washer fluid LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 437 of 1007

AUTOMATIC GEARBOX - JATCO

44-2 ADJUSTMENTS

Gearbox fluid - drain & refill

$% 44.24.02

Drain

1.Position vehicle on ramp.

WARNING: Observe due care when draining

gearbox fluid as the fluid can be very hot.

2.Apply handbrake and position chocks under

front and rear wheels.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Position container under gearbox.

NOTE: The fluid should be drained with the

transmission at normal operating temperature.

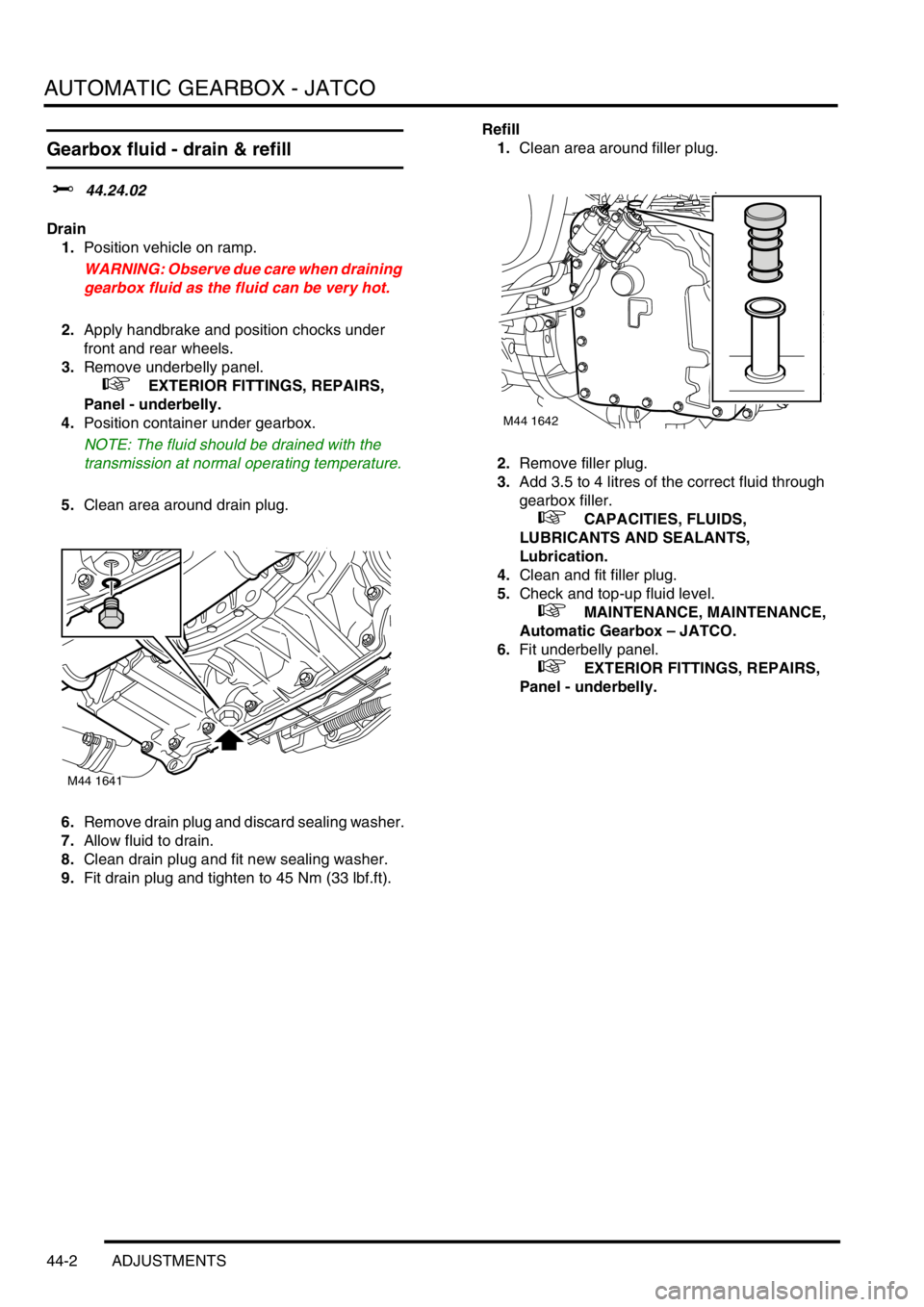

5.Clean area around drain plug.

6.Remove drain plug and discard sealing washer.

7.Allow fluid to drain.

8.Clean drain plug and fit new sealing washer.

9.Fit drain plug and tighten to 45 Nm (33 lbf.ft).Refill

1.Clean area around filler plug.

2.Remove filler plug.

3.Add 3.5 to 4 litres of the correct fluid through

gearbox filler.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

4.Clean and fit filler plug.

5.Check and top-up fluid level.

+ MAINTENANCE, MAINTENANCE,

Automatic Gearbox – JATCO.

