fuel pump LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 115 of 1007

TORQUE WRENCH SETTINGS

06-12

Fuel Delivery System – Diesel

TORQUE DESCRIPTION METRIC IMPERIAL

Air cleaner cover Allen screws 8 Nm 6 lbf.ft

Condenser to radiator bolts 3 Nm 2.2 lbf.ft

Filler neck to body nuts and bolt 9 Nm 6.5 lbf.ft

Fuel cooler to mounting bracket bolts 10 Nm 7 lbf.ft

Fuel cooler matrix to bonnet locking platform nuts 10 Nm 7 lbf.ft

Fuel cut-off (inertia) switch to bracket nuts 2 Nm 1.5 lbf.ft

Fuel injector clamp nuts 10 Nm 7 lbf.ft

Fuel injector pipe union nuts 20 Nm 15 lbf.ft

Fuel injection pump nuts 24 Nm 18 lbf.ft

Fuel injection pump sprocket nut 65 Nm 48 lbf.ft

Fuel injector studs 10 Nm 7 lbf.ft

Fuel pressure regulator Torx screws 9 Nm 6.5 lbf.ft

Fuel pressure sensor 38 Nm 28 lbf.ft

Fuel pump/sender unit to tank locking ring 35 Nm 26 lbf.ft

Fuel rails to support bracket bolt 10 Nm 7.5 lbf.ft

Fuel rail Allen screws 24 Nm 18 lbf.ft

Fuel tank to body bolts 45 Nm 33 lbf.ft

Glow plugs20 Nm 15 lbf.ft

High pressure fuel pipe union nuts 20 Nm 15 lbf.ft

Intercooler to radiator bolts 3 Nm 2.2 lbf.ft

Low pressure fuel rail bolts 10 Nm 7 lbf.ft

Timing case access plug 30 Nm 22 lbf.ft

Turbocharger boost control solenoid valve mounting bracket to turbocharger bolts 10 Nm 7 lbf.ft

Turbocharger boost control solenoid valve to mounting rubber nuts 5 Nm 3.7 lbf.ft

Turbocharger boost pressure sensor to inlet manifold bolt 8 Nm 6 lbf.ft

Turbocharger oil drain pipe bracket bolts 20 Nm 15 lbf.ft

Turbocharger oil drain pipe flange bolts 8 Nm 6 lbf.ft

Turbocharger oil feed pipe banjo bolts 22 Nm 16 lbf.ft

Turbocharger outlet pipe to bracket bolts:

⇒ 6 mm10 Nm 7 lbf.ft

⇒ 8 mm20 Nm 15 lbf.ft

Turbocharger to exhaust manifold bolts 50 Nm 37 lbf.ft

Page 116 of 1007

TORQUE WRENCH SETTINGS

06-13

Fuel delivery system – Petrol

1 Tighten in sequence using the procedure defined in 'Repairs' section.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, REPAIRS, Sensor - combined - manifold absolute

pressure/Intake air temperature (MAP/IAT).

TORQUE DESCRIPTION METRIC IMPERIAL

Air cleaner to battery tray bolts 9 Nm 7 lbf.ft

Fuel filler neck to body nuts and bolt 9 Nm 7 lbf.ft

Fuel pump/sender unit to tank locking ring 35 Nm 26 lbf.ft

Fuel rail to inlet manifold bolt 8 Nm 6 lbf.ft

Fuel tank to body bolts 40 Nm 29 lbf.ft

Heated Oxygen (HO

2S) Sensor 40 Nm 29 lbf.ft

Ignition coils to LH inlet manifold nuts and bolts - KV6 - Up to 03 Model Year 9 Nm 7 lbf.ft

Inertia (fuel cut-off) switch 2 Nm 1.5 lbf.ft

Intake Air Control Valve (IACV) to throttle body Allen screws 6 Nm 4.5 lbf.ft

Subframe to body bolts 190 Nm 140 lbf.ft

Throttle housing to inlet manifold bolts

1 (K1.8)

⇒1st. stage4 Nm 3 lbf.ft

⇒2nd. stage9 Nm 7 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 8 Nm 6 lbf.ft

Throttle actuator support bracket to throttle body Torx screws (vehicles with cruise

