washer fluid LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 169 of 1007

MAINTENANCE

10-22 MAINTENANCE

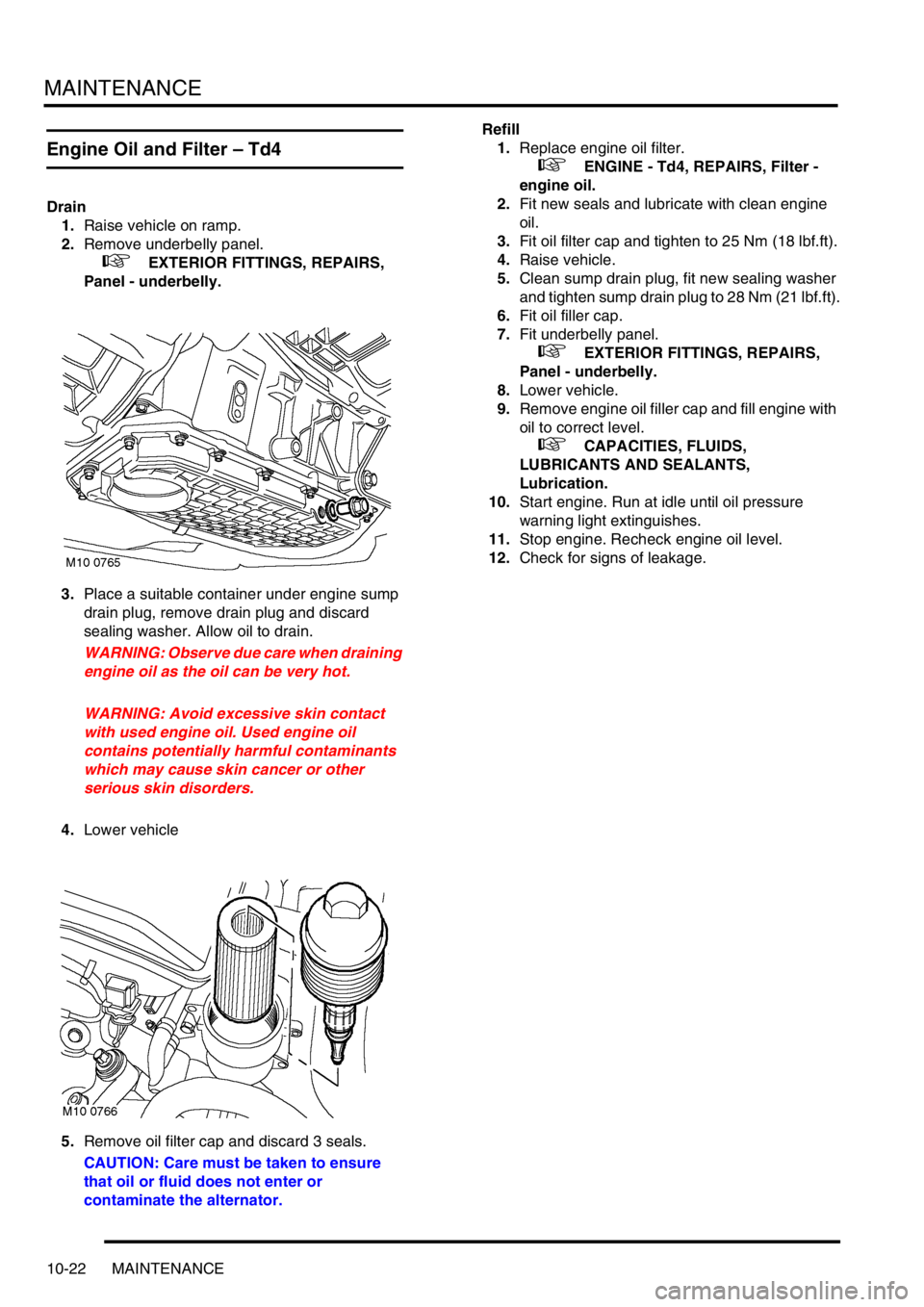

Engine Oil and Filter – Td4

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove drain plug and discard

sealing washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Lower vehicle

5.Remove oil filter cap and discard 3 seals.

CAUTION: Care must be taken to ensure

that oil or fluid does not enter or

contaminate the alternator.Refill

1.Replace engine oil filter.

+ ENGINE - Td4, REPAIRS, Filter -

engine oil.

2.Fit new seals and lubricate with clean engine

oil.

3.Fit oil filter cap and tighten to 25 Nm (18 lbf.ft).

4.Raise vehicle.

5.Clean sump drain plug, fit new sealing washer

and tighten sump drain plug to 28 Nm (21 lbf.ft).

6.Fit oil filler cap.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Lower vehicle.

9.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

10.Start engine. Run at idle until oil pressure

warning light extinguishes.

11.Stop engine. Recheck engine oil level.

12.Check for signs of leakage.

