check engine LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 366 of 1007

COOLING SYSTEM - K SERIES KV6

ADJUSTMENTS 26-3-1

COOLING SYS TEM - K SER IES KV6 ADJUST ME NTS

Coolant - drain and refill

$% 26.10.01

Drain

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Visually check engine and cooling system for

signs of coolant leaks.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Examine hoses for signs of cracking, distortion

and security of connections.

4.Remove expansion tank filler cap.

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

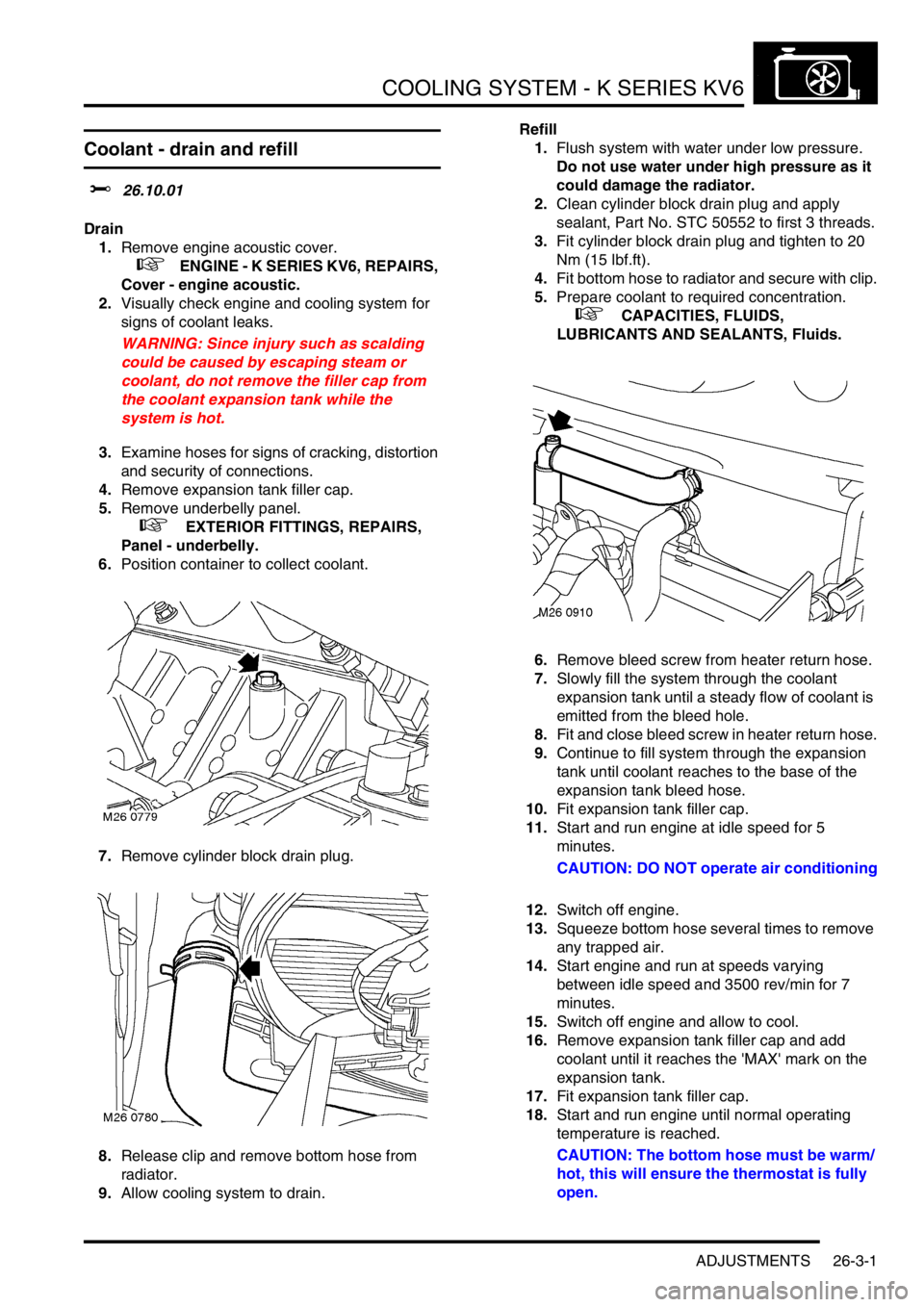

6.Position container to collect coolant.