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M44 1641

M44 1642

Page 499 of 1007

STEERING

57-6 REPAIRS

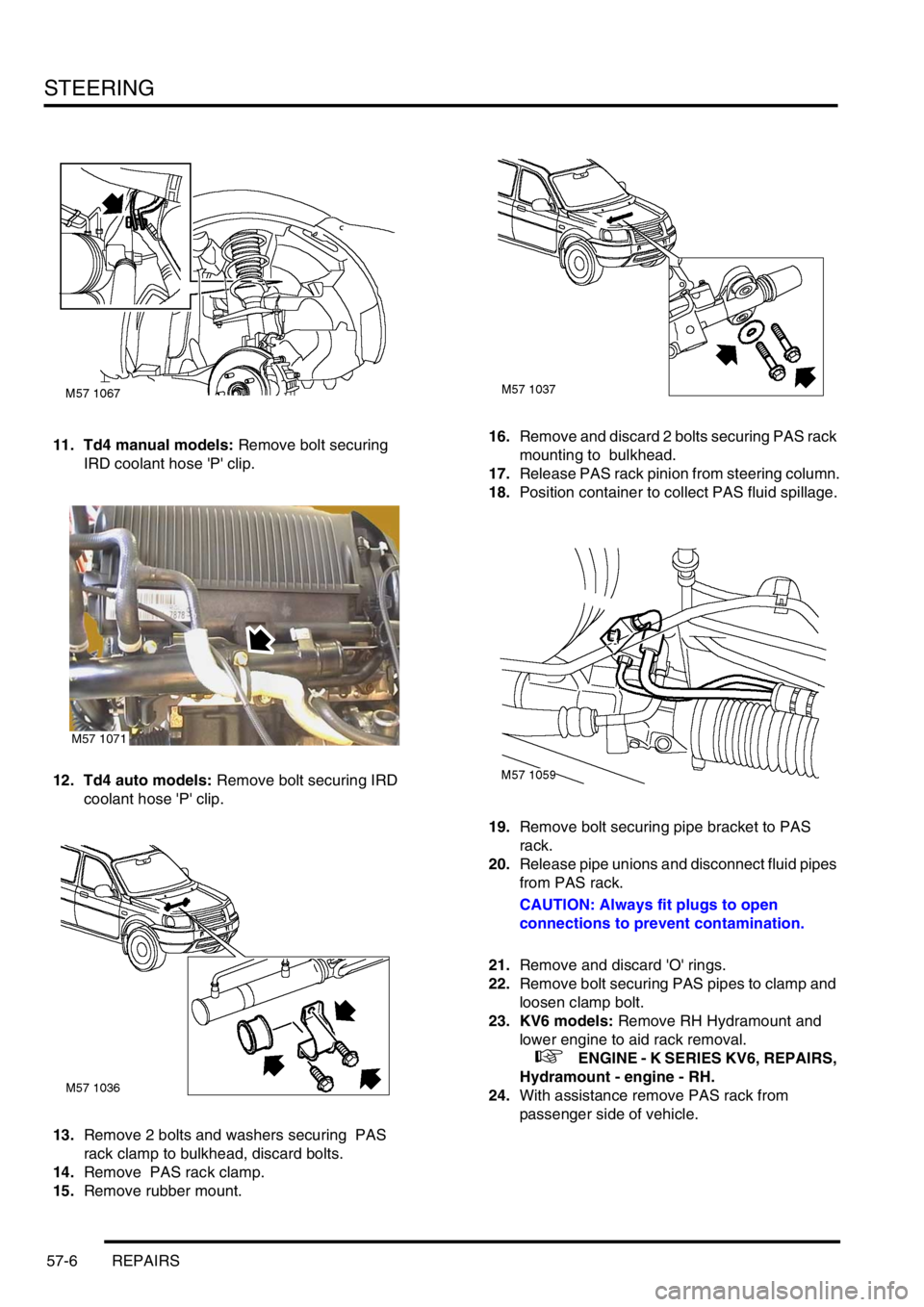

11. Td4 manual models: Remove bolt securing

IRD coolant hose 'P' clip.

12. Td4 auto models: Remove bolt securing IRD

coolant hose 'P' clip.

13.Remove 2 bolts and washers securing PAS

rack clamp to bulkhead, discard bolts.

14.Remove PAS rack clamp.

15.Remove rubber mount.16.Remove and discard 2 bolts securing PAS rack

mounting to bulkhead.

17.Release PAS rack pinion from steering column.

18.Position container to collect PAS fluid spillage.

19.Remove bolt securing pipe bracket to PAS

rack.

20.Release pipe unions and disconnect fluid pipes

from PAS rack.

CAUTION: Always fit plugs to open

connections to prevent contamination.

21.Remove and discard 'O' rings.

22.Remove bolt securing PAS pipes to clamp and

loosen clamp bolt.

23. KV6 models: Remove RH Hydramount and

lower engine to aid rack removal.

+ ENGINE - K SERIES KV6, REPAIRS,

Hydramount - engine - RH.

24.With assistance remove PAS rack from

passenger side of vehicle.