Page 170 of 1007

MAINTENANCE

MAINTENANCE 10-23

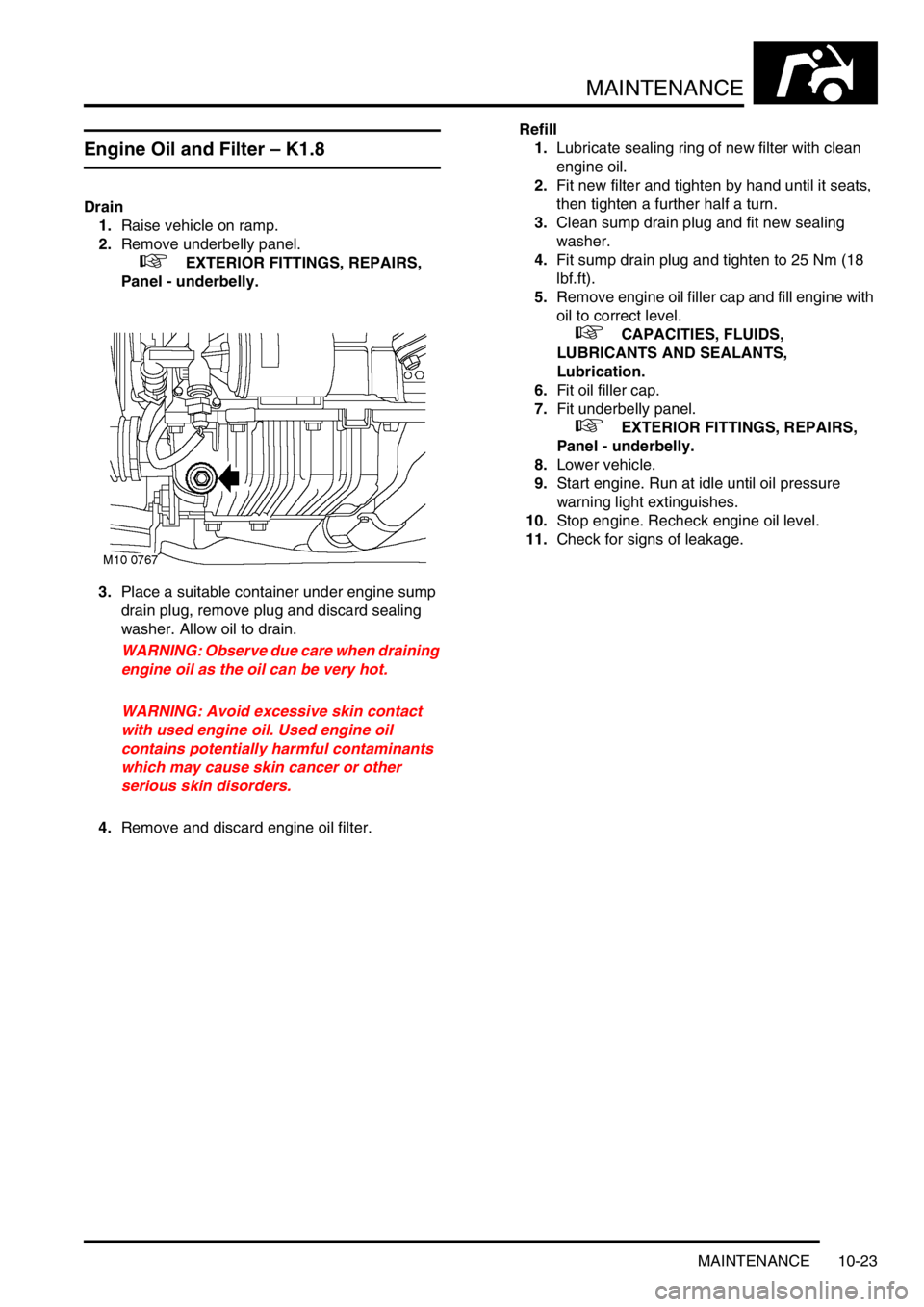

Engine Oil and Filter – K1.8

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove plug and discard sealing

washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Remove and discard engine oil filter.Refill

1.Lubricate sealing ring of new filter with clean

engine oil.

2.Fit new filter and tighten by hand until it seats,

then tighten a further half a turn.

3.Clean sump drain plug and fit new sealing

washer.

4.Fit sump drain plug and tighten to 25 Nm (18

lbf.ft).

5.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6.Fit oil filler cap.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Lower vehicle.

9.Start engine. Run at idle until oil pressure

warning light extinguishes.

10.Stop engine. Recheck engine oil level.

11.Check for signs of leakage.

