fuel filter LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 145 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-2

Fluids

Fuel

Always use the following recommended fuels:

Petrol engines

Use unleaded petrol with a minimum octane rating of

95 RON to ENN 228 specification.

In an emergency (and only if the correct fuel is

unavailable), lower octane rated fuel can be used for

very limited periods of moderate, low speed

motoring, provided engine 'knocking' does not occur.

Fuels of 90 RON is used in certain markets; 90 RON

fuel can be used regularly ONLY if the engine has

been tuned specifically to suit low octane fuel.

Certain markets use fuel containing a 23% Ethanol

additive.

K1.8 and KV6 engines are also available for use with

a low octane leaded fuel specification in some

markets.

Diesel engines

Use a good quality diesel fuel or automotive gas oil

(AGO) conforming to EN 590 specification.

It is important that the sulphur content of diesel fuel

does not exceed 0.3%.

Ensure the fuel filter element is changed at the

recommended intervals.

+ MAINTENANCE, MAINTENANCE, Fuel

Filter - Diesel.

Brake Fluid

Use only DOT 4 brake fluid. DO NOT use brake fluid

of a different specification.

PAS fluid

Use Texaco 9226 fluid.Anti-freeze solutions

The overall anti-freeze concentration should not fall,

by volume, below 50% to ensure that the anti-

corrosion properties of the coolant are maintained.

Anti-freeze concentrations greater than 60% are not

recommended as cooling efficiency will be impaired.

Use Havoline Extended Life Coolant (XLC), or any

ethylene glycol based anti-freeze (containing no

methanol) with only Organic Acid Technology (OAT)

corrosion inhibitors, to protect the cooling system.

CAUTION: No other anti-freeze should be used

with Havoline Extended Life Coolant.

The cooling system should be drained, flushed and

refilled with the correct amount of anti-freeze

solution at the intervals given on the Service

Maintenance Check Sheet.

After filling with anti-freeze solution, attach a warning

label to a prominent position on the vehicle stating

the type of anti-freeze contained in the cooling

system to ensure that the correct type is used for

topping-up.

The following recommended quantities of anti-freeze

will provide frost protection to -36 °C (-33 °F):

Engine – Td4

Engine – K1.8

Engine – KV6

Concentration 50%

Amount of anti-freeze 3.75 litres

(6.625 imp. pts)

Concentration 50%

Amount of anti-freeze 2.9 litres

(5.125 imp. pts)

Concentration 50%

Amount of anti-freeze 3.9 litres

(6.875 imp. pts, )

Page 157 of 1007

MAINTENANCE

10-10 MAINTENANCE

Fuel Filter - Petrol

Replace

1.Renew fuel filter.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filter - main.

Fuel Filter - Diesel

Replace

1.Replace fuel filter element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Filter - main - up to 03MY.

Fuel Pump and Filter assembly - Diesel -

03 Model Year onwards

Remove

1.Remove fuel pump and filter assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Pump and filter assembly - from

03MY.

2.Remove all traces of dirt from fuel pump and

filter assembly.

WARNING: Suitable eye protection must be

worn.

Refit

1.Fit fuel pump and filter assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Pump and filter assembly - from

03MY.