control only)9 Nm 7 lbf.ft

Throttle position sensor to housing Torx screws 1.5 Nm 1.1 lbf.ft

VIS motor to inlet manifold chamber screws (KV6 only) 8 Nm 6 lbf.ft

Page 117 of 1007

TORQUE WRENCH SETTINGS

06-14

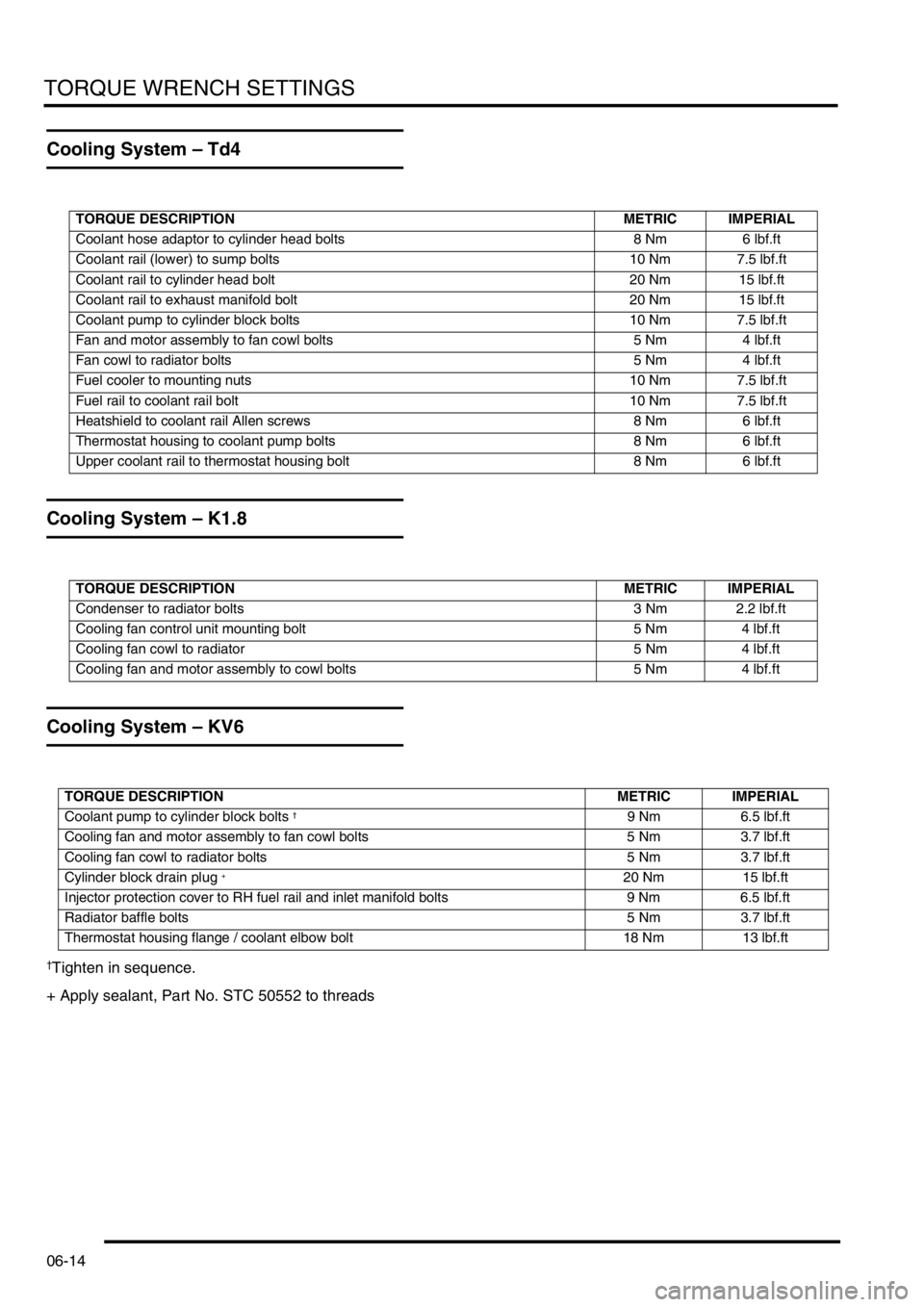

Cooling System – Td4

Cooling System – K1.8

Cooling System – KV6

†Tighten in sequence.

+ Apply sealant, Part No. STC 50552 to threads

TORQUE DESCRIPTION METRIC IMPERIAL

Coolant hose adaptor to cylinder head bolts 8 Nm 6 lbf.ft

Coolant rail (lower) to sump bolts 10 Nm 7.5 lbf.ft

Coolant rail to cylinder head bolt 20 Nm 15 lbf.ft

Coolant rail to exhaust manifold bolt 20 Nm 15 lbf.ft

Coolant pump to cylinder block bolts 10 Nm 7.5 lbf.ft

Fan and motor assembly to fan cowl bolts 5 Nm 4 lbf.ft

Fan cowl to radiator bolts 5 Nm 4 lbf.ft

Fuel cooler to mounting nuts 10 Nm 7.5 lbf.ft

Fuel rail to coolant rail bolt 10 Nm 7.5 lbf.ft

Heatshield to coolant rail Allen screws 8 Nm 6 lbf.ft

Thermostat housing to coolant pump bolts 8 Nm 6 lbf.ft

Upper coolant rail to thermostat housing bolt 8 Nm 6 lbf.ft

TORQUE DESCRIPTION METRIC IMPERIAL

Condenser to radiator bolts 3 Nm 2.2 lbf.ft

Cooling fan control unit mounting bolt 5 Nm 4 lbf.ft

Cooling fan cowl to radiator 5 Nm 4 lbf.ft

Cooling fan and motor assembly to cowl bolts 5 Nm 4 lbf.ft

TORQUE DESCRIPTION METRIC IMPERIAL

Coolant pump to cylinder block bolts

†9 Nm 6.5 lbf.ft

Cooling fan and motor assembly to fan cowl bolts 5 Nm 3.7 lbf.ft

Cooling fan cowl to radiator bolts 5 Nm 3.7 lbf.ft

Cylinder block drain plug

+20 Nm 15 lbf.ft

Injector protection cover to RH fuel rail and inlet manifold bolts 9 Nm 6.5 lbf.ft

