fuel pump LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 349 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-28 REPAIRS

Filter - main

$% 19.25.02

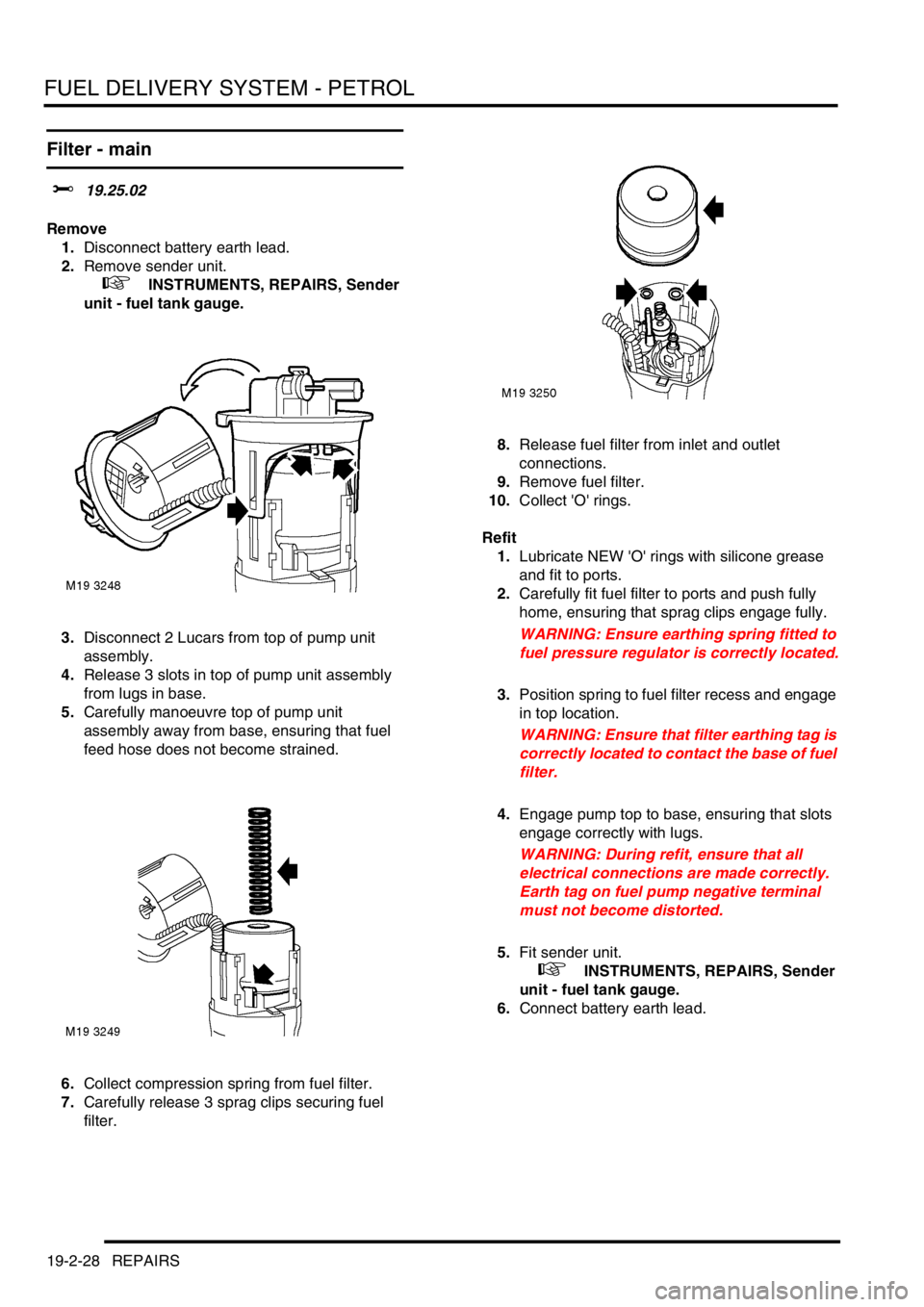

Remove

1.Disconnect battery earth lead.

2.Remove sender unit.

+ INSTRUMENTS, REPAIRS, Sender

unit - fuel tank gauge.

3.Disconnect 2 Lucars from top of pump unit

assembly.

4.Release 3 slots in top of pump unit assembly

from lugs in base.

5.Carefully manoeuvre top of pump unit

assembly away from base, ensuring that fuel

feed hose does not become strained.

6.Collect compression spring from fuel filter.

7.Carefully release 3 sprag clips securing fuel

filter.8.Release fuel filter from inlet and outlet

connections.

9.Remove fuel filter.

10.Collect 'O' rings.

Refit

1.Lubricate NEW 'O' rings with silicone grease

and fit to ports.

2.Carefully fit fuel filter to ports and push fully

home, ensuring that sprag clips engage fully.

WARNING: Ensure earthing spring fitted to

fuel pressure regulator is correctly located.

3.Position spring to fuel filter recess and engage

in top location.

WARNING: Ensure that filter earthing tag is

correctly located to contact the base of fuel

filter.

4.Engage pump top to base, ensuring that slots

engage correctly with lugs.

WARNING: During refit, ensure that all

electrical connections are made correctly.

Earth tag on fuel pump negative terminal

must not become distorted.

5.Fit sender unit.

+ INSTRUMENTS, REPAIRS, Sender

unit - fuel tank gauge.

6.Connect battery earth lead.

Page 350 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-29

Pump - fuel

$% 19.45.08

WARNING: If fuel tank is full, using a fuel

recovery appliance, drain excess fuel from fuel

filler neck until a level below height of fuel pump

is obtained.