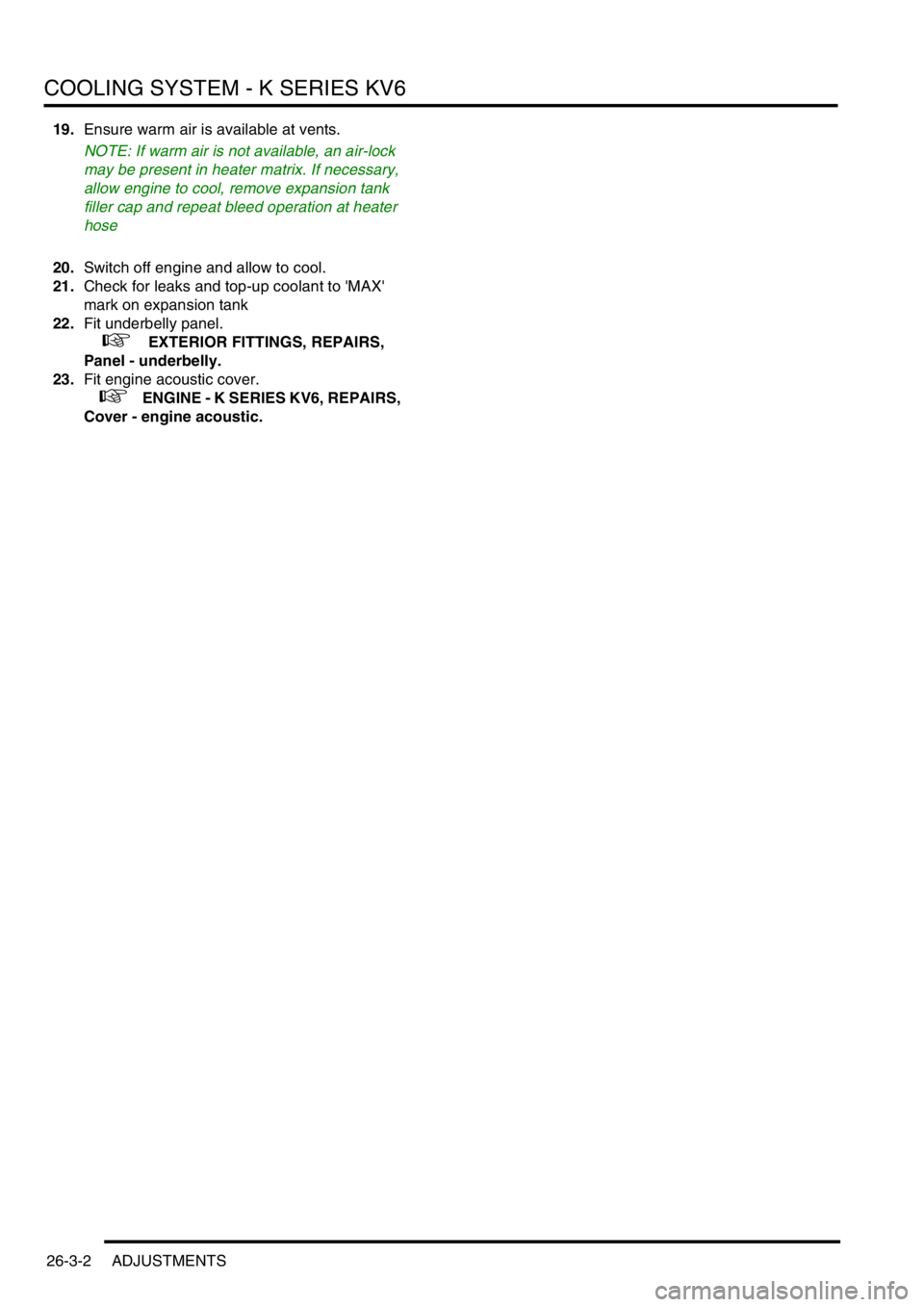

7.Remove cylinder block drain plug.

8.Release clip and remove bottom hose from

radiator.

9.Allow cooling system to drain.Refill

1.Flush system with water under low pressure.

Do not use water under high pressure as it

could damage the radiator.

2.Clean cylinder block drain plug and apply

sealant, Part No. STC 50552 to first 3 threads.

3.Fit cylinder block drain plug and tighten to 20

Nm (15 lbf.ft).

4.Fit bottom hose to radiator and secure with clip.

5.Prepare coolant to required concentration.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

