oil LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 35 of 1007

GENERAL INFORMATION

03-4

Materials –

lkeep lids on containers of solvents;

lonly use the minimum quantity;

lconsider alternative materials;

lminimise over-spray when painting.

Gases –

luse the correct equipment for collecting

refrigerants;

ldon't burn rubbish on site.

Discharges to water

Most sites will have two systems for discharging

water: storm drains and foul drains. Storm drains

should only receive clean water, foul drains will take

dirty water.

The foul drain will accept many of the normal waste

waters such as washing water, detergents and

domestic type wastes, but oil, petrol, solvent, acids,

hydraulic oil, antifreeze and other such substances

should never be poured down the drain. If in any

doubt, speak to the local Water Company first.

Every precaution must be taken to prevent spillage of

oil, fuel, solvents etc. reaching the drains. All

handling of such materials must take place well away

from the drains and preferably in an area with a kerb

or wall around it, to prevent discharge into the drain.

If a spillage occurs, it should be soaked up

immediately. Having a spill kit available will make this

easier.

Additional precautions

Check whether the surface water drains are

connected to an oil/water separator, this could

reduce the pollution if an incident was to occur. Oil/

water separators require regular maintenance to

ensure effectiveness.

Checklist

Always adhere to the following:

Disposal –

lnever pour anything down a drain without first

checking that it is environmentally safe to do so,

and that it does not contravene any local

regulations or bye-laws;

lhave oil traps emptied regularly.

Spillage prevention –

lstore liquids in a walled area;

lmake sure the taps on liquid containers are

secure and cannot be accidentally turned on;

lprotect bulk storage tanks from vandalism by

locking the valves;

ltransfer liquids from one container to another in

an area away from open drains;

lensure lids are replaced securely on containers;

lhave spill kits available near to points of storage

and handling of liquids.Spill kits

Special materials are available to absorb a number of

different substances. They can be in granular form,

ready to use and bought in convenient containers for

storage. Disposal of used spill-absorbing material is

dealt with in the 'Waste Management' section.

Land contamination

Oils, fuels and solvents etc. can contaminate any soil

that they are allowed to contact. Such materials

should never be disposed of by pouring onto soil and

every precaution must be taken to prevent spillage

reaching soil. Waste materials stored on open

ground could also leak, or have polluting substances

washed off them that would contaminate the land.

Always store these materials in suitable skips or

other similarly robust containers.

Checklist

Always adhere to the following:

ldon't pour or spill anything onto the soil or bare

ground;

ldon't store waste materials on bare ground, see

'Spillage prevention' list.

Legal compliance

Some sites may have a discharge consent for

effluent discharge to the foul drain for a car wash etc.

It is important to know what materials are allowed in

the drain and to check the results of any monitoring

carried out by the Water Company.

Where paint spraying operations are carried out it

may be necessary to apply to the Local Authority for

an air emissions licence to operate the plant. If such

a licence is in operation, additional precautions will

be necessary to comply with the requirements, and

the results of any air quality monitoring must be

checked regularly.

Checklist

Always adhere to the following:

lknow what legal consents and licences apply to

the operations;

lcheck that the emissions and discharges

comply with legal requirements.

Page 36 of 1007

GENERAL INFORMATION

03-5

Local issues

A number of environmental issues will be of

particular concern to residents and other neighbours

close to the site. The sensitivity of these issues will

depend on the proximity of the site and the layout

and amount of activity carried on at the site.

Noise is a major concern and therefore consideration

should be given to the time spent carrying out noisy

activities and the location of those activities that can

cause excessive noise.

Car alarm testing, panel beating, hammering and

other such noisy activities should, whenever

possible, be carried out indoors with doors and

windows shut, or as far away from houses as

possible.

Running vehicle engines may be an outside activity

which could cause nuisance to neighbours because

of both noise and smell.

Be sensitive to the time of day when these activities

are carried out and minimise the time of the noisy

operation, particularly in the early morning and late

evening.

Another local concern will be the smell from the

various materials used. Using less solvent, paint and

petrol could help prevent this annoyance.

Local residents and other business users will also be

concerned about traffic congestion, noise and

exhaust fumes, be sensitive to these concerns and

try to minimise inconvenience from deliveries,

customers and servicing operations.