Page 171 of 1007

MAINTENANCE

10-24 MAINTENANCE

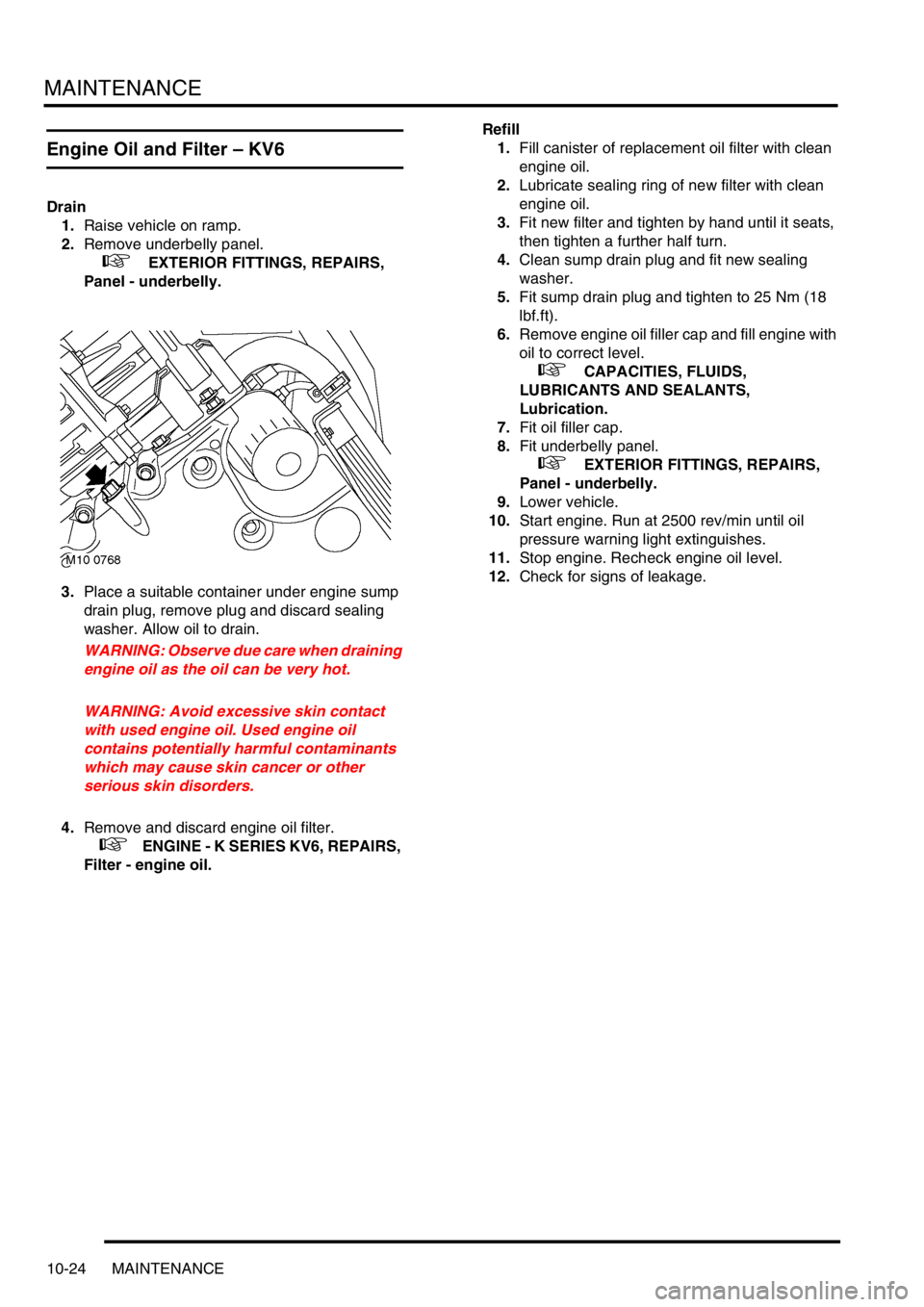

Engine Oil and Filter – KV6

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove plug and discard sealing

washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Remove and discard engine oil filter.

+ ENGINE - K SERIES KV6, REPAIRS,

Filter - engine oil.Refill

1.Fill canister of replacement oil filter with clean

engine oil.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit new filter and tighten by hand until it seats,

then tighten a further half turn.

4.Clean sump drain plug and fit new sealing

washer.

5.Fit sump drain plug and tighten to 25 Nm (18

lbf.ft).

6.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

7.Fit oil filler cap.

8.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

9.Lower vehicle.

10.Start engine. Run at 2500 rev/min until oil

pressure warning light extinguishes.

11.Stop engine. Recheck engine oil level.

12.Check for signs of leakage.