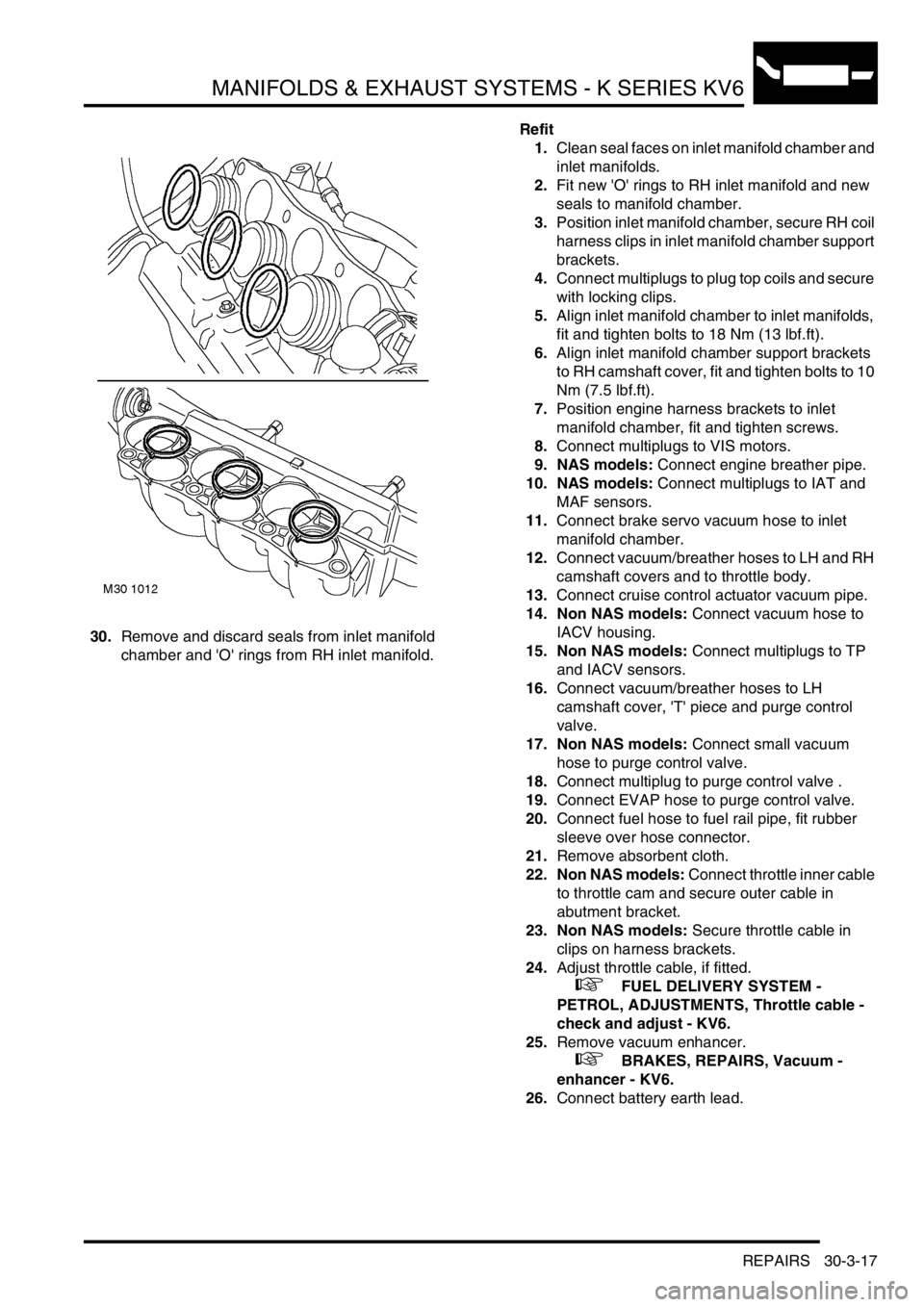

6.Remove bleed screw from heater return hose.

7.Slowly fill the system through the coolant

expansion tank until a steady flow of coolant is

emitted from the bleed hole.

8.Fit and close bleed screw in heater return hose.

9.Continue to fill system through the expansion

tank until coolant reaches to the base of the

expansion tank bleed hose.

10.Fit expansion tank filler cap.

11.Start and run engine at idle speed for 5

minutes.

CAUTION: DO NOT operate air conditioning

12.Switch off engine.

13.Squeeze bottom hose several times to remove

any trapped air.

14.Start engine and run at speeds varying

between idle speed and 3500 rev/min for 7

minutes.

15.Switch off engine and allow to cool.

16.Remove expansion tank filler cap and add

coolant until it reaches the 'MAX' mark on the

expansion tank.

17.Fit expansion tank filler cap.

18.Start and run engine until normal operating

temperature is reached.

CAUTION: The bottom hose must be warm/

hot, this will ensure the thermostat is fully

open.

Page 367 of 1007

COOLING SYSTEM - K SERIES KV6

26-3-2 ADJUSTMENTS

19.Ensure warm air is available at vents.

NOTE: If warm air is not available, an air-lock

may be present in heater matrix. If necessary,

allow engine to cool, remove expansion tank

filler cap and repeat bleed operation at heater

hose

20.Switch off engine and allow to cool.

21.Check for leaks and top-up coolant to 'MAX'

mark on expansion tank

22.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

23.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 390 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

