fuse box LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 24 of 1007

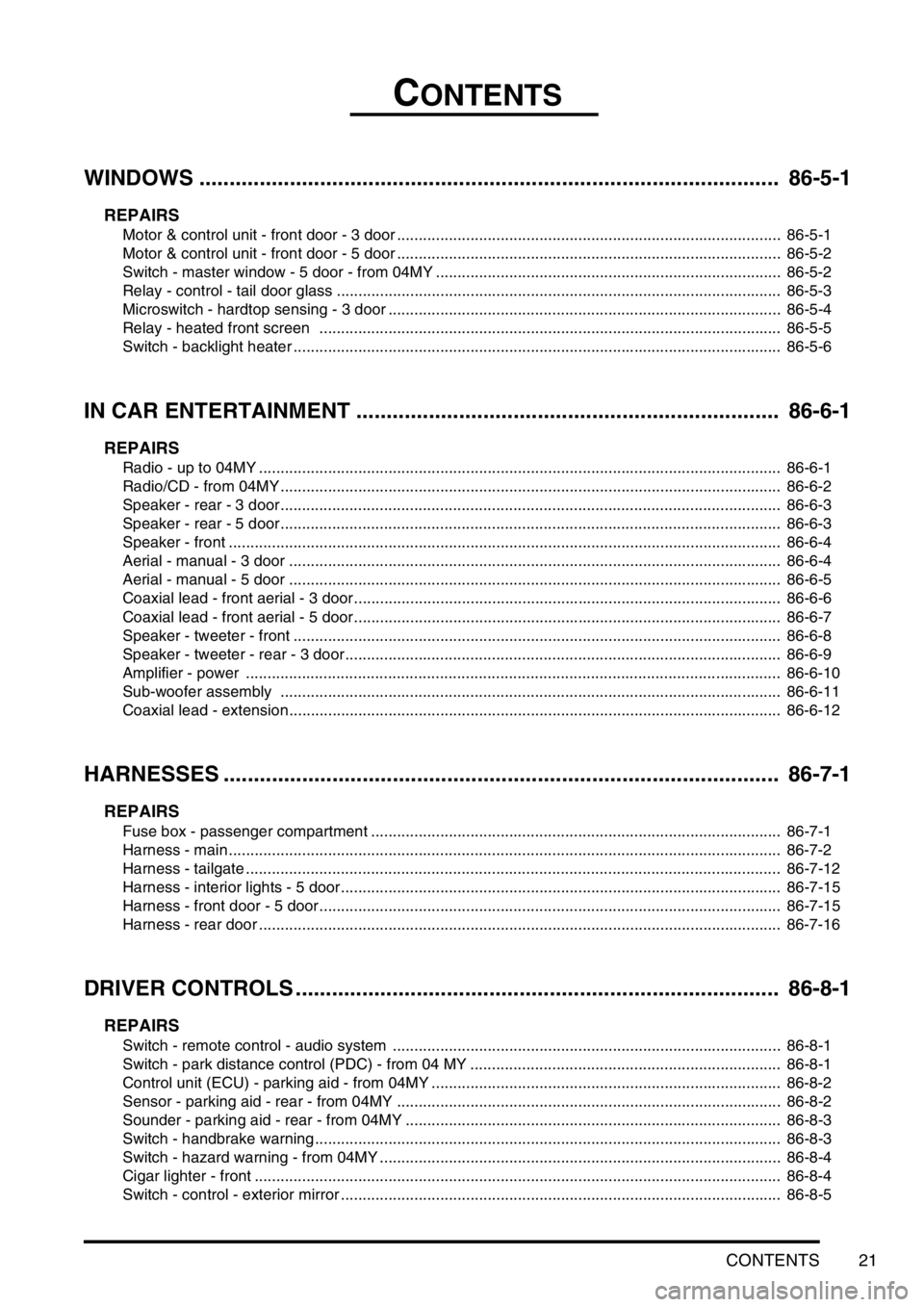

CONTENTS

CONTENTS 21

WINDOWS ................................................................................................ 86-5-1

REPAIRS

Motor & control unit - front door - 3 door ......................................................................................... 86-5-1

Motor & control unit - front door - 5 door ......................................................................................... 86-5-2

Switch - master window - 5 door - from 04MY ................................................................................ 86-5-2

Relay - control - tail door glass ....................................................................................................... 86-5-3

Microswitch - hardtop sensing - 3 door ........................................................................................... 86-5-4

Relay - heated front screen ........................................................................................................... 86-5-5

Switch - backlight heater ................................................................................................................. 86-5-6

IN CAR ENTERTAINMENT ...................................................................... 86-6-1

REPAIRS

Radio - up to 04MY ......................................................................................................................... 86-6-1

Radio/CD - from 04MY .................................................................................................................... 86-6-2

Speaker - rear - 3 door .................................................................................................................... 86-6-3

Speaker - rear - 5 door .................................................................................................................... 86-6-3

Speaker - front ................................................................................................................................ 86-6-4

Aerial - manual - 3 door .................................................................................................................. 86-6-4

Aerial - manual - 5 door .................................................................................................................. 86-6-5

Coaxial lead - front aerial - 3 door ................................................................................................... 86-6-6

Coaxial lead - front aerial - 5 door ................................................................................................... 86-6-7

Speaker - tweeter - front ................................................................................................................. 86-6-8

Speaker - tweeter - rear - 3 door ..................................................................................................... 86-6-9

Amplifier - power ............................................................................................................................ 86-6-10

Sub-woofer assembly .................................................................................................................... 86-6-11

Coaxial lead - extension.................................................................................................................. 86-6-12

HARNESSES ............................................................................................ 86-7-1

REPAIRS

Fuse box - passenger compartment ............................................................................................... 86-7-1