Checklist

Always adhere to the following:

lidentify where the neighbours who are likely to

be affected are situated;

lminimise noise, smells and traffic nuisance;

lprevent litter by putting waste in the correct

containers;

lhave waste skips emptied regularly.Use of resource

Another environmental concern is the waste of

materials and energy that can occur in day to day

activities.

Electricity for heating, lighting and compressed air

uses resources and releases pollution during its

generation.

Fuel used for heating, running cars or vans and

mobile plant is another limited resource which

consumes large amounts of energy during its

extraction and refining processes.

Water has to be cleaned, piped to site and disposed

of, all of which creates more potential pollution;

Oil, spares, paint etc., have all produced pollution in

the process of manufacture and they become a

waste disposal problem if discarded.

Checklist

Always adhere to the following:

Electricity and heating –

lkeep doors and windows closed in the winter;

lswitch off machinery or lights when not needed;

luse energy efficient heating systems;

lswitch off computers and photocopiers when

not needed.

Fuel –

ldon't run engines unnecessarily;

lthink about whether journeys are necessary and

drive to conserve fuel.

Water –

ldon't leave taps and hose pipes running;

lmend leaks quickly, don't be wasteful.

Compressed air –

ldon't leave valves open;

lmend leaks quickly;

ldon't leave the compressor running when not

needed.

Use of environmentally damaging materials –

lcheck whether a less toxic material is available.

Handling and storage of materials –

lhave the correct facilities available for handling

liquids to prevent spillage and wastage as listed

above;

lprovide suitable locations for storage to prevent

frost damage or other deterioration.

Page 37 of 1007

GENERAL INFORMATION

03-6

Waste Management

One of the major ways that pollution can be reduced

is by the careful handling, storage and disposal of all

waste materials that occur on sites. Legislation

makes it illegal to dispose of waste materials other

than to licensed waste carriers and disposal sites.

This means that it is necessary to not only know what

the waste materials are, but also to have the

necessary documentation and licenses.

Handling and storage of waste

Ensure that waste materials are not poured down the

drain or onto soils. They should be stored in such a

way as to prevent the escape of material to land,

water or air.

They must also be segregated into different types of

waste e.g. oil, metals, batteries, used vehicle

components. This will prevent any reaction between

different materials and assist in disposal.

Disposal of waste

Disposal of waste materials must only be to waste

carriers who are licensed to carry those particular

waste materials and all the necessary

documentation must be completed. The waste

carrier is responsible for ensuring that the waste is

taken to the correct disposal sites.Dispose of waste in accordance with the following

guidelines:

lFuel, hydraulic fluid, anti-freeze and oil –

keep separate and dispose of to specialist

contractor.

lRefrigerant – collect using specialist

equipment and containers, and reuse.

lDetergents – safe to pour down the foul drain

if diluted.

lPaint, thinners – keep separate and dispose of

to specialist contractor.

lComponents – send back to supplier for

refurbishment, or disassemble and reuse any

suitable parts. Dispose of the remainder in

ordinary waste.

lSmall parts – reuse any suitable parts, dispose

of the remainder in ordinary waste.

lMetals – can be sold if kept separate from

general waste.

lTyres – keep separate and dispose of to

specialist contractor.

lPackaging – compact as much as possible and

dispose of in ordinary waste.

lAsbestos-containing – keep separate and

dispose of to specialist contractor.

lOily and fuel wastes (e.g. rags, used spill kit

material) – keep separate and dispose of to

specialist contractor.

lAir filters – keep separate and dispose of to

specialist contractor.

lRubber/plastics – dispose of in ordinary

waste.

lHoses – dispose of in ordinary waste.

lBatteries – keep separate and dispose of to

specialist contractor.

lAirbags (explosives) – keep separate and

dispose of to specialist contractor.

lElectrical components – send back to

supplier for refurbishment, or disassemble and

reuse any suitable parts. Dispose of the

remainder in ordinary waste.

lElectronic components – send back to

supplier for refurbishment, or disassemble and

reuse any suitable parts. Dispose of the

remainder in ordinary waste.

lCatalysts – can be sold if kept separate from

general waste.

lUsed spill-absorbing material – keep

separate and dispose of to specialist contractor.

lOffice waste – recycle paper and toner/ink

cartridges, dispose of the remainder in ordinary

waste.