Page 404 of 1007

INTERMEDIATE REDUCTION DRIVE

ADJUSTMENTS 41-1

INTERMEDIATE RE DUCTION DRIVE ADJUST ME NTS

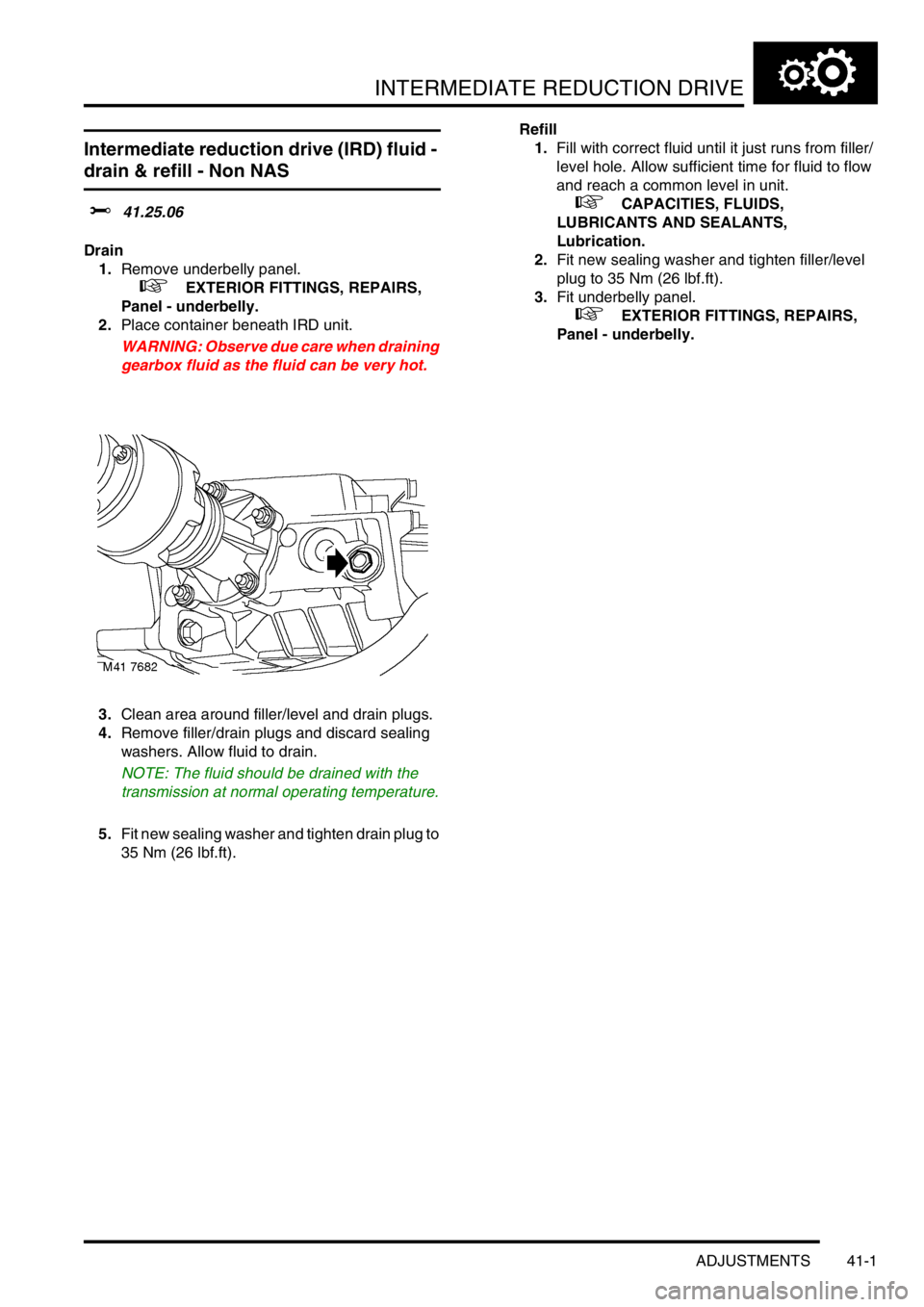

Intermediate reduction drive (IRD) fluid -

drain & refill - Non NAS

$% 41.25.06

Drain

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Place container beneath IRD unit.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Clean area around filler/level and drain plugs.

4.Remove filler/drain plugs and discard sealing

washers. Allow fluid to drain.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

5.Fit new sealing washer and tighten drain plug to

35 Nm (26 lbf.ft).Refill

1.Fill with correct fluid until it just runs from filler/

level hole. Allow sufficient time for fluid to flow

and reach a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

2.Fit new sealing washer and tighten filler/level

plug to 35 Nm (26 lbf.ft).

3.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Page 405 of 1007

INTERMEDIATE REDUCTION DRIVE

41-2 ADJUSTMENTS

Intermediate reduction drive (IRD)

lubrication system - drain & refill - NAS

$% 41.25.06

Drain

1.Remove underbelly panel

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Place container beneath IRD unit.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

3.Clean area around filler/level and drain plugs.

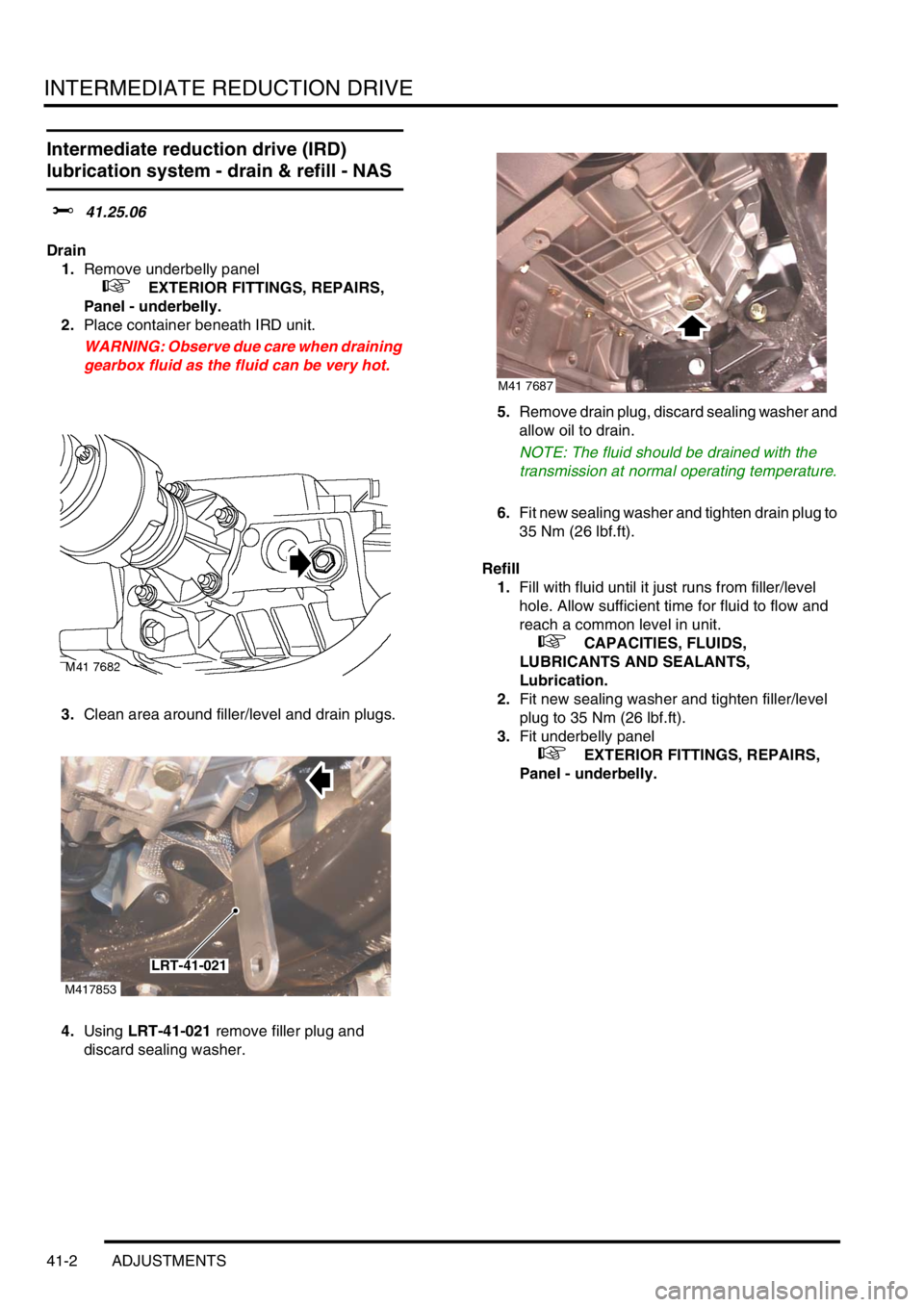

4.Using LRT-41-021 remove filler plug and

discard sealing washer.5.Remove drain plug, discard sealing washer and

allow oil to drain.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

6.Fit new sealing washer and tighten drain plug to

35 Nm (26 lbf.ft).

Refill

1.Fill with fluid until it just runs from filler/level

hole. Allow sufficient time for fluid to flow and

reach a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

2.Fit new sealing washer and tighten filler/level

plug to 35 Nm (26 lbf.ft).