REPAIRS 30-3-17

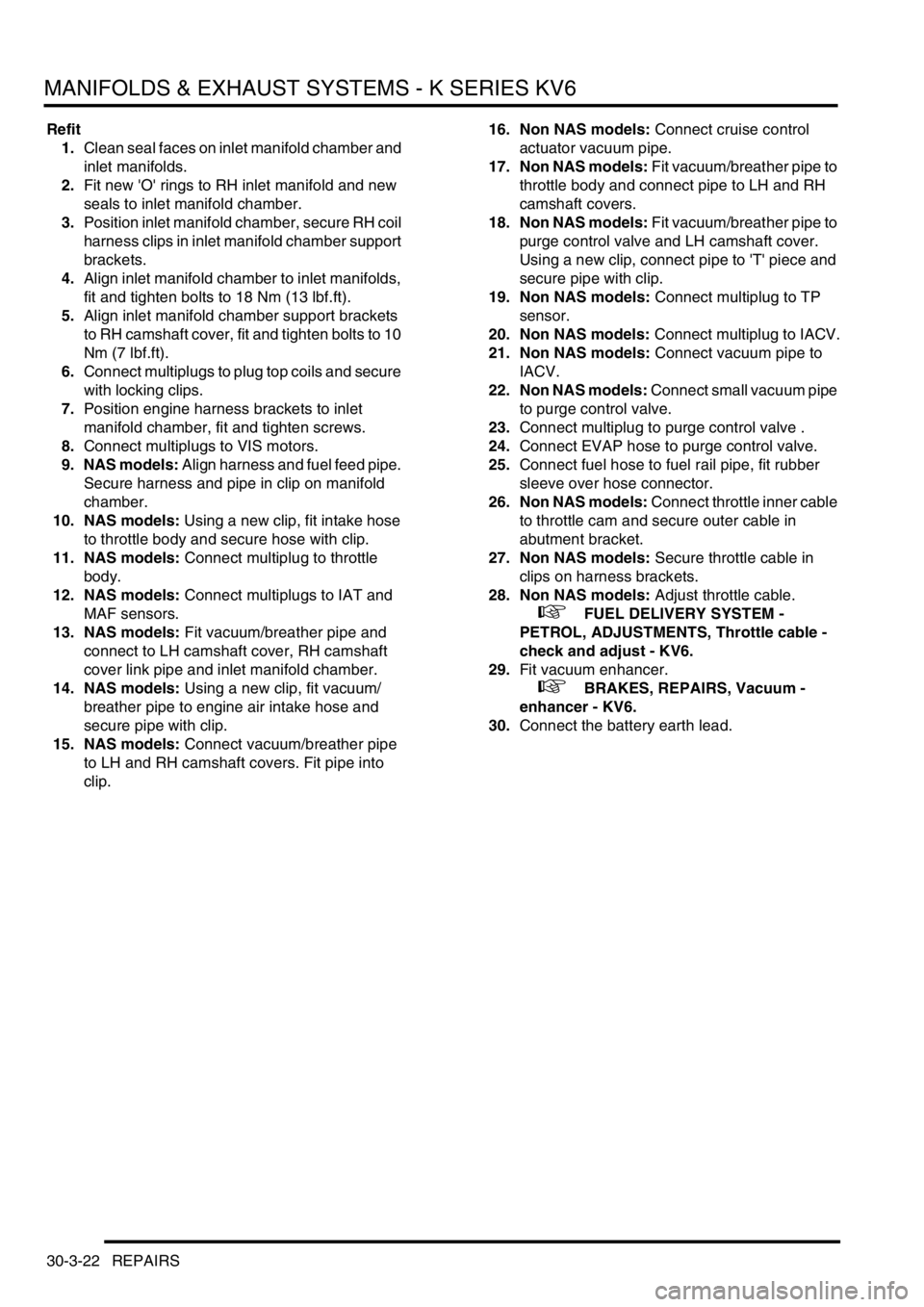

30.Remove and discard seals from inlet manifold

chamber and 'O' rings from RH inlet manifold.Refit

1.Clean seal faces on inlet manifold chamber and

inlet manifolds.

2.Fit new 'O' rings to RH inlet manifold and new

seals to manifold chamber.

3.Position inlet manifold chamber, secure RH coil

harness clips in inlet manifold chamber support

brackets.

4.Connect multiplugs to plug top coils and secure

with locking clips.

5.Align inlet manifold chamber to inlet manifolds,

fit and tighten bolts to 18 Nm (13 lbf.ft).

6.Align inlet manifold chamber support brackets

to RH camshaft cover, fit and tighten bolts to 10

Nm (7.5 lbf.ft).

7.Position engine harness brackets to inlet

manifold chamber, fit and tighten screws.

8.Connect multiplugs to VIS motors.

9. NAS models: Connect engine breather pipe.

10. NAS models: Connect multiplugs to IAT and

MAF sensors.

11.Connect brake servo vacuum hose to inlet

manifold chamber.

12.Connect vacuum/breather hoses to LH and RH

camshaft covers and to throttle body.

13.Connect cruise control actuator vacuum pipe.

14. Non NAS models: Connect vacuum hose to

IACV housing.

15. Non NAS models: Connect multiplugs to TP

and IACV sensors.

16.Connect vacuum/breather hoses to LH

camshaft cover, 'T' piece and purge control

valve.

17. Non NAS models: Connect small vacuum

hose to purge control valve.

18.Connect multiplug to purge control valve .

19.Connect EVAP hose to purge control valve.

20.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

21.Remove absorbent cloth.

22. Non NAS models: Connect throttle inner cable

to throttle cam and secure outer cable in

abutment bracket.

23. Non NAS models: Secure throttle cable in

clips on harness brackets.

24.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

25.Remove vacuum enhancer.

+ BRAKES, REPAIRS, Vacuum -

enhancer - KV6.

26.Connect battery earth lead.

Page 395 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

30-3-22 REPAIRS

Refit

1.Clean seal faces on inlet manifold chamber and

inlet manifolds.

2.Fit new 'O' rings to RH inlet manifold and new

seals to inlet manifold chamber.

3.Position inlet manifold chamber, secure RH coil

harness clips in inlet manifold chamber support

brackets.

4.Align inlet manifold chamber to inlet manifolds,

fit and tighten bolts to 18 Nm (13 lbf.ft).

5.Align inlet manifold chamber support brackets

to RH camshaft cover, fit and tighten bolts to 10

Nm (7 lbf.ft).

6.Connect multiplugs to plug top coils and secure

with locking clips.

7.Position engine harness brackets to inlet

manifold chamber, fit and tighten screws.

8.Connect multiplugs to VIS motors.

9. NAS models: Align harness and fuel feed pipe.

Secure harness and pipe in clip on manifold

chamber.

10. NAS models: Using a new clip, fit intake hose

to throttle body and secure hose with clip.

11. NAS models: Connect multiplug to throttle

body.

12. NAS models: Connect multiplugs to IAT and

MAF sensors.