Page 38 of 1007

GENERAL INFORMATION

03-7

General fitting instructions

Precautions against damage

To avoid damage to the vehicle when carrying out

repairs, always adhere to the following:

lAlways fit wing and seat covers before

commencing work. Avoid spilling brake fluid or

battery acid on paintwork; immediately wash off

with water if this occurs.

lDisconnect the battery earth lead before starting

work, see ELECTRICAL PRECAUTIONS.

lAlways use the recommended service tool or a

satisfactory equivalent where specified.

lProtect exposed bearing surfaces, sealing

surfaces and screw threads from damage.

Component removal

Whenever possible, clean components and

surrounding area before removal.

lBlank off openings exposed by component

removal.

lImmediately seal fuel, oil or hydraulic lines when

apertures are exposed; use plastic caps or

plugs to prevent loss of fluid and ingress of dirt.

lClose open ends of oilways exposed by

component removal with tapered hardwood

plugs or conspicuous plastic plugs.

lImmediately a component is removed, place it in

a suitable container; use a separate container

for each component and its associated parts.

lClean bench and provide marking materials,

labels, containers and locking wire before

dismantling a component.

Dismantling

Observe scrupulous cleanliness when dismantling

components, particularly when brake, fuel or

hydraulic system parts are being worked on. A

particle of dirt or a cloth fragment could cause a

serious malfunction if trapped in these systems.Use the following procedures:

lBlow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

O-rings used for sealing are correctly replaced

or renewed if disturbed during the process.

lUse marking ink to identify mating parts and

ensure correct reassembly. Do not use a centre

punch or scriber to mark parts, they could

initiate cracks or distortion in marked

components.

lWire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

lWire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

lDo not discard a part due for renewal until after

comparing it with a new part to ensure that its

correct replacement has been obtained.

Cleaning components

Always use the recommended cleaning agent or

equivalent. Ensure that adequate ventilation is

provided when volatile degreasing agents are being

used. Do not use degreasing equipment for

components containing items which could be

damaged by the use of this process.

When washing under bonnet, never direct water onto

ECM, as water ingress may occur resulting in

damage to electrical components inside.

General Inspection

All components should be inspected for wear or

damage before being reassembled.

lNever inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an

incipient failure.

lWhen a component is to be checked

dimensionally against recommended values,

use the appropriate measuring equipment

(surface plates, micrometers, dial gauges etc.).

Ensure the measuring equipment is calibrated

and in good serviceable condition.

lReject a component if its dimensions are

outside the specified tolerances, or if it appears

to be damaged.

lA part may be refitted if its critical dimension is

exactly to its tolerance limit and it appears to be

in satisfactory condition.

lUse 'Plastigauge' 12 Type PG-1 for checking

bearing surface clearances.

Page 40 of 1007

GENERAL INFORMATION

03-9

Oil seals

General

Always renew oil seals which have been removed

from their working location (whether as an individual

component or as part of an assembly). NEVER use

a seal which has been improperly stored or handled,

such as hung on a hook or nail.

lCarefully examine seal before fitting to ensure

that it is clean and undamaged.

lEnsure the surface on which the new seal is to

run is free of burrs or scratches. Renew the

component if the original sealing surface cannot

be completely restored.

lProtect the seal from any surface which it has to

pass when being fitted. Use a protective sleeve

or tape to cover the relevant surface.

lCertain oil seals are coated with a protective

wax and must be fitted dry unless stated

otherwise. Where an oil seal needs to be

lubricated prior to fitment, lubricate the sealing

lips with a recommended lubricant before use to

prevent damage during initial use. On dual

lipped seals, smear the area between the lips

with grease.

lIf a seal spring is provided, ensure that it is fitted

correctly.

lPlace lip of seal towards fluid to be sealed and

slide into position on shaft. Use fitting sleeve

where possible to protect sealing lip from

damage by sharp corners, threads or splines. If

a fitting sleeve is not available, use plastic tube

or tape to prevent damage to the sealing lip.

