check engine LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 307 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-2 REPAIRS

Spark plugs - from 03MY

$% 18.20.02

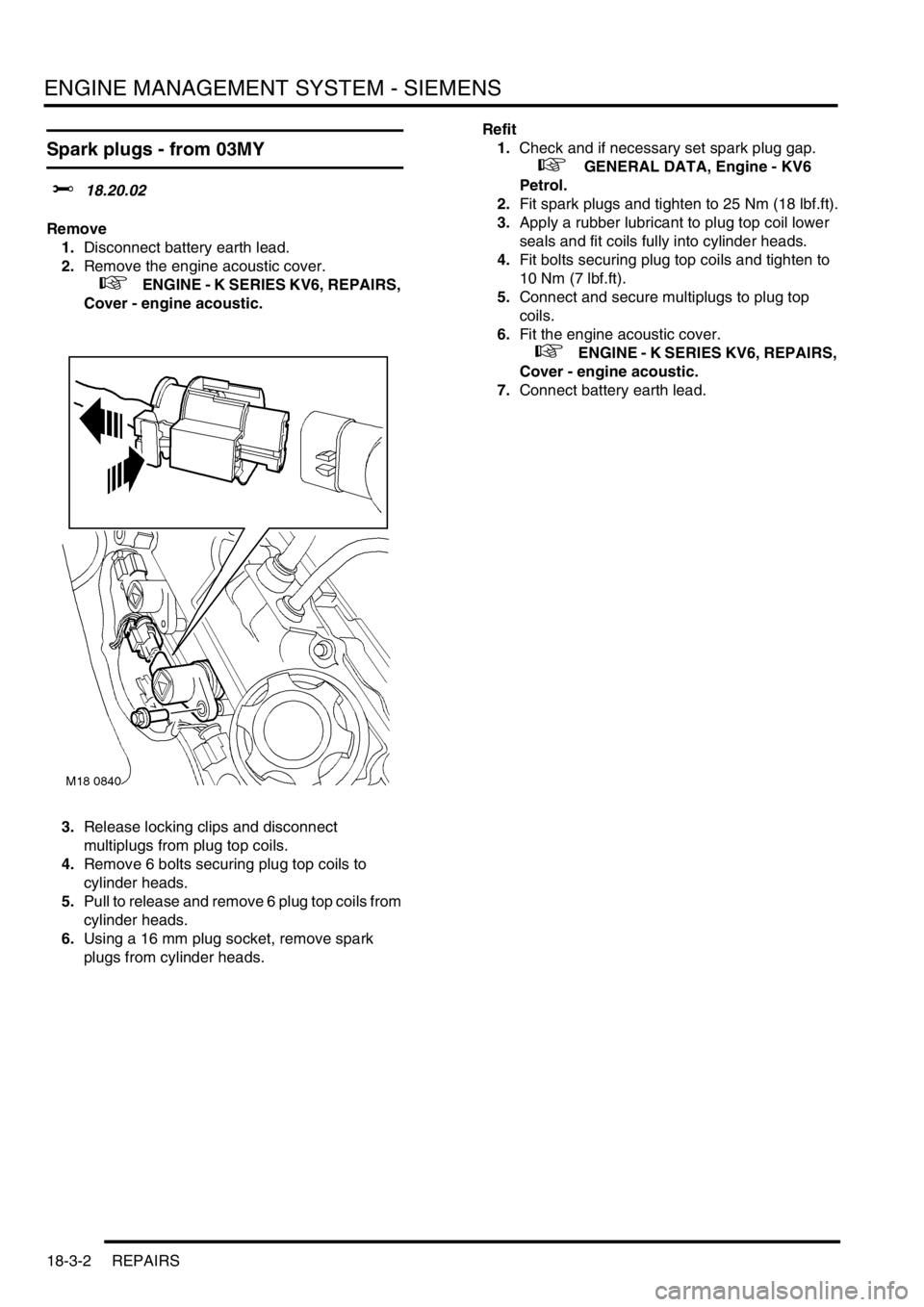

Remove

1.Disconnect battery earth lead.