3.Fit underbelly panel

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M417853

LRT-41-021

M41 7687

Page 429 of 1007

INTERMEDIATE REDUCTION DRIVE

41-26 REPAIRS

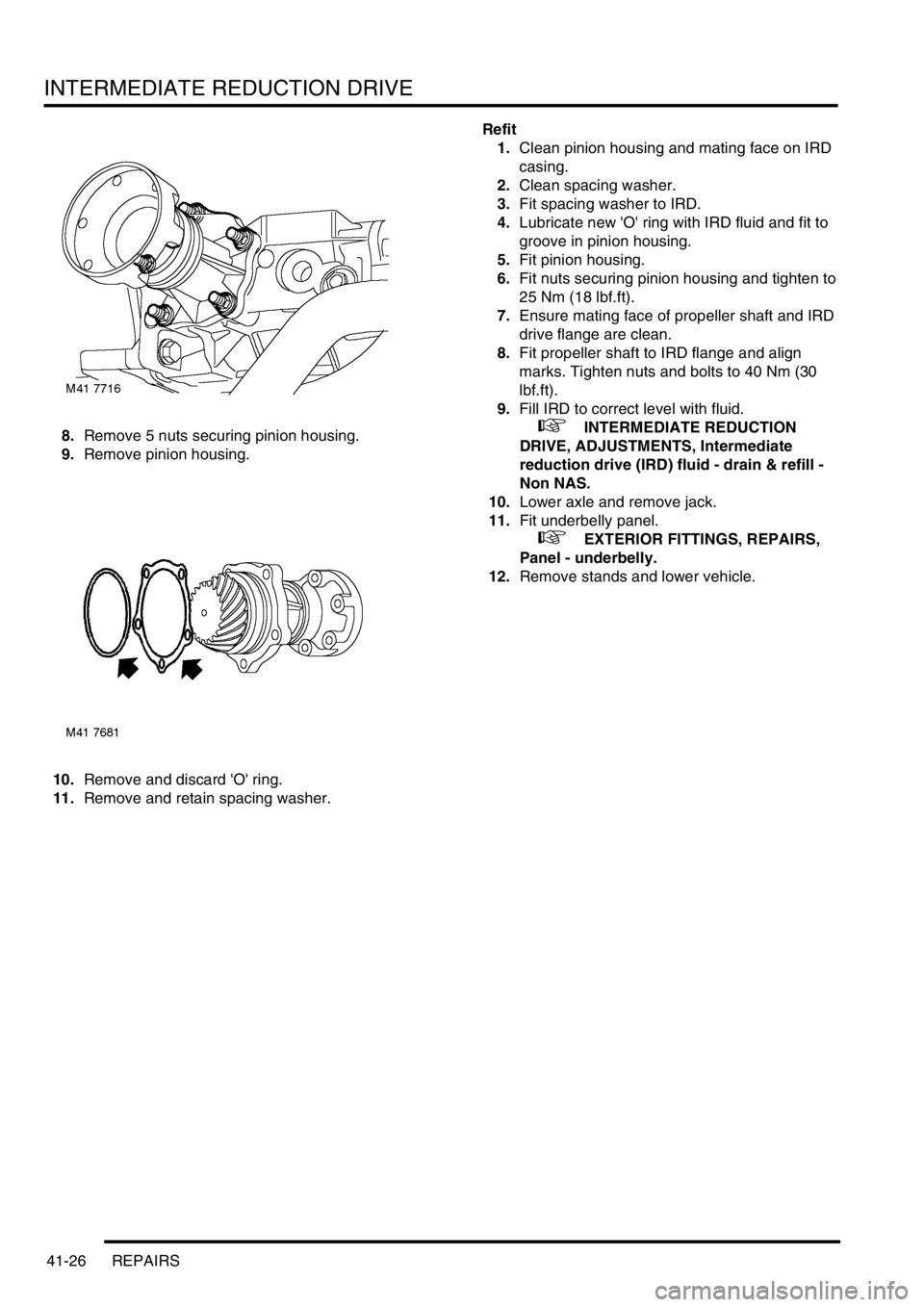

8.Remove 5 nuts securing pinion housing.

9.Remove pinion housing.

10.Remove and discard 'O' ring.

11.Remove and retain spacing washer.Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit nuts securing pinion housing and tighten to

25 Nm (18 lbf.ft).

7.Ensure mating face of propeller shaft and IRD

drive flange are clean.

8.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

9.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

10.Lower axle and remove jack.

11.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

12.Remove stands and lower vehicle.