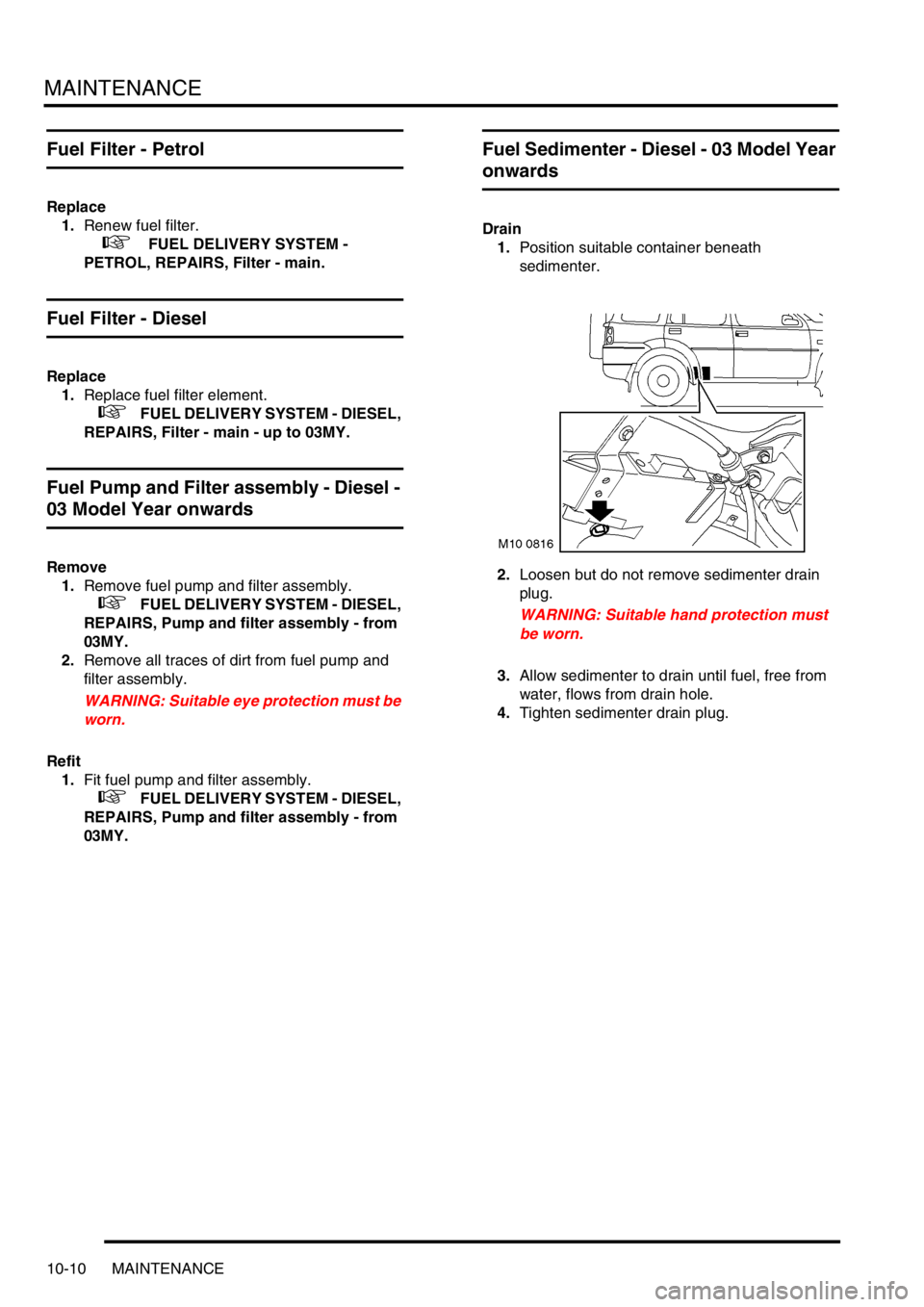

Fuel Sedimenter - Diesel - 03 Model Year

onwards

Drain

1.Position suitable container beneath

sedimenter.

2.Loosen but do not remove sedimenter drain

plug.

WARNING: Suitable hand protection must

be worn.

3.Allow sedimenter to drain until fuel, free from

water, flows from drain hole.

4.Tighten sedimenter drain plug.

Page 160 of 1007

MAINTENANCE

MAINTENANCE 10-13

Vent filter - turbocharger boost control

solenoid valve - Td4

Replace

1.Replace turbocharger solenoid valve vent filter.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Vent filter - turbocharger boost

control solenoid valve - Td4.

Spark Plugs – K1.8

Check & Renew

1.Check spark plugs condition and gap. Renew if

necessary.

+ ENGINE MANAGEMENT SYSTEM -

MEMS, REPAIRS, Spark plugs.

Spark Plugs – KV6

Check & Renew

1.Check spark plugs condition and gap. Renew if

necessary.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Spark plugs - up to

03MY.

Air Cleaner – Petrol Models

Replace

1.Replace air cleaner element.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Element - air cleaner -

KV6.

Clean

1.Clean the drain hole in filter casing.

