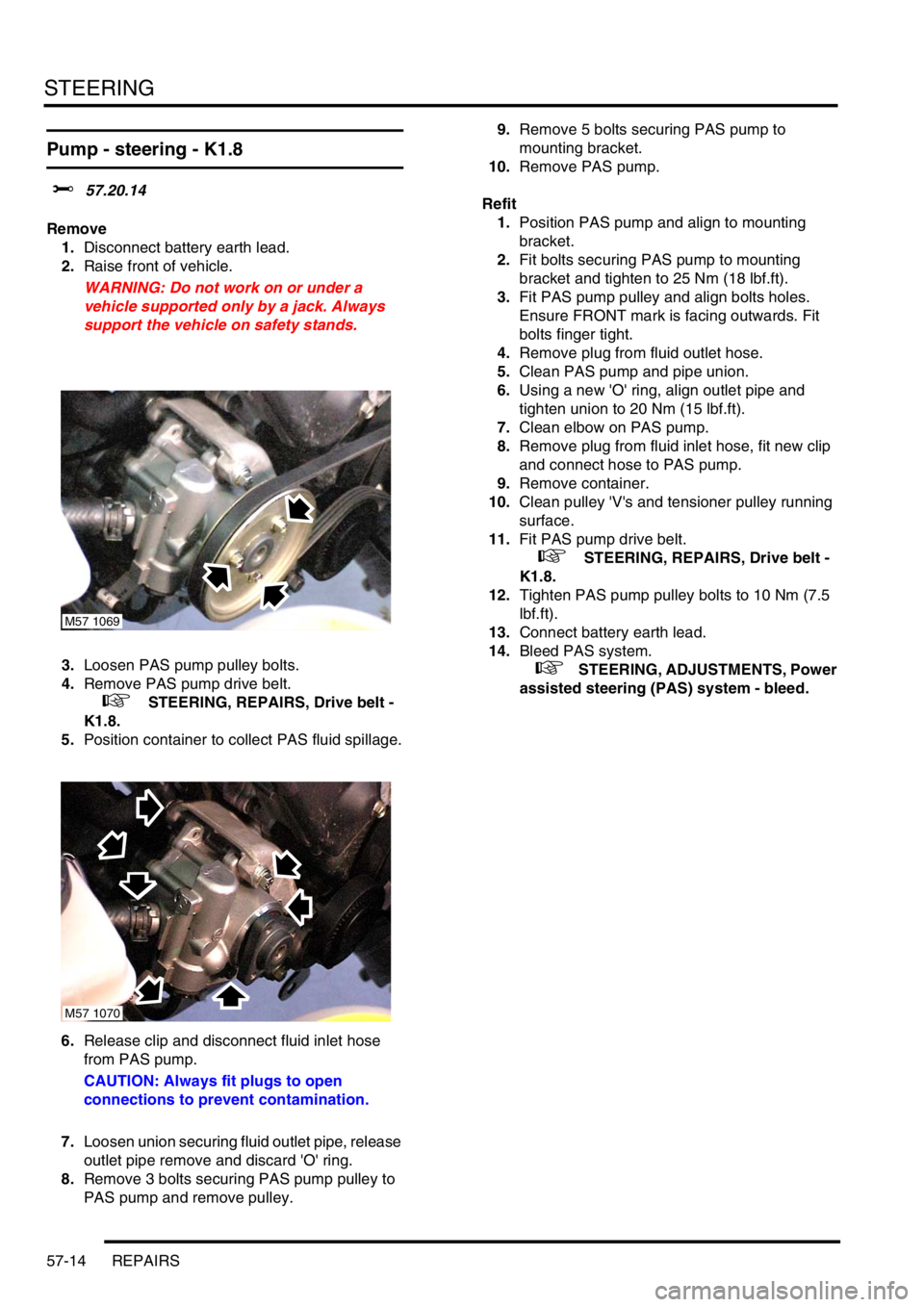

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Loosen PAS pump pulley bolts.

4.Remove PAS pump drive belt.

+ STEERING, REPAIRS, Drive belt -

K1.8.

5.Position container to collect PAS fluid spillage.

6.Release clip and disconnect fluid inlet hose

from PAS pump.

CAUTION: Always fit plugs to open

connections to prevent contamination.

7.Loosen union securing fluid outlet pipe, release

outlet pipe remove and discard 'O' ring.

8.Remove 3 bolts securing PAS pump pulley to

PAS pump and remove pulley.9.Remove 5 bolts securing PAS pump to

mounting bracket.

10.Remove PAS pump.

Refit

1.Position PAS pump and align to mounting

bracket.

2.Fit bolts securing PAS pump to mounting

bracket and tighten to 25 Nm (18 lbf.ft).

3.Fit PAS pump pulley and align bolts holes.

Ensure FRONT mark is facing outwards. Fit

bolts finger tight.

4.Remove plug from fluid outlet hose.

5.Clean PAS pump and pipe union.

6.Using a new 'O' ring, align outlet pipe and

tighten union to 20 Nm (15 lbf.ft).

7.Clean elbow on PAS pump.

8.Remove plug from fluid inlet hose, fit new clip

and connect hose to PAS pump.

9.Remove container.

10.Clean pulley 'V's and tensioner pulley running

surface.

11.Fit PAS pump drive belt.

+ STEERING, REPAIRS, Drive belt -

K1.8.

12.Tighten PAS pump pulley bolts to 10 Nm (7.5

lbf.ft).

13.Connect battery earth lead.

14.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

M57 1069

M57 1070