Page 430 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-27

Seal - pinion gear housing - K1.8

$% 41.29.11

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

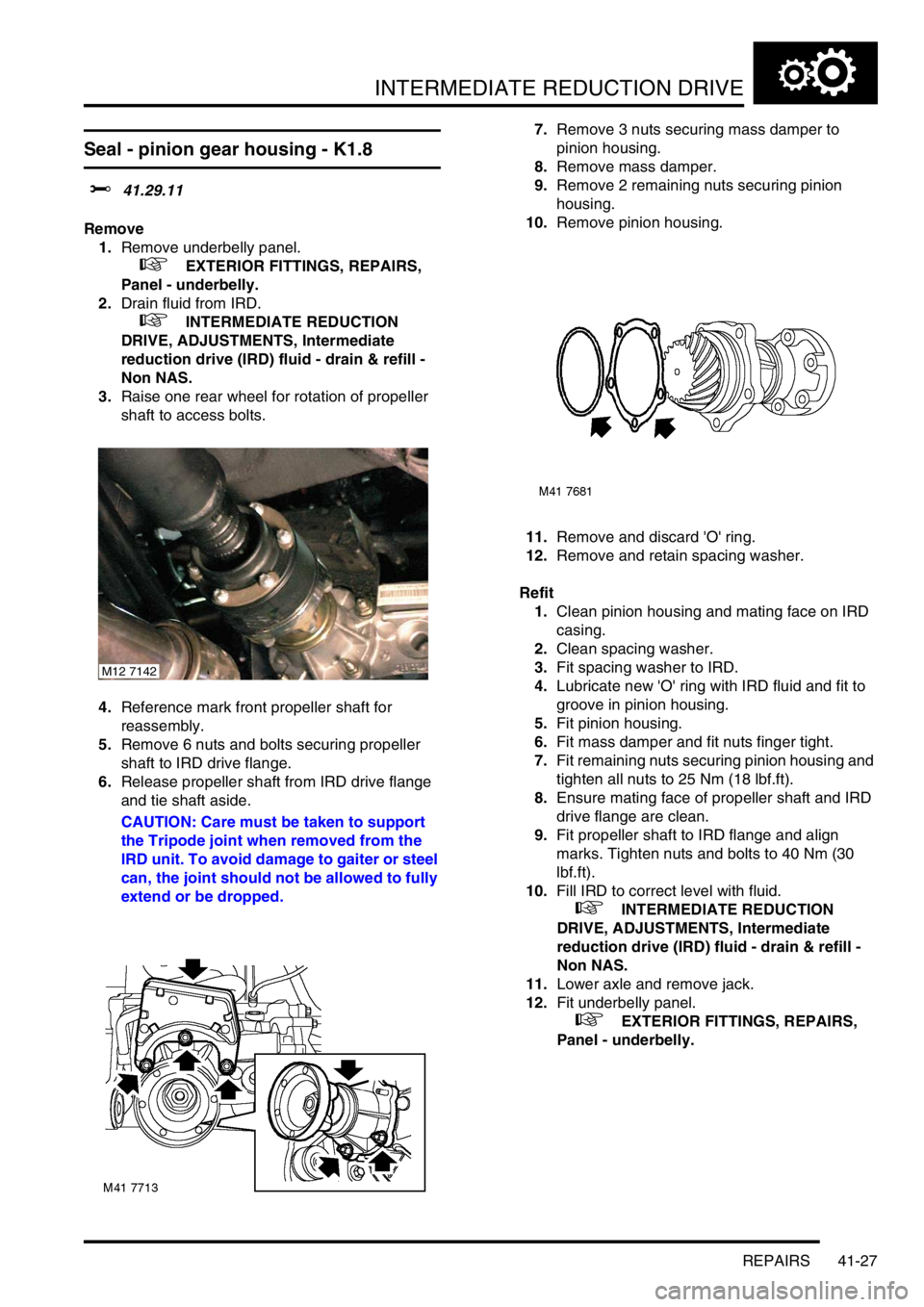

3.Raise one rear wheel for rotation of propeller

shaft to access bolts.

4.Reference mark front propeller shaft for

reassembly.

5.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

6.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.7.Remove 3 nuts securing mass damper to

pinion housing.

8.Remove mass damper.

9.Remove 2 remaining nuts securing pinion

housing.

10.Remove pinion housing.

11.Remove and discard 'O' ring.

12.Remove and retain spacing washer.

Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit mass damper and fit nuts finger tight.

7.Fit remaining nuts securing pinion housing and

tighten all nuts to 25 Nm (18 lbf.ft).

8.Ensure mating face of propeller shaft and IRD

drive flange are clean.

9.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

10.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

11.Lower axle and remove jack.