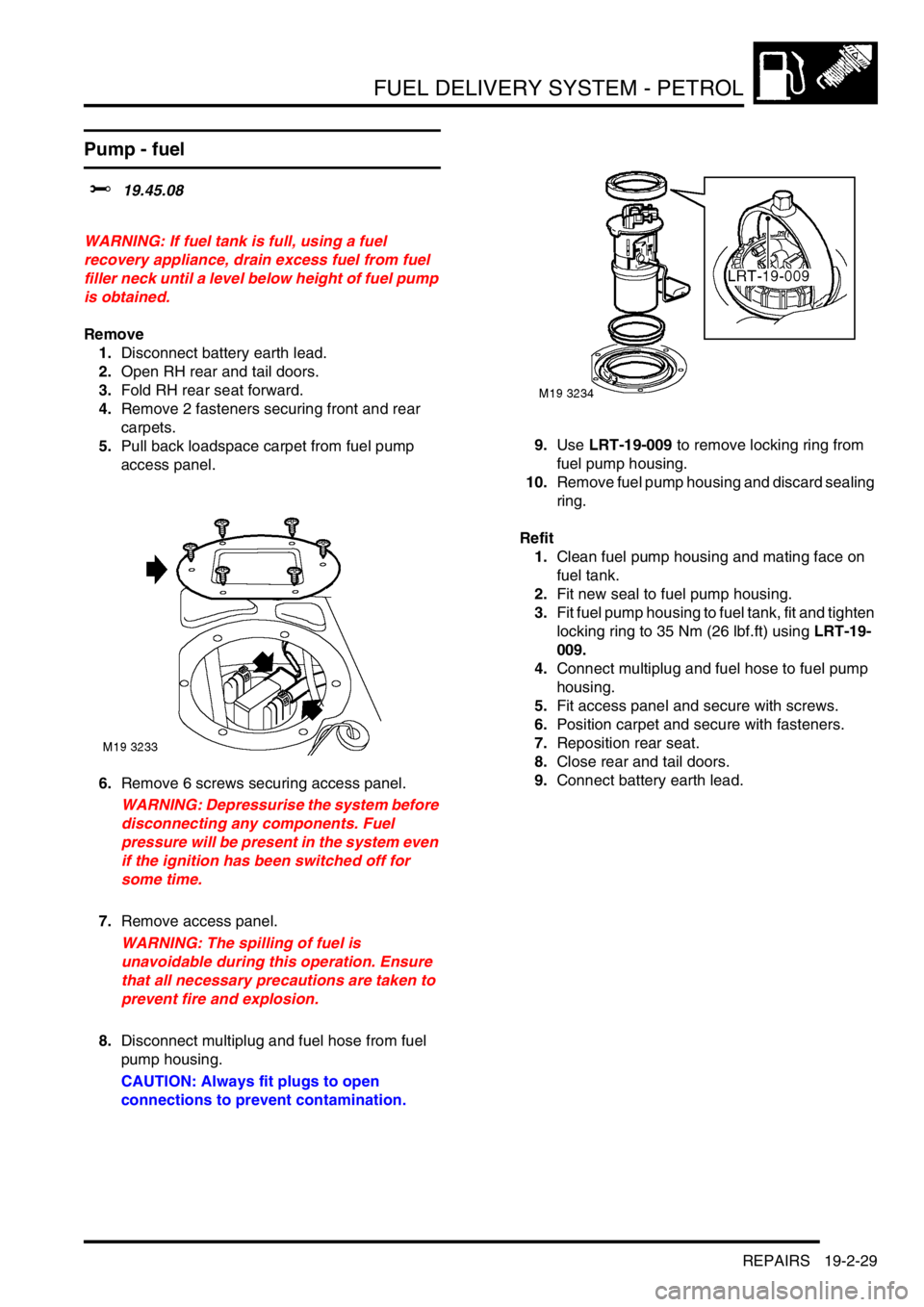

Remove

1.Disconnect battery earth lead.

2.Open RH rear and tail doors.

3.Fold RH rear seat forward.

4.Remove 2 fasteners securing front and rear

carpets.

5.Pull back loadspace carpet from fuel pump

access panel.

6.Remove 6 screws securing access panel.

WARNING: Depressurise the system before

disconnecting any components. Fuel

pressure will be present in the system even

if the ignition has been switched off for

some time.

7.Remove access panel.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

8.Disconnect multiplug and fuel hose from fuel

pump housing.

CAUTION: Always fit plugs to open

connections to prevent contamination.9.Use LRT-19-009 to remove locking ring from

fuel pump housing.

10.Remove fuel pump housing and discard sealing

ring.

Refit

1.Clean fuel pump housing and mating face on

fuel tank.

2.Fit new seal to fuel pump housing.

3.Fit fuel pump housing to fuel tank, fit and tighten

locking ring to 35 Nm (26 lbf.ft) using LRT-19-

009.

4.Connect multiplug and fuel hose to fuel pump

housing.

5.Fit access panel and secure with screws.

6.Position carpet and secure with fasteners.

7.Reposition rear seat.

8.Close rear and tail doors.

9.Connect battery earth lead.