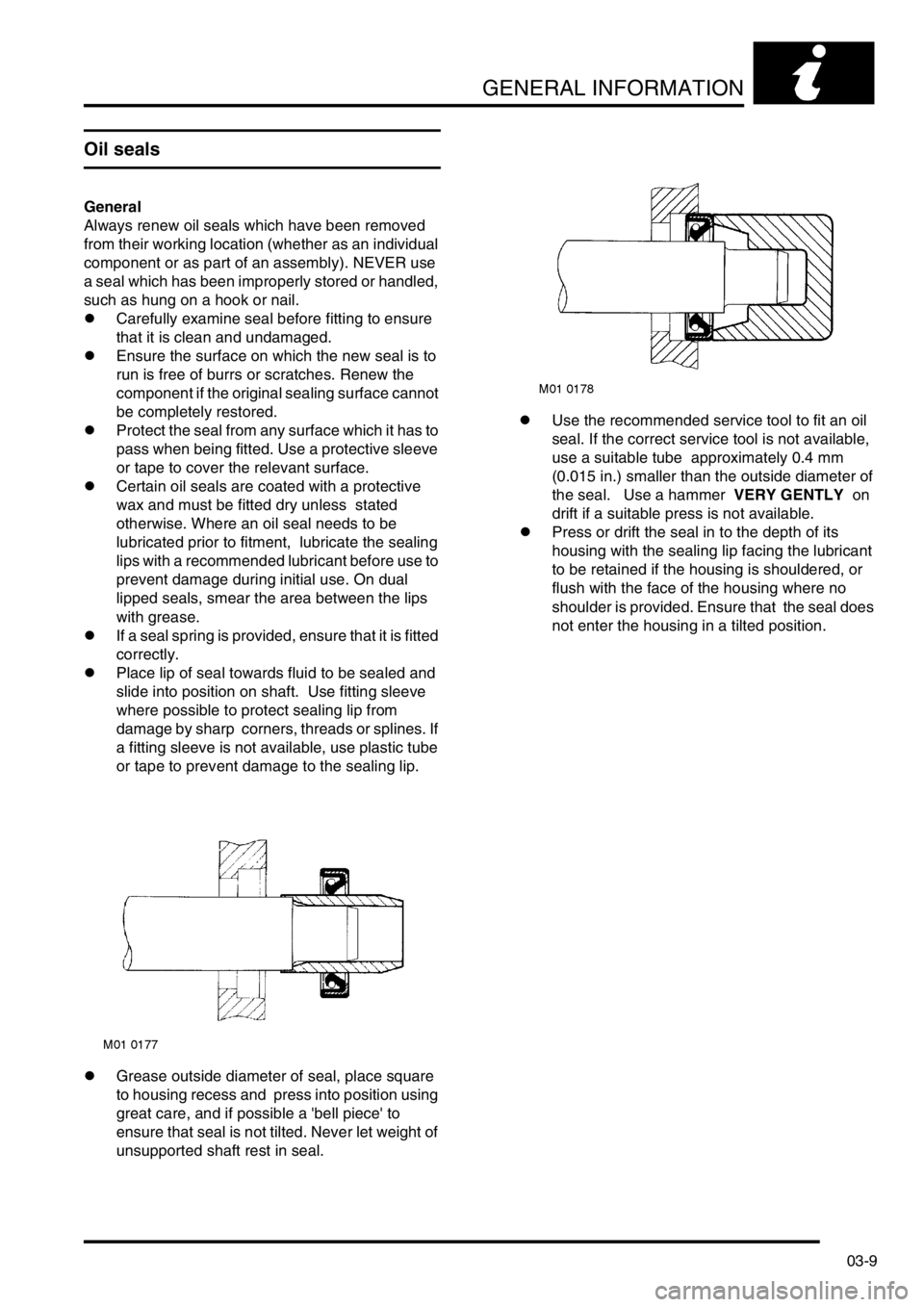

lGrease outside diameter of seal, place square

to housing recess and press into position using

great care, and if possible a 'bell piece' to

ensure that seal is not tilted. Never let weight of

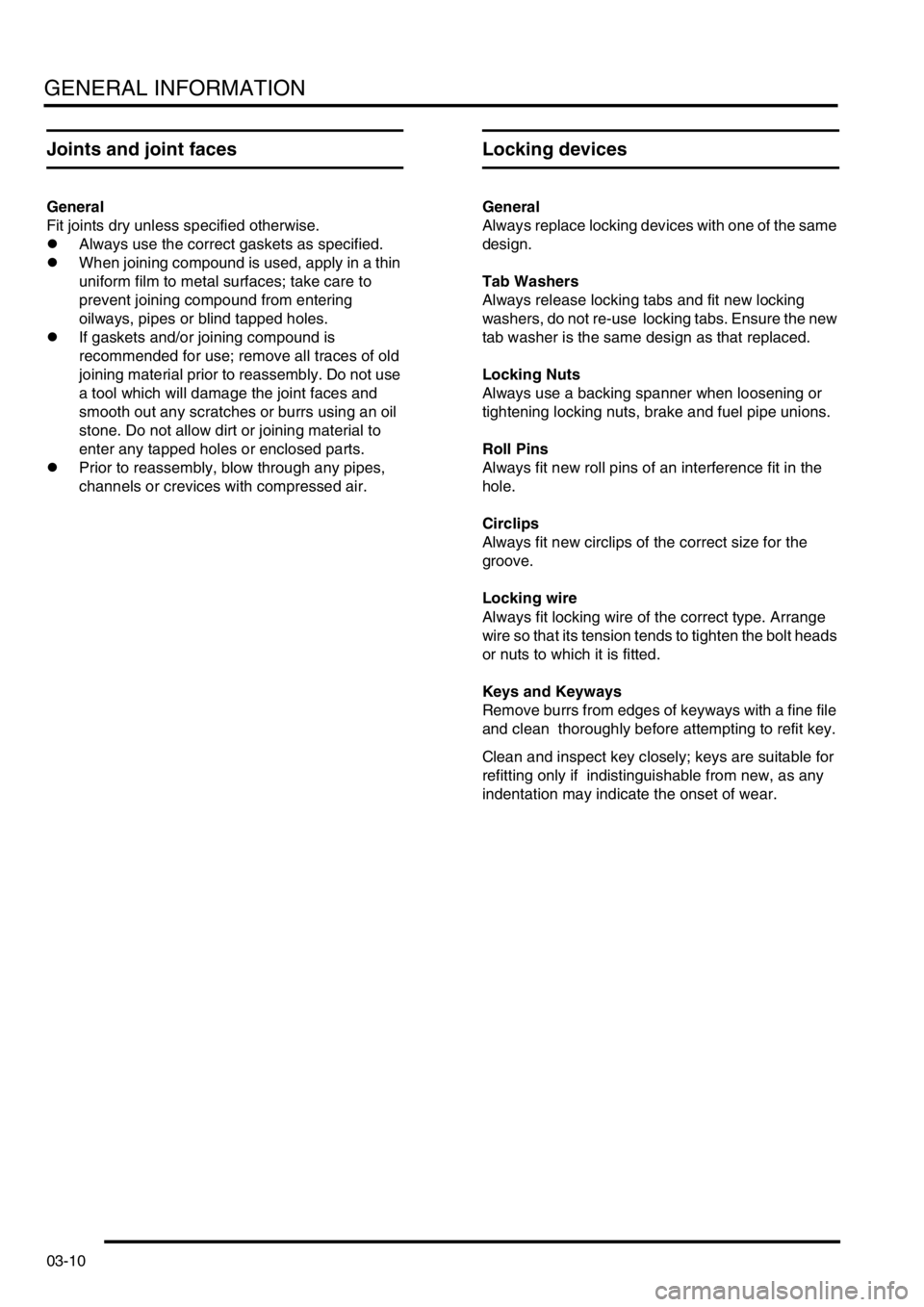

unsupported shaft rest in seal.lUse the recommended service tool to fit an oil

seal. If the correct service tool is not available,

use a suitable tube approximately 0.4 mm

(0.015 in.) smaller than the outside diameter of

the seal. Use a hammer VERY GENTLY on

drift if a suitable press is not available.

lPress or drift the seal in to the depth of its

housing with the sealing lip facing the lubricant

to be retained if the housing is shouldered, or

flush with the face of the housing where no

shoulder is provided. Ensure that the seal does

not enter the housing in a tilted position.