Radiator baffle bolts 5 Nm 3.7 lbf.ft

Thermostat housing flange / coolant elbow bolt 18 Nm 13 lbf.ft

Page 131 of 1007

TORQUE WRENCH SETTINGS

06-28

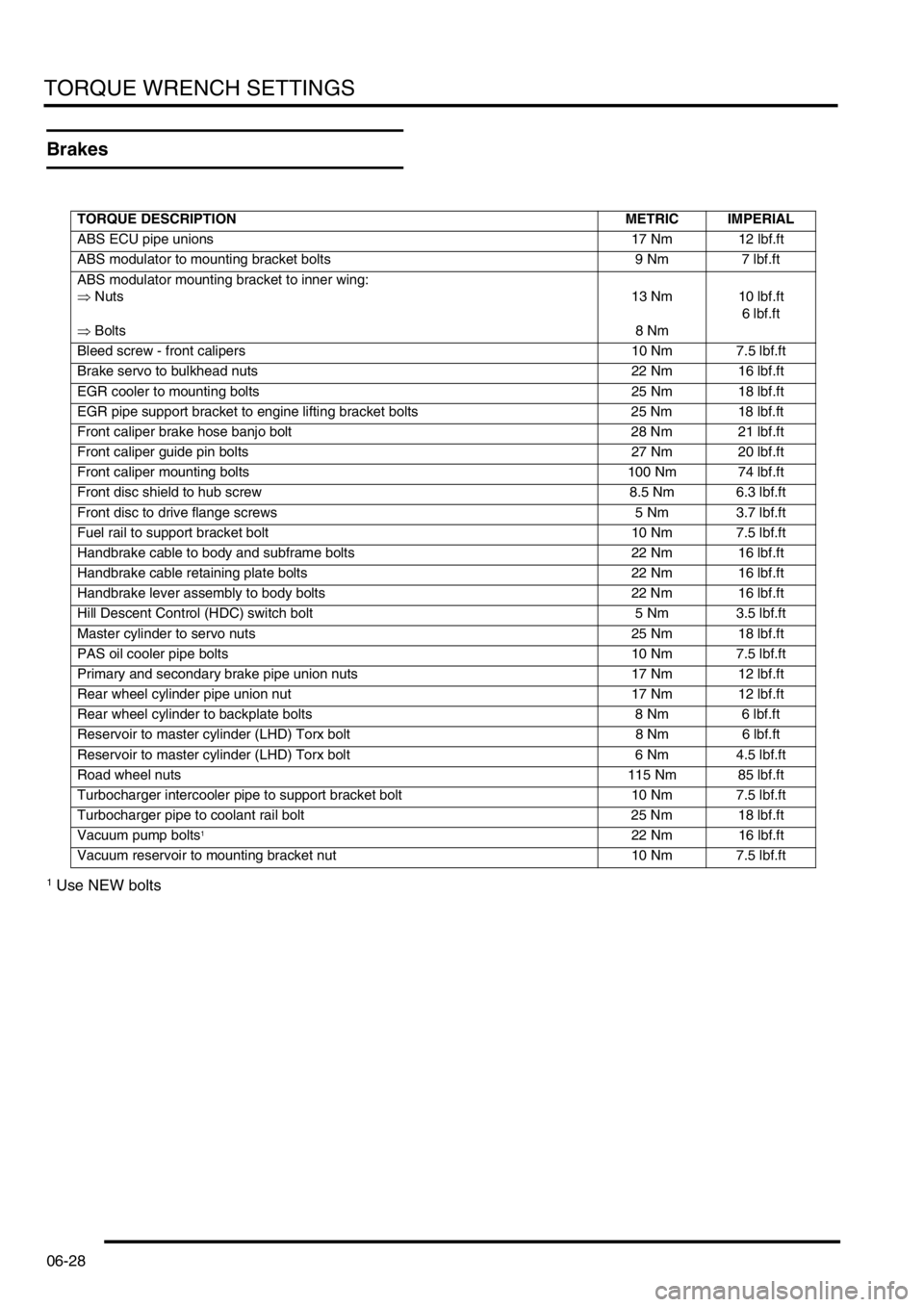

Brakes

1 Use NEW bolts

TORQUE DESCRIPTION METRIC IMPERIAL

ABS ECU pipe unions 17 Nm 12 lbf.ft

ABS modulator to mounting bracket bolts 9 Nm 7 lbf.ft

ABS modulator mounting bracket to inner wing:

⇒ Nuts

⇒ Bolts13 Nm

8 Nm10 lbf.ft

6 lbf.ft

Bleed screw - front calipers 10 Nm 7.5 lbf.ft

Brake servo to bulkhead nuts 22 Nm 16 lbf.ft

EGR cooler to mounting bolts 25 Nm 18 lbf.ft

EGR pipe support bracket to engine lifting bracket bolts 25 Nm 18 lbf.ft

Front caliper brake hose banjo bolt 28 Nm 21 lbf.ft

Front caliper guide pin bolts 27 Nm 20 lbf.ft

Front caliper mounting bolts 100 Nm 74 lbf.ft

Front disc shield to hub screw 8.5 Nm 6.3 lbf.ft

Front disc to drive flange screws 5 Nm 3.7 lbf.ft

Fuel rail to support bracket bolt 10 Nm 7.5 lbf.ft

Handbrake cable to body and subframe bolts 22 Nm 16 lbf.ft

Handbrake cable retaining plate bolts 22 Nm 16 lbf.ft

Handbrake lever assembly to body bolts 22 Nm 16 lbf.ft

Hill Descent Control (HDC) switch bolt 5 Nm 3.5 lbf.ft

Master cylinder to servo nuts 25 Nm 18 lbf.ft

PAS oil cooler pipe bolts 10 Nm 7.5 lbf.ft

Primary and secondary brake pipe union nuts 17 Nm 12 lbf.ft

Rear wheel cylinder pipe union nut 17 Nm 12 lbf.ft

Rear wheel cylinder to backplate bolts 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 6 Nm 4.5 lbf.ft

Road wheel nuts 115 Nm 85 lbf.ft

Turbocharger intercooler pipe to support bracket bolt 10 Nm 7.5 lbf.ft

Turbocharger pipe to coolant rail bolt 25 Nm 18 lbf.ft

Vacuum pump bolts

122 Nm 16 lbf.ft

Vacuum reservoir to mounting bracket nut 10 Nm 7.5 lbf.ft

Page 157 of 1007

MAINTENANCE

10-10 MAINTENANCE

Fuel Filter - Petrol

Replace

1.Renew fuel filter.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Filter - main.