Page 351 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-30 REPAIRS

Tank - Non NAS

$% 19.55.01

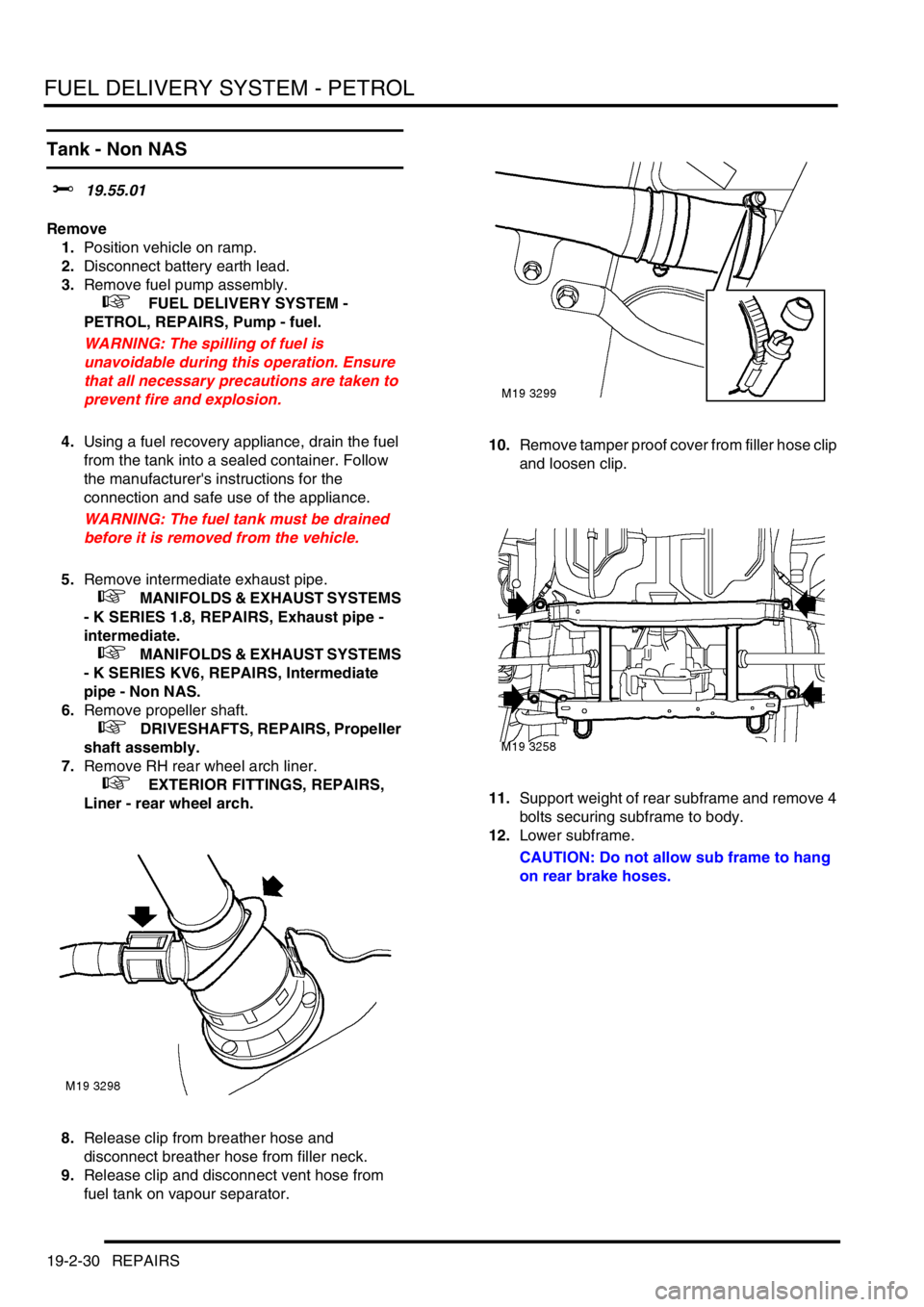

Remove

1.Position vehicle on ramp.

2.Disconnect battery earth lead.

3.Remove fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

4.Using a fuel recovery appliance, drain the fuel

from the tank into a sealed container. Follow

the manufacturer's instructions for the

connection and safe use of the appliance.

WARNING: The fuel tank must be drained

before it is removed from the vehicle.

5.Remove intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

intermediate.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - Non NAS.

6.Remove propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

7.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

8.Release clip from breather hose and

disconnect breather hose from filler neck.

9.Release clip and disconnect vent hose from

fuel tank on vapour separator.10.Remove tamper proof cover from filler hose clip

and loosen clip.

11.Support weight of rear subframe and remove 4

bolts securing subframe to body.

12.Lower subframe.

CAUTION: Do not allow sub frame to hang

on rear brake hoses.

