check engine LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 178 of 1007

ENGINE - K SERIES KV6

ADJUSTMENTS 12-3-1

ENGIN E - K SERIES KV6 ADJUST ME NTS

Engine oil pressure check

$% 12.90.09.01

Check

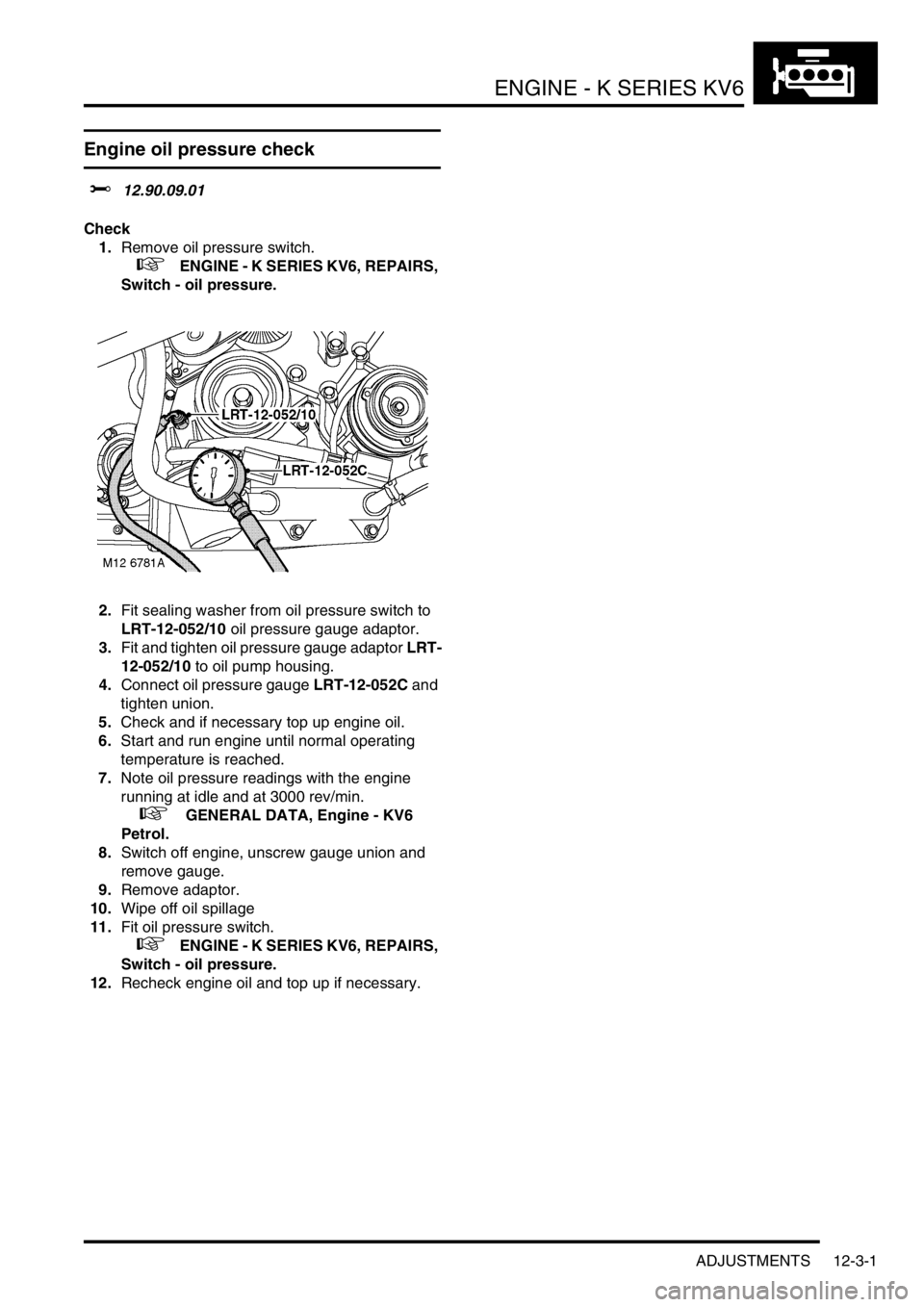

1.Remove oil pressure switch.

+ ENGINE - K SERIES KV6, REPAIRS,

Switch - oil pressure.

2.Fit sealing washer from oil pressure switch to

LRT-12-052/10 oil pressure gauge adaptor.

3.Fit and tighten oil pressure gauge adaptor LRT-

12-052/10 to oil pump housing.

4.Connect oil pressure gauge LRT-12-052C and

tighten union.

5.Check and if necessary top up engine oil.

6.Start and run engine until normal operating

temperature is reached.

7.Note oil pressure readings with the engine

running at idle and at 3000 rev/min.

+ GENERAL DATA, Engine - KV6

Petrol.

8.Switch off engine, unscrew gauge union and

remove gauge.

9.Remove adaptor.

10.Wipe off oil spillage

11.Fit oil pressure switch.

+ ENGINE - K SERIES KV6, REPAIRS,

Switch - oil pressure.

12.Recheck engine oil and top up if necessary.

Page 189 of 1007

ENGINE - K SERIES KV6

12-3-12 REPAIRS

Crankshaft rear oil seal

$% 12.21.20

Remove

1.Remove torque converter drive plate.

+ ENGINE - K SERIES KV6, REPAIRS,

Torque converter drive plate.

2.Remove and discard 5 bolts securing

crankshaft rear oil seal to cylinder block.