Page 196 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-19

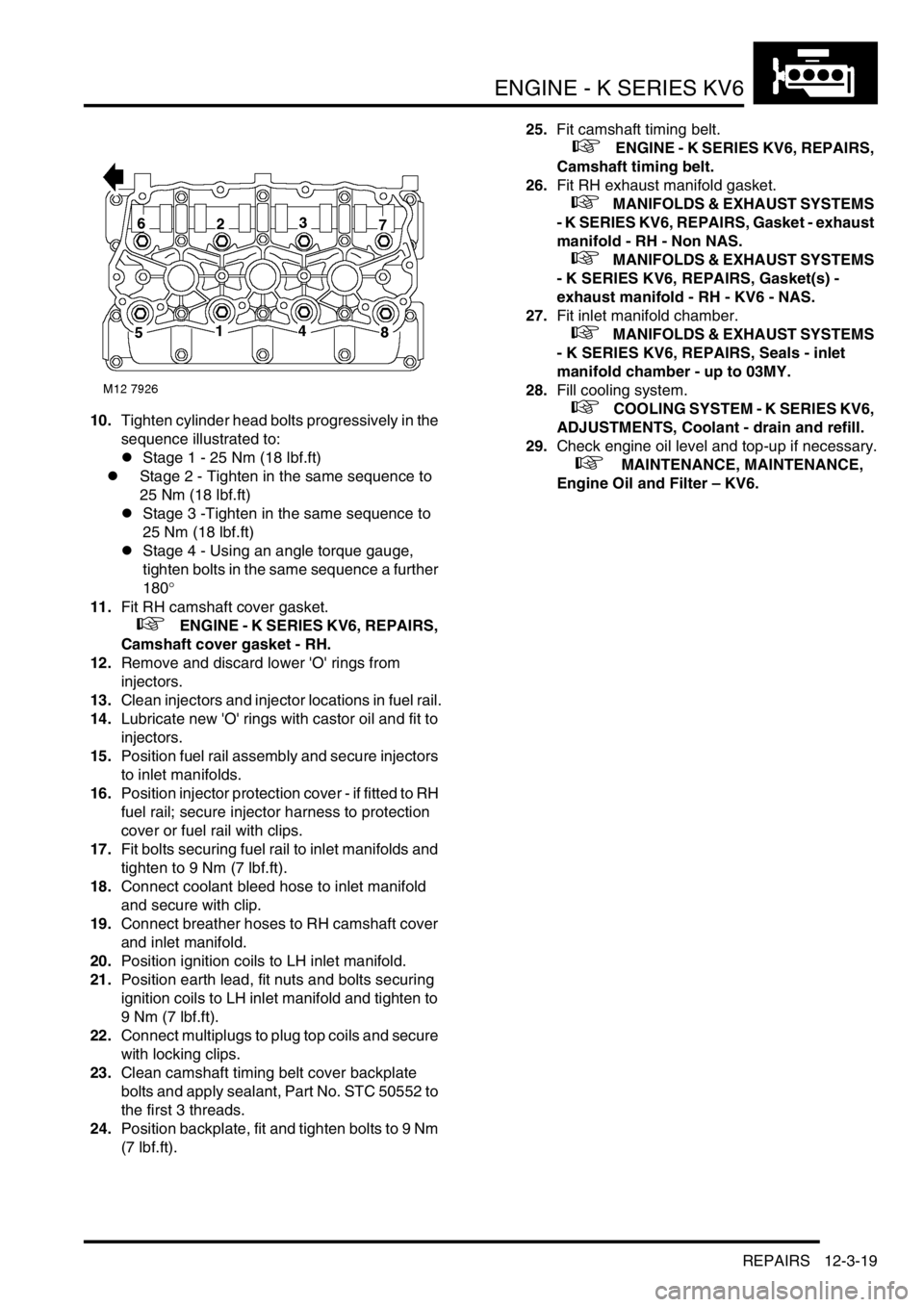

10.Tighten cylinder head bolts progressively in the

sequence illustrated to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - Tighten in the same sequence to

25 Nm (18 lbf.ft)

lStage 3 -Tighten in the same sequence to

25 Nm (18 lbf.ft)

lStage 4 - Using an angle torque gauge,

tighten bolts in the same sequence a further

180°

11.Fit RH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - RH.

12.Remove and discard lower 'O' rings from

injectors.

13.Clean injectors and injector locations in fuel rail.

14.Lubricate new 'O' rings with castor oil and fit to

injectors.

15.Position fuel rail assembly and secure injectors

to inlet manifolds.

16.Position injector protection cover - if fitted to RH

fuel rail; secure injector harness to protection

cover or fuel rail with clips.

17.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

18.Connect coolant bleed hose to inlet manifold

and secure with clip.

19.Connect breather hoses to RH camshaft cover

and inlet manifold.

20.Position ignition coils to LH inlet manifold.

21.Position earth lead, fit nuts and bolts securing

ignition coils to LH inlet manifold and tighten to

9 Nm (7 lbf.ft).

22.Connect multiplugs to plug top coils and secure

with locking clips.

23.Clean camshaft timing belt cover backplate

bolts and apply sealant, Part No. STC 50552 to

the first 3 threads.

24.Position backplate, fit and tighten bolts to 9 Nm

(7 lbf.ft).25.Fit camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

26.Fit RH exhaust manifold gasket.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket - exhaust

manifold - RH - Non NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket(s) -

exhaust manifold - RH - KV6 - NAS.

27.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

28.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

29.Check engine oil level and top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Page 294 of 1007