Fuel Filter - Diesel

Replace

1.Replace fuel filter element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Filter - main - up to 03MY.

Fuel Pump and Filter assembly - Diesel -

03 Model Year onwards

Remove

1.Remove fuel pump and filter assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Pump and filter assembly - from

03MY.

2.Remove all traces of dirt from fuel pump and

filter assembly.

WARNING: Suitable eye protection must be

worn.

Refit

1.Fit fuel pump and filter assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Pump and filter assembly - from

03MY.

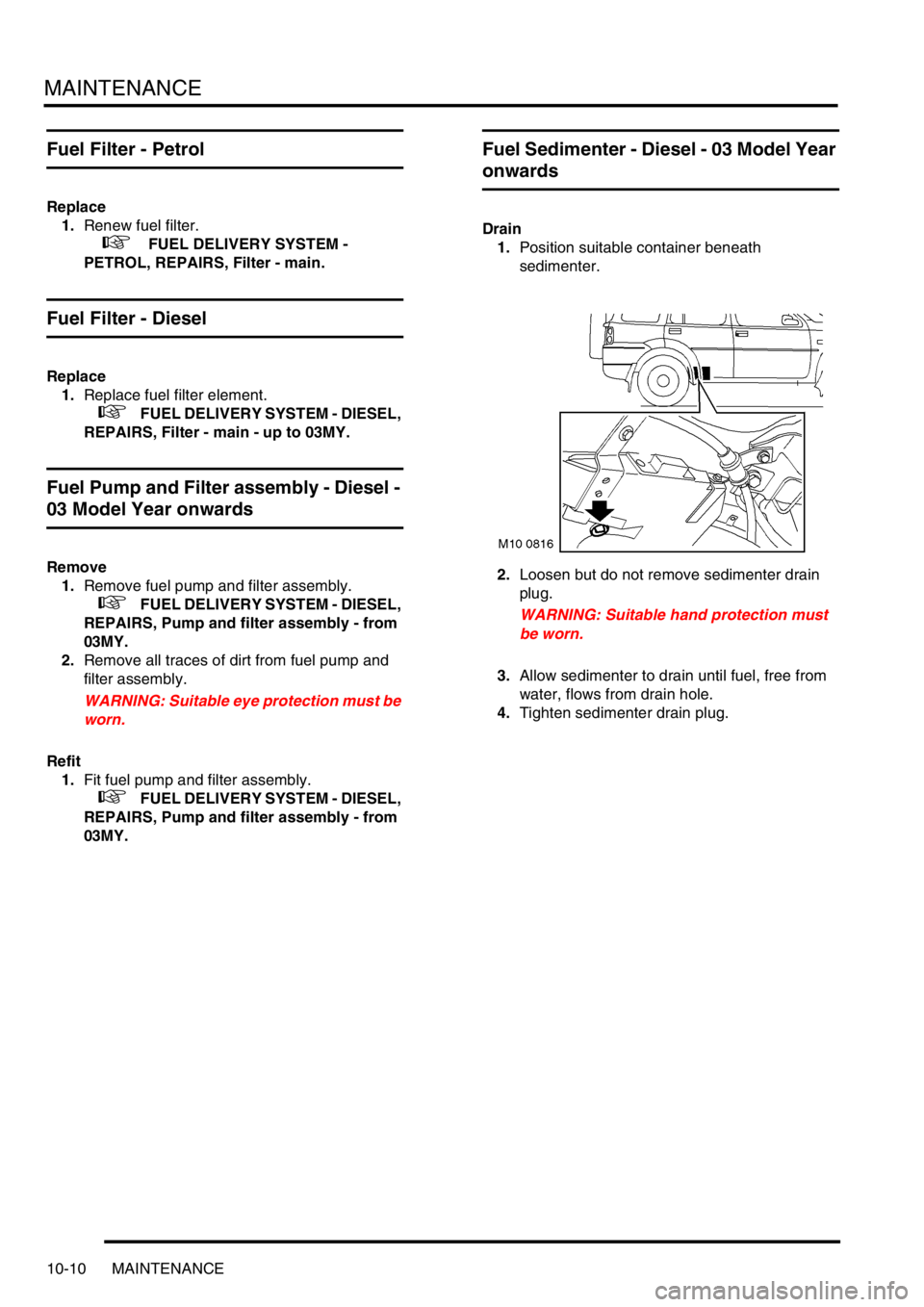

Fuel Sedimenter - Diesel - 03 Model Year

onwards

Drain

1.Position suitable container beneath

sedimenter.

2.Loosen but do not remove sedimenter drain

plug.

WARNING: Suitable hand protection must

be worn.

3.Allow sedimenter to drain until fuel, free from

water, flows from drain hole.

4.Tighten sedimenter drain plug.