12.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M12 7142

Page 432 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-29

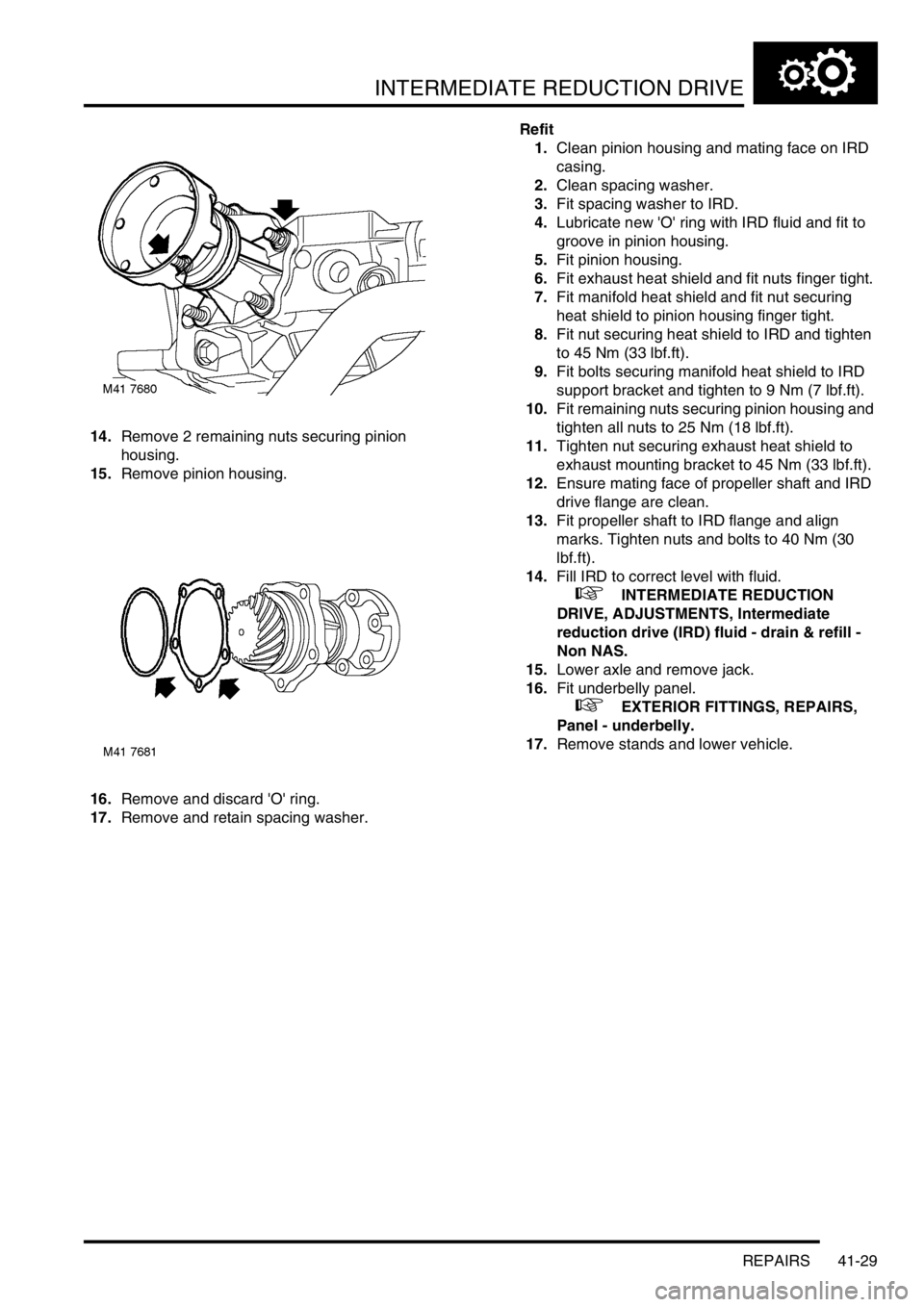

14.Remove 2 remaining nuts securing pinion

housing.

15.Remove pinion housing.

16.Remove and discard 'O' ring.

17.Remove and retain spacing washer.Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit exhaust heat shield and fit nuts finger tight.

7.Fit manifold heat shield and fit nut securing

heat shield to pinion housing finger tight.

8.Fit nut securing heat shield to IRD and tighten

to 45 Nm (33 lbf.ft).

9.Fit bolts securing manifold heat shield to IRD

support bracket and tighten to 9 Nm (7 lbf.ft).

10.Fit remaining nuts securing pinion housing and

tighten all nuts to 25 Nm (18 lbf.ft).

11.Tighten nut securing exhaust heat shield to

exhaust mounting bracket to 45 Nm (33 lbf.ft).

12.Ensure mating face of propeller shaft and IRD

drive flange are clean.

13.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

14.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

15.Lower axle and remove jack.

16.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

17.Remove stands and lower vehicle.