M57 1071

Page 500 of 1007

STEERING

REPAIRS 57-7

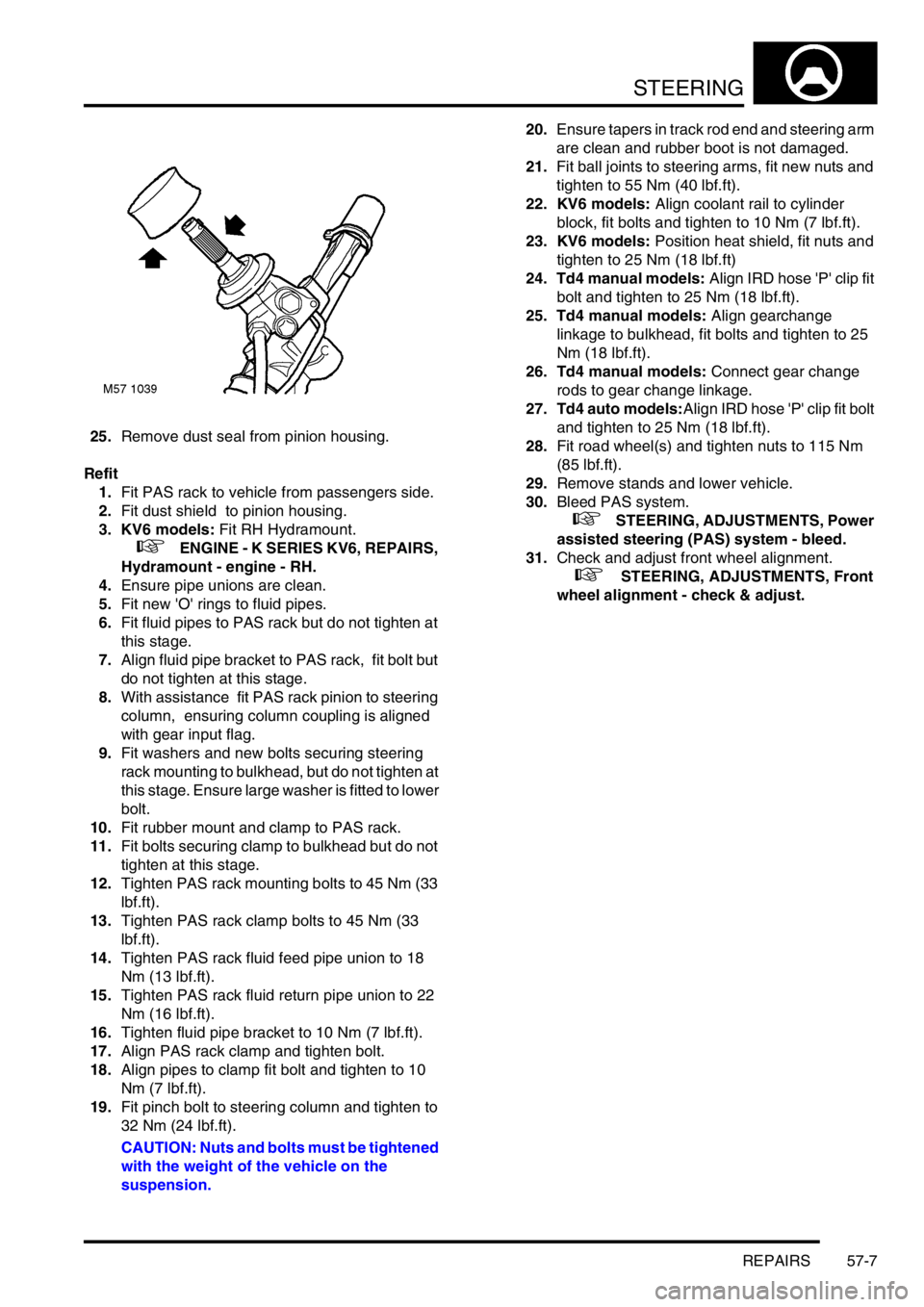

25.Remove dust seal from pinion housing.

Refit

1.Fit PAS rack to vehicle from passengers side.

2.Fit dust shield to pinion housing.

3. KV6 models: Fit RH Hydramount.

+ ENGINE - K SERIES KV6, REPAIRS,

Hydramount - engine - RH.

4.Ensure pipe unions are clean.

5.Fit new 'O' rings to fluid pipes.

6.Fit fluid pipes to PAS rack but do not tighten at

this stage.

7.Align fluid pipe bracket to PAS rack, fit bolt but

do not tighten at this stage.

8.With assistance fit PAS rack pinion to steering

column, ensuring column coupling is aligned

with gear input flag.

9.Fit washers and new bolts securing steering

rack mounting to bulkhead, but do not tighten at

this stage. Ensure large washer is fitted to lower

bolt.

10.Fit rubber mount and clamp to PAS rack.

11.Fit bolts securing clamp to bulkhead but do not

tighten at this stage.

12.Tighten PAS rack mounting bolts to 45 Nm (33

lbf.ft).

13.Tighten PAS rack clamp bolts to 45 Nm (33

lbf.ft).

14.Tighten PAS rack fluid feed pipe union to 18

Nm (13 lbf.ft).

15.Tighten PAS rack fluid return pipe union to 22

Nm (16 lbf.ft).

16.Tighten fluid pipe bracket to 10 Nm (7 lbf.ft).

17.Align PAS rack clamp and tighten bolt.

18.Align pipes to clamp fit bolt and tighten to 10

Nm (7 lbf.ft).

19.Fit pinch bolt to steering column and tighten to

32 Nm (24 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.20.Ensure tapers in track rod end and steering arm

are clean and rubber boot is not damaged.

21.Fit ball joints to steering arms, fit new nuts and

tighten to 55 Nm (40 lbf.ft).

22. KV6 models: Align coolant rail to cylinder

block, fit bolts and tighten to 10 Nm (7 lbf.ft).

23. KV6 models: Position heat shield, fit nuts and

tighten to 25 Nm (18 lbf.ft)

24. Td4 manual models: Align IRD hose 'P' clip fit

bolt and tighten to 25 Nm (18 lbf.ft).