13. NAS models: Fit vacuum/breather pipe and

connect to LH camshaft cover, RH camshaft

cover link pipe and inlet manifold chamber.

14. NAS models: Using a new clip, fit vacuum/

breather pipe to engine air intake hose and

secure pipe with clip.

15. NAS models: Connect vacuum/breather pipe

to LH and RH camshaft covers. Fit pipe into

clip.16. Non NAS models: Connect cruise control

actuator vacuum pipe.

17. Non NAS models: Fit vacuum/breather pipe to

throttle body and connect pipe to LH and RH

camshaft covers.

18. Non NAS models: Fit vacuum/breather pipe to

purge control valve and LH camshaft cover.

Using a new clip, connect pipe to 'T' piece and

secure pipe with clip.

19. Non NAS models: Connect multiplug to TP

sensor.

20. Non NAS models: Connect multiplug to IACV.

21. Non NAS models: Connect vacuum pipe to

IACV.

22. Non NAS models: Connect small vacuum pipe

to purge control valve.

23.Connect multiplug to purge control valve .

24.Connect EVAP hose to purge control valve.

25.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

26. Non NAS models: Connect throttle inner cable

to throttle cam and secure outer cable in

abutment bracket.

27. Non NAS models: Secure throttle cable in

clips on harness brackets.

28. Non NAS models: Adjust throttle cable.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

29.Fit vacuum enhancer.

+ BRAKES, REPAIRS, Vacuum -

enhancer - KV6.

30.Connect the battery earth lead.

Page 436 of 1007

AUTOMATIC GEARBOX - JATCO

ADJUSTMENTS 44-1

AUTOMATIC GE ARBOX - JATCO ADJUST ME NTS

Inhibitor switch - adjust

$% 44.15.18

Adjust

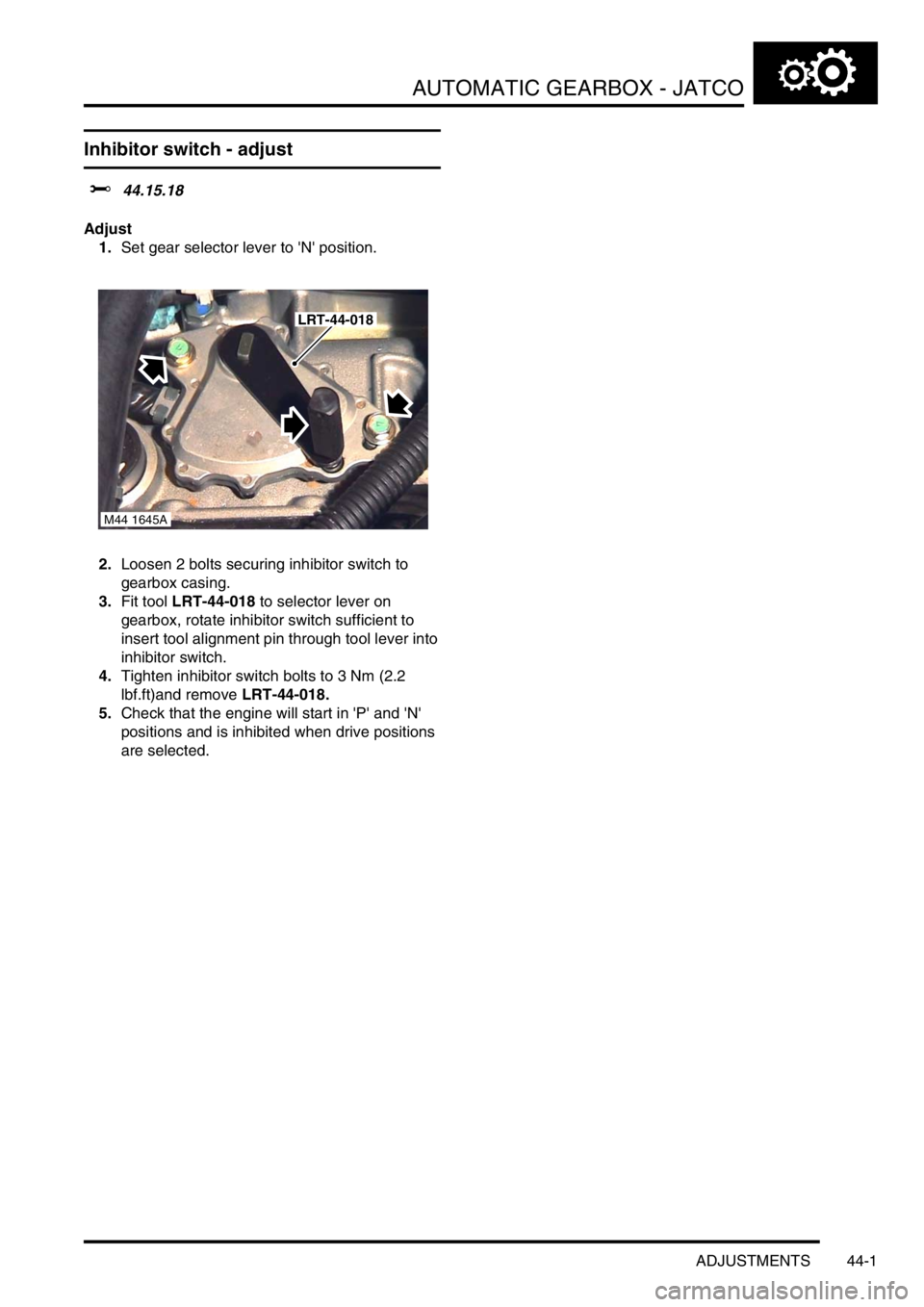

1.Set gear selector lever to 'N' position.