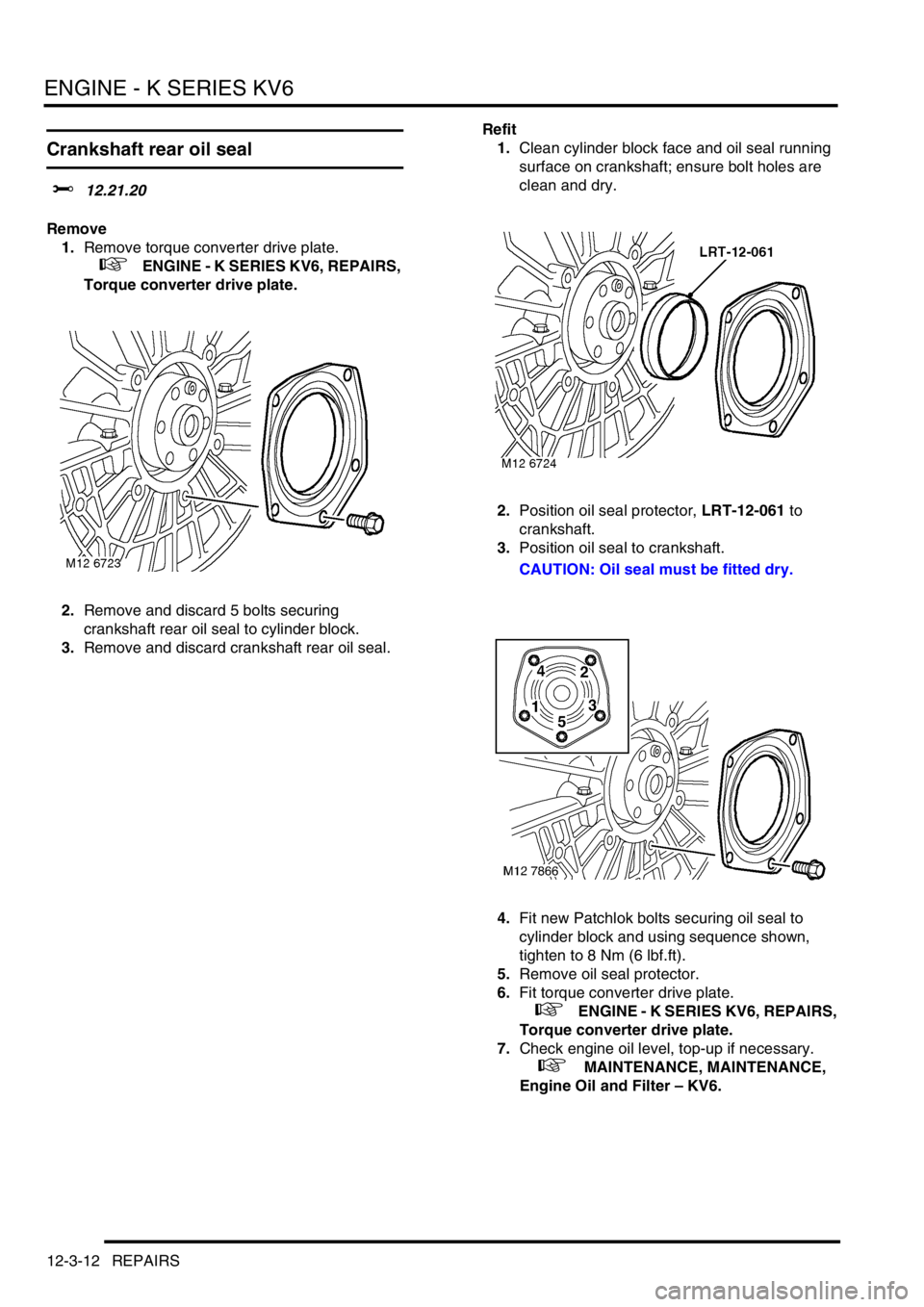

3.Remove and discard crankshaft rear oil seal.Refit

1.Clean cylinder block face and oil seal running

surface on crankshaft; ensure bolt holes are

clean and dry.

2.Position oil seal protector, LRT-12-061 to

crankshaft.

3.Position oil seal to crankshaft.

CAUTION: Oil seal must be fitted dry.

4.Fit new Patchlok bolts securing oil seal to

cylinder block and using sequence shown,

tighten to 8 Nm (6 lbf.ft).

5.Remove oil seal protector.

6.Fit torque converter drive plate.

+ ENGINE - K SERIES KV6, REPAIRS,

Torque converter drive plate.

7.Check engine oil level, top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Page 192 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-15

Refit

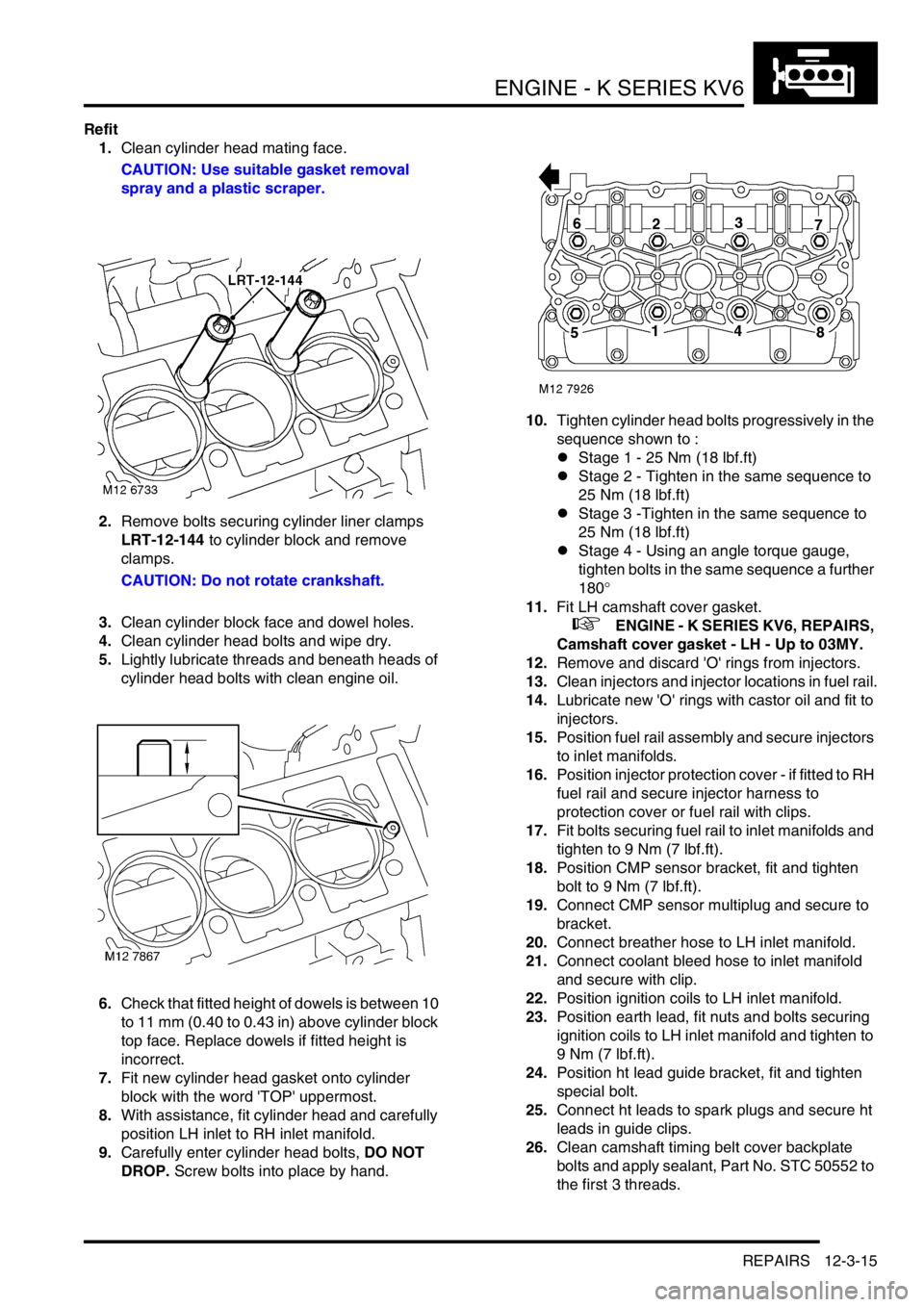

1.Clean cylinder head mating face.