Page 352 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-31

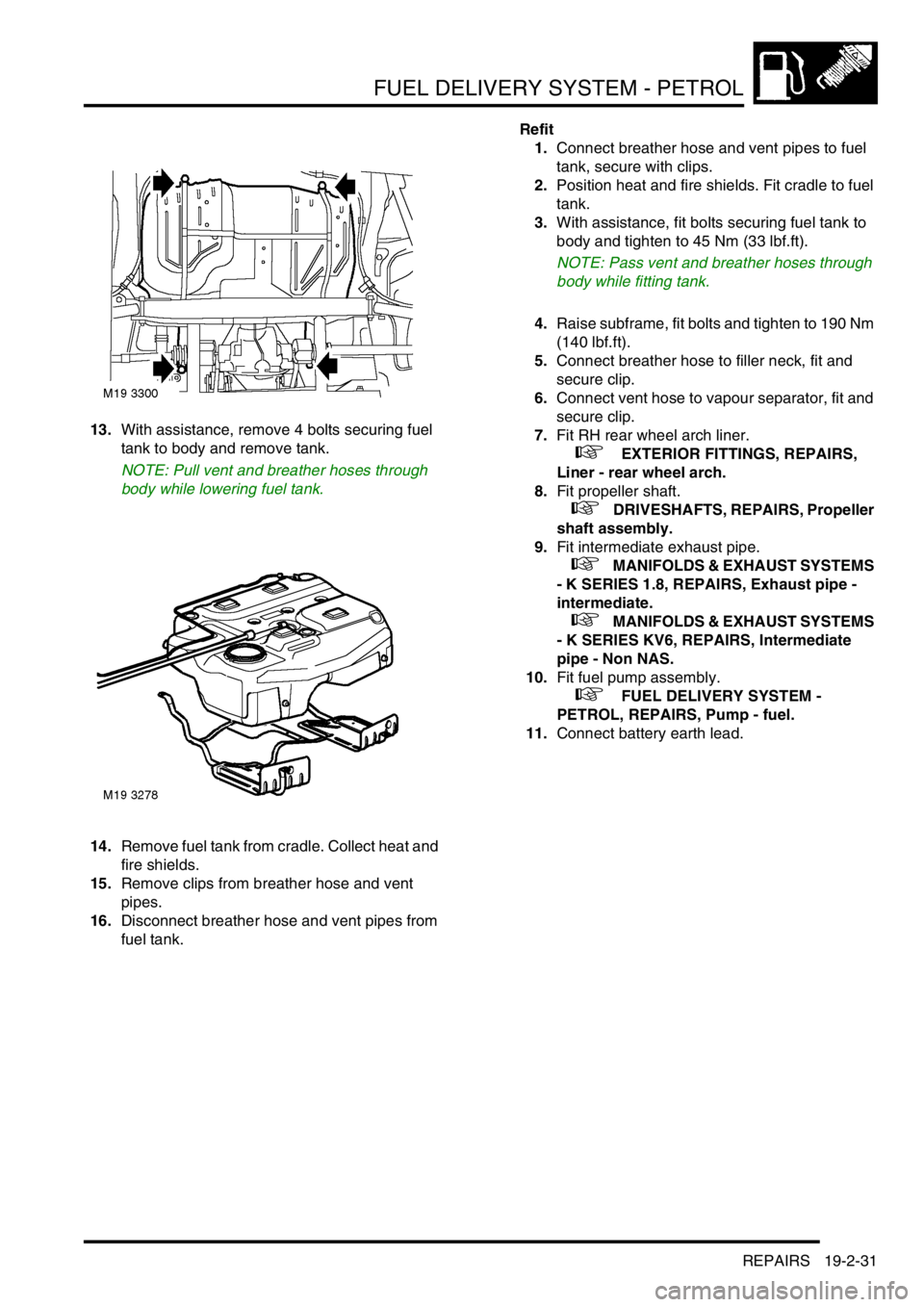

13.With assistance, remove 4 bolts securing fuel

tank to body and remove tank.

NOTE: Pull vent and breather hoses through

body while lowering fuel tank.

14.Remove fuel tank from cradle. Collect heat and

fire shields.

15.Remove clips from breather hose and vent

pipes.

16.Disconnect breather hose and vent pipes from

fuel tank.Refit

1.Connect breather hose and vent pipes to fuel

tank, secure with clips.

2.Position heat and fire shields. Fit cradle to fuel

tank.

3.With assistance, fit bolts securing fuel tank to

body and tighten to 45 Nm (33 lbf.ft).

NOTE: Pass vent and breather hoses through

body while fitting tank.

4.Raise subframe, fit bolts and tighten to 190 Nm

(140 lbf.ft).

5.Connect breather hose to filler neck, fit and

secure clip.

6.Connect vent hose to vapour separator, fit and

secure clip.

7.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

8.Fit propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

9.Fit intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES 1.8, REPAIRS, Exhaust pipe -

intermediate.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - Non NAS.

10.Fit fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

11.Connect battery earth lead.