Page 303 of 1007

EMISSION CONTROL

17-1-12 REPAIRS

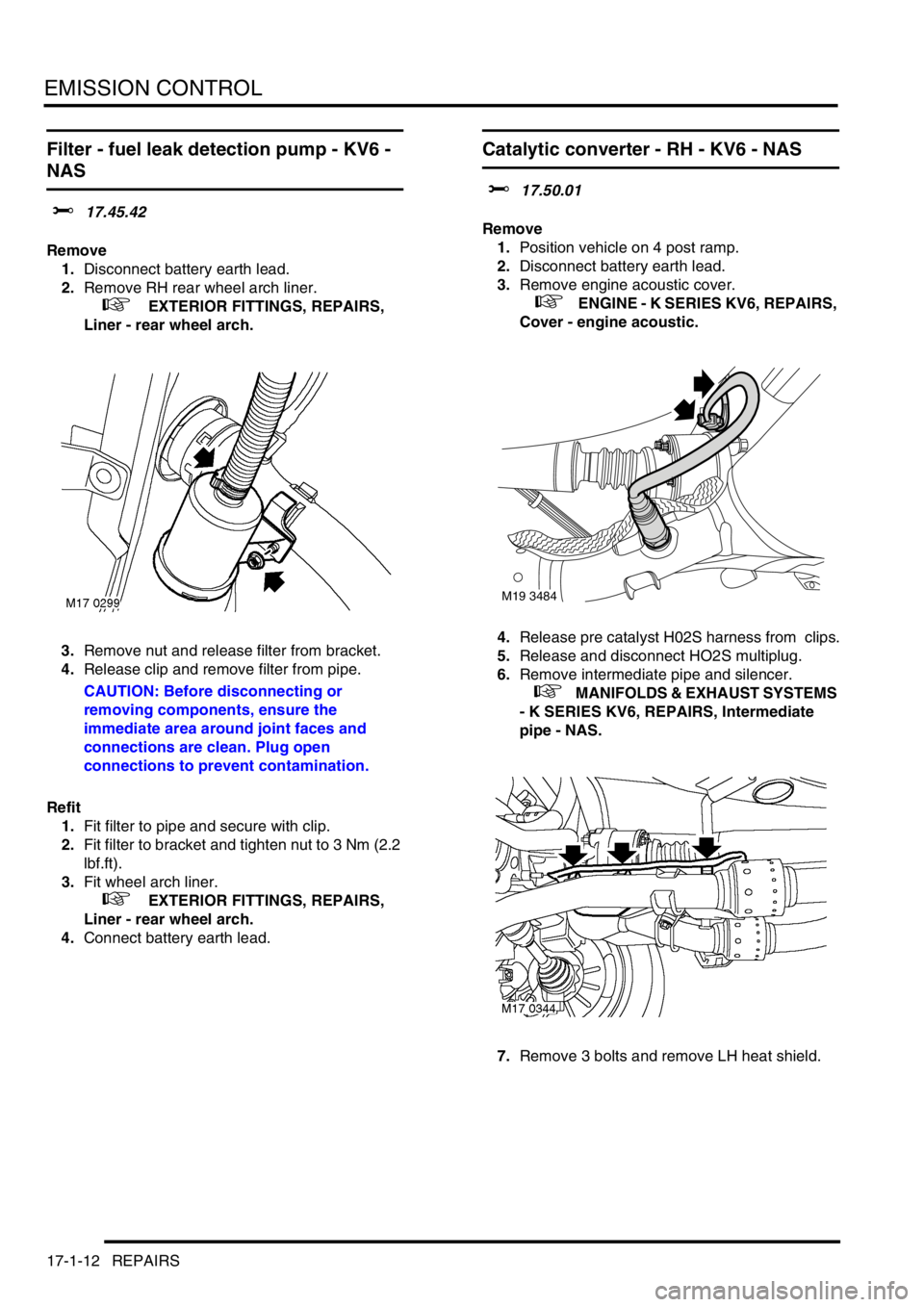

Filter - fuel leak detection pump - KV6 -

NAS

$% 17.45.42

Remove

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Remove nut and release filter from bracket.

4.Release clip and remove filter from pipe.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

Refit

1.Fit filter to pipe and secure with clip.

2.Fit filter to bracket and tighten nut to 3 Nm (2.2

lbf.ft).

3.Fit wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

4.Connect battery earth lead.

Catalytic converter - RH - KV6 - NAS

$% 17.50.01

Remove

1.Position vehicle on 4 post ramp.

2.Disconnect battery earth lead.

3.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

4.Release pre catalyst H02S harness from clips.

5.Release and disconnect HO2S multiplug.

6.Remove intermediate pipe and silencer.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

7.Remove 3 bolts and remove LH heat shield.