Harness - main ................................................................................................................................ 86-7-2

Harness - tailgate ............................................................................................................................ 86-7-12

Harness - interior lights - 5 door ...................................................................................................... 86-7-15

Harness - front door - 5 door ........................................................................................................... 86-7-15

Harness - rear door ......................................................................................................................... 86-7-16

DRIVER CONTROLS ................................................................................ 86-8-1

REPAIRS

Switch - remote control - audio system .......................................................................................... 86-8-1

Switch - park distance control (PDC) - from 04 MY ........................................................................ 86-8-1

Control unit (ECU) - parking aid - from 04MY ................................................................................. 86-8-2

Sensor - parking aid - rear - from 04MY ......................................................................................... 86-8-2

Sounder - parking aid - rear - from 04MY ....................................................................................... 86-8-3

Switch - handbrake warning ............................................................................................................ 86-8-3

Switch - hazard warning - from 04MY ............................................................................................. 86-8-4

Cigar lighter - front .......................................................................................................................... 86-8-4

Switch - control - exterior mirror ...................................................................................................... 86-8-5

Page 26 of 1007

INTRODUCTION

01-1

INTRODUCTION

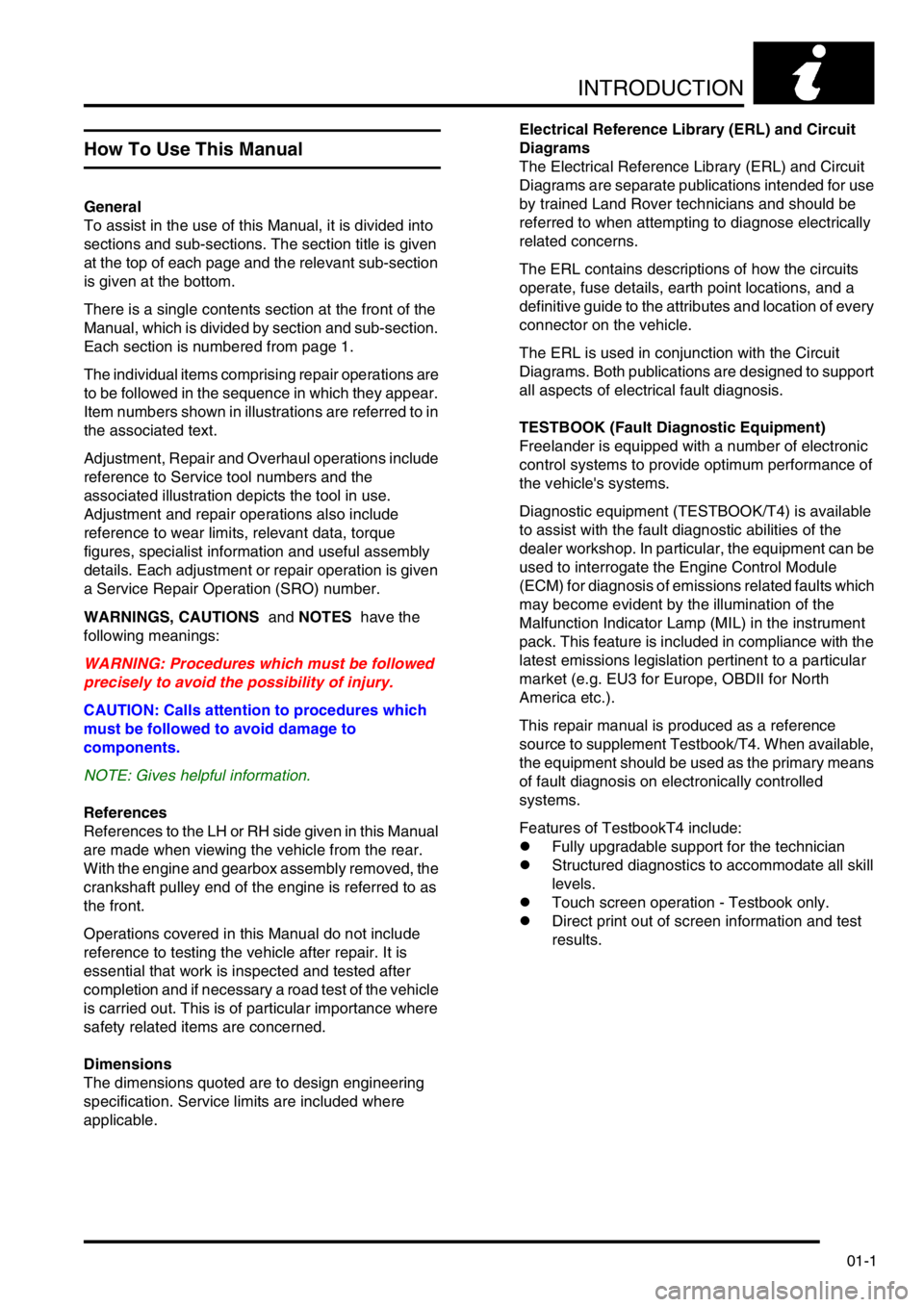

How To Use This Manual

General

To assist in the use of this Manual, it is divided into

sections and sub-sections. The section title is given

at the top of each page and the relevant sub-section

is given at the bottom.

There is a single contents section at the front of the

Manual, which is divided by section and sub-section.

Each section is numbered from page 1.

The individual items comprising repair operations are

to be followed in the sequence in which they appear.

Item numbers shown in illustrations are referred to in

the associated text.

Adjustment, Repair and Overhaul operations include

reference to Service tool numbers and the

associated illustration depicts the tool in use.

Adjustment and repair operations also include

reference to wear limits, relevant data, torque

figures, specialist information and useful assembly

details. Each adjustment or repair operation is given

a Service Repair Operation (SRO) number.