EMISSION CONTROL

REPAIRS 17-1-3

REPAIRS

Valve - depression limiter - Td4

$% 17.10.25

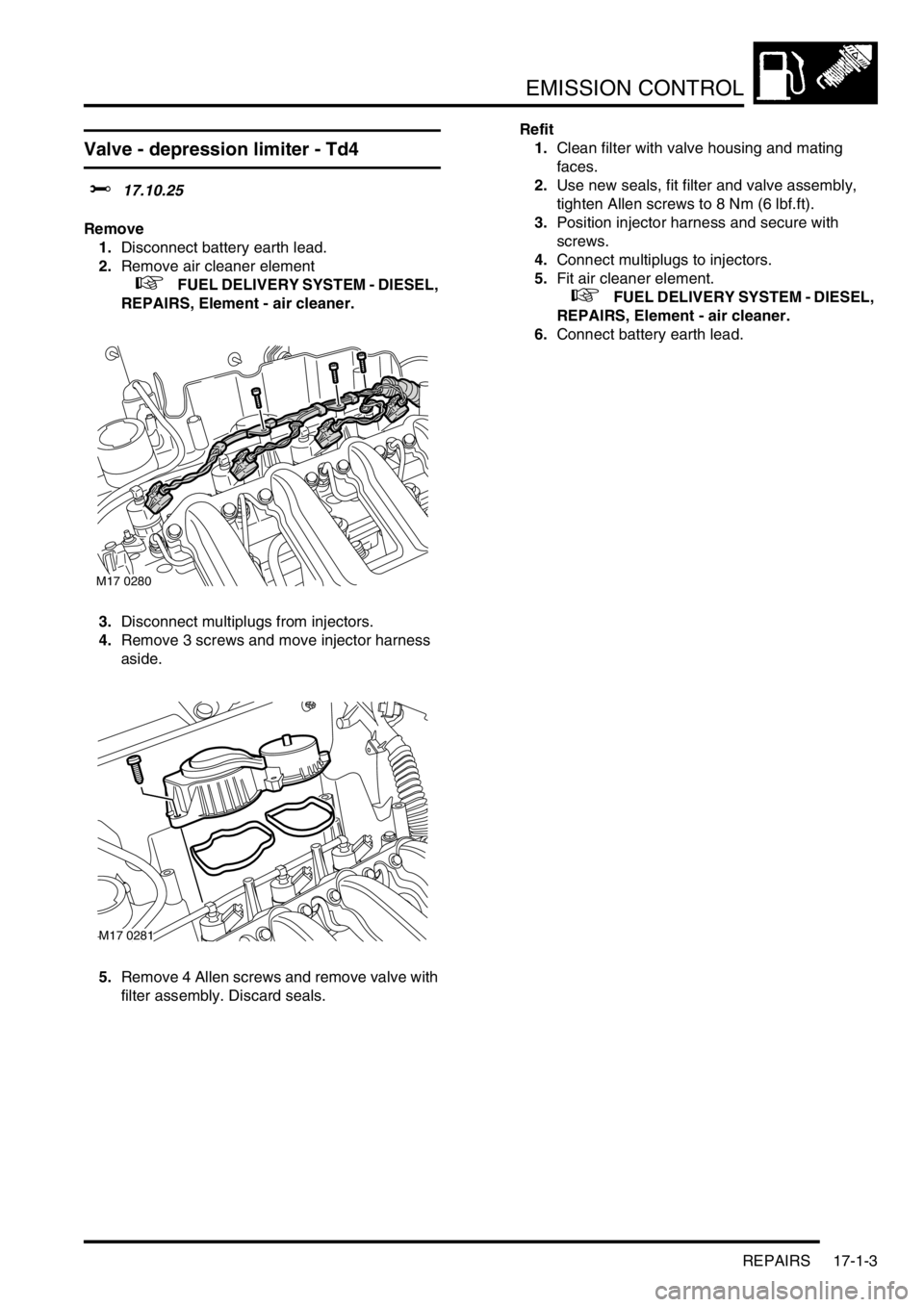

Remove

1.Disconnect battery earth lead.

2.Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Disconnect multiplugs from injectors.

4.Remove 3 screws and move injector harness

aside.

5.Remove 4 Allen screws and remove valve with

filter assembly. Discard seals.Refit

1.Clean filter with valve housing and mating

faces.

2.Use new seals, fit filter and valve assembly,

tighten Allen screws to 8 Nm (6 lbf.ft).

3.Position injector harness and secure with

screws.

4.Connect multiplugs to injectors.

5.Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

6.Connect battery earth lead.