CAUTION: Use suitable gasket removal

spray and a plastic scraper.

2.Remove bolts securing cylinder liner clamps

LRT-12-144 to cylinder block and remove

clamps.

CAUTION: Do not rotate crankshaft.

3.Clean cylinder block face and dowel holes.

4.Clean cylinder head bolts and wipe dry.

5.Lightly lubricate threads and beneath heads of

cylinder head bolts with clean engine oil.

6.Check that fitted height of dowels is between 10

to 11 mm (0.40 to 0.43 in) above cylinder block

top face. Replace dowels if fitted height is

incorrect.

7.Fit new cylinder head gasket onto cylinder

block with the word 'TOP' uppermost.

8.With assistance, fit cylinder head and carefully

position LH inlet to RH inlet manifold.

9.Carefully enter cylinder head bolts, DO NOT

DROP. Screw bolts into place by hand.10.Tighten cylinder head bolts progressively in the

sequence shown to :

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - Tighten in the same sequence to

25 Nm (18 lbf.ft)

lStage 3 -Tighten in the same sequence to

25 Nm (18 lbf.ft)

lStage 4 - Using an angle torque gauge,

tighten bolts in the same sequence a further

180°

11.Fit LH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - LH - Up to 03MY.

12.Remove and discard 'O' rings from injectors.

13.Clean injectors and injector locations in fuel rail.

14.Lubricate new 'O' rings with castor oil and fit to

injectors.

15.Position fuel rail assembly and secure injectors

to inlet manifolds.

16.Position injector protection cover - if fitted to RH

fuel rail and secure injector harness to

protection cover or fuel rail with clips.

17.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

18.Position CMP sensor bracket, fit and tighten

bolt to 9 Nm (7 lbf.ft).

19.Connect CMP sensor multiplug and secure to

bracket.

20.Connect breather hose to LH inlet manifold.

21.Connect coolant bleed hose to inlet manifold

and secure with clip.

22.Position ignition coils to LH inlet manifold.

23.Position earth lead, fit nuts and bolts securing

ignition coils to LH inlet manifold and tighten to

9 Nm (7 lbf.ft).

24.Position ht lead guide bracket, fit and tighten

special bolt.

25.Connect ht leads to spark plugs and secure ht

leads in guide clips.

26.Clean camshaft timing belt cover backplate

bolts and apply sealant, Part No. STC 50552 to

the first 3 threads.

Page 193 of 1007

ENGINE - K SERIES KV6

12-3-16 REPAIRS

27.Position backplate, fit and tighten bolts to 9 Nm.

28.Fit camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

29.Fit LH exhaust manifold gasket.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket - exhaust

manifold - LH - Non NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket(s) -

exhaust manifold - LH - NAS.

30.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

31.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

32.Check engine oil level and top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Cylinder head gasket - RH

$% 12.29.03

Remove

1.Disconnect battery earth lead.

2.Drain cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

3.Remove inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

4.Remove RH exhaust manifold gasket.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket - exhaust

manifold - RH - Non NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket(s) -

exhaust manifold - RH - KV6 - NAS.