WARNINGS, CAUTIONS and NOTES have the

following meanings:

WARNING: Procedures which must be followed

precisely to avoid the possibility of injury.

CAUTION: Calls attention to procedures which

must be followed to avoid damage to

components.

NOTE: Gives helpful information.

References

References to the LH or RH side given in this Manual

are made when viewing the vehicle from the rear.

With the engine and gearbox assembly removed, the

crankshaft pulley end of the engine is referred to as

the front.

Operations covered in this Manual do not include

reference to testing the vehicle after repair. It is

essential that work is inspected and tested after

completion and if necessary a road test of the vehicle

is carried out. This is of particular importance where

safety related items are concerned.

Dimensions

The dimensions quoted are to design engineering

specification. Service limits are included where

applicable.Electrical Reference Library (ERL) and Circuit

Diagrams

The Electrical Reference Library (ERL) and Circuit

Diagrams are separate publications intended for use

by trained Land Rover technicians and should be

referred to when attempting to diagnose electrically

related concerns.

The ERL contains descriptions of how the circuits

operate, fuse details, earth point locations, and a

definitive guide to the attributes and location of every

connector on the vehicle.

The ERL is used in conjunction with the Circuit

Diagrams. Both publications are designed to support

all aspects of electrical fault diagnosis.

TESTBOOK (Fault Diagnostic Equipment)

Freelander is equipped with a number of electronic

control systems to provide optimum performance of

the vehicle's systems.

Diagnostic equipment (TESTBOOK/T4) is available

to assist with the fault diagnostic abilities of the

dealer workshop. In particular, the equipment can be

used to interrogate the Engine Control Module

(ECM) for diagnosis of emissions related faults which

may become evident by the illumination of the

Malfunction Indicator Lamp (MIL) in the instrument

pack. This feature is included in compliance with the

latest emissions legislation pertinent to a particular

market (e.g. EU3 for Europe, OBDII for North

America etc.).

This repair manual is produced as a reference

source to supplement Testbook/T4. When available,

the equipment should be used as the primary means

of fault diagnosis on electronically controlled

systems.

Features of TestbookT4 include:

lFully upgradable support for the technician

lStructured diagnostics to accommodate all skill

levels.

lTouch screen operation - Testbook only.

lDirect print out of screen information and test

results.