2.Loosen 2 bolts securing inhibitor switch to

gearbox casing.

3.Fit tool LRT-44-018 to selector lever on

gearbox, rotate inhibitor switch sufficient to

insert tool alignment pin through tool lever into

inhibitor switch.

4.Tighten inhibitor switch bolts to 3 Nm (2.2

lbf.ft)and remove LRT-44-018.

5.Check that the engine will start in 'P' and 'N'

positions and is inhibited when drive positions

are selected.

M44 1645A

LRT-44-018

Page 438 of 1007

AUTOMATIC GEARBOX - JATCO

ADJUSTMENTS 44-3

Selector cable - adjust

$% 44.30.04

Adjust

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

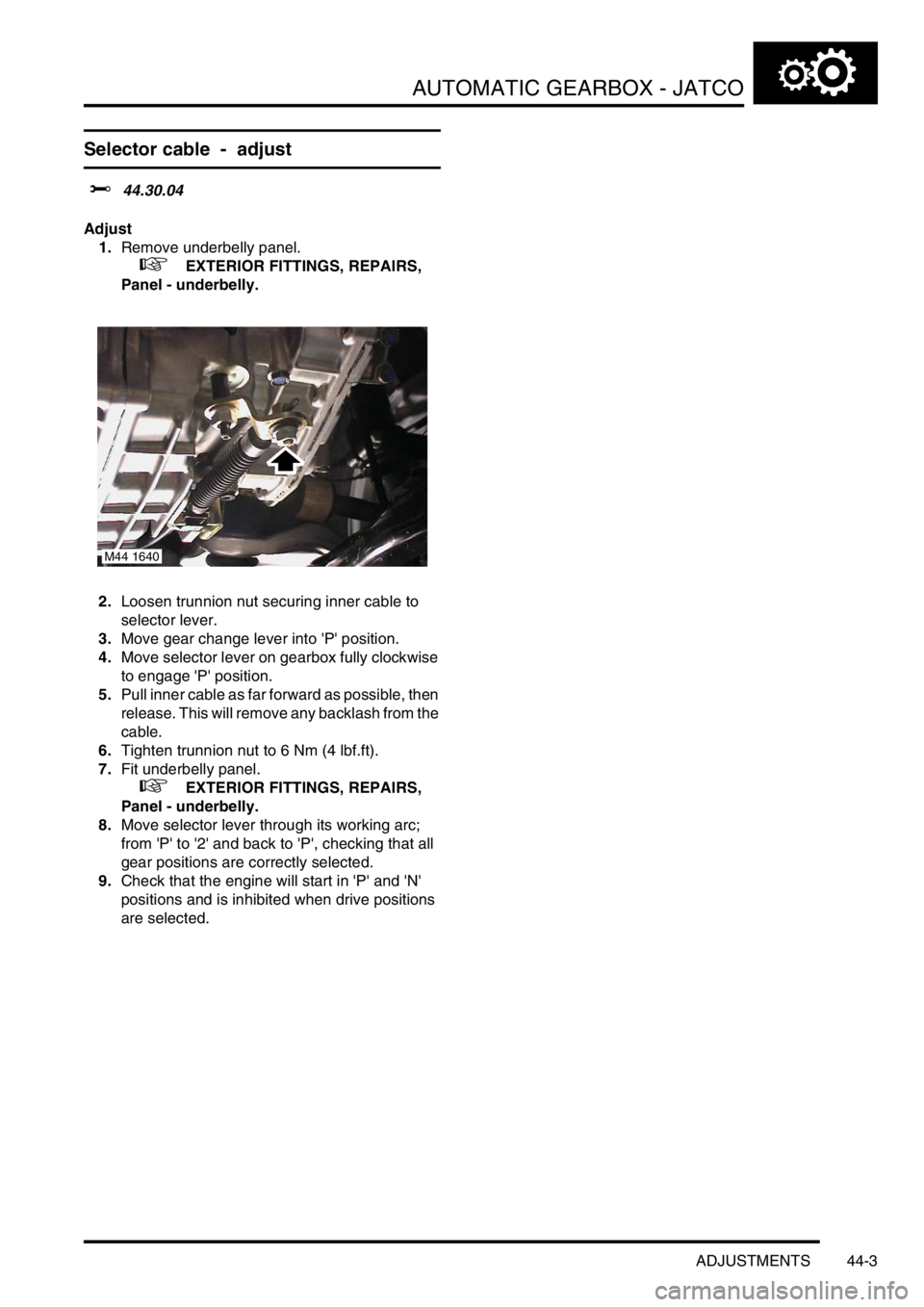

2.Loosen trunnion nut securing inner cable to

selector lever.

3.Move gear change lever into 'P' position.

4.Move selector lever on gearbox fully clockwise

to engage 'P' position.

5.Pull inner cable as far forward as possible, then

release. This will remove any backlash from the

cable.

6.Tighten trunnion nut to 6 Nm (4 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Move selector lever through its working arc;

from 'P' to '2' and back to 'P', checking that all

gear positions are correctly selected.