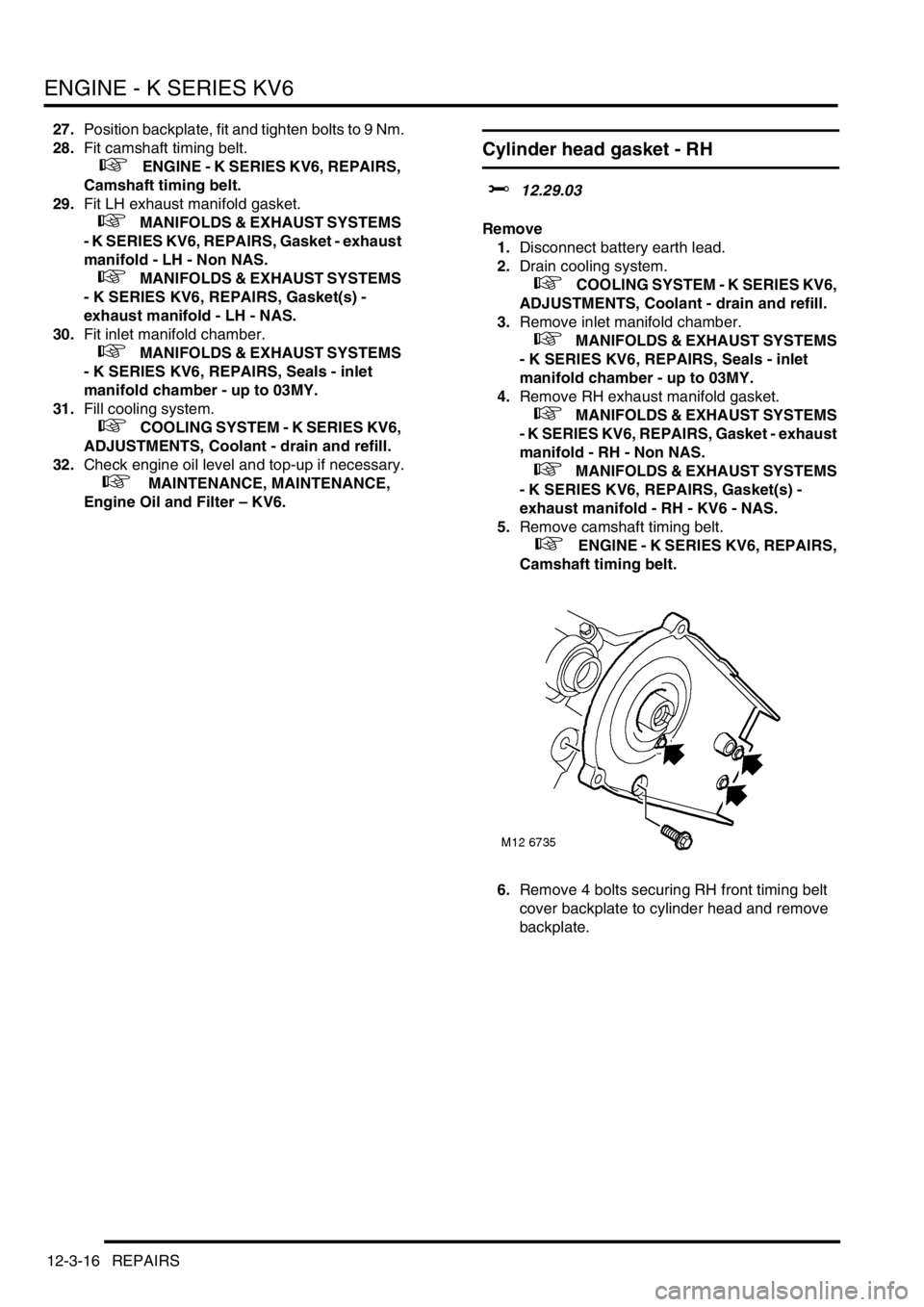

5.Remove camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

6.Remove 4 bolts securing RH front timing belt

cover backplate to cylinder head and remove

backplate.

Page 195 of 1007

ENGINE - K SERIES KV6

12-3-18 REPAIRS

13.Release injectors from manifolds and carefully

lay fuel rail and injectors aside.

CAUTION: Always fit plugs to open

connections to prevent contamination.

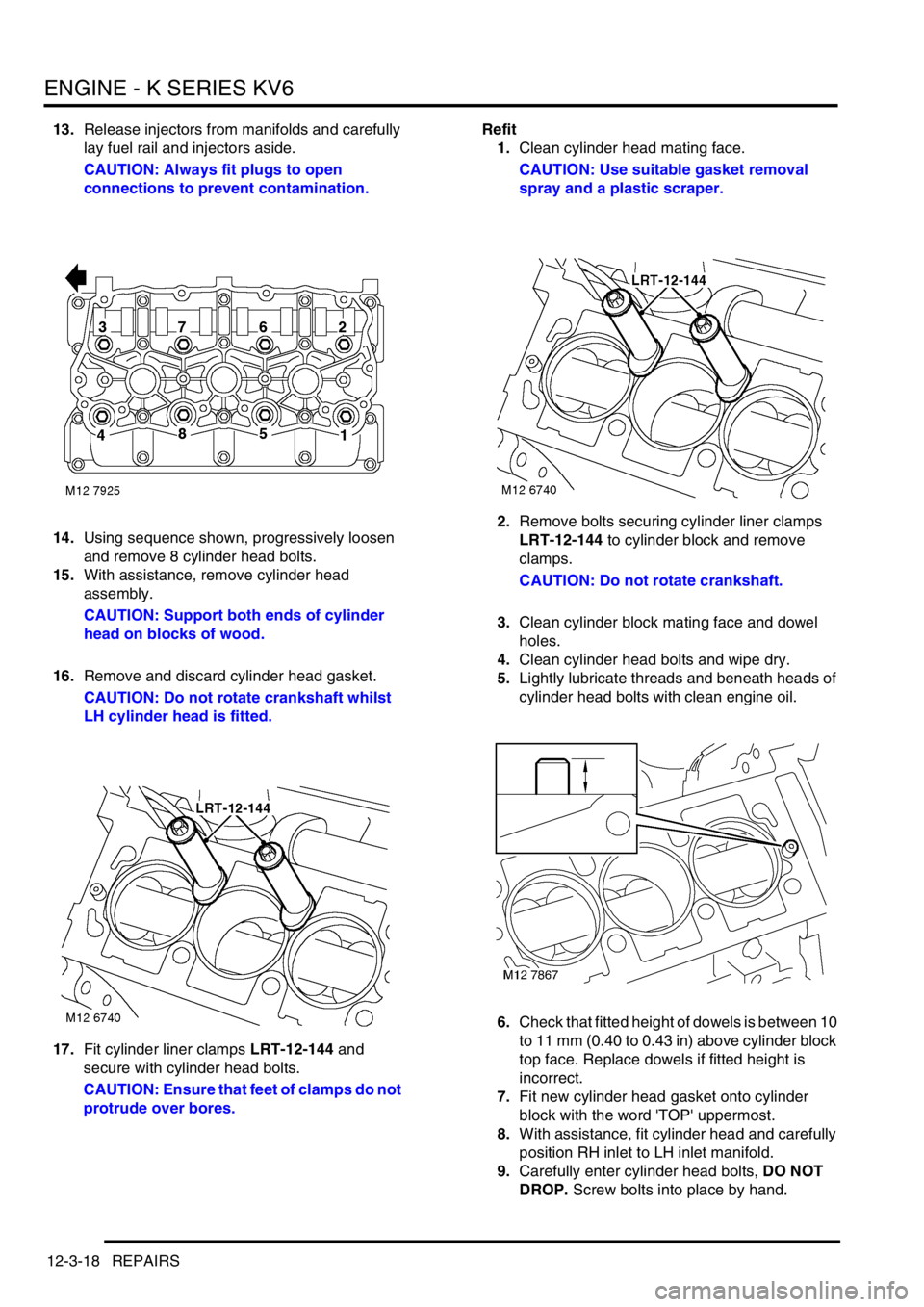

14.Using sequence shown, progressively loosen

and remove 8 cylinder head bolts.

15.With assistance, remove cylinder head

assembly.

CAUTION: Support both ends of cylinder

head on blocks of wood.

16.Remove and discard cylinder head gasket.

CAUTION: Do not rotate crankshaft whilst

LH cylinder head is fitted.

17.Fit cylinder liner clamps LRT-12-144 and

secure with cylinder head bolts.

CAUTION: Ensure that feet of clamps do not

protrude over bores.Refit

1.Clean cylinder head mating face.

CAUTION: Use suitable gasket removal

spray and a plastic scraper.

2.Remove bolts securing cylinder liner clamps

LRT-12-144 to cylinder block and remove

clamps.

CAUTION: Do not rotate crankshaft.

3.Clean cylinder block mating face and dowel

holes.

4.Clean cylinder head bolts and wipe dry.

5.Lightly lubricate threads and beneath heads of

cylinder head bolts with clean engine oil.

6.Check that fitted height of dowels is between 10

to 11 mm (0.40 to 0.43 in) above cylinder block

top face. Replace dowels if fitted height is

incorrect.

7.Fit new cylinder head gasket onto cylinder

block with the word 'TOP' uppermost.

8.With assistance, fit cylinder head and carefully

position RH inlet to LH inlet manifold.

9.Carefully enter cylinder head bolts, DO NOT

DROP. Screw bolts into place by hand.