M17 0280

M17 0281

Page 303 of 1007

EMISSION CONTROL

17-1-12 REPAIRS

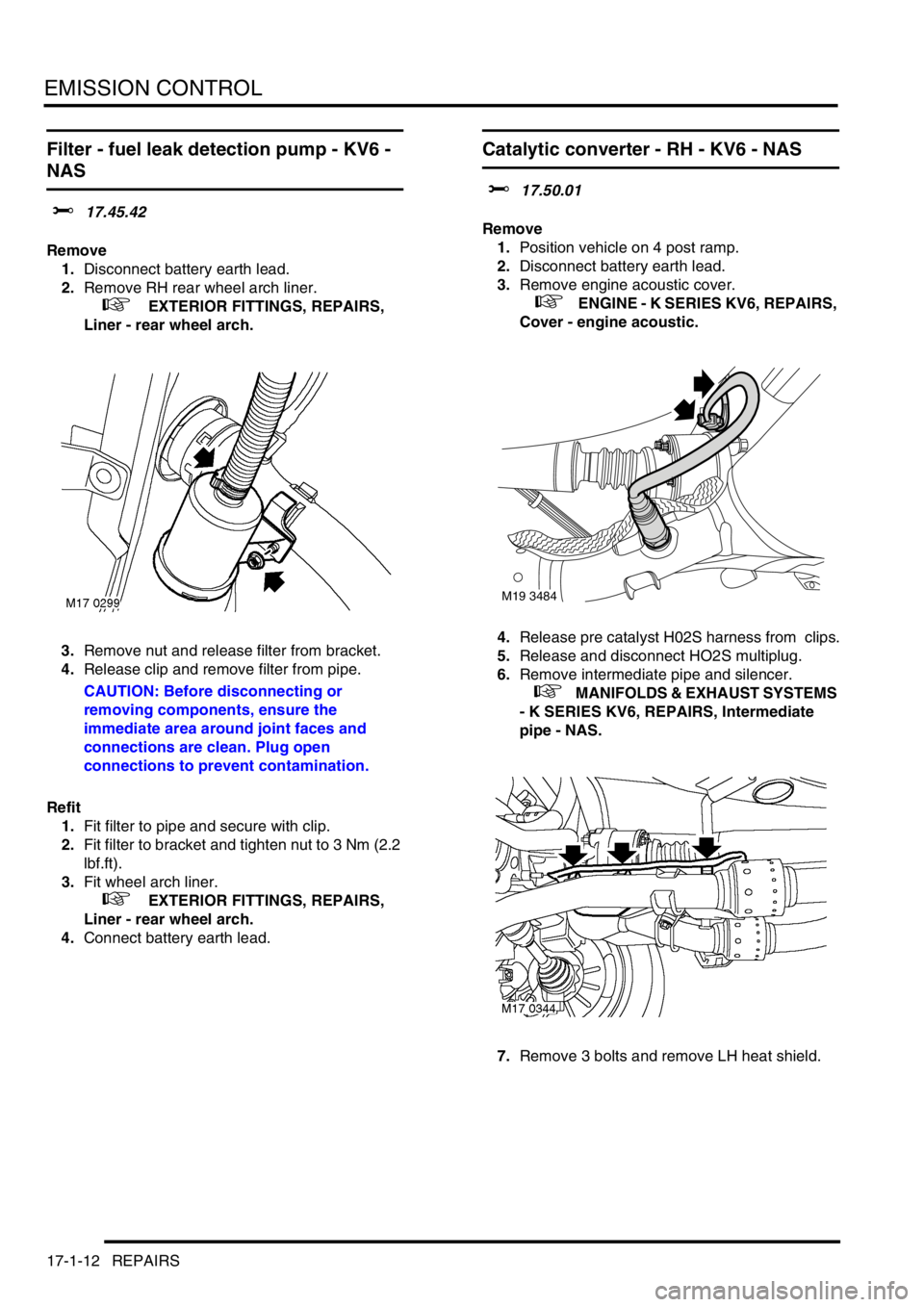

Filter - fuel leak detection pump - KV6 -

NAS

$% 17.45.42

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Remove nut and release filter from bracket.

4.Release clip and remove filter from pipe.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

Refit

1.Fit filter to pipe and secure with clip.

2.Fit filter to bracket and tighten nut to 3 Nm (2.2

lbf.ft).

3.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Connect battery earth lead.

Catalytic converter - RH - KV6 - NAS

$% 17.50.01

Remove

1.Position vehicle on 4 post ramp.

2.Disconnect battery earth lead.

3.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

4.Release pre catalyst H02S harness from clips.

5.Release and disconnect HO2S multiplug.

6.Remove intermediate pipe and silencer.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

7.Remove 3 bolts and remove LH heat shield.

M19 3484

Page 325 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-4 ADJUSTMENTS

Fuel system - depressurise - K1.8

$% 19.50.02

Check

1.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

2.Disconnect fuel feed hose from fuel rail.

3.Connect feed hose to fuel rail once pressure

has relieved.