2.Remove the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release locking clips and disconnect

multiplugs from plug top coils.

4.Remove 6 bolts securing plug top coils to

cylinder heads.

5.Pull to release and remove 6 plug top coils from

cylinder heads.

6.Using a 16 mm plug socket, remove spark

plugs from cylinder heads.Refit

1.Check and if necessary set spark plug gap.

+ GENERAL DATA, Engine - KV6

Petrol.

2.Fit spark plugs and tighten to 25 Nm (18 lbf.ft).

3.Apply a rubber lubricant to plug top coil lower

seals and fit coils fully into cylinder heads.

4.Fit bolts securing plug top coils and tighten to

10 Nm (7 lbf.ft).

5.Connect and secure multiplugs to plug top

coils.

6.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 316 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-11

5.Fit new Torx screws and wave washers, tighten

Torx screws to 1.5 Nm (1.1 lbf.ft).

6.Connect multiplug to TP sensor.

7.Operate throttle cable cam 2 or 3 times and

ensure that full travel to the throttle open and

the throttle closed positions is available.

8.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

9.Connect battery earth lead.

NOTE: A ‘throttle initialisation’ procedure

MUST be carried out using TestBook/T4

whenever the TP sensor is removed or

renewed.

Sensor - thermostat monitoring (TM) -

KV6 - NAS

$% 18.30.21

Remove

1.Disconnect battery earth lead.

2.Remove coolant expansion tank cap to release

pressure and refit cap.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Position absorbent cloth under TM sensor to

collect spillage.

4.Disconnect multiplug from TM sensor.

5.Release and remove sensor. Discard seal.

Refit

1.Clean sensor and mating face.

2.Using a new seal, fit and secure sensor.

3.Connect multiplug to sensor.

4.Remove absorbent cloth.

5.Check for leaks and fill expansion tank to 'MAX'

mark.

6.Connect battery earth lead.