Page 196 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-19

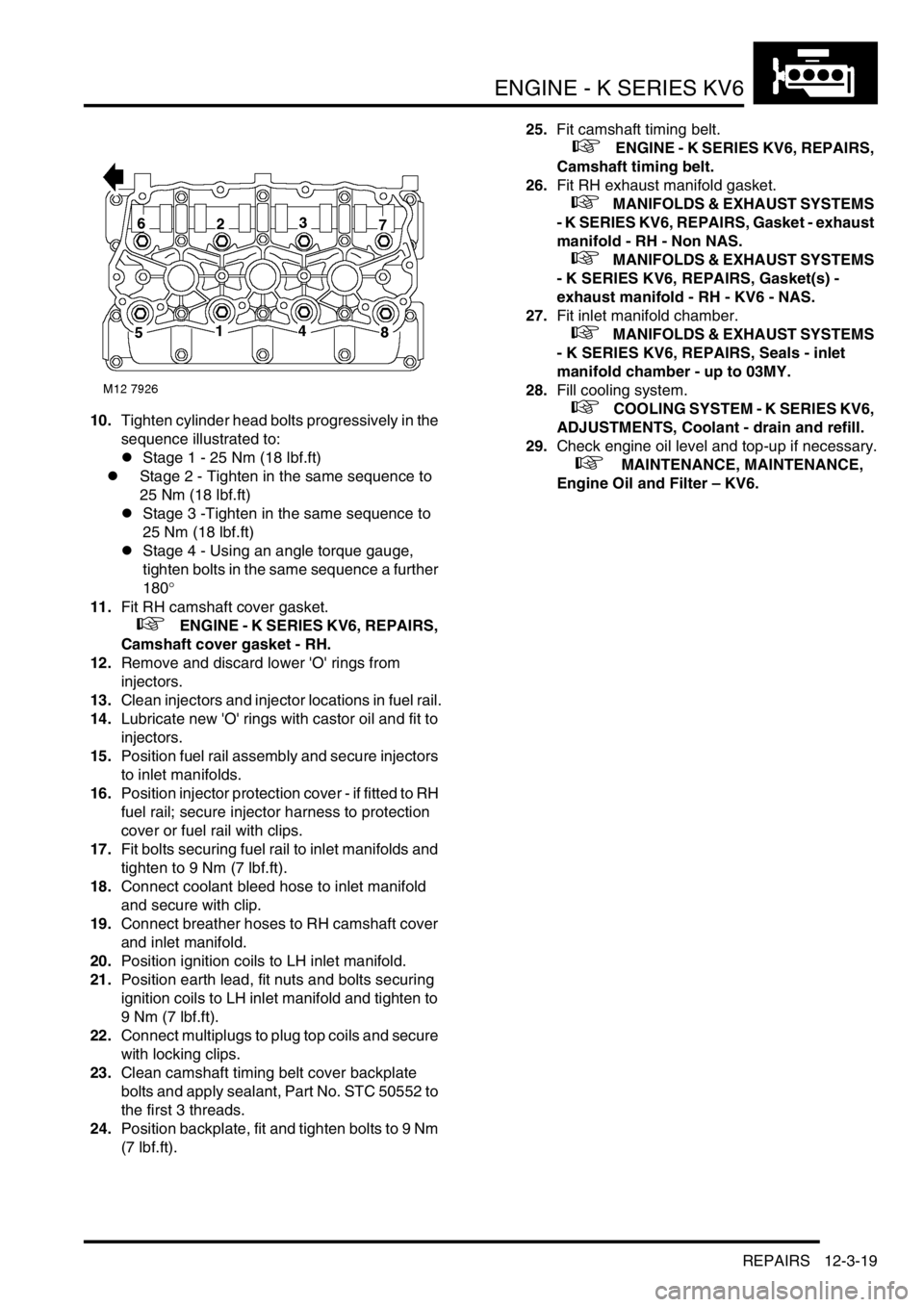

10.Tighten cylinder head bolts progressively in the

sequence illustrated to:

lStage 1 - 25 Nm (18 lbf.ft)

lStage 2 - Tighten in the same sequence to

25 Nm (18 lbf.ft)

lStage 3 -Tighten in the same sequence to

25 Nm (18 lbf.ft)

lStage 4 - Using an angle torque gauge,

tighten bolts in the same sequence a further

180°

11.Fit RH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - RH.

12.Remove and discard lower 'O' rings from

injectors.

13.Clean injectors and injector locations in fuel rail.

14.Lubricate new 'O' rings with castor oil and fit to

injectors.

15.Position fuel rail assembly and secure injectors

to inlet manifolds.

16.Position injector protection cover - if fitted to RH

fuel rail; secure injector harness to protection

cover or fuel rail with clips.

17.Fit bolts securing fuel rail to inlet manifolds and

tighten to 9 Nm (7 lbf.ft).

18.Connect coolant bleed hose to inlet manifold

and secure with clip.

19.Connect breather hoses to RH camshaft cover

and inlet manifold.

20.Position ignition coils to LH inlet manifold.

21.Position earth lead, fit nuts and bolts securing

ignition coils to LH inlet manifold and tighten to

9 Nm (7 lbf.ft).

22.Connect multiplugs to plug top coils and secure

with locking clips.

23.Clean camshaft timing belt cover backplate

bolts and apply sealant, Part No. STC 50552 to

the first 3 threads.

24.Position backplate, fit and tighten bolts to 9 Nm

(7 lbf.ft).25.Fit camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

26.Fit RH exhaust manifold gasket.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket - exhaust

manifold - RH - Non NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Gasket(s) -

exhaust manifold - RH - KV6 - NAS.

27.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

28.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

29.Check engine oil level and top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Page 198 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-21

Refit

1.Clean mating surfaces of camshaft cover and

carrier.

2.Clean inside of camshaft cover. If necessary,

wash oil separator elements in solvent and

blow dry.

3.Position new gasket to camshaft carrier with

arrows on gasket pointing towards inlet

manifold.