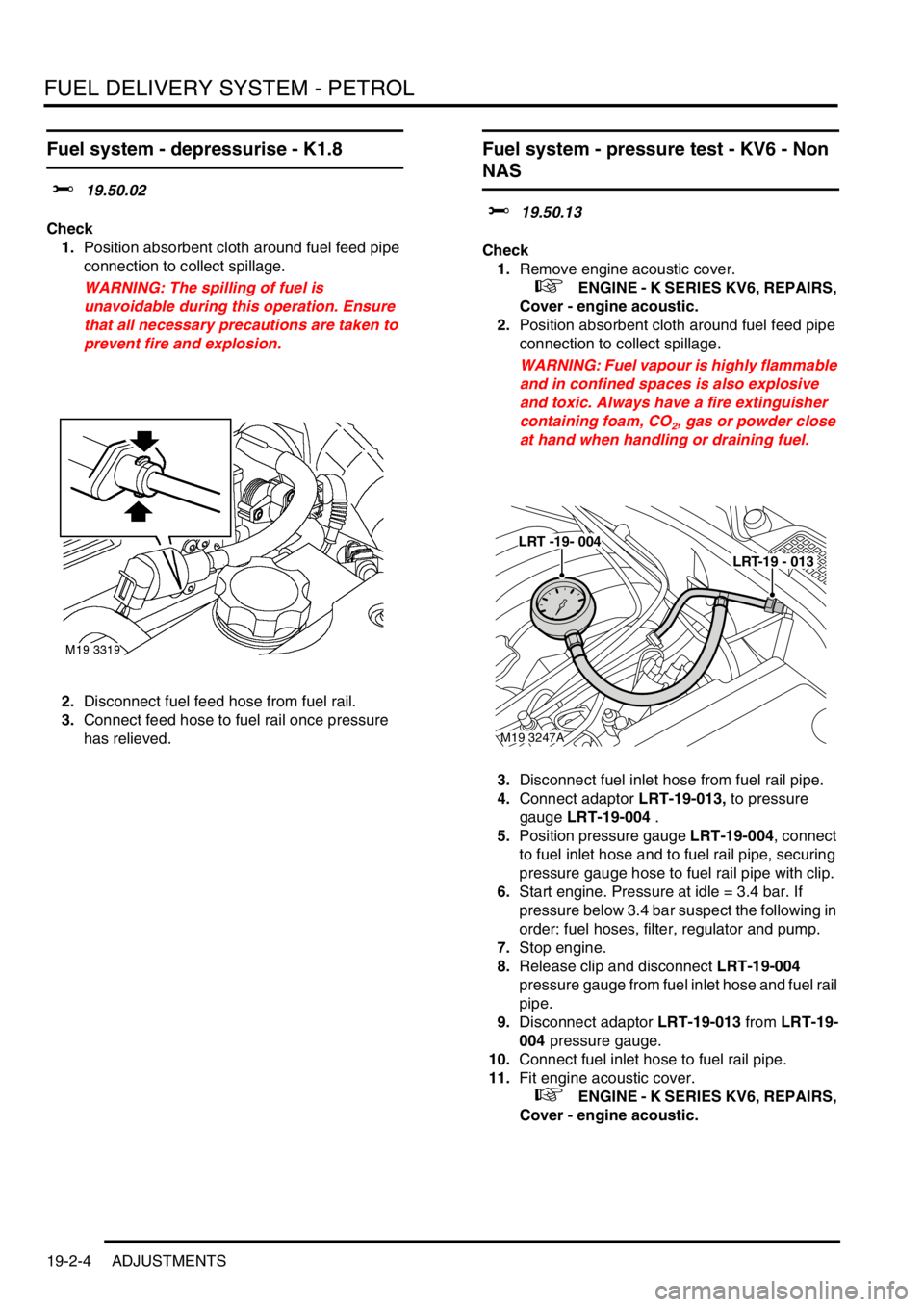

Fuel system - pressure test - KV6 - Non

NAS

$% 19.50.13

Check

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3.Disconnect fuel inlet hose from fuel rail pipe.

4.Connect adaptor LRT-19-013, to pressure

gauge LRT-19-004 .

5.Position pressure gauge LRT-19-004, connect

to fuel inlet hose and to fuel rail pipe, securing

pressure gauge hose to fuel rail pipe with clip.

6.Start engine. Pressure at idle = 3.4 bar. If

pressure below 3.4 bar suspect the following in

order: fuel hoses, filter, regulator and pump.

7.Stop engine.

8.Release clip and disconnect LRT-19-004

pressure gauge from fuel inlet hose and fuel rail

pipe.

9.Disconnect adaptor LRT-19-013 from LRT-19-

004 pressure gauge.

10.Connect fuel inlet hose to fuel rail pipe.