Page 41 of 1007

GENERAL INFORMATION

03-10

Joints and joint faces

General

Fit joints dry unless specified otherwise.

lAlways use the correct gaskets as specified.

lWhen joining compound is used, apply in a thin

uniform film to metal surfaces; take care to

prevent joining compound from entering

oilways, pipes or blind tapped holes.

lIf gaskets and/or joining compound is

recommended for use; remove all traces of old

joining material prior to reassembly. Do not use

a tool which will damage the joint faces and

smooth out any scratches or burrs using an oil

stone. Do not allow dirt or joining material to

enter any tapped holes or enclosed parts.

lPrior to reassembly, blow through any pipes,

channels or crevices with compressed air.

Locking devices

General

Always replace locking devices with one of the same

design.

Tab Washers

Always release locking tabs and fit new locking

washers, do not re-use locking tabs. Ensure the new

tab washer is the same design as that replaced.

Locking Nuts

Always use a backing spanner when loosening or

tightening locking nuts, brake and fuel pipe unions.

Roll Pins

Always fit new roll pins of an interference fit in the

hole.

Circlips

Always fit new circlips of the correct size for the

groove.

Locking wire

Always fit locking wire of the correct type. Arrange

wire so that its tension tends to tighten the bolt heads

or nuts to which it is fitted.

Keys and Keyways

Remove burrs from edges of keyways with a fine file

and clean thoroughly before attempting to refit key.

Clean and inspect key closely; keys are suitable for

refitting only if indistinguishable from new, as any

indentation may indicate the onset of wear.

Page 42 of 1007

GENERAL INFORMATION

03-11

Split pins

Always fit new split-pins of the correct size for the

hole in the bolt or stud.

Screw threads

General

Metric threads to ISO standards are used.

Damaged nuts, bolts and screws must always be

discarded. Cleaning damaged threads with a die or

tap impairs the strength and closeness of fit of the

threads and is not recommended.

Always ensure that replacement bolts are at least

equal in strength to those replaced.

Castellated nuts must not be slackened to accept a

split-pin, except in recommended cases when this

forms part of an adjustment.

Do not allow oil or grease to enter blind threaded

holes. The hydraulic action on screwing in the bolt or

stud could split the housing.

Always tighten a nut or bolt to the recommended

torque figure. Damaged or corroded threads can

affect the torque reading.

To check or re-tighten a bolt or screw to a specified

torque figure, first loosen a quarter of a turn, then

retighten to the correct torque figure.

Oil thread lightly before tightening to ensure a free

running thread, except in the case of threads treated

with sealant/lubricant, and self-locking nuts.