M19 3484

Page 325 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-4 ADJUSTMENTS

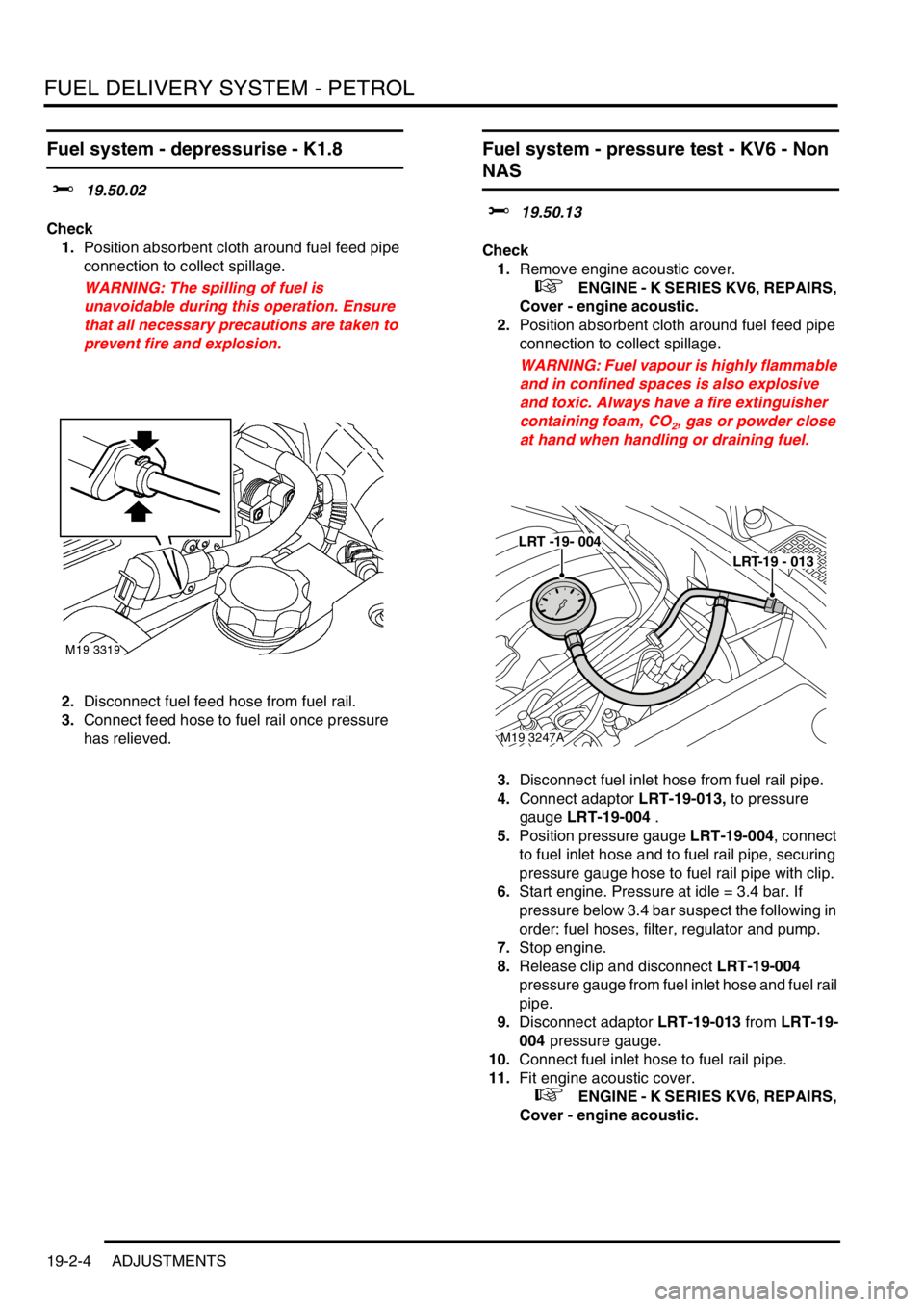

Fuel system - depressurise - K1.8

$% 19.50.02

Check

1.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

2.Disconnect fuel feed hose from fuel rail.

3.Connect feed hose to fuel rail once pressure

has relieved.

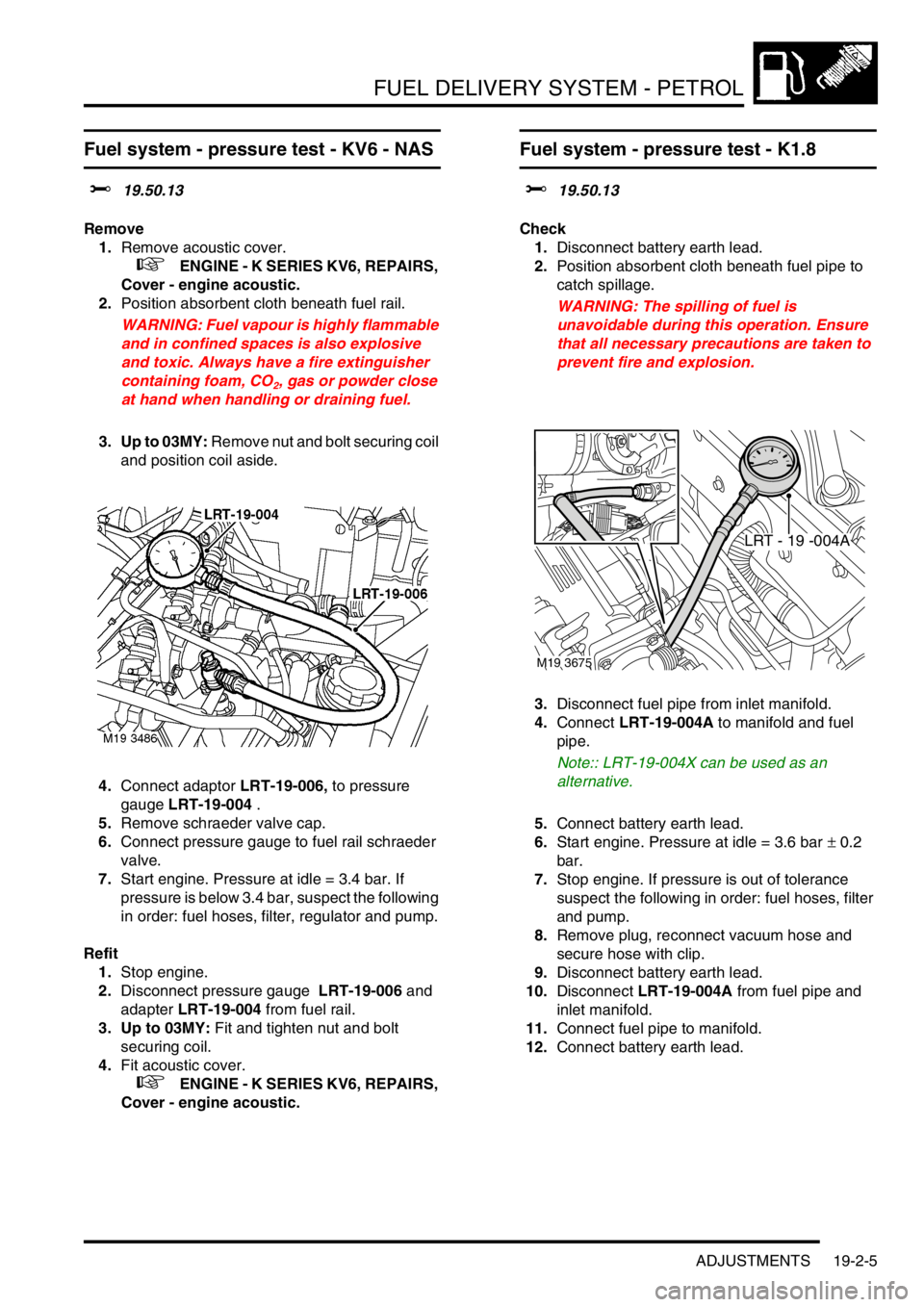

Fuel system - pressure test - KV6 - Non

NAS

$% 19.50.13

Check

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3.Disconnect fuel inlet hose from fuel rail pipe.