25. Td4 manual models: Align gearchange

linkage to bulkhead, fit bolts and tighten to 25

Nm (18 lbf.ft).

26. Td4 manual models: Connect gear change

rods to gear change linkage.

27. Td4 auto models:Align IRD hose 'P' clip fit bolt

and tighten to 25 Nm (18 lbf.ft).

28.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

29.Remove stands and lower vehicle.

30.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

31.Check and adjust front wheel alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.

Page 505 of 1007

STEERING

57-12 REPAIRS

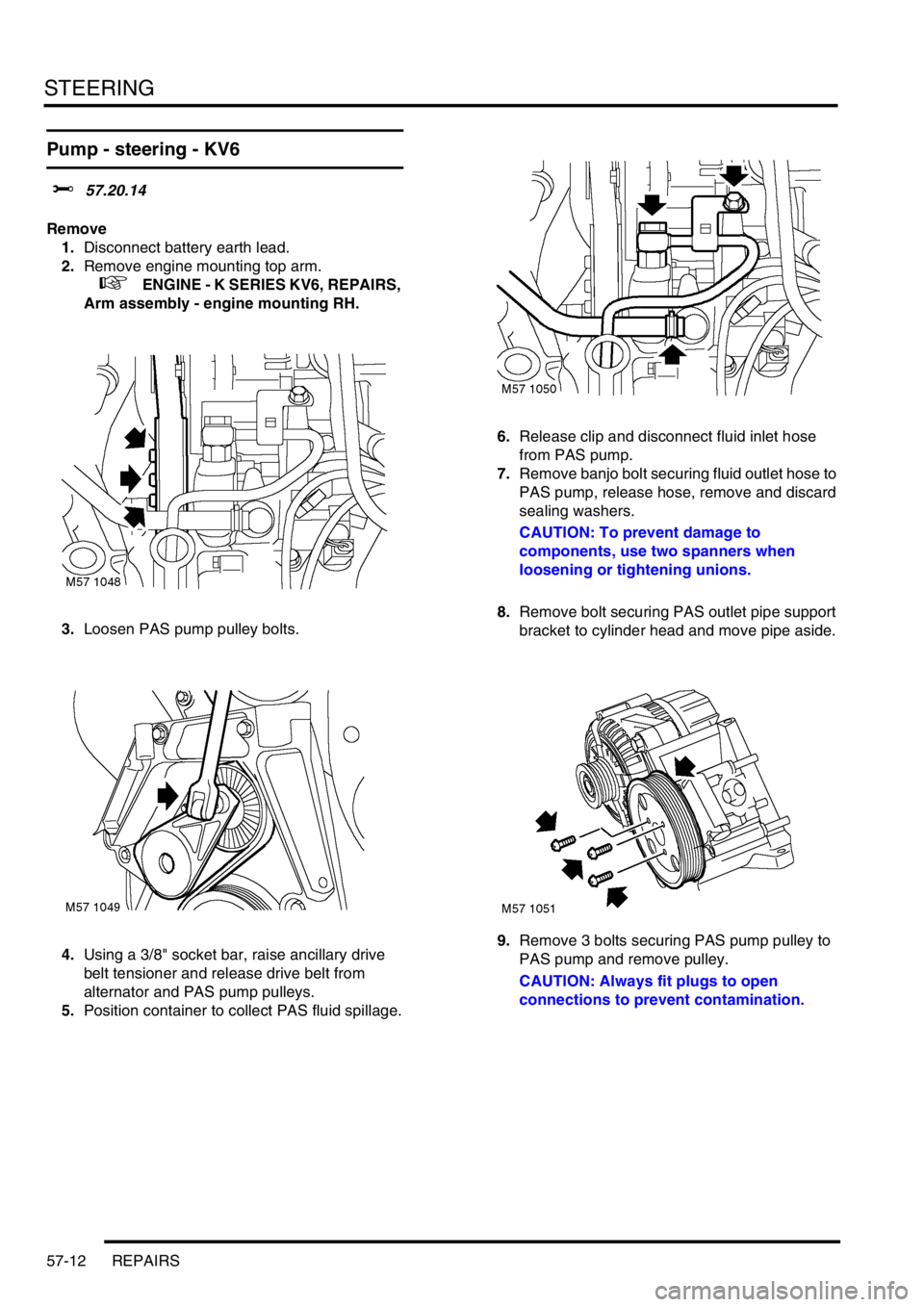

Pump - steering - KV6

$% 57.20.14

Remove

1.Disconnect battery earth lead.

2.Remove engine mounting top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

3.Loosen PAS pump pulley bolts.

4.Using a 3/8" socket bar, raise ancillary drive

belt tensioner and release drive belt from

alternator and PAS pump pulleys.

5.Position container to collect PAS fluid spillage.6.Release clip and disconnect fluid inlet hose

from PAS pump.

7.Remove banjo bolt securing fluid outlet hose to

PAS pump, release hose, remove and discard

sealing washers.

CAUTION: To prevent damage to

components, use two spanners when

loosening or tightening unions.

8.Remove bolt securing PAS outlet pipe support

bracket to cylinder head and move pipe aside.