Page 43 of 1007

GENERAL INFORMATION

03-12

Bolt identification

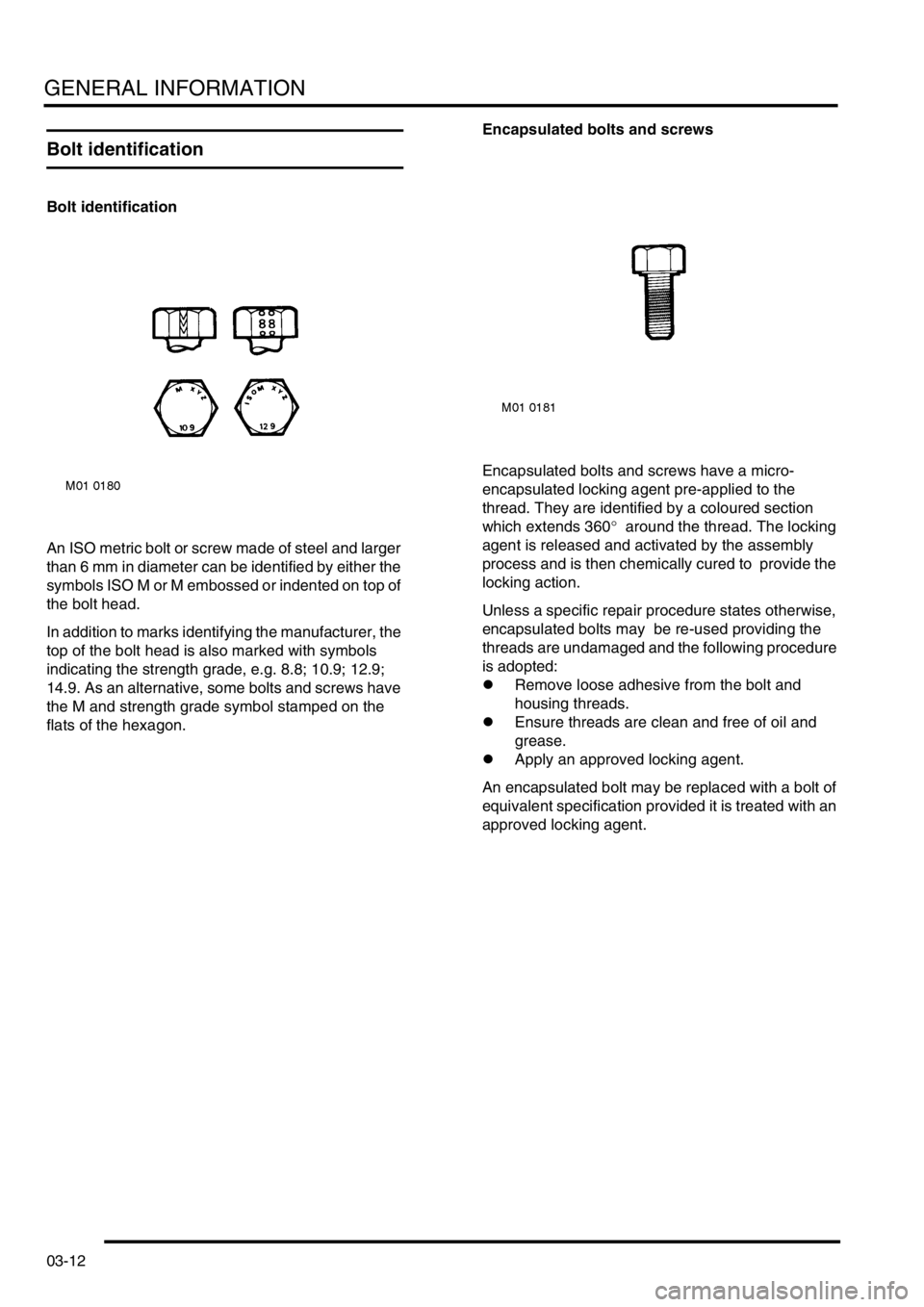

Bolt identification

An ISO metric bolt or screw made of steel and larger

than 6 mm in diameter can be identified by either the

symbols ISO M or M embossed or indented on top of

the bolt head.

In addition to marks identifying the manufacturer, the

top of the bolt head is also marked with symbols

indicating the strength grade, e.g. 8.8; 10.9; 12.9;

14.9. As an alternative, some bolts and screws have

the M and strength grade symbol stamped on the

flats of the hexagon.Encapsulated bolts and screws

Encapsulated bolts and screws have a micro-

encapsulated locking agent pre-applied to the

thread. They are identified by a coloured section

which extends 360° around the thread. The locking

agent is released and activated by the assembly

process and is then chemically cured to provide the

locking action.

Unless a specific repair procedure states otherwise,

encapsulated bolts may be re-used providing the

threads are undamaged and the following procedure

is adopted:

lRemove loose adhesive from the bolt and

housing threads.

lEnsure threads are clean and free of oil and

grease.

lApply an approved locking agent.

An encapsulated bolt may be replaced with a bolt of

equivalent specification provided it is treated with an

approved locking agent.

Page 50 of 1007

GENERAL INFORMATION

03-19

Electrical precautions

General

The following guidelines are intended to ensure the

safety of the operator and ensure the prevention of

damage to the electrical and electronic components

fitted to the vehicle. Where necessary, specific

precautions are detailed in the individual procedures

of this manual.

Equipment

Prior to commencing any test procedure on the

vehicle, ensure that the relevant test equipment is

working correctly and any harness or connectors are

in good condition. It is particularly important to check

the condition of the lead and plugs of mains operated

equipment.

Polarity

Never reverse connect the vehicle battery and

always ensure the correct polarity when connecting

test equipment.

High Voltage Circuits

Whenever disconnecting live ht circuits, always use

insulated pliers and never allow the open end of the

ht lead to contact other components, particularly

ECU's.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, high

voltage spikes can occur on these terminals.