11.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M19 3247A

LRT-19 - 013

LRT -19- 004

Page 326 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-5

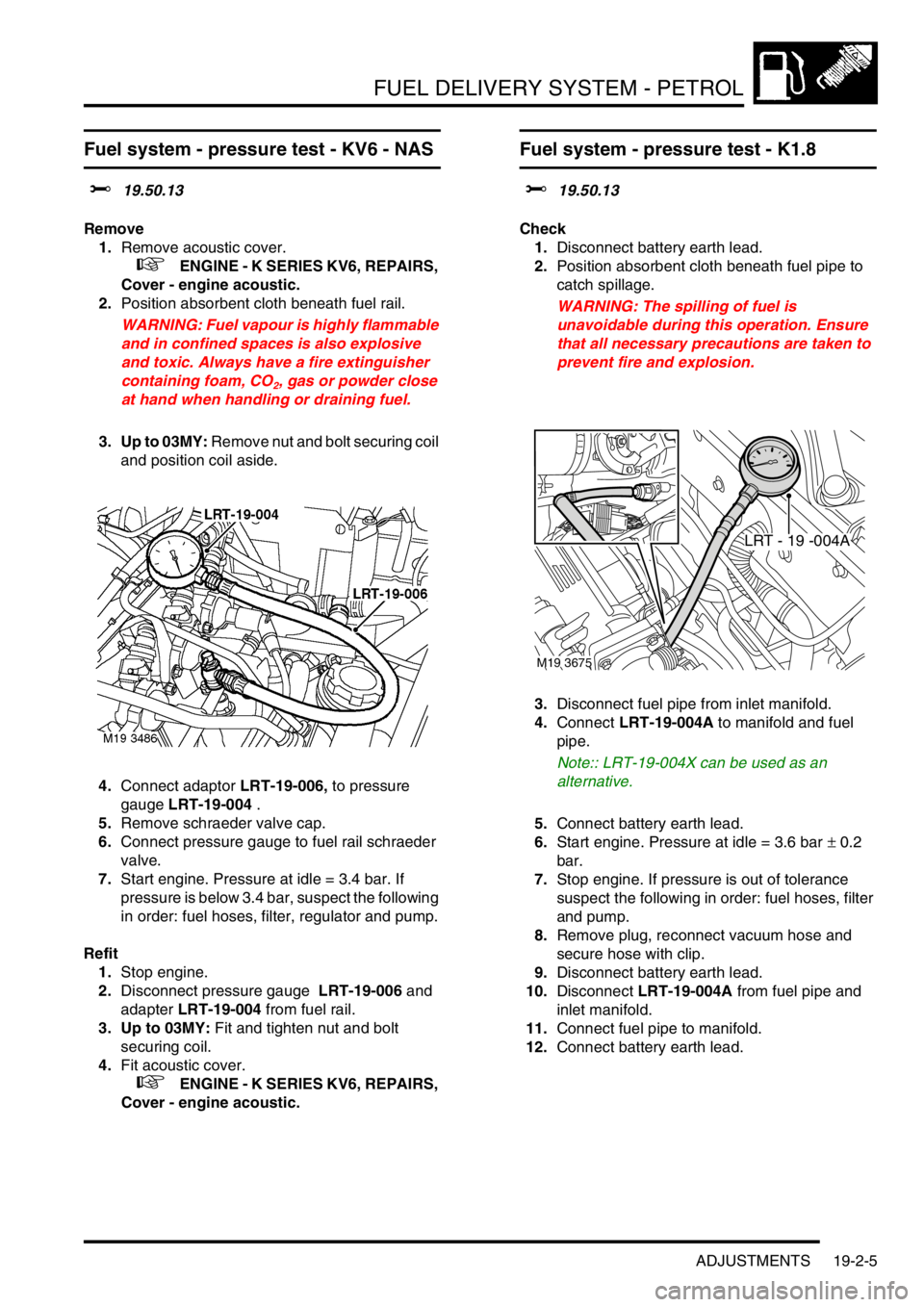

Fuel system - pressure test - KV6 - NAS

$% 19.50.13

Remove

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth beneath fuel rail.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

4.Connect adaptor LRT-19-006, to pressure

gauge LRT-19-004 .

5.Remove schraeder valve cap.

6.Connect pressure gauge to fuel rail schraeder

valve.

7.Start engine. Pressure at idle = 3.4 bar. If

pressure is below 3.4 bar, suspect the following

in order: fuel hoses, filter, regulator and pump.

Refit

1.Stop engine.

2.Disconnect pressure gauge LRT-19-006 and

adapter LRT-19-004 from fuel rail.

3. Up to 03MY: Fit and tighten nut and bolt

securing coil.

4.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Fuel system - pressure test - K1.8

$% 19.50.13

Check

1.Disconnect battery earth lead.

2.Position absorbent cloth beneath fuel pipe to

catch spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Disconnect fuel pipe from inlet manifold.

4.Connect LRT-19-004A to manifold and fuel

pipe.

Note:: LRT-19-004X can be used as an

alternative.

5.Connect battery earth lead.

6.Start engine. Pressure at idle = 3.6 bar ± 0.2

bar.

7.Stop engine. If pressure is out of tolerance

suspect the following in order: fuel hoses, filter

and pump.

8.Remove plug, reconnect vacuum hose and

secure hose with clip.

9.Disconnect battery earth lead.

10.Disconnect LRT-19-004A from fuel pipe and

inlet manifold.

11.Connect fuel pipe to manifold.

12.Connect battery earth lead.