9.Remove 3 bolts securing PAS pump pulley to

PAS pump and remove pulley.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 506 of 1007

STEERING

REPAIRS 57-13

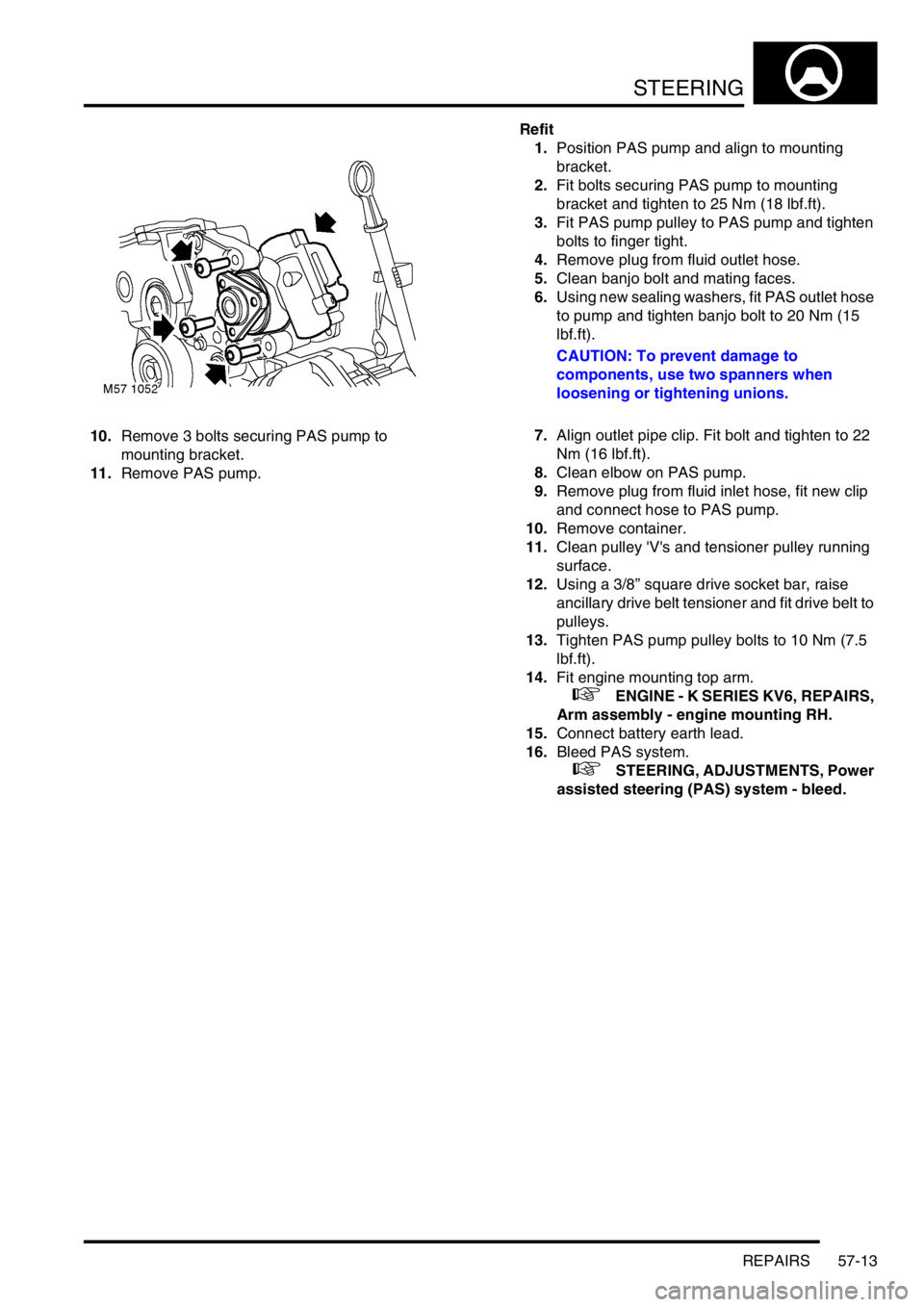

10.Remove 3 bolts securing PAS pump to

mounting bracket.

11.Remove PAS pump.Refit

1.Position PAS pump and align to mounting

bracket.

2.Fit bolts securing PAS pump to mounting

bracket and tighten to 25 Nm (18 lbf.ft).

3.Fit PAS pump pulley to PAS pump and tighten

bolts to finger tight.

4.Remove plug from fluid outlet hose.

5.Clean banjo bolt and mating faces.

6.Using new sealing washers, fit PAS outlet hose

to pump and tighten banjo bolt to 20 Nm (15

lbf.ft).

CAUTION: To prevent damage to

components, use two spanners when

loosening or tightening unions.

7.Align outlet pipe clip. Fit bolt and tighten to 22

Nm (16 lbf.ft).

8.Clean elbow on PAS pump.

9.Remove plug from fluid inlet hose, fit new clip

and connect hose to PAS pump.

10.Remove container.

11.Clean pulley 'V's and tensioner pulley running

surface.

12.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

13.Tighten PAS pump pulley bolts to 10 Nm (7.5

lbf.ft).

14.Fit engine mounting top arm.

+ ENGINE - K SERIES KV6, REPAIRS,

Arm assembly - engine mounting RH.

15.Connect battery earth lead.

16.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

Page 508 of 1007

STEERING

REPAIRS 57-15

Pump - steering - Td4

$% 57.20.14

Remove

1.Disconnect battery earth lead.

2.Remove hydramount.