4.Connect adaptor LRT-19-013, to pressure

gauge LRT-19-004 .

5.Position pressure gauge LRT-19-004, connect

to fuel inlet hose and to fuel rail pipe, securing

pressure gauge hose to fuel rail pipe with clip.

6.Start engine. Pressure at idle = 3.4 bar. If

pressure below 3.4 bar suspect the following in

order: fuel hoses, filter, regulator and pump.

7.Stop engine.

8.Release clip and disconnect LRT-19-004

pressure gauge from fuel inlet hose and fuel rail

pipe.

9.Disconnect adaptor LRT-19-013 from LRT-19-

004 pressure gauge.

10.Connect fuel inlet hose to fuel rail pipe.

11.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M19 3247A

LRT-19 - 013

LRT -19- 004

Page 326 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-5

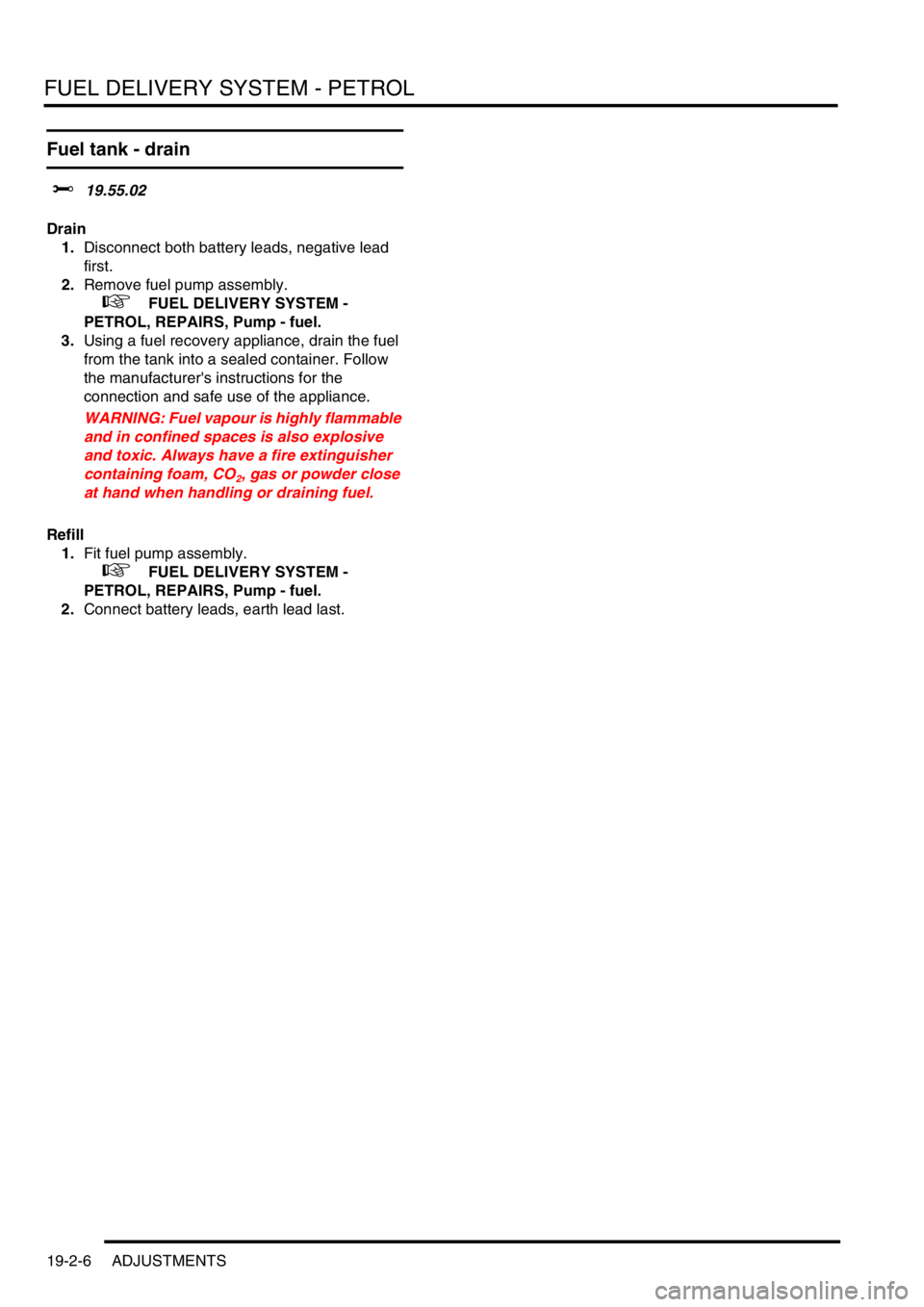

Fuel system - pressure test - KV6 - NAS

$% 19.50.13

Remove

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth beneath fuel rail.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

4.Connect adaptor LRT-19-006, to pressure

gauge LRT-19-004 .

5.Remove schraeder valve cap.

6.Connect pressure gauge to fuel rail schraeder

valve.

7.Start engine. Pressure at idle = 3.4 bar. If

pressure is below 3.4 bar, suspect the following

in order: fuel hoses, filter, regulator and pump.

Refit

1.Stop engine.