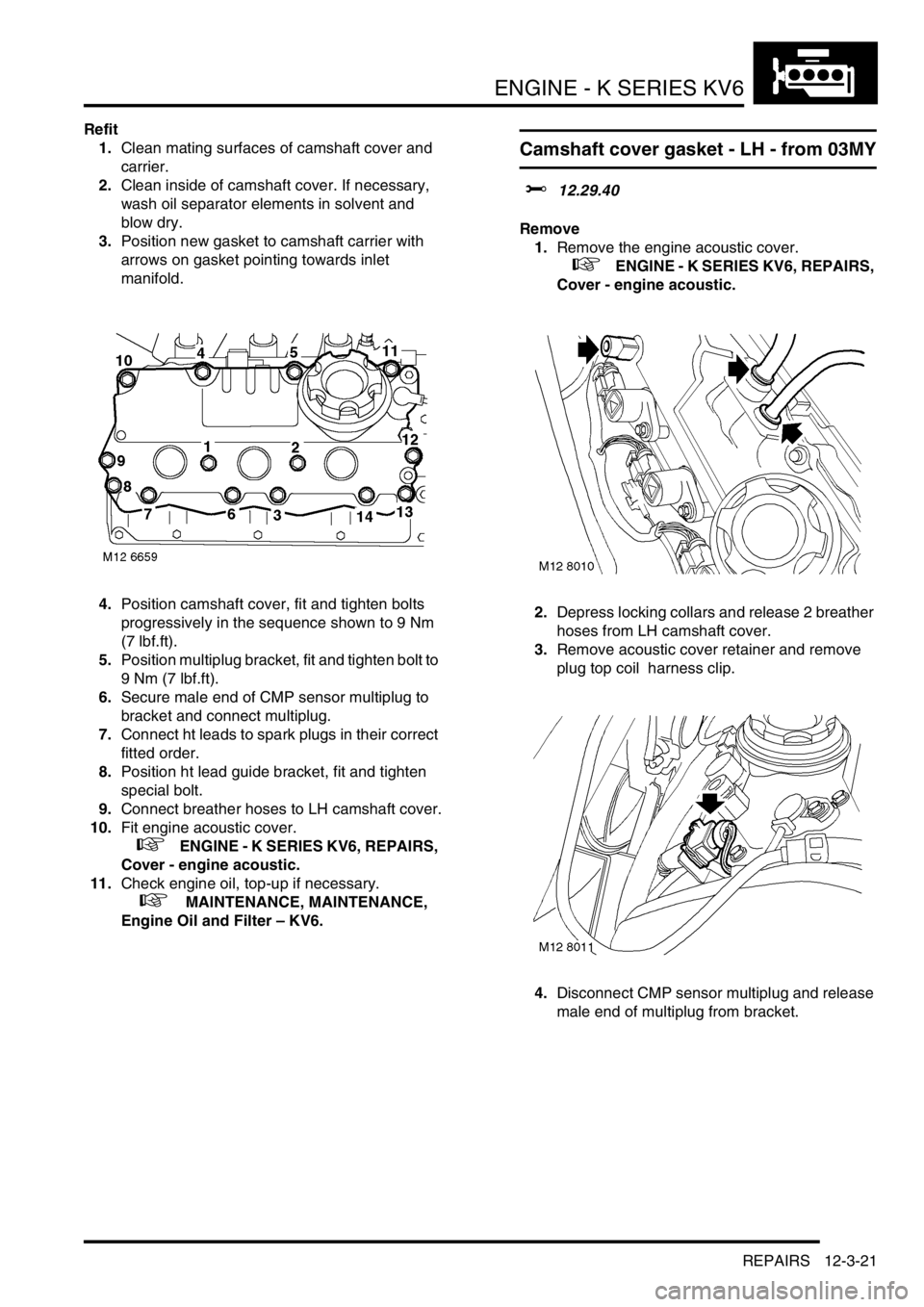

4.Position camshaft cover, fit and tighten bolts

progressively in the sequence shown to 9 Nm

(7 lbf.ft).

5.Position multiplug bracket, fit and tighten bolt to

9 Nm (7 lbf.ft).

6.Secure male end of CMP sensor multiplug to

bracket and connect multiplug.

7.Connect ht leads to spark plugs in their correct

fitted order.

8.Position ht lead guide bracket, fit and tighten

special bolt.

9.Connect breather hoses to LH camshaft cover.

10.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

11.Check engine oil, top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Camshaft cover gasket - LH - from 03MY

$% 12.29.40

Remove

1.Remove the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Depress locking collars and release 2 breather

hoses from LH camshaft cover.

3.Remove acoustic cover retainer and remove

plug top coil harness clip.

4.Disconnect CMP sensor multiplug and release

male end of multiplug from bracket.

Page 199 of 1007

ENGINE - K SERIES KV6

12-3-22 REPAIRS

5.Remove bolt securing multiplug bracket which

also retains front HO2S multiplug, move

bracket and multiplug aside.

6.Withdraw multiplug lock and disconnect

multiplug from each plug top coil.

7.Remove bolt securing each plug top coil to

camshaft cover and remove 3 plug top coils.