M18 0764

Page 322 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-1

FUEL DELIVERY SYST EM - PE TROL ADJUST ME NTS

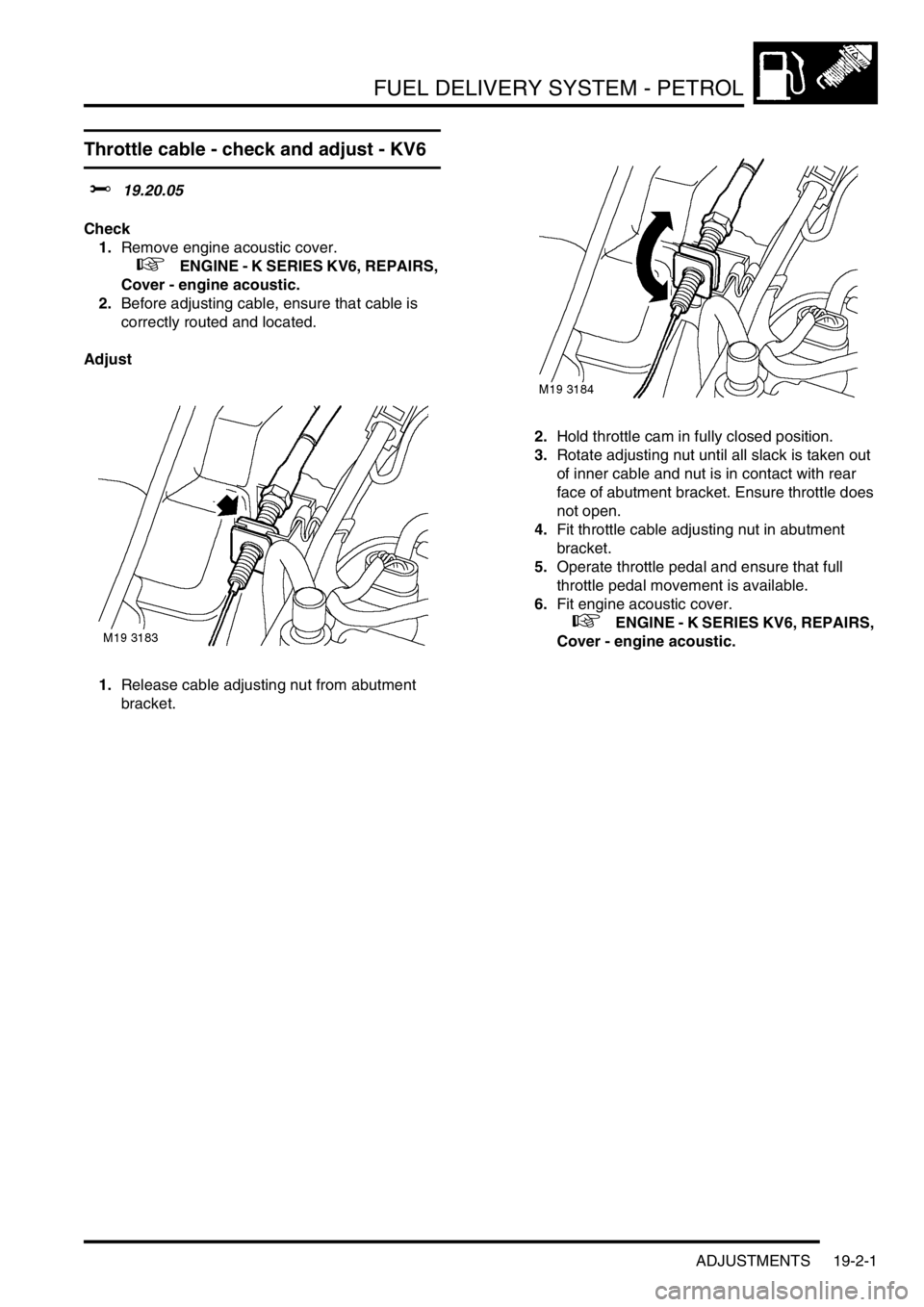

Throttle cable - check and adjust - KV6

$% 19.20.05

Check

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Before adjusting cable, ensure that cable is

correctly routed and located.

Adjust

1.Release cable adjusting nut from abutment

bracket.2.Hold throttle cam in fully closed position.

3.Rotate adjusting nut until all slack is taken out

of inner cable and nut is in contact with rear

face of abutment bracket. Ensure throttle does

not open.

4.Fit throttle cable adjusting nut in abutment

bracket.

5.Operate throttle pedal and ensure that full

throttle pedal movement is available.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 323 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-2 ADJUSTMENTS