9.Check that the engine will start in 'P' and 'N'

positions and is inhibited when drive positions

are selected.

M44 1640

Page 451 of 1007

AUTOMATIC GEARBOX - JATCO

44-16 REPAIRS

35.Remove 2 top bolts securing gearbox to

engine.

36.Release gearbox from 2 dowels.

37.Remove gearbox assembly.

38.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Disconnect lifting equipment.

7.Clean CKP sensor and mating face.

8.Fit CKP sensor, fit bolt and tighten to 9 Nm (7

lbf.ft).

9.Position fluid cooler, tighten M12 bolts to 85 Nm

(63 lbf.ft) and M8 bolt to 25 Nm (18 lbf.ft).

10.Connect hoses to fluid cooler.

11.Clean fluid cooler unions.

12.Lubricate new 'O' rings with clean transmission

fluid and fit 'O' rings to fluid cooler hoses.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

13.Connect fluid cooler hoses to gearbox and

tighten unions to 18 Nm (13 lbf.ft).

14.Clean starter motor mating faces.

15.Position starter motor to gearbox, align CKP

sensor multiplug bracket, fit and tighten bolts to

45 Nm (33 lbf.ft).

16.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

17.Position IRD cooling hose retainer, fit bolt and

tighten to 25 Nm (18 lbf.ft).

18.Align marks on drive plate to torque converter.

19.Fit bolts securing drive plate to torque converter

and tighten bolts to 45 Nm (33 lbf.ft).

20.Clean torque converter access plate.

M44 1689

A

M44 1668

Page 457 of 1007

AUTOMATIC GEARBOX - JATCO

44-22 REPAIRS

42.Remove 2 top bolts securing gearbox to

engine.

43.Release gearbox from 2 dowels.

44.Manoeuvre and lower gearbox to floor.

45.Fit converter retaining plate and secure with

bolts.Refit

1.Remove torque converter retaining plate.

2.Ensure converter is fully located in oil pump

drive by checking depth 'A' as illustrated. Depth

A = 4 mm.

3.Clean gearbox to engine mating faces, dowels

and dowel holes.

4.Fit gearbox assembly.

5.Fit bolts securing gearbox and tighten to 85 Nm

(63 lbf.ft).

6.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

7.Position LH mounting to body, fit and tighten

bolts to 48 Nm (35 lbf.ft).

8.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

9.Disconnect lifting equipment.

10.Remove nuts and bolts securing lifting brackets

to gearbox and remove brackets.

11.Connect engine and gearbox harness

multiplugs to main harness.

12.Secure multiplugs to clips.

13.Position engine earth lead and secure with bolt.

14.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - KV6.

15.Clean throttle housing and manifold chamber

mating faces.

16.Fit new seal to inlet manifold chamber.

17.Position throttle housing to manifold chamber,

fit Torx screws and tighten to 7 Nm (7 lbf.ft).

18.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket, if fitted.

19.Connect hose to cruise control actuator.

20.Secure breather hoses to throttle housing, if

fitted.

21.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

22.Clean CKP sensor and mating face.