Page 354 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-33

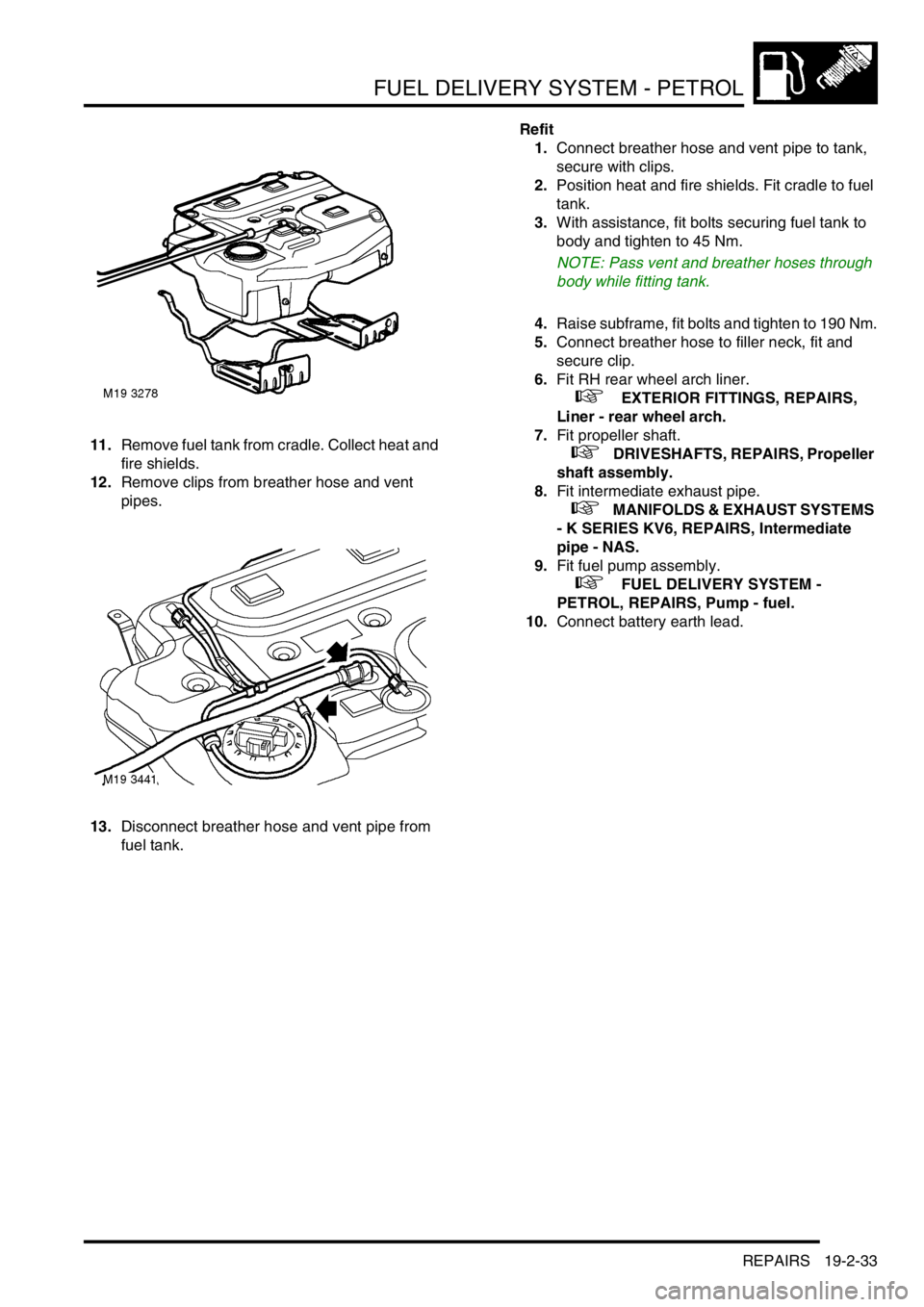

11.Remove fuel tank from cradle. Collect heat and

fire shields.

12.Remove clips from breather hose and vent

pipes.

13.Disconnect breather hose and vent pipe from

fuel tank.Refit

1.Connect breather hose and vent pipe to tank,

secure with clips.

2.Position heat and fire shields. Fit cradle to fuel

tank.

3.With assistance, fit bolts securing fuel tank to

body and tighten to 45 Nm.

NOTE: Pass vent and breather hoses through

body while fitting tank.

4.Raise subframe, fit bolts and tighten to 190 Nm.

5.Connect breather hose to filler neck, fit and

secure clip.

6.Fit RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

7.Fit propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

8.Fit intermediate exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Intermediate

pipe - NAS.

9.Fit fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

10.Connect battery earth lead.

Page 357 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-36 REPAIRS

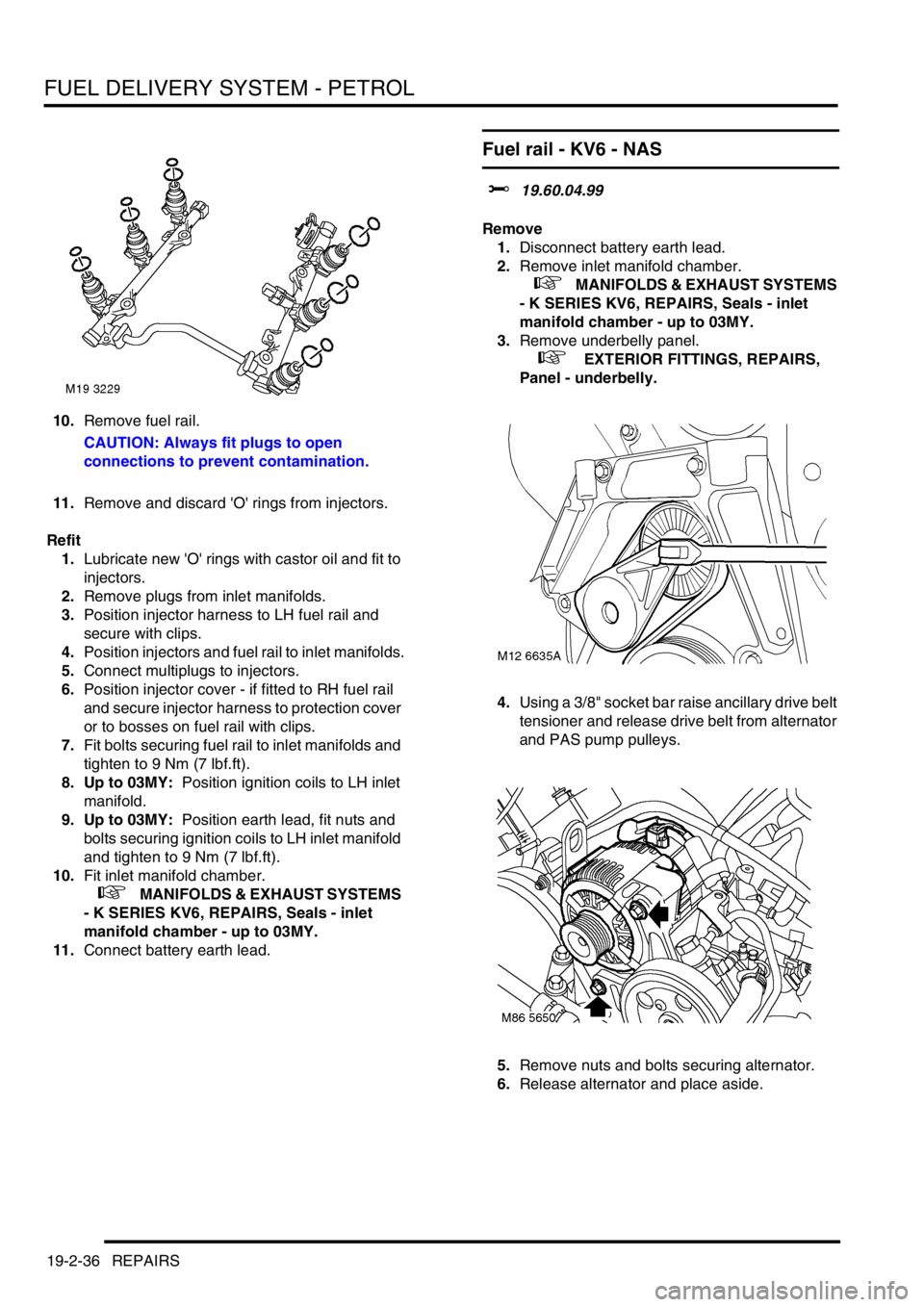

10.Remove fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.