+ ENGINE - Td4, REPAIRS,

Hydramount - engine - RH.

3.Loosen 3 PAS pump pulley bolts.

4.Remove ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

5.Raise engine on hoist.

6.Remove bolts and remove PAS pump pulley.

7.Cover alternator to prevent PAS oil

contamination.

8.Place container beneath PAS pump, release

clip and remove feed hose to pump. Allow fluid

to drain.

CAUTION: Care must be taken to ensure

that oil or fluid does not enter or

contaminate the alternator.9.Remove banjo bolt securing fluid outlet hose to

PAS pump, release hose, remove and discard

sealing washers.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

10.Remove 4 bolts and remove PAS pump.

11.Remove 5 Torx bolts securing PAS pump to

mounting brackets. Collect mounting brackets.

Refit

1.Position PAS pump to mounting brackets, fit

and tighten Torx bolts to 25 Nm (18 lbf.ft).

2.Position pump to mounting, fit bolts and tighten

M8 bolts to 25 Nm (18 lbf.ft) and M6 bolts to 10

Nm (7.5 lbf.ft).

3.Using new sealing washers, fit PAS outlet hose

to pump and tighten banjo bolt to 25 Nm (18

lbf.ft).

4.Clean PAS pump and mating faces.

5.Fit inlet hose to PAS pump and secure with new

clip.

6.Fit PAS pump pulley to PAS pump and tighten

bolts to finger tight.

7.Fit ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

8.Tighten PAS pump pulley bolts to 10 Nm (7.5

lbf.ft).

9.Fit hydramount.

+ ENGINE - Td4, REPAIRS,

Hydramount - engine - RH.

10.Connect battery earth lead.

Page 540 of 1007

REAR SUSPENSION

REPAIRS 64-5

7.Fit hub to damper and tighten bolts to 205 Nm

(151 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

8.Fit nut, bolt and washers securing transverse

links to hub and tighten nut to 105 Nm (77 lbf.ft).

9.Fit trailing link to hub and tighten nut and bolt to

120 Nm (89 lbf.ft).

NOTE: Ensure that washers are fitted to both

ends of bolts

10.Clean ABS sensor, smear sensor with an anti-

seize grease and fit sensor to hub.

CAUTION: Ensure ABS sensor is fully

located into hub, so that sensor touches

pole wheel teeth.

11.Fit brake pipe to wheel cylinder and tighten

union to 14 Nm (10 lbf.ft).

12.Fit clip securing brakepipe to bracket.

13.Fit and secure handbrake cable to backplate.

14.Fit brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

15.Fit new drive shaft nut and tighten to 400 Nm

(295 lbf.ft). Stake nut to shaft.

16.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

17.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

18.Remove stands and lower vehicle.

Damper

$% 64.30.02

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Clamp brake hose to prevent fluid loss.

4.Position absorbent cloth to catch spillage.

5.Loosen brake pipe union to hose and release

union.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove clip securing brake hose to bracket on

damper. Release brake hose from bracket.

7.Release ABS sensor harness and brake hose

from damper.

8.Release ABS sensor from hub.