M44 1689

A

M44 1668

Page 461 of 1007

AUTOMATIC GEARBOX - JATCO

44-26 REPAIRS

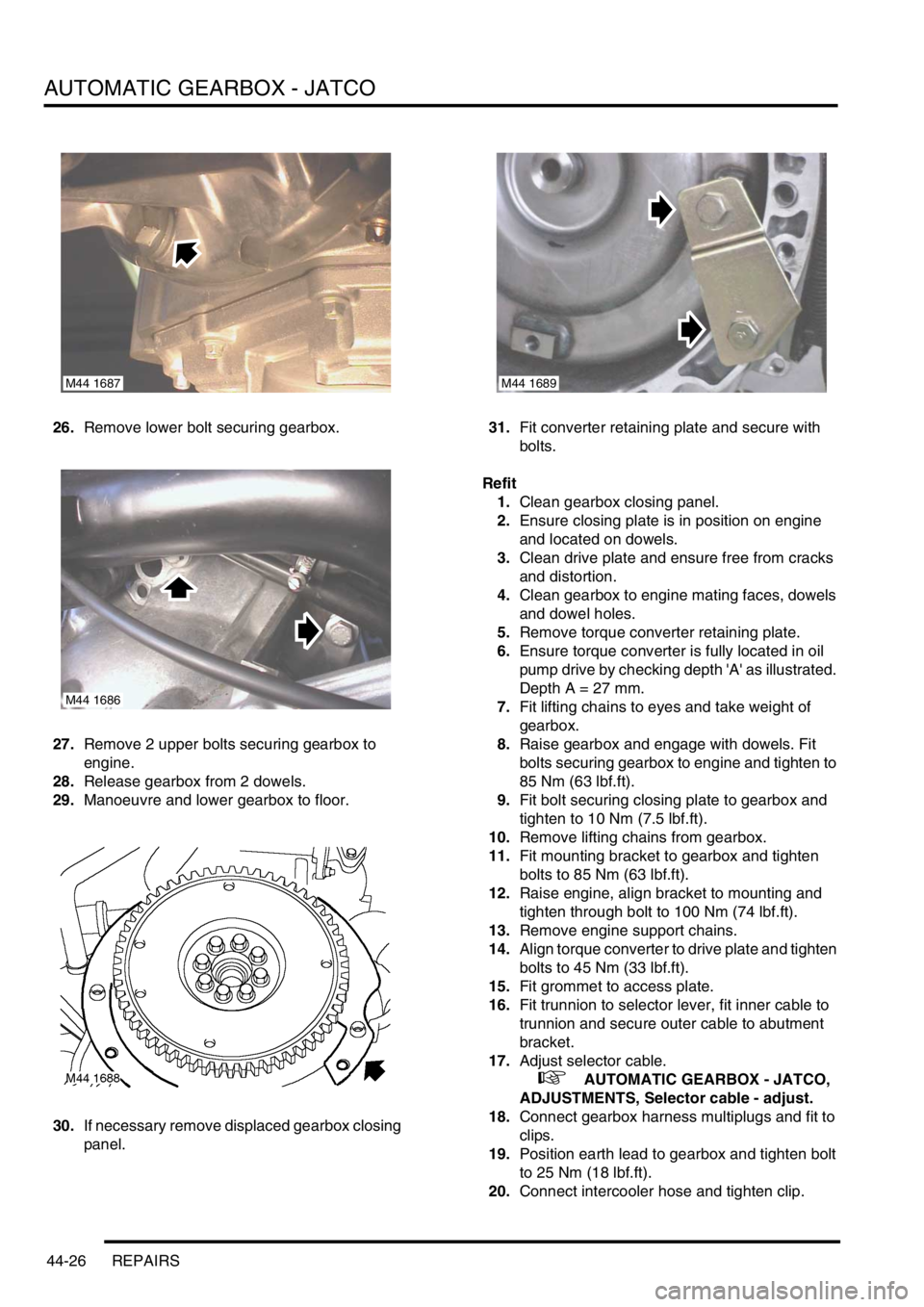

26.Remove lower bolt securing gearbox.

27.Remove 2 upper bolts securing gearbox to

engine.

28.Release gearbox from 2 dowels.

29.Manoeuvre and lower gearbox to floor.

30.If necessary remove displaced gearbox closing

panel.31.Fit converter retaining plate and secure with

bolts.

Refit

1.Clean gearbox closing panel.

2.Ensure closing plate is in position on engine

and located on dowels.

3.Clean drive plate and ensure free from cracks

and distortion.

4.Clean gearbox to engine mating faces, dowels

and dowel holes.

5.Remove torque converter retaining plate.

6.Ensure torque converter is fully located in oil

pump drive by checking depth 'A' as illustrated.

Depth A = 27 mm.

7.Fit lifting chains to eyes and take weight of

gearbox.

8.Raise gearbox and engage with dowels. Fit

bolts securing gearbox to engine and tighten to

85 Nm (63 lbf.ft).

9.Fit bolt securing closing plate to gearbox and

tighten to 10 Nm (7.5 lbf.ft).

10.Remove lifting chains from gearbox.

11.Fit mounting bracket to gearbox and tighten

bolts to 85 Nm (63 lbf.ft).

12.Raise engine, align bracket to mounting and

tighten through bolt to 100 Nm (74 lbf.ft).

13.Remove engine support chains.

14.Align torque converter to drive plate and tighten

bolts to 45 Nm (33 lbf.ft).

15.Fit grommet to access plate.

16.Fit trunnion to selector lever, fit inner cable to

trunnion and secure outer cable to abutment

bracket.

17.Adjust selector cable.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Selector cable - adjust.

18.Connect gearbox harness multiplugs and fit to

clips.

19.Position earth lead to gearbox and tighten bolt

to 25 Nm (18 lbf.ft).

20.Connect intercooler hose and tighten clip.

M44 1687

M44 1686

M44 1689

Page 494 of 1007

STEERING

ADJUSTMENTS 57-1

STEERING ADJUST ME NTS

Power assisted steering (PAS) system -

bleed

$% 57.15.02

Check

1.Switch off engine.

2.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

3.Fit reservoir filler cap.

Adjust

1.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

2.Remove filler cap from reservoir and fill

reservoir to 'UPPER' mark with Dexron II D

power steering fluid. Fluid must always be

present in reservoir while bleeding.

3.Start engine and allow to run at idle for 10

seconds. Stop engine.

4.Top-up steering fluid reservoir.

5.Start engine and turn steering fully to LH and

RH locks. Stop engine.

CAUTION: Do not hold steering at full lock

for longer than 10 seconds.

6.Top-up steering fluid reservoir.

7.Start and run engine for 2 minutes, turn

steering fully to RH and LH locks.

Cable - key interlock - adjust

$% 57.40.52

Check

1.Select position 'P'.

2.Remove key from starter switch.

3.Check that selector lever cannot be moved

from 'P' position.

4.Insert and turn key to position II.

5.Depress brake pedal and check that selector

lever can be moved from 'P' position, and key

cannot be removed from starter switch. Key

should only rotate back to a position between I

and 0.

Adjust

1.Select position 'P'.

2.Remove key from starter switch.

3.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

4.Loosen bolt securing cable clamp.

5.Pull cable away from interlock mechanism until

spring pressure is felt. Correct adjustment is

cable free play removed without compressing

spring. When correct tighten interlock cable

clamp screw to 6 Nm (4.5 lbf.ft).

6.Recheck cable operation.

7.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.