Page 133 of 1007

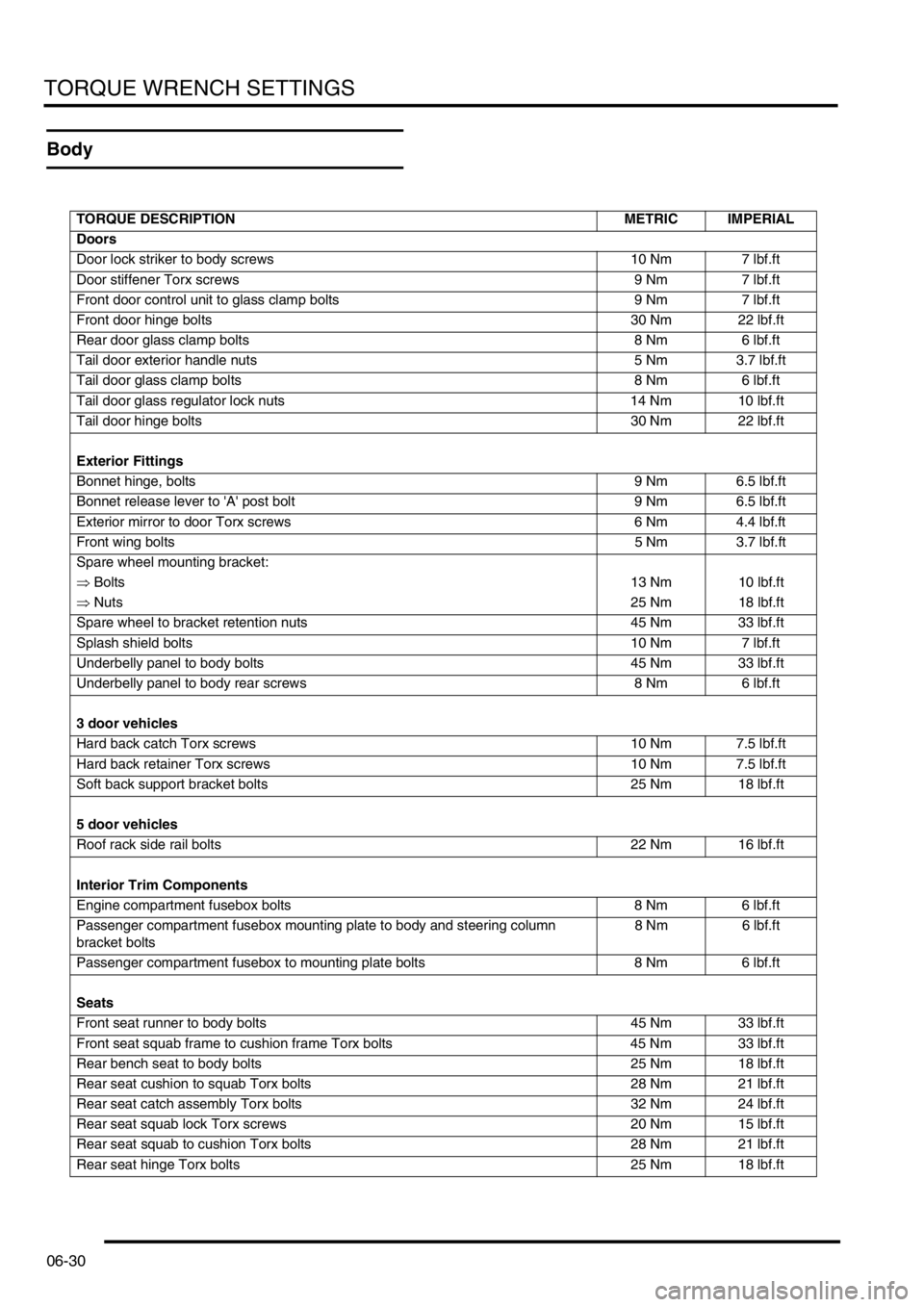

TORQUE WRENCH SETTINGS

06-30

Body

TORQUE DESCRIPTION METRIC IMPERIAL

Doors

Door lock striker to body screws 10 Nm 7 lbf.ft

Door stiffener Torx screws 9 Nm 7 lbf.ft

Front door control unit to glass clamp bolts 9 Nm 7 lbf.ft

Front door hinge bolts 30 Nm 22 lbf.ft

Rear door glass clamp bolts 8 Nm 6 lbf.ft

Tail door exterior handle nuts 5 Nm 3.7 lbf.ft

Tail door glass clamp bolts 8 Nm 6 lbf.ft

Tail door glass regulator lock nuts 14 Nm 10 lbf.ft

Tail door hinge bolts 30 Nm 22 lbf.ft

Exterior Fittings

Bonnet hinge, bolts 9 Nm 6.5 lbf.ft

Bonnet release lever to 'A' post bolt 9 Nm 6.5 lbf.ft

Exterior mirror to door Torx screws 6 Nm 4.4 lbf.ft

Front wing bolts5 Nm 3.7 lbf.ft

Spare wheel mounting bracket:

⇒ Bolts13 Nm 10 lbf.ft

⇒ Nuts25 Nm 18 lbf.ft

Spare wheel to bracket retention nuts 45 Nm 33 lbf.ft

Splash shield bolts 10 Nm 7 lbf.ft

Underbelly panel to body bolts 45 Nm 33 lbf.ft

Underbelly panel to body rear screws 8 Nm 6 lbf.ft

3 door vehicles

Hard back catch Torx screws 10 Nm 7.5 lbf.ft

Hard back retainer Torx screws 10 Nm 7.5 lbf.ft

Soft back support bracket bolts 25 Nm 18 lbf.ft

5 door vehicles

Roof rack side rail bolts 22 Nm 16 lbf.ft

Interior Trim Components

Engine compartment fusebox bolts 8 Nm 6 lbf.ft

Passenger compartment fusebox mounting plate to body and steering column

bracket bolts8 Nm 6 lbf.ft

Passenger compartment fusebox to mounting plate bolts 8 Nm 6 lbf.ft

Seats

Front seat runner to body bolts 45 Nm 33 lbf.ft

Front seat squab frame to cushion frame Torx bolts 45 Nm 33 lbf.ft

Rear bench seat to body bolts 25 Nm 18 lbf.ft

Rear seat cushion to squab Torx bolts 28 Nm 21 lbf.ft

Rear seat catch assembly Torx bolts 32 Nm 24 lbf.ft

Rear seat squab lock Torx screws 20 Nm 15 lbf.ft

Rear seat squab to cushion Torx bolts 28 Nm 21 lbf.ft

Rear seat hinge Torx bolts 25 Nm 18 lbf.ft

Page 138 of 1007

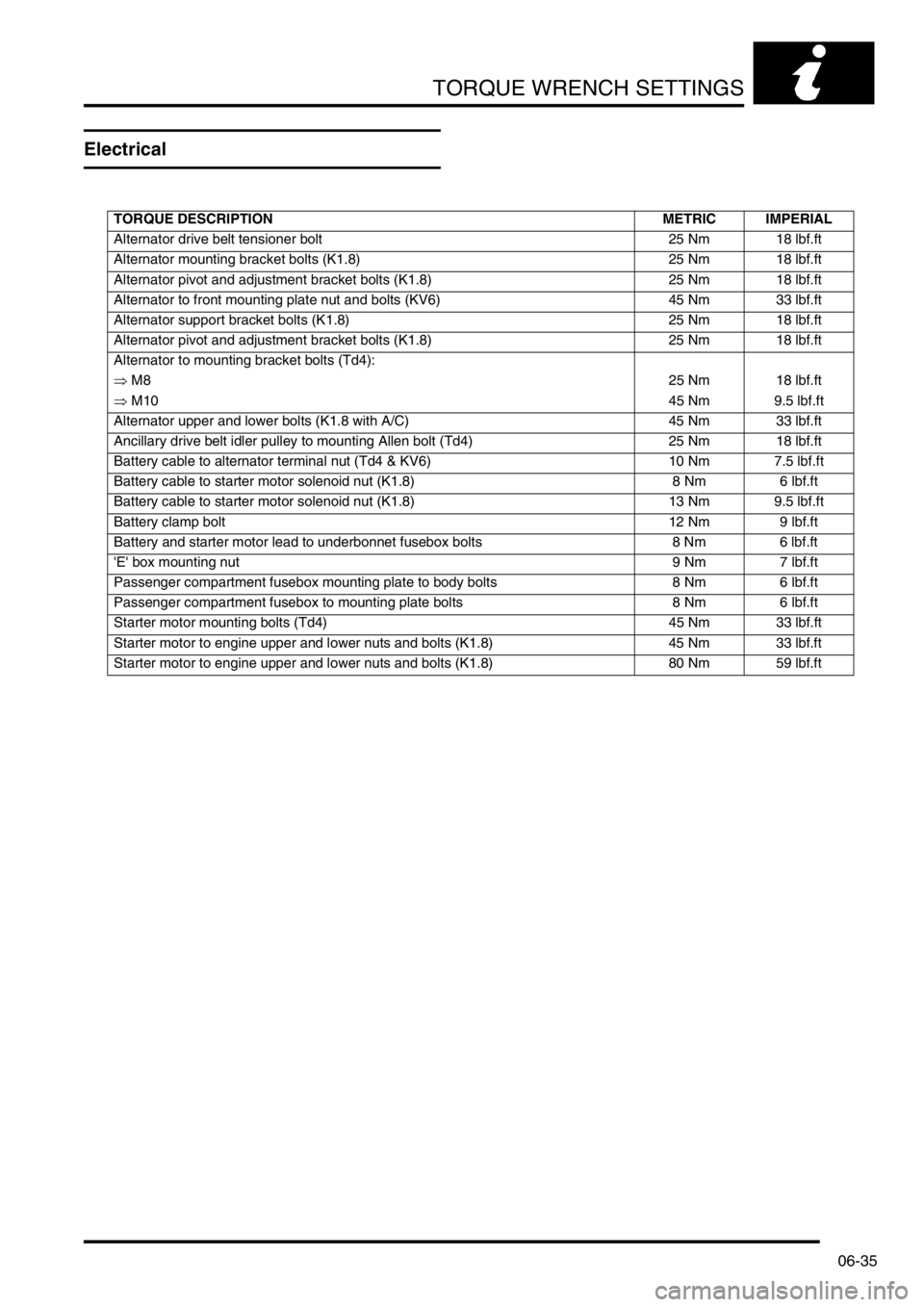

TORQUE WRENCH SETTINGS

06-35

Electrical

TORQUE DESCRIPTION METRIC IMPERIAL

Alternator drive belt tensioner bolt 25 Nm 18 lbf.ft

Alternator mounting bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator pivot and adjustment bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator to front mounting plate nut and bolts (KV6) 45 Nm 33 lbf.ft

Alternator support bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator pivot and adjustment bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator to mounting bracket bolts (Td4):