11.Remove and discard 'O' rings from injectors.

Refit

1.Lubricate new 'O' rings with castor oil and fit to

injectors.

2.Remove plugs from inlet manifolds.

3.Position injector harness to LH fuel rail and

secure with clips.

4.Position injectors and fuel rail to inlet manifolds.

5.Connect multiplugs to injectors.

6.Position injector cover - if fitted to RH fuel rail

and secure injector harness to protection cover

or to bosses on fuel rail with clips.

7.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

8. Up to 03MY: Position ignition coils to LH inlet

manifold.

9. Up to 03MY: Position earth lead, fit nuts and

bolts securing ignition coils to LH inlet manifold

and tighten to 9 Nm (7 lbf.ft).

10.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

11.Connect battery earth lead.

Fuel rail - KV6 - NAS

$% 19.60.04.99

Remove

1.Disconnect battery earth lead.

2.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Using a 3/8" socket bar raise ancillary drive belt

tensioner and release drive belt from alternator

and PAS pump pulleys.

5.Remove nuts and bolts securing alternator.

6.Release alternator and place aside.

Page 362 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-41

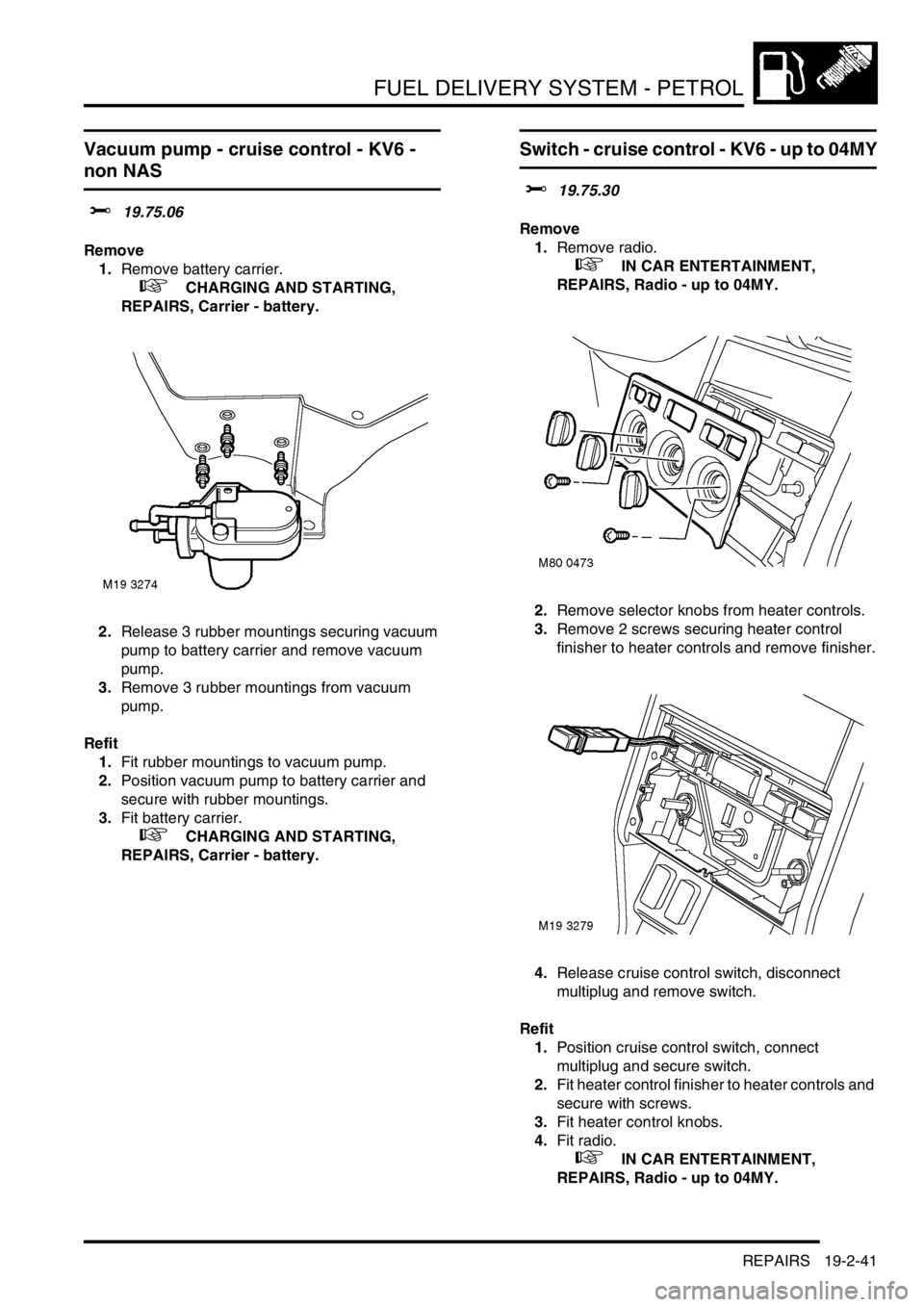

Vacuum pump - cruise control - KV6 -

non NAS

$% 19.75.06

Remove

1.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

2.Release 3 rubber mountings securing vacuum

pump to battery carrier and remove vacuum

pump.