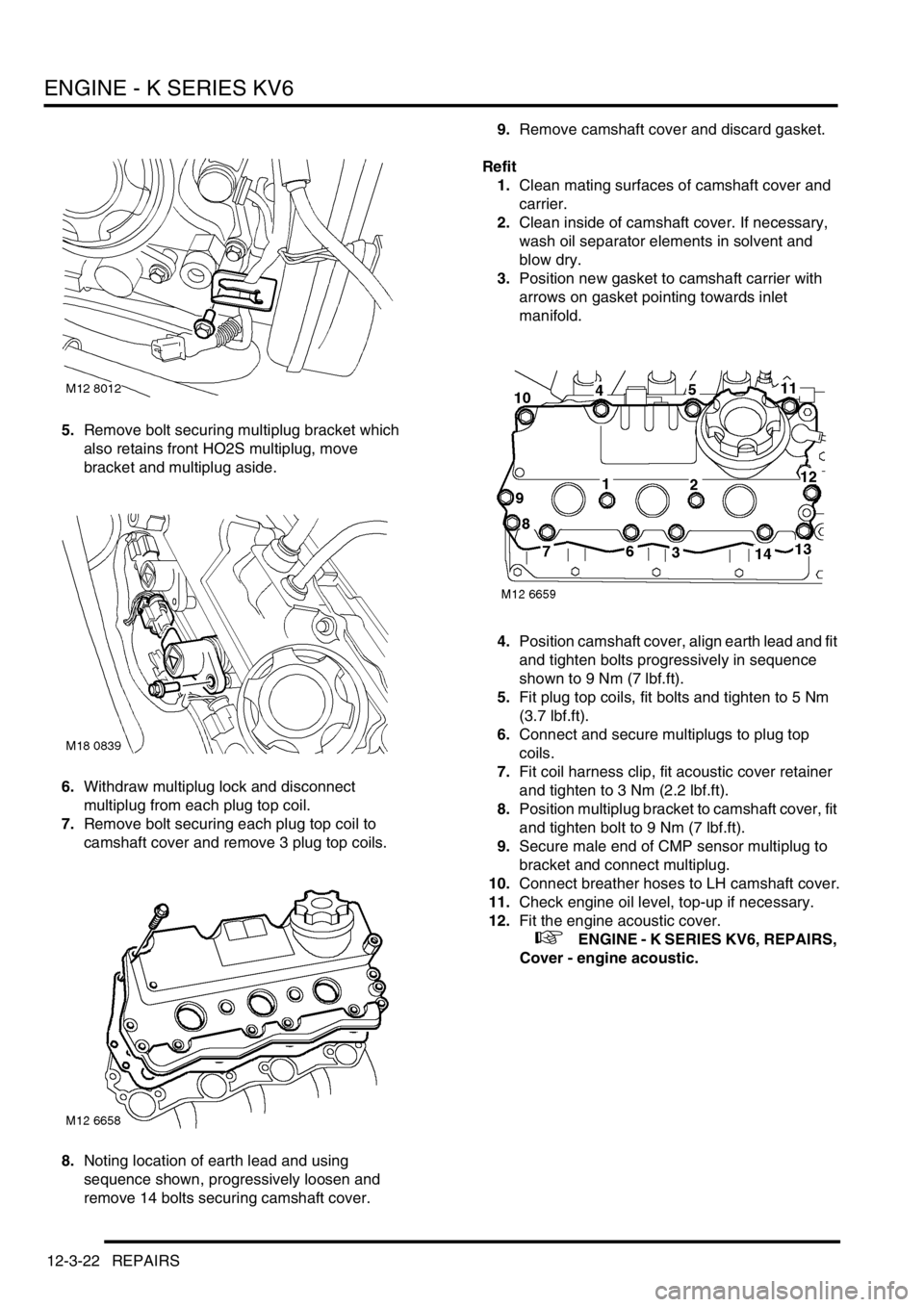

8.Noting location of earth lead and using

sequence shown, progressively loosen and

remove 14 bolts securing camshaft cover.9.Remove camshaft cover and discard gasket.

Refit

1.Clean mating surfaces of camshaft cover and

carrier.

2.Clean inside of camshaft cover. If necessary,

wash oil separator elements in solvent and

blow dry.

3.Position new gasket to camshaft carrier with

arrows on gasket pointing towards inlet

manifold.

4.Position camshaft cover, align earth lead and fit

and tighten bolts progressively in sequence

shown to 9 Nm (7 lbf.ft).

5.Fit plug top coils, fit bolts and tighten to 5 Nm

(3.7 lbf.ft).

6.Connect and secure multiplugs to plug top

coils.

7.Fit coil harness clip, fit acoustic cover retainer

and tighten to 3 Nm (2.2 lbf.ft).

8.Position multiplug bracket to camshaft cover, fit

and tighten bolt to 9 Nm (7 lbf.ft).

9.Secure male end of CMP sensor multiplug to

bracket and connect multiplug.

10.Connect breather hoses to LH camshaft cover.

11.Check engine oil level, top-up if necessary.

12.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 201 of 1007

ENGINE - K SERIES KV6

12-3-24 REPAIRS

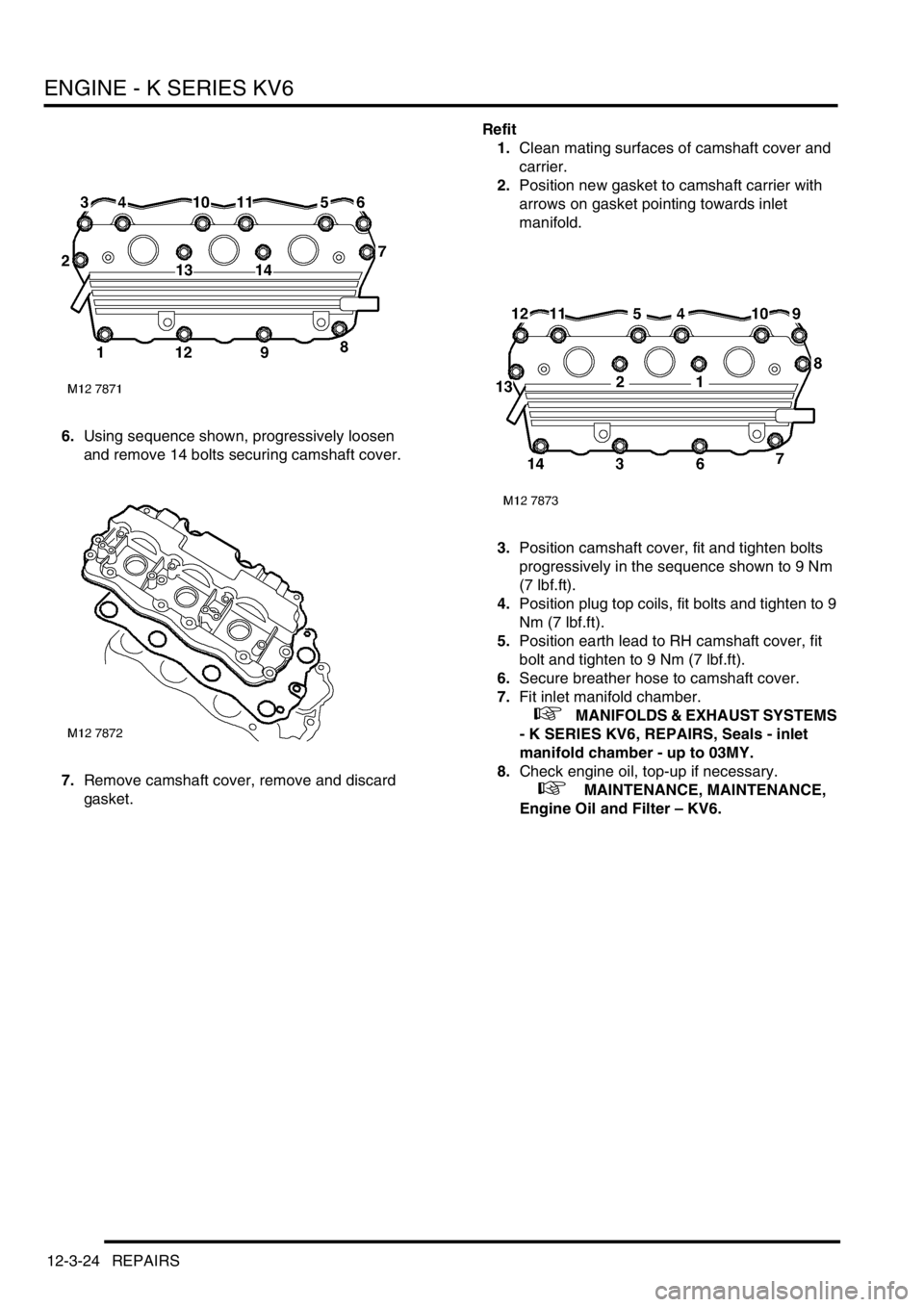

6.Using sequence shown, progressively loosen

and remove 14 bolts securing camshaft cover.