⇒ M825 Nm 18 lbf.ft

⇒ M1045 Nm 9.5 lbf.ft

Alternator upper and lower bolts (K1.8 with A/C) 45 Nm 33 lbf.ft

Ancillary drive belt idler pulley to mounting Allen bolt (Td4) 25 Nm 18 lbf.ft

Battery cable to alternator terminal nut (Td4 & KV6) 10 Nm 7.5 lbf.ft

Battery cable to starter motor solenoid nut (K1.8) 8 Nm 6 lbf.ft

Battery cable to starter motor solenoid nut (K1.8) 13 Nm 9.5 lbf.ft

Battery clamp bolt 12 Nm 9 lbf.ft

Battery and starter motor lead to underbonnet fusebox bolts 8 Nm 6 lbf.ft

'E' box mounting nut 9 Nm 7 lbf.ft

Passenger compartment fusebox mounting plate to body bolts 8 Nm 6 lbf.ft

Passenger compartment fusebox to mounting plate bolts 8 Nm 6 lbf.ft

Starter motor mounting bolts (Td4) 45 Nm 33 lbf.ft

Starter motor to engine upper and lower nuts and bolts (K1.8) 45 Nm 33 lbf.ft

Starter motor to engine upper and lower nuts and bolts (K1.8) 80 Nm 59 lbf.ft

Page 148 of 1007

MAINTENANCE

MAINTENANCE 10-1

MAINTENANCE MAINTENANCE

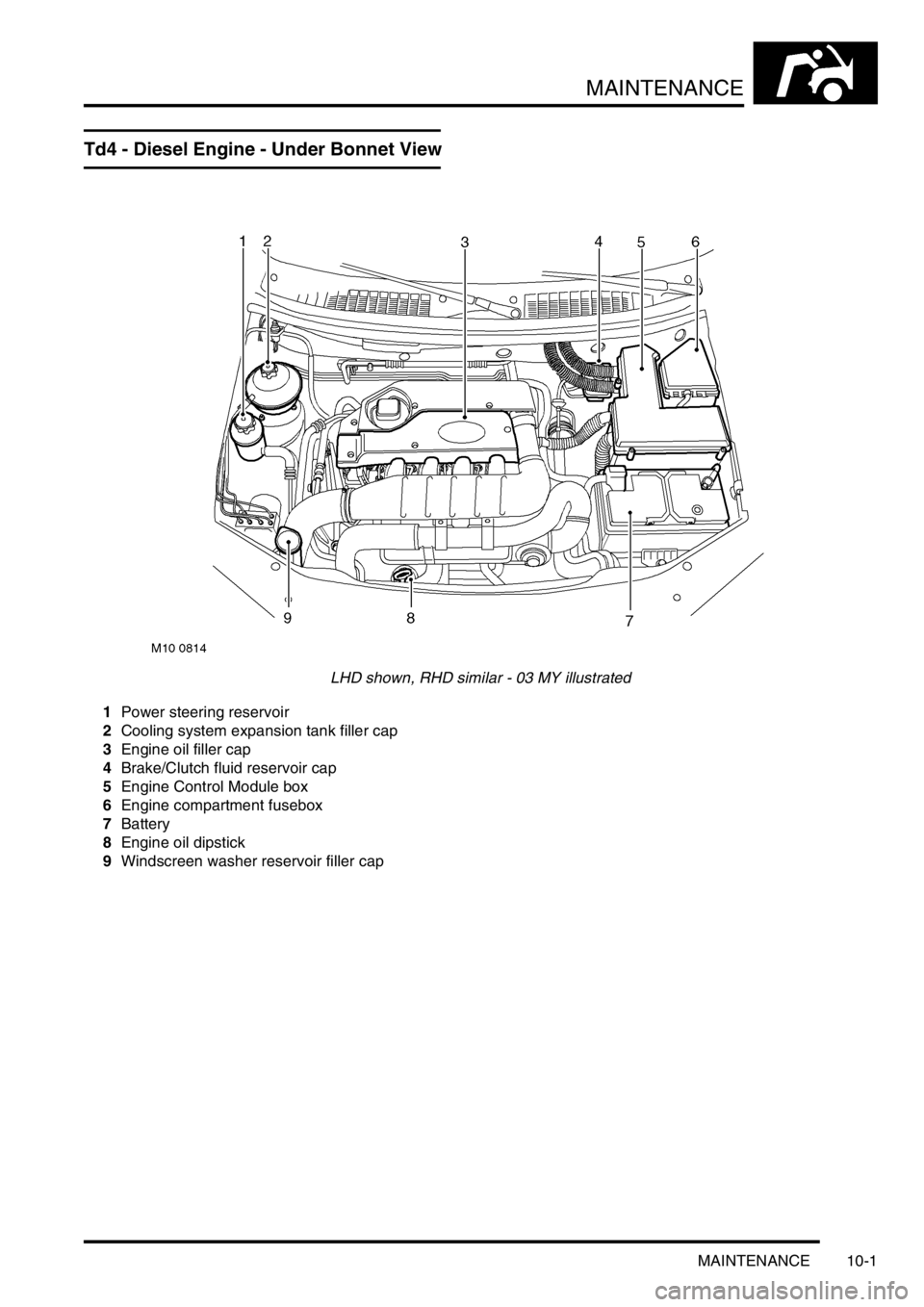

Td4 - Diesel Engine - Under Bonnet View

LHD shown, RHD similar - 03 MY illustrated

1Power steering reservoir

2Cooling system expansion tank filler cap

3Engine oil filler cap

4Brake/Clutch fluid reservoir cap

5Engine Control Module box

6Engine compartment fusebox

7Battery

8Engine oil dipstick

9Windscreen washer reservoir filler cap

Page 149 of 1007

MAINTENANCE

10-2 MAINTENANCE

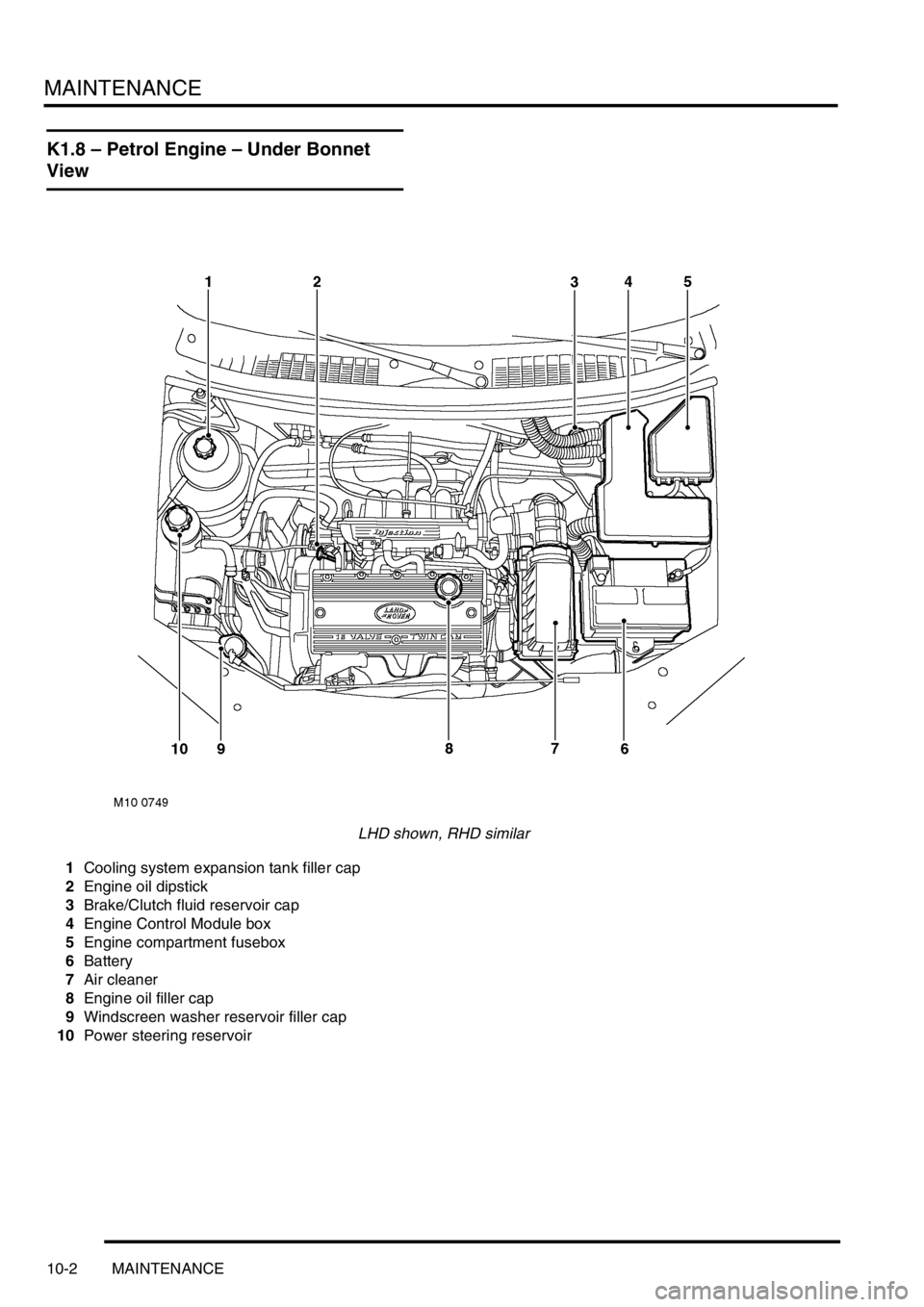

K1.8 – Petrol Engine – Under Bonnet

View

LHD shown, RHD similar

1Cooling system expansion tank filler cap

2Engine oil dipstick

3Brake/Clutch fluid reservoir cap

4Engine Control Module box

5Engine compartment fusebox

6Battery

7Air cleaner

8Engine oil filler cap