Page 433 of 1007

INTERMEDIATE REDUCTION DRIVE

41-30 REPAIRS

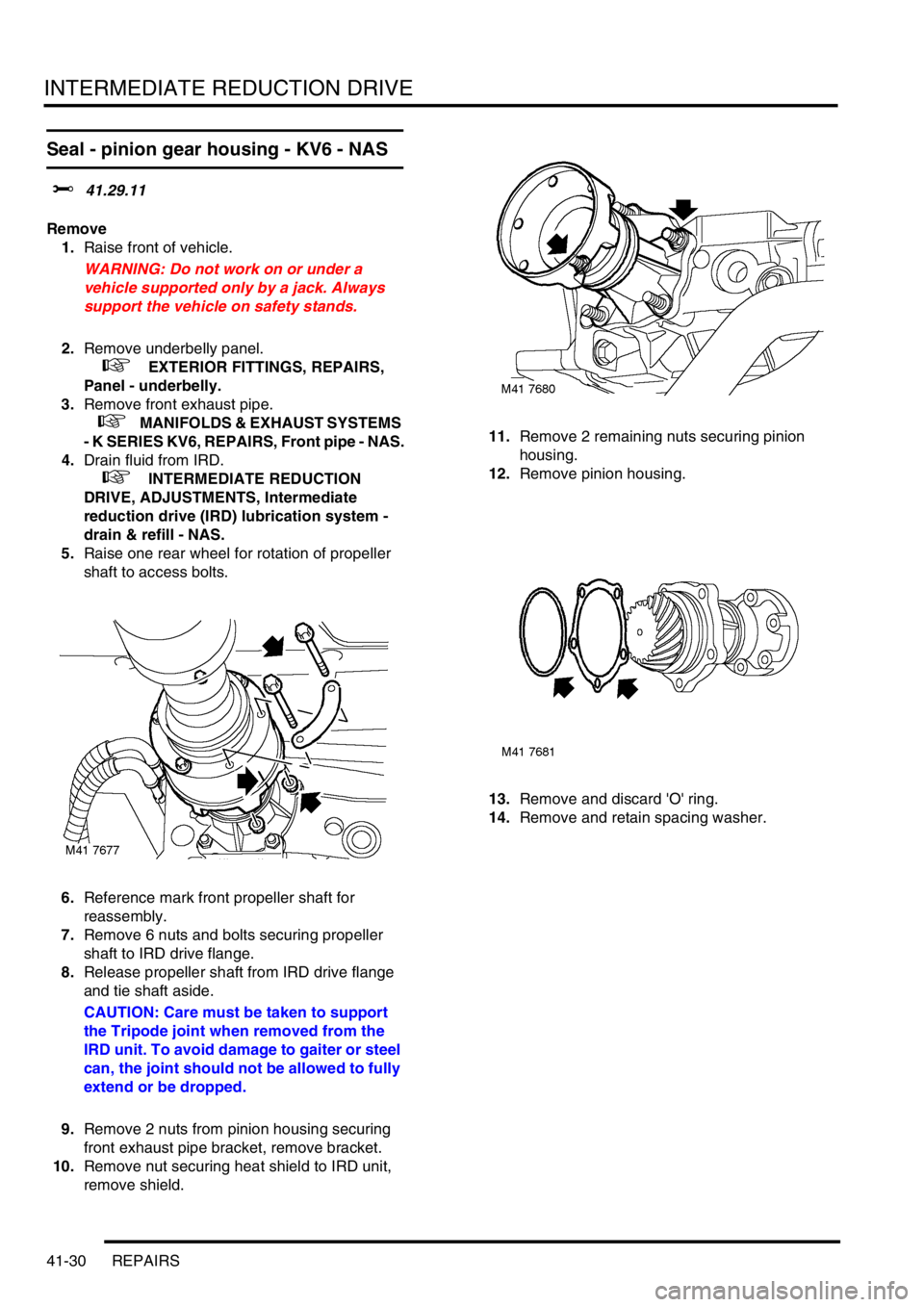

Seal - pinion gear housing - KV6 - NAS

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Remove front exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

4.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

5.Raise one rear wheel for rotation of propeller

shaft to access bolts.

6.Reference mark front propeller shaft for

reassembly.

7.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

8.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

9.Remove 2 nuts from pinion housing securing

front exhaust pipe bracket, remove bracket.

10.Remove nut securing heat shield to IRD unit,

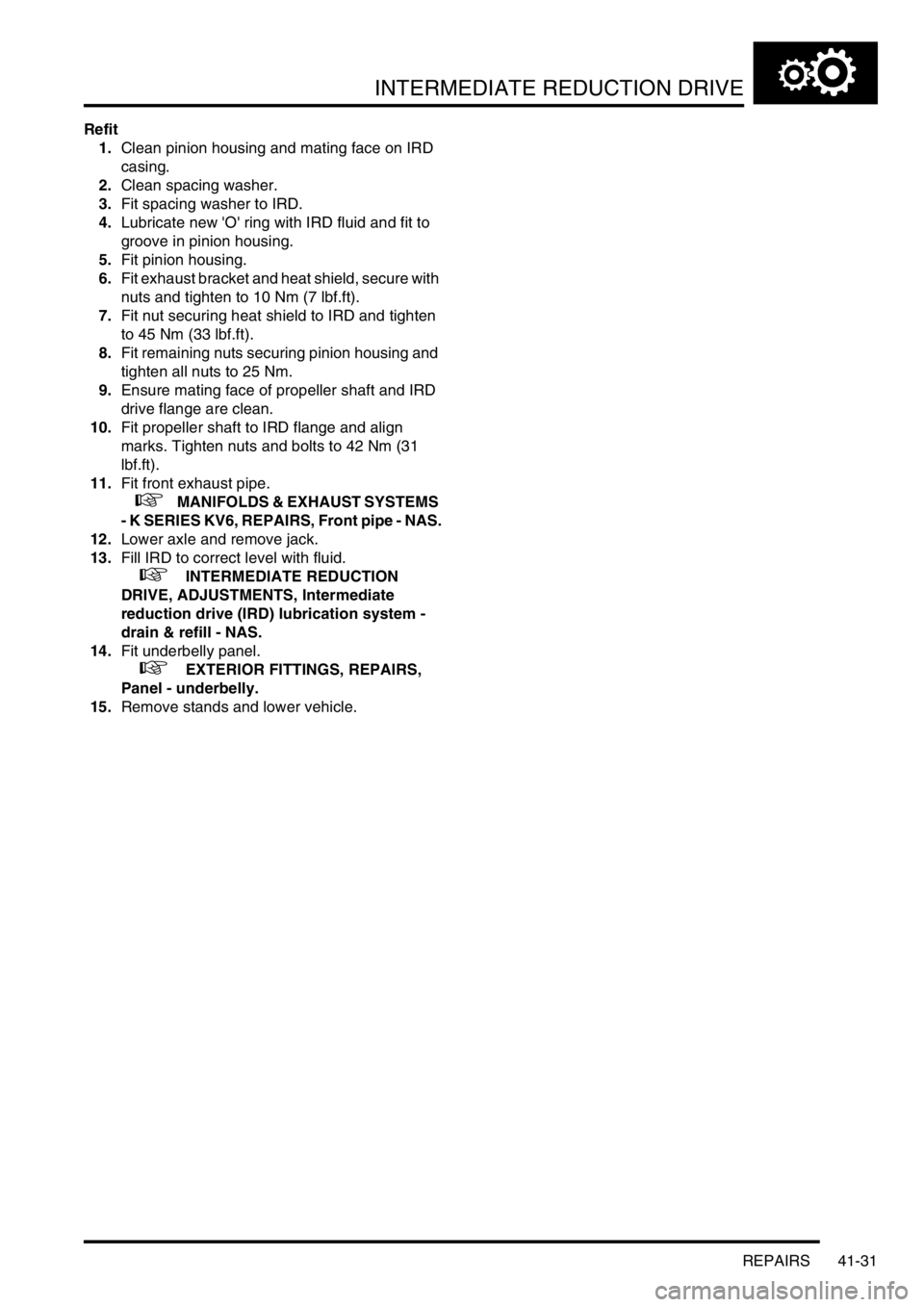

remove shield.11.Remove 2 remaining nuts securing pinion

housing.

12.Remove pinion housing.

13.Remove and discard 'O' ring.

14.Remove and retain spacing washer.

Page 434 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-31

Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit exhaust bracket and heat shield, secure with

nuts and tighten to 10 Nm (7 lbf.ft).

7.Fit nut securing heat shield to IRD and tighten

to 45 Nm (33 lbf.ft).

8.Fit remaining nuts securing pinion housing and

tighten all nuts to 25 Nm.

9.Ensure mating face of propeller shaft and IRD

drive flange are clean.

10.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

11.Fit front exhaust pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

12.Lower axle and remove jack.

13.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

14.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

15.Remove stands and lower vehicle.