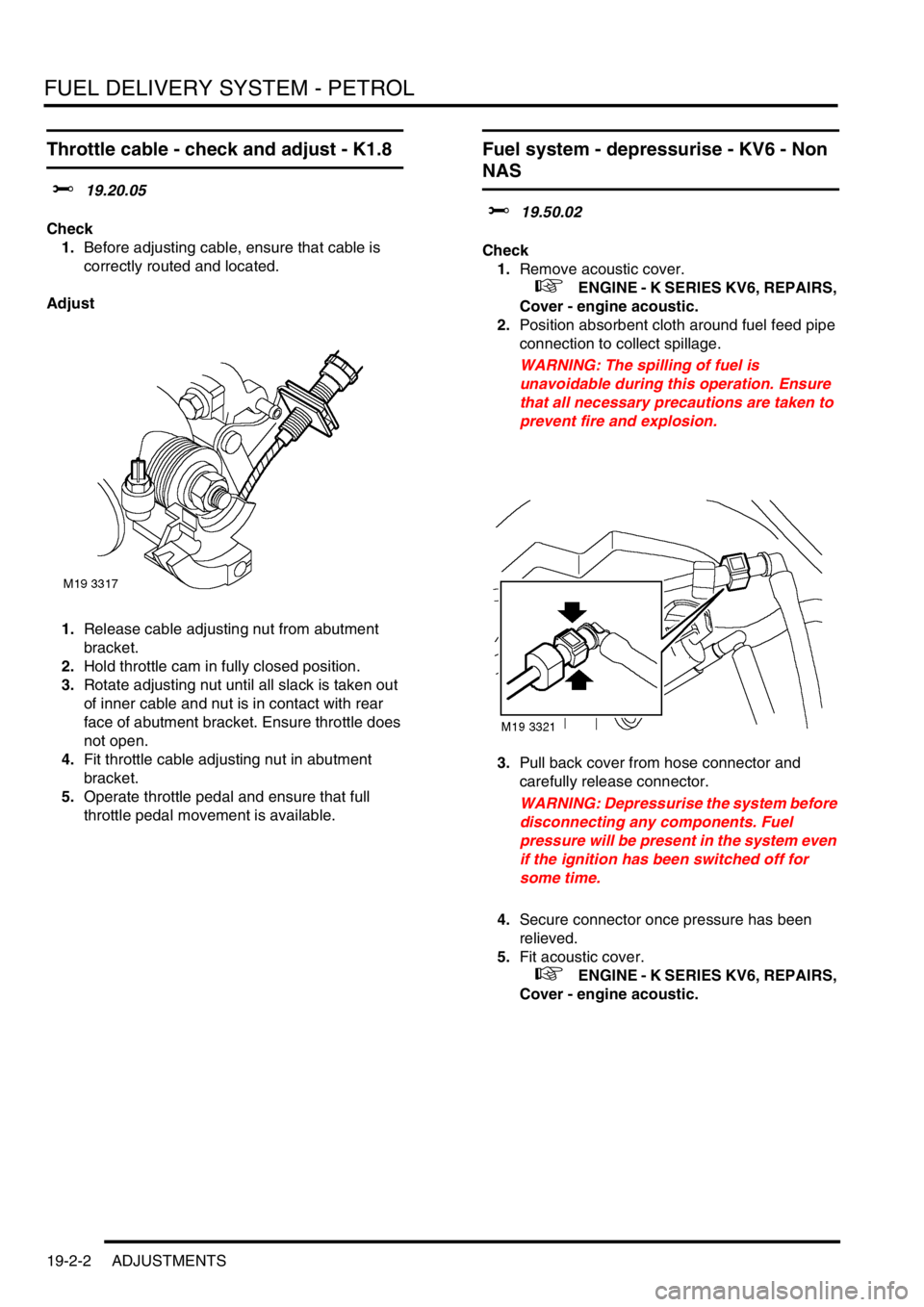

Throttle cable - check and adjust - K1.8

$% 19.20.05

Check

1.Before adjusting cable, ensure that cable is

correctly routed and located.

Adjust

1.Release cable adjusting nut from abutment

bracket.

2.Hold throttle cam in fully closed position.

3.Rotate adjusting nut until all slack is taken out

of inner cable and nut is in contact with rear

face of abutment bracket. Ensure throttle does

not open.

4.Fit throttle cable adjusting nut in abutment

bracket.

5.Operate throttle pedal and ensure that full

throttle pedal movement is available.

Fuel system - depressurise - KV6 - Non

NAS

$% 19.50.02

Check

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Pull back cover from hose connector and

carefully release connector.

WARNING: Depressurise the system before

disconnecting any components. Fuel

pressure will be present in the system even

if the ignition has been switched off for

some time.

4.Secure connector once pressure has been

relieved.