9Windscreen washer reservoir filler cap

10Power steering reservoir

Page 150 of 1007

MAINTENANCE

MAINTENANCE 10-3

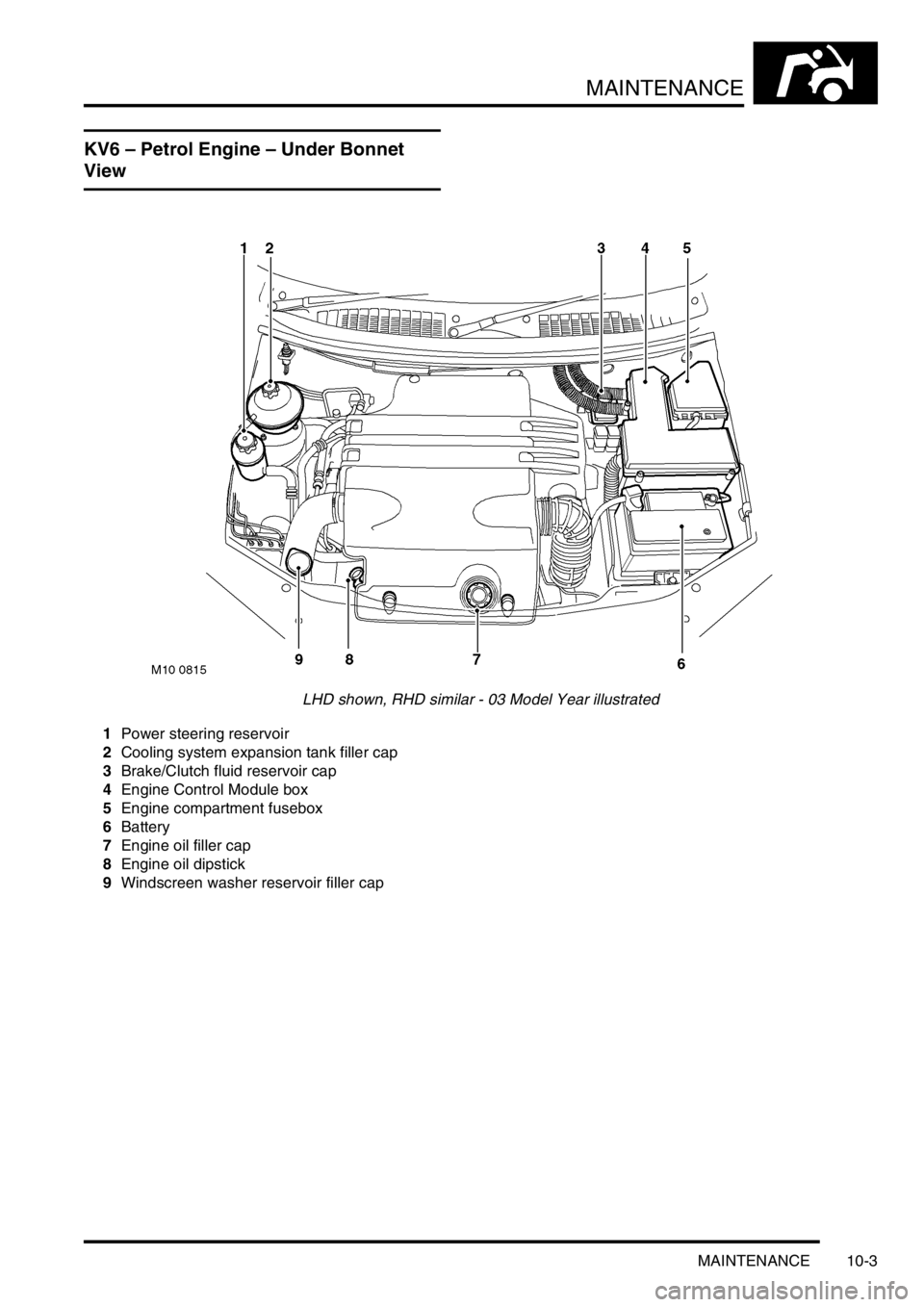

KV6 – Petrol Engine – Under Bonnet

View

LHD shown, RHD similar - 03 Model Year illustrated

1Power steering reservoir

2Cooling system expansion tank filler cap

3Brake/Clutch fluid reservoir cap

4Engine Control Module box

5Engine compartment fusebox

6Battery

7Engine oil filler cap

8Engine oil dipstick

9Windscreen washer reservoir filler cap

Page 203 of 1007

ENGINE - K SERIES KV6

12-3-26 REPAIRS

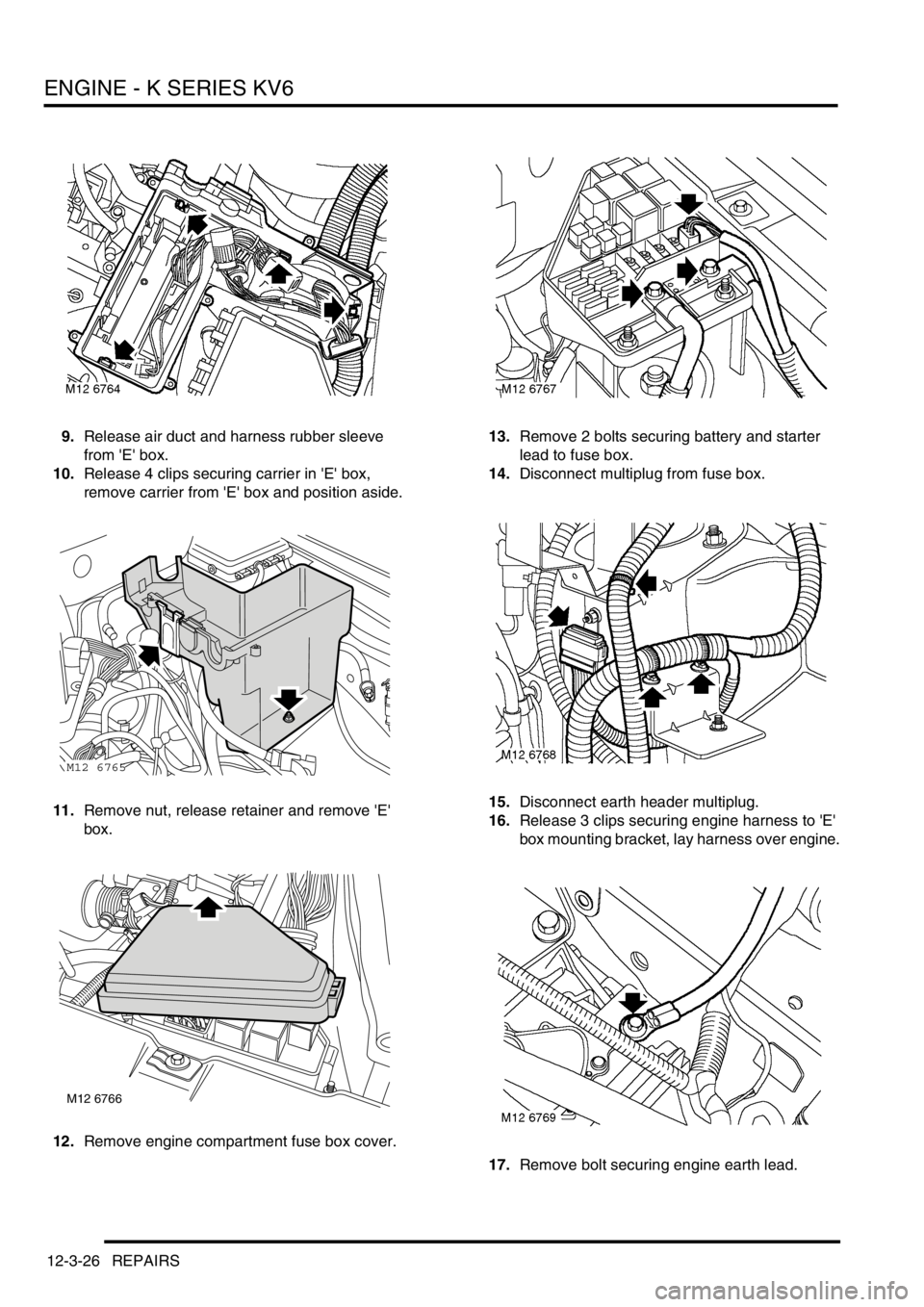

9.Release air duct and harness rubber sleeve

from 'E' box.

10.Release 4 clips securing carrier in 'E' box,

remove carrier from 'E' box and position aside.

11.Remove nut, release retainer and remove 'E'

box.

12.Remove engine compartment fuse box cover.13.Remove 2 bolts securing battery and starter

lead to fuse box.

14.Disconnect multiplug from fuse box.

15.Disconnect earth header multiplug.

16.Release 3 clips securing engine harness to 'E'

box mounting bracket, lay harness over engine.

17.Remove bolt securing engine earth lead.

M12 6765

M12 6766

Page 211 of 1007

ENGINE - K SERIES KV6

12-3-34 REPAIRS

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm (295 lbf.ft).

39.Stake nut to shaft.

40.Fit front road wheels, fit and tighten nuts to 115

Nm (85 lbf.ft).

41.Lower vehicle on ramp.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket, if fitted.

48.Secure throttle cable in clips on harness

brackets, if fitted.

49.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

50.Connect hose to purge control valve.

51.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