Connectors and harnesses

The engine compartment of a vehicle is a particularly

hostile environment for electrical components and

connectors:

lAlways ensure electrically related items are dry

and oil free before disconnecting and

connecting test equipment.

lEnsure disconnected multiplugs and sensors

are protected from being contaminated with oil,

coolant or other solutions. Contamination could

impair performance or result in catastrophic

failure.

lNever force connectors apart using tools to

prise apart or by pulling on the wiring harness.

lAlways ensure locking tabs are disengaged

before disconnection, and match orientation to

enable correct reconnection.

lEnsure that any protection (covers, insulation

etc.) is replaced if disturbed.Having confirmed a component to be faulty:

lSwitch off the ignition and disconnect the

battery.

lRemove the component and support the

disconnected harness.

lWhen replacing the component, keep oily hands

away from electrical connection areas and push

connectors home until any locking tabs fully

engage.

Battery disconnection

Before disconnecting the battery, disable the alarm

system and switch off all electrical equipment. If the

radio is to be serviced, ensure the security code has

been deactivated.

CAUTION: To prevent damage to electrical

components, always disconnect the battery

when working on the vehicle's electrical system.

The ground lead must be disconnected first and

reconnected last.

CAUTION: Always ensure that battery leads are

routed correctly and are not close to any

potential chafing points.

Battery charging

Only recharge the battery with it removed from the

vehicle. Always ensure any battery charging area is

well ventilated and that every precaution is taken to

avoid naked flames and sparks.

Ignition system safety precautions

The vehicle's ignition system produces high voltages

and the following precautions should be observed

before carrying out any work on the system:

WARNING: Before commencing work on an

ignition system, ensure all high tension

terminals, adapters and diagnostic equipment

are adequately insulated and shielded to prevent

accidental personal contacts and minimise the

risk of shock. Wearers of surgically implanted

pacemaker devices should not be in close

proximity of ignition circuits or diagnostic

equipment.

Page 52 of 1007

GENERAL INFORMATION

03-21

It should be noted that these precautions are not

restricted to operations performed when servicing

the SRS system, the same care should be exercised

when working on ancillary systems and components

located in the vicinity of SRS components; these

include but are not limited to:

lSteering system – steering wheel airbag,

rotary coupler.

lFront fascia – passenger front airbag (where

fitted); SRS DCU behind centre console, on

transmission tunnel under the HeVAC system.

lFront seats – seat belt pre-tensioners, integral

with seat belt buckle assembly.

lElectrical system – SRS harnesses, link leads

and connectors.

Making the SRS system safe

Before working on or in the vicinity of SRS

components, ensure the system is rendered safe by

performing the following procedures:

lRemove the ignition key from the ignition switch.

lDisconnect both battery leads, earth lead first.

lWait 10 minutes for the SRS DCU back-up

power circuit to discharge.

The SRS system uses energy reserve capacitors

that keep the system active in the event of electrical

supply failure under crash conditions. It is necessary

to allow the capacitor sufficient time to discharge (10

minutes) in order to avoid the risk of accidental

deployment.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.Installation

In order to assure system integrity, it is essential that

the SRS system is regularly checked and maintained

so that it is ready for effective operation in the event

of a collision. Carefully inspect SRS components

before installation. Do not install a part that shows

signs of being dropped or improperly handled, such

as dents, cracks or deformation.

WARNING: The integrity of SRS system

components is critical for safety reasons. Ensure

the following precautions are always adhered to:

lNever install used SRS components from

another vehicle or attempt to repair an SRS

component.

lWhen repairing an SRS system only use

genuine new parts.

lNever apply electrical power to an SRS

component unless instructed to do so as

part of an approved test procedure.

lSpecial Torx bolts are necessary for

installing the airbag module — do not use

other bolts. Ensure bolts are tightened to the

correct torque.

lAlways use new fixings when replacing an

SRS component.

lEnsure the SRS Diagnostic Control Unit

(DCU) is always installed correctly. There

must not be any gap between the DCU and

the bracket to which it is mounted. An

incorrectly mounted DCU could cause the

system to malfunction.

CAUTION: Ensure SRS components are not

contaminated with oil, grease, detergent or

water.

Ensure that SRS component fixings are correctly

positioned and torqued during service and repair.

CAUTION: Torque wrenches should be regularly

checked for accuracy to ensure that all fixings

are tightened to the correct torque.

If you suspect an airbag assembly could be

defective, install a new unit and dispose of the old

unit. Manually deploy the old unit before disposal.