2.Disconnect pressure gauge LRT-19-006 and

adapter LRT-19-004 from fuel rail.

3. Up to 03MY: Fit and tighten nut and bolt

securing coil.

4.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Fuel system - pressure test - K1.8

$% 19.50.13

Check

1.Disconnect battery earth lead.

2.Position absorbent cloth beneath fuel pipe to

catch spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Disconnect fuel pipe from inlet manifold.

4.Connect LRT-19-004A to manifold and fuel

pipe.

Note:: LRT-19-004X can be used as an

alternative.

5.Connect battery earth lead.

6.Start engine. Pressure at idle = 3.6 bar ± 0.2

bar.

7.Stop engine. If pressure is out of tolerance

suspect the following in order: fuel hoses, filter

and pump.

8.Remove plug, reconnect vacuum hose and

secure hose with clip.

9.Disconnect battery earth lead.

10.Disconnect LRT-19-004A from fuel pipe and

inlet manifold.

11.Connect fuel pipe to manifold.

12.Connect battery earth lead.

LRT - 19 -004A

M19 3675

Page 327 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-6 ADJUSTMENTS

Fuel tank - drain

$% 19.55.02

Drain

1.Disconnect both battery leads, negative lead

first.

2.Remove fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

3.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

Refill

1.Fit fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

2.Connect battery leads, earth lead last.

Page 338 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-17

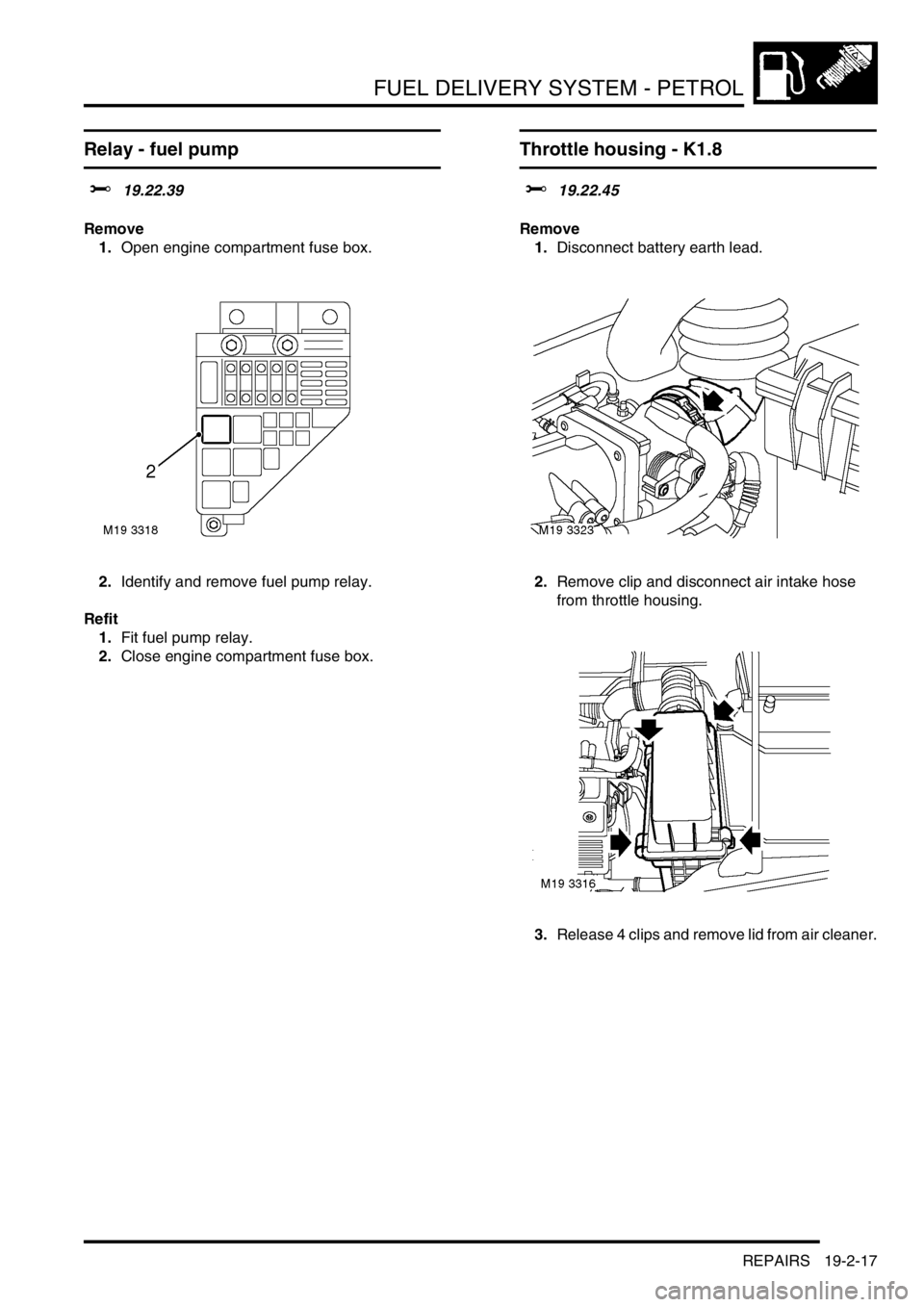

Relay - fuel pump

$% 19.22.39

Remove

1.Open engine compartment fuse box.

2.Identify and remove fuel pump relay.

Refit

1.Fit fuel pump relay.

2.Close engine compartment fuse box.

Throttle housing - K1.8

$% 19.22.45

Remove

1.Disconnect battery earth lead.

2.Remove clip and disconnect air intake hose

from throttle housing.

3.Release 4 clips and remove lid from air cleaner.