LRT - 19 -004A

M19 3675

Page 349 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-28 REPAIRS

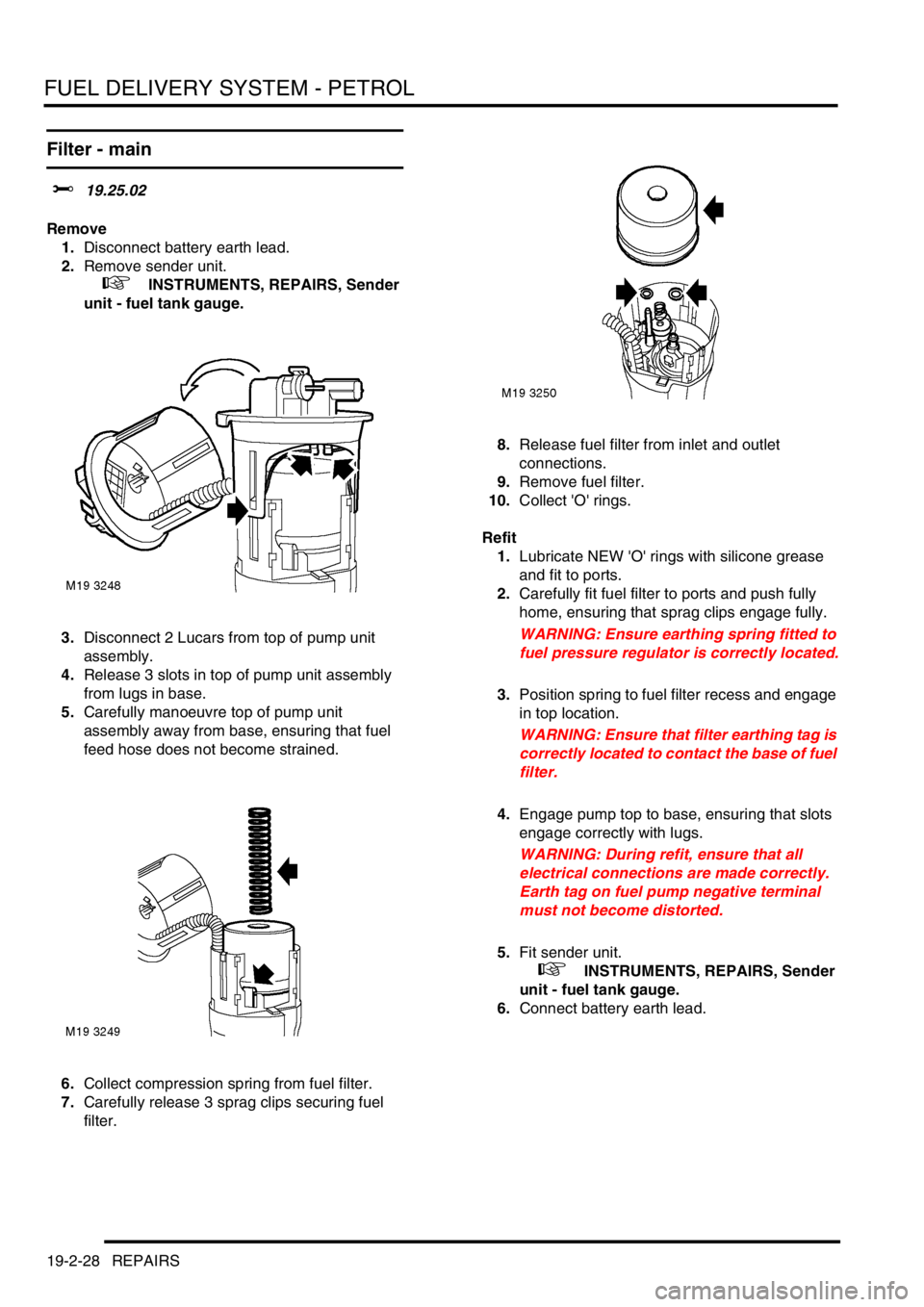

Filter - main

$% 19.25.02

Remove

1.Disconnect battery earth lead.

2.Remove sender unit.

+ INSTRUMENTS, REPAIRS, Sender

unit - fuel tank gauge.

3.Disconnect 2 Lucars from top of pump unit

assembly.

4.Release 3 slots in top of pump unit assembly

from lugs in base.

5.Carefully manoeuvre top of pump unit

assembly away from base, ensuring that fuel

feed hose does not become strained.

6.Collect compression spring from fuel filter.

7.Carefully release 3 sprag clips securing fuel

filter.8.Release fuel filter from inlet and outlet

connections.

9.Remove fuel filter.

10.Collect 'O' rings.

Refit

1.Lubricate NEW 'O' rings with silicone grease

and fit to ports.

2.Carefully fit fuel filter to ports and push fully

home, ensuring that sprag clips engage fully.

WARNING: Ensure earthing spring fitted to

fuel pressure regulator is correctly located.

3.Position spring to fuel filter recess and engage

in top location.

WARNING: Ensure that filter earthing tag is

correctly located to contact the base of fuel

filter.

4.Engage pump top to base, ensuring that slots

engage correctly with lugs.

WARNING: During refit, ensure that all

electrical connections are made correctly.

Earth tag on fuel pump negative terminal

must not become distorted.

5.Fit sender unit.

+ INSTRUMENTS, REPAIRS, Sender

unit - fuel tank gauge.

6.Connect battery earth lead.

Page 566 of 1007

BRAKES

REPAIRS 70-17

14.Check wheel cylinder pistons for freedom of

movement.

15.Check brake adjuster threads, nut and

handbrake linkage for wear. Renew if

necessary.

16.Check condition of return springs and renew if

necessary.

17.Ensure brake adjuster is fully off.

Refit

1.Position adjuster and expander to brake shoes

and fit return springs.

2.Smear brake shoe contact points with Molykote

111 grease.

3.Remove elastic band from wheel cylinder.

4.Manoeuvre brake shoes around rear hub and

locate to abutment and wheel cylinder.

5.Fit brake shoe retaining pins and secure with

clips.

6.Connect hand brake cable to brake shoe lever.

7.Fit brake drum.

+ BRAKES, REPAIRS, Drum - rear.

8.Apply brake pedal a min. of 30 times to ensure

full adjustment of rear brake shoes after

refitting.

9.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

10.Remove stands and lower vehicle.

Servo assembly - LHD

$% 70.50.01

Remove

1. Td4 models: Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

2.Remove brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - LHD.

3. Td4 models: Remove bolt securing vacuum

reservoir and position reservoir aside.

4.Remove screw securing fuel filter housing to

bracket.

5.Release fuel filter housing from bracket.

6.Release and disconnect vacuum hose from

servo.

7.Remove and discard vacuum hose seal.

8.Release brake pipes from clips on bulkhead.

M70 1089