Page 579 of 1007

BRAKES

70-30 REPAIRS

Modulator unit

$% 70.65.49

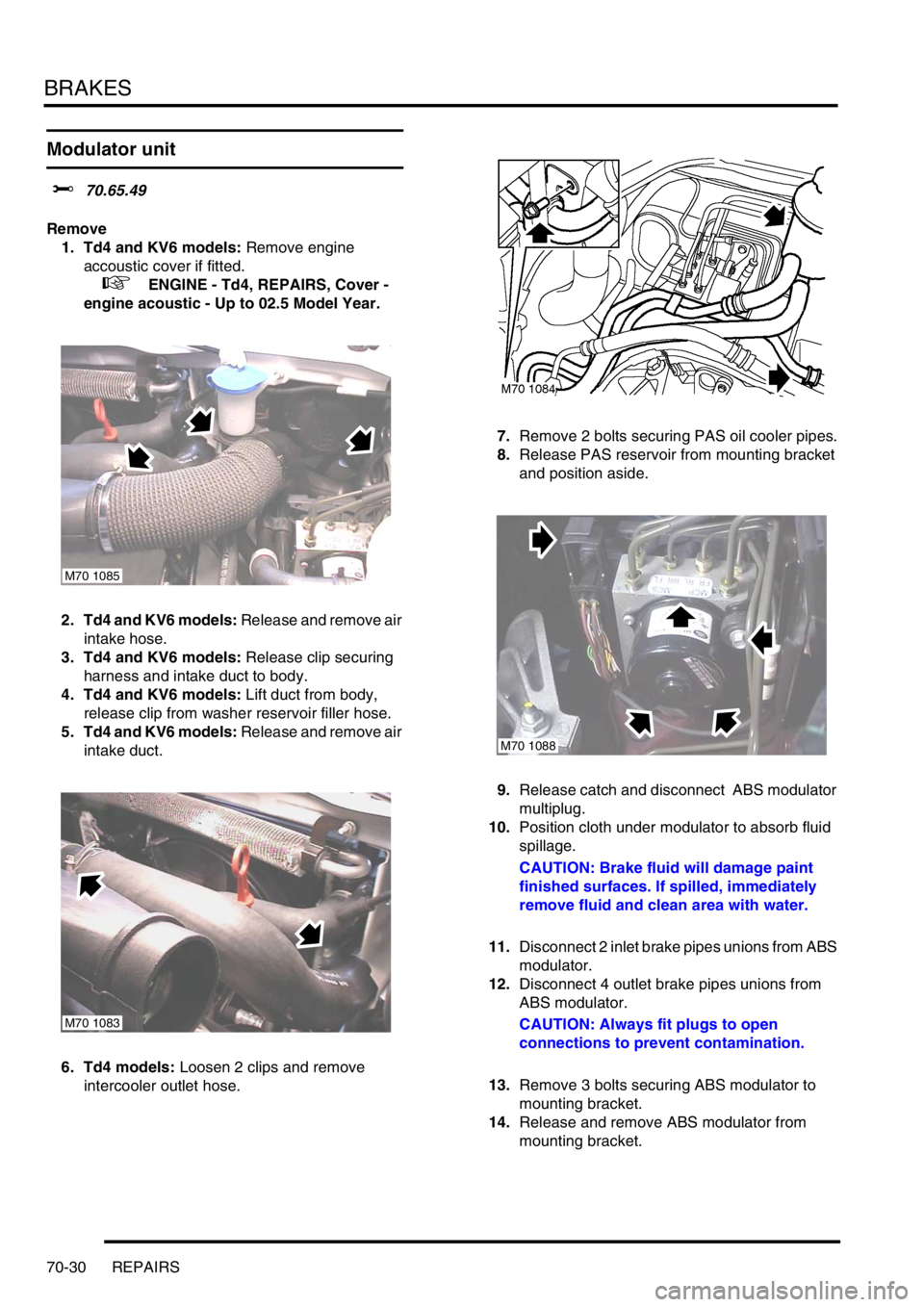

Remove

1. Td4 and KV6 models: Remove engine

accoustic cover if fitted.

+ ENGINE - Td4, REPAIRS, Cover -

engine acoustic - Up to 02.5 Model Year.

2. Td4 and KV6 models: Release and remove air

intake hose.

3. Td4 and KV6 models: Release clip securing

harness and intake duct to body.

4. Td4 and KV6 models: Lift duct from body,

release clip from washer reservoir filler hose.

5. Td4 and KV6 models: Release and remove air

intake duct.

6. Td4 models: Loosen 2 clips and remove

intercooler outlet hose.7.Remove 2 bolts securing PAS oil cooler pipes.

8.Release PAS reservoir from mounting bracket

and position aside.

9.Release catch and disconnect ABS modulator

multiplug.

10.Position cloth under modulator to absorb fluid

spillage.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

11.Disconnect 2 inlet brake pipes unions from ABS

modulator.

12.Disconnect 4 outlet brake pipes unions from

ABS modulator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

13.Remove 3 bolts securing ABS modulator to

mounting bracket.

14.Release and remove ABS modulator from

mounting bracket.

M70 1085

M70 1083

M70 1088

Page 756 of 1007

PANEL REPAIRS

BODY REPAIRS 77-2-1

PANEL REPAIRS

General

Body shells are of monocoque construction. Front and rear sections of the shell are designed as 'energy absorbing'

zones. This means they are designed to deform progressively when subjected to impact in order to minimise the

likelihood of injury to vehicle occupants.

It is essential that design dimensions and strength are restored in accident rectification. It is important that neither

structural weakness nor excessive local stiffness are introduced into the vehicle during body repair.

Repairs usually involve a combination of operations ranging from straightening procedures to renewal of individual

panels or panel assemblies. The repairer will determine the repair method and this decision will take into account a

balance of economics between labour and material costs and the availability of repair facilities in both equipment and

skills. It may also involve considerations of the vehicles' downtime, replacement vehicle availability and repair turn-

around time.

It is expected that a repairer will select the best and most economic repair method possible, making use of the facilities

available. The instructions given are intended to assist a skilled body repairer by expanding approved procedures for

panel replacement. The objective is to restore the vehicle to a safe running condition by carrying out a repair which is

as close as is feasible to original standard. The results should not advertise to the experienced eye that the vehicle

has been damaged, although the repair might not be identical in all respects to the original factory build. Commercial

bodyshop repair facilities cannot always duplicate methods of construction used during production.

Operations covered in this Manual do not include reference to testing the vehicle after repair. It is essential that work

is inspected and suspension geometry checked after completion. Where necessary a road test of the vehicle should

be carried out, particularly where safety-related items are concerned.

Where major units have been disconnected or removed it is necessary to ensure that fluid levels are checked and

topped up where necessary. It is also necessary to ensure that the repaired vehicle is in a roadworthy condition in

respect of tyre pressures, lights, washer fluid etc.

Body repairs often involve the removal of mechanical and electrical units and associated wiring. Where necessary,

refer to the relevant section of the Workshop Manual for removal and refitting instructions.

Body components

Taking into consideration the differences in body styles, suspension systems and engine and transmission layouts,

the location of the following components as applicable to a particular vehicle is critical:

lFront suspension upper damper mountings.

lFront suspension or sub frame mountings.

lRear suspension upper damper mountings.

lRear suspension mountings or lower pivots.

Additional points which can be used to check alignment and assembly are:

lInner holes in crossmember - side - main floor.

lHoles in front longitudinals.

lHoles in side members.

lHoles in rear longitudinals.

lHoles in rear lower panels or extension rear floor.