7.Remove camshaft cover, remove and discard

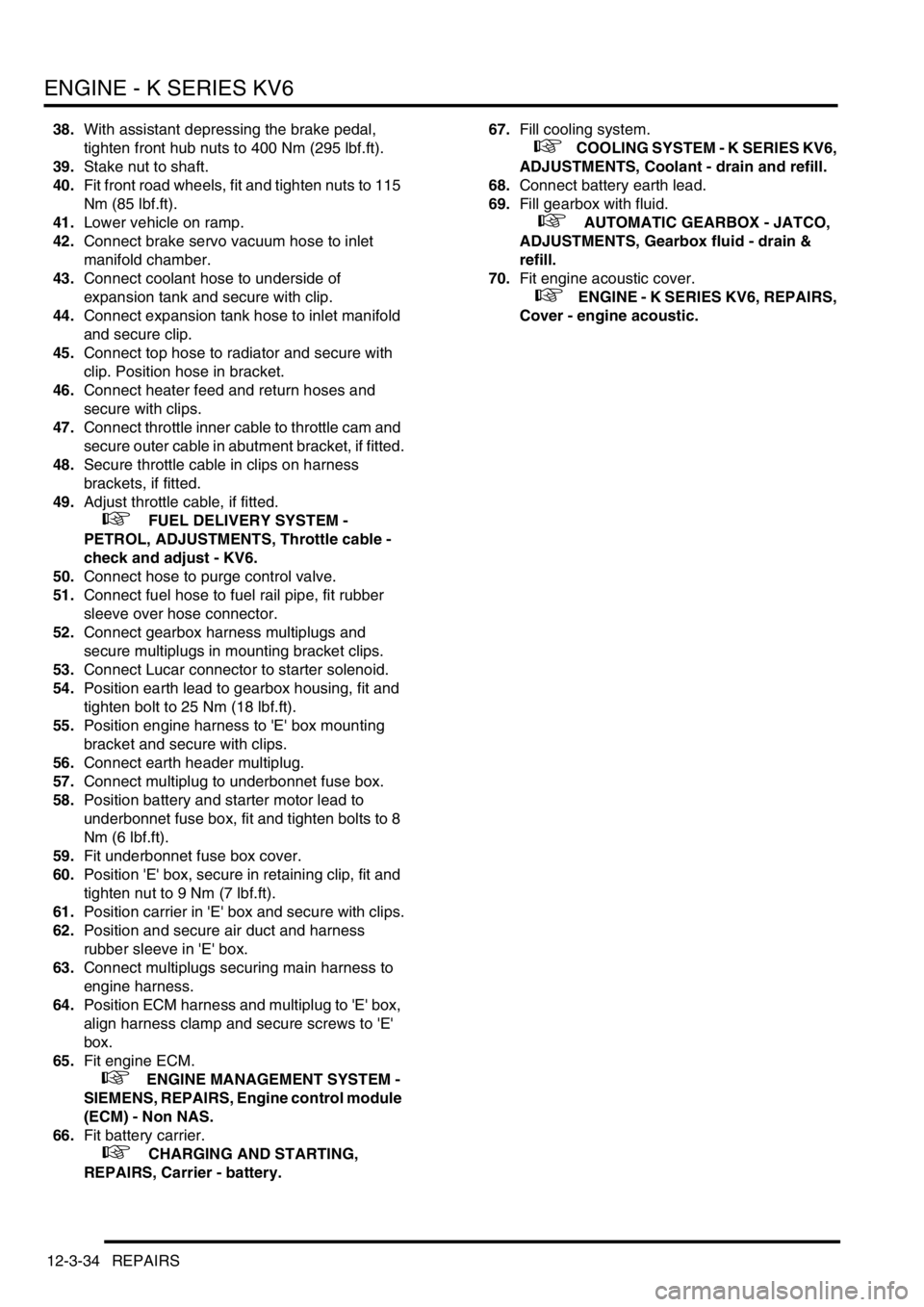

gasket.Refit

1.Clean mating surfaces of camshaft cover and

carrier.

2.Position new gasket to camshaft carrier with

arrows on gasket pointing towards inlet

manifold.

3.Position camshaft cover, fit and tighten bolts

progressively in the sequence shown to 9 Nm

(7 lbf.ft).

4.Position plug top coils, fit bolts and tighten to 9

Nm (7 lbf.ft).

5.Position earth lead to RH camshaft cover, fit

bolt and tighten to 9 Nm (7 lbf.ft).

6.Secure breather hose to camshaft cover.

7.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

8.Check engine oil, top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Page 211 of 1007

ENGINE - K SERIES KV6

12-3-34 REPAIRS

38.With assistant depressing the brake pedal,

tighten front hub nuts to 400 Nm (295 lbf.ft).

39.Stake nut to shaft.

40.Fit front road wheels, fit and tighten nuts to 115

Nm (85 lbf.ft).

41.Lower vehicle on ramp.

42.Connect brake servo vacuum hose to inlet

manifold chamber.

43.Connect coolant hose to underside of

expansion tank and secure with clip.

44.Connect expansion tank hose to inlet manifold

and secure clip.

45.Connect top hose to radiator and secure with

clip. Position hose in bracket.

46.Connect heater feed and return hoses and

secure with clips.

47.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket, if fitted.

48.Secure throttle cable in clips on harness

brackets, if fitted.

49.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

50.Connect hose to purge control valve.

51.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

52.Connect gearbox harness multiplugs and

secure multiplugs in mounting bracket clips.

53.Connect Lucar connector to starter solenoid.

54.Position earth lead to gearbox housing, fit and

tighten bolt to 25 Nm (18 lbf.ft).

55.Position engine harness to 'E' box mounting

bracket and secure with clips.

56.Connect earth header multiplug.

57.Connect multiplug to underbonnet fuse box.

58.Position battery and starter motor lead to

underbonnet fuse box, fit and tighten bolts to 8

Nm (6 lbf.ft).

59.Fit underbonnet fuse box cover.

60.Position 'E' box, secure in retaining clip, fit and

tighten nut to 9 Nm (7 lbf.ft).

61.Position carrier in 'E' box and secure with clips.

62.Position and secure air duct and harness

rubber sleeve in 'E' box.

63.Connect multiplugs securing main harness to

engine harness.

64.Position ECM harness and multiplug to 'E' box,

align harness clamp and secure screws to 'E'

box.

65.Fit engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - Non NAS.

66.Fit battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.67.Fill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

68.Connect battery earth lead.

69.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

70.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.