5.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 324 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-3

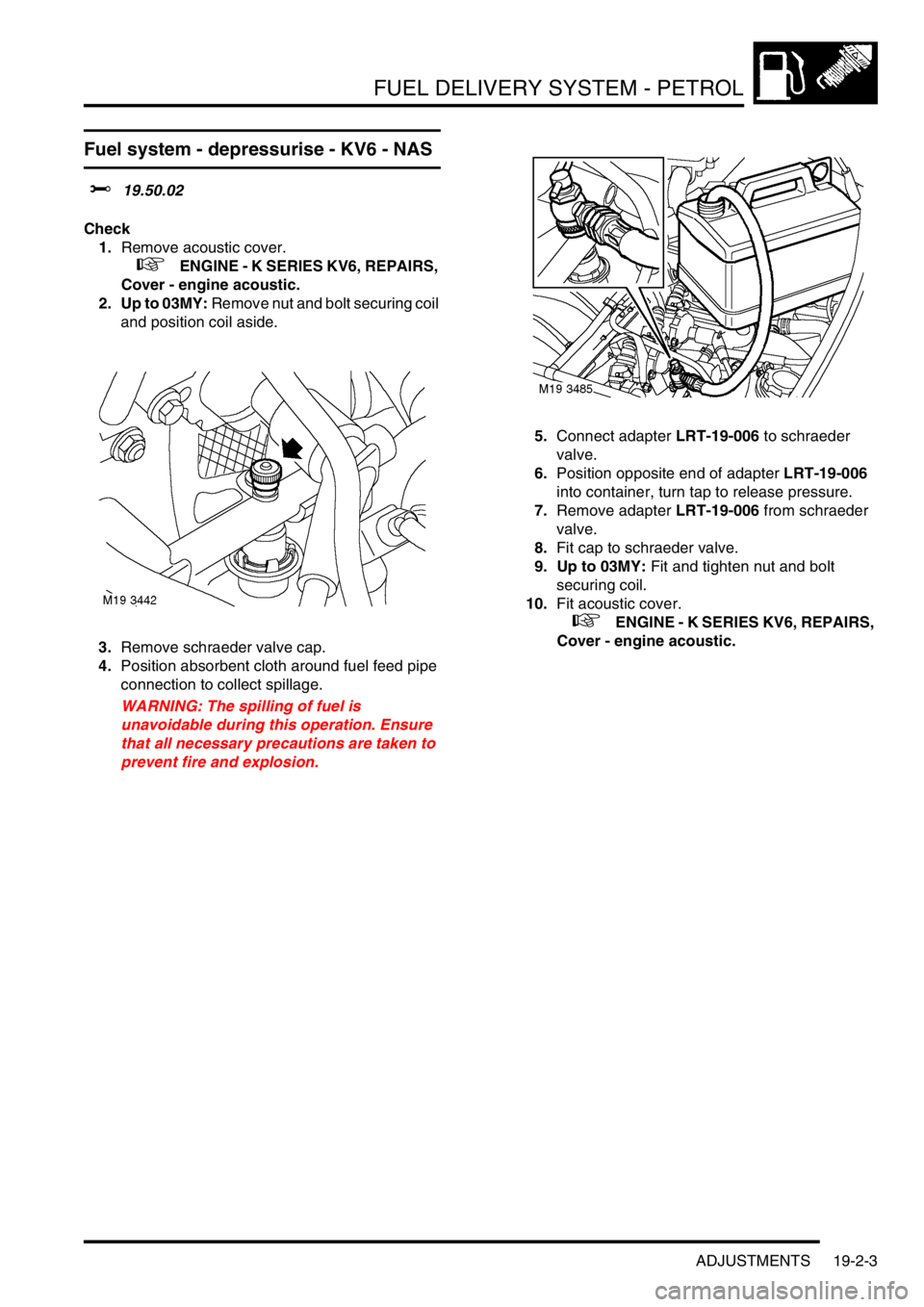

Fuel system - depressurise - KV6 - NAS

$% 19.50.02

Check

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

3.Remove schraeder valve cap.

4.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.5.Connect adapter LRT-19-006 to schraeder

valve.

6.Position opposite end of adapter LRT-19-006

into container, turn tap to release pressure.

7.Remove adapter LRT-19-006 from schraeder

valve.

8.Fit cap to schraeder valve.

9. Up to 03MY: Fit and tighten nut and bolt

securing coil.

10.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 325 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-4 ADJUSTMENTS