Apertures for windscreen, backlight, bonnet and doors can be measured and checked using the dimensional

information provided and also by offering up an undamaged component as a gauge.

Straightening

Whenever possible, structural members should be cold straightened under tension. Do not attempt to straighten with

a single pull but rework the damaged area using a series of pulls, releasing tension between each stage and using

the opportunity to check alignment.

Page 780 of 1007

PANEL REPAIRS

REPAIRS 77-2-25

REPAIRS

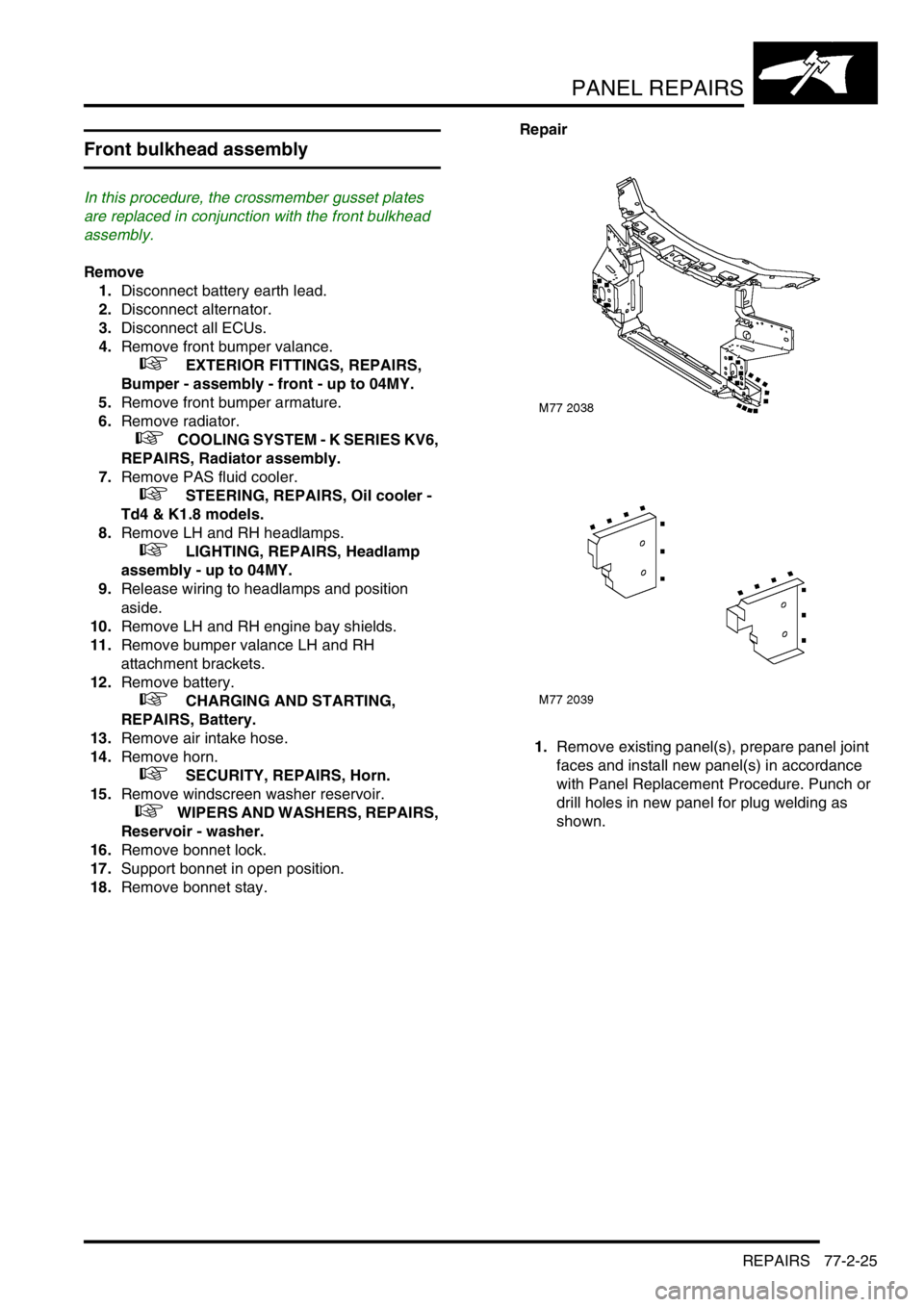

Front bulkhead assembly

In this procedure, the crossmember gusset plates

are replaced in conjunction with the front bulkhead

assembly.

Remove

1.Disconnect battery earth lead.

2.Disconnect alternator.

3.Disconnect all ECUs.

4.Remove front bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5.Remove front bumper armature.

6.Remove radiator.

+ COOLING SYSTEM - K SERIES KV6,

REPAIRS, Radiator assembly.

7.Remove PAS fluid cooler.

+ STEERING, REPAIRS, Oil cooler -

Td4 & K1.8 models.

8.Remove LH and RH headlamps.

+ LIGHTING, REPAIRS, Headlamp

assembly - up to 04MY.

9.Release wiring to headlamps and position

aside.

10.Remove LH and RH engine bay shields.

11.Remove bumper valance LH and RH

attachment brackets.

12.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Remove air intake hose.

14.Remove horn.

+ SECURITY, REPAIRS, Horn.

15.Remove windscreen washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer.

16.Remove bonnet lock.

17.Support bonnet in open position.

18.Remove bonnet stay. Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.