52.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

53.Connect Lucar connector to starter solenoid.

54.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm (18 lbf.ft).

55.Position engine harness to 'E' box mounting

bracket and secure with clips.

56.Connect earth header multiplug.

57.Connect multiplug to underbonnet fuse box.

58.Position battery and starter motor lead to

underbonnet fuse box, fit and tighten bolts to 8

Nm (6 lbf.ft).

59.Fit underbonnet fuse box cover.

60.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm (7 lbf.ft).

61.Position carrier in 'E' box and secure with clips.

62.Position and secure air duct and harness

rubber sleeve in 'E' box.

63.Connect multiplugs securing main harness to

engine harness.

64.Position ECM harness and multiplug to 'E' box,

align harness clamp and secure screws to 'E'

box.

65.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - Non NAS.

66.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.67.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

68.Connect battery earth lead.

69.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

70.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 213 of 1007

ENGINE - K SERIES KV6

12-3-36 REPAIRS

17.Rotate heated front screen relay anti-clockwise

and release it from 'E' box bracket.

18.Release 4 clips and remove carrier from 'E' box.

19.Remove nut, release retainer and remove 'E'

box.20.Remove engine compartment fuse box cover.

21.Remove 2 bolts securing battery and starter

lead to fuse box.

22.Disconnect multiplug from fuse box.

23.Disconnect earth header multiplug.

24.Release 3 clips securing engine harness to 'E'

box mounting bracket, lay harness over engine.

M12 6765

M12 6766