3.Remove 3 rubber mountings from vacuum

pump.

Refit

1.Fit rubber mountings to vacuum pump.

2.Position vacuum pump to battery carrier and

secure with rubber mountings.

3.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

Switch - cruise control - KV6 - up to 04MY

$% 19.75.30

Remove

1.Remove radio.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio - up to 04MY.

2.Remove selector knobs from heater controls.

3.Remove 2 screws securing heater control

finisher to heater controls and remove finisher.

4.Release cruise control switch, disconnect

multiplug and remove switch.

Refit

1.Position cruise control switch, connect

multiplug and secure switch.

2.Fit heater control finisher to heater controls and

secure with screws.

3.Fit heater control knobs.

4.Fit radio.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio - up to 04MY.

Page 457 of 1007

AUTOMATIC GEARBOX - JATCO

44-22 REPAIRS

42.Remove 2 top bolts securing gearbox to

engine.

43.Release gearbox from 2 dowels.

44.Manoeuvre and lower gearbox to floor.

45.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

7.Position LH mounting to body, fit and tighten

bolts to 48 Nm (35 lbf.ft).

8.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

9.Disconnect lifting equipment.

10.Remove nuts and bolts securing lifting brackets

to gearbox and remove brackets.

11.Connect engine and gearbox harness

multiplugs to main harness.

12.Secure multiplugs to clips.

13.Position engine earth lead and secure with bolt.

14.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - KV6.

15.Clean throttle housing and manifold chamber

mating faces.

16.Fit new seal to inlet manifold chamber.

17.Position throttle housing to manifold chamber,

fit Torx screws and tighten to 7 Nm (7 lbf.ft).

18.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket, if fitted.

19.Connect hose to cruise control actuator.

20.Secure breather hoses to throttle housing, if

fitted.

21.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

22.Clean CKP sensor and mating face.

M44 1689

A

M44 1668

Page 569 of 1007

BRAKES

70-20 REPAIRS

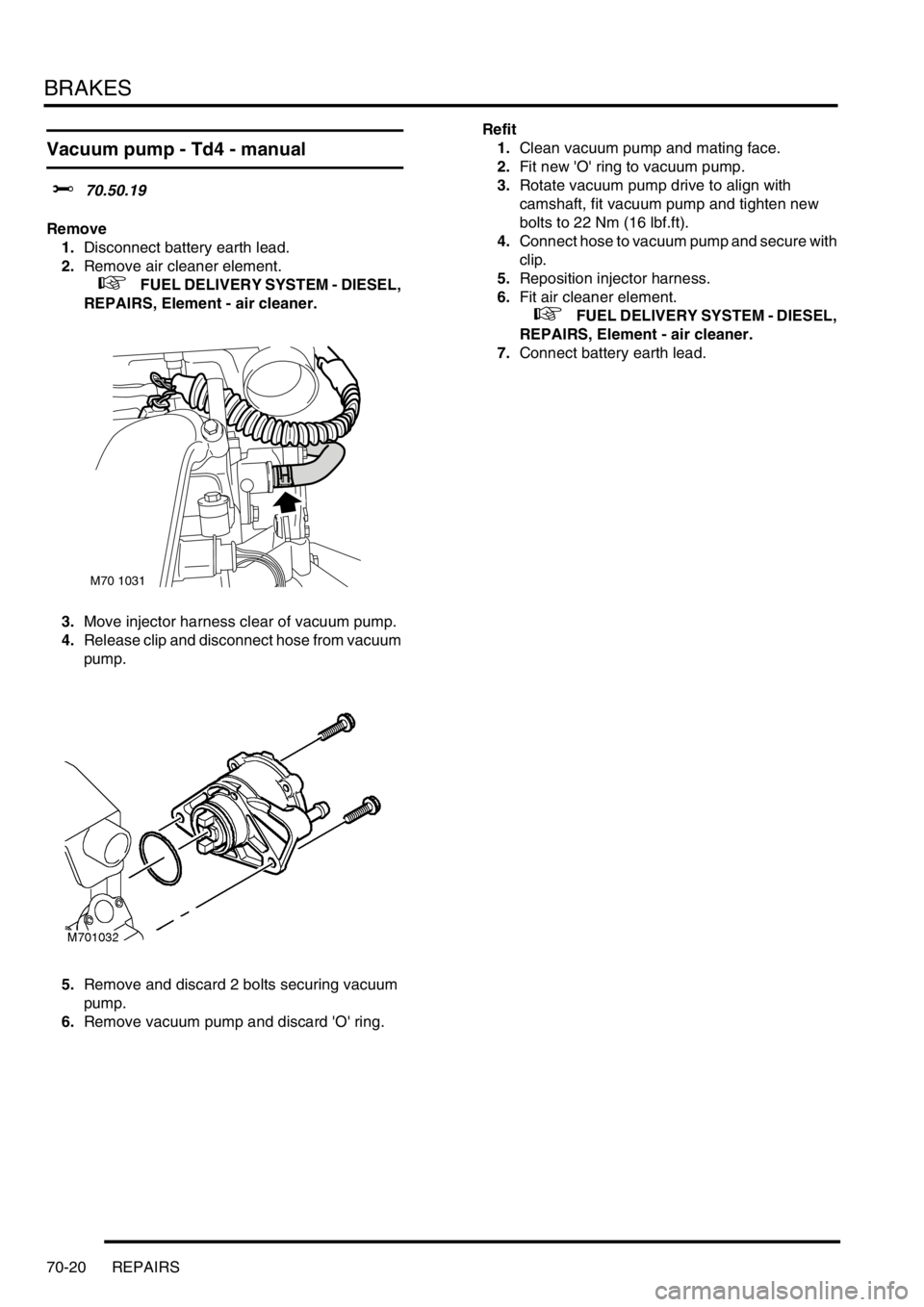

Vacuum pump - Td4 - manual

$% 70.50.19

Remove

1.Disconnect battery earth lead.

2.Remove air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Move injector harness clear of vacuum pump.

4.Release clip and disconnect hose from vacuum

pump.

5.Remove and discard 2 bolts securing vacuum

pump.

6.Remove vacuum pump and discard 'O' ring.Refit

1.Clean vacuum pump and mating face.

2.Fit new 'O' ring to vacuum pump.

3.Rotate vacuum pump drive to align with

camshaft, fit vacuum pump and tighten new

bolts to 22 Nm (16 lbf.ft).

4.Connect hose to vacuum pump and secure with

clip.

5.Reposition injector harness.

6.Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

7.Connect battery earth lead.

M70 1031

Page 570 of 1007

BRAKES

REPAIRS 70-21

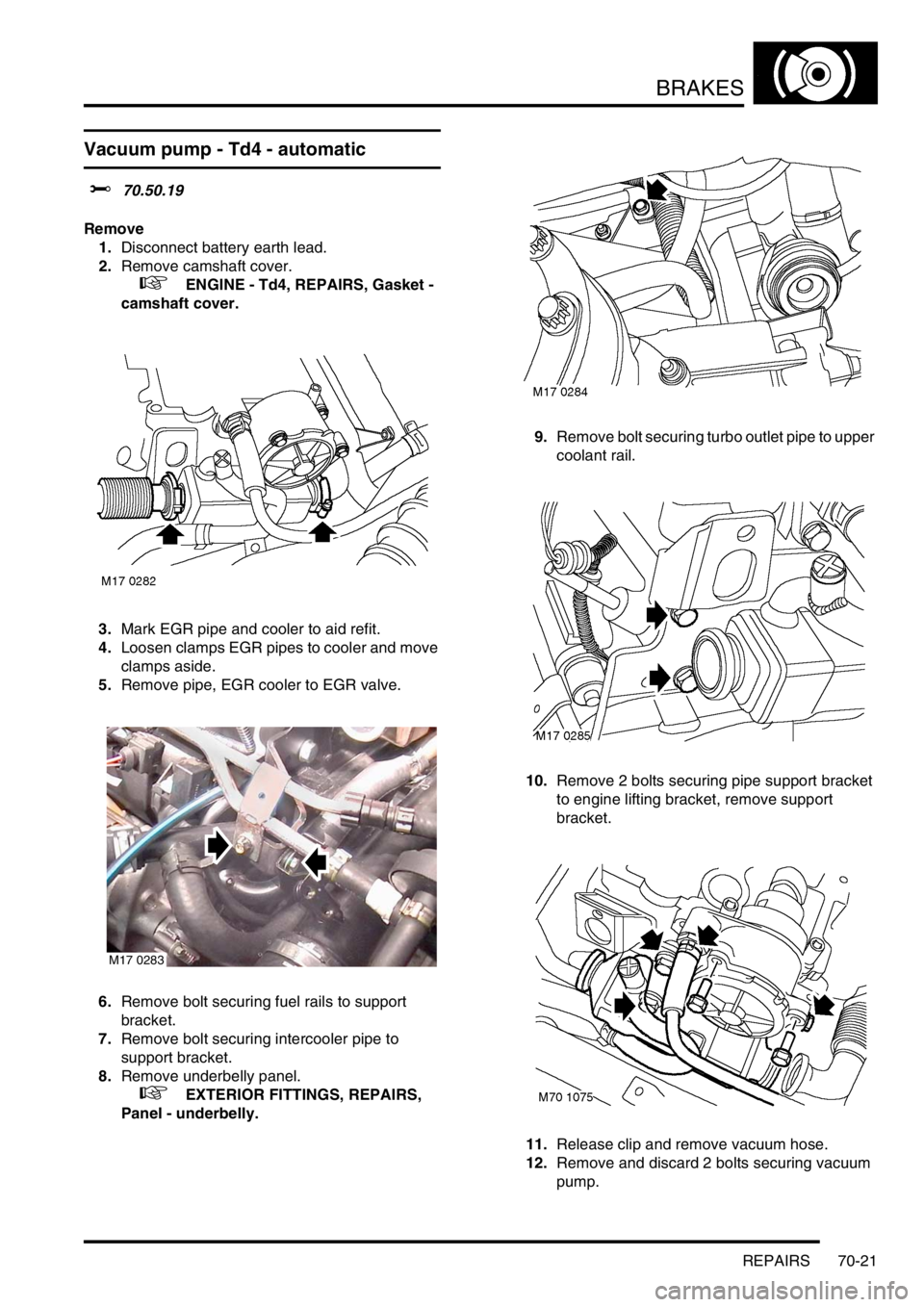

Vacuum pump - Td4 - automatic

$% 70.50.19

Remove

1.Disconnect battery earth lead.

2.Remove camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

3.Mark EGR pipe and cooler to aid refit.

4.Loosen clamps EGR pipes to cooler and move

clamps aside.

5.Remove pipe, EGR cooler to EGR valve.

6.Remove bolt securing fuel rails to support

bracket.

7.Remove bolt securing intercooler pipe to

support bracket.

8.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.9.Remove bolt securing turbo outlet pipe to upper

coolant rail.

10.Remove 2 bolts securing pipe support bracket

to engine lifting bracket, remove support

bracket.

11.Release clip and remove vacuum hose.

12.Remove and discard 2 bolts securing vacuum

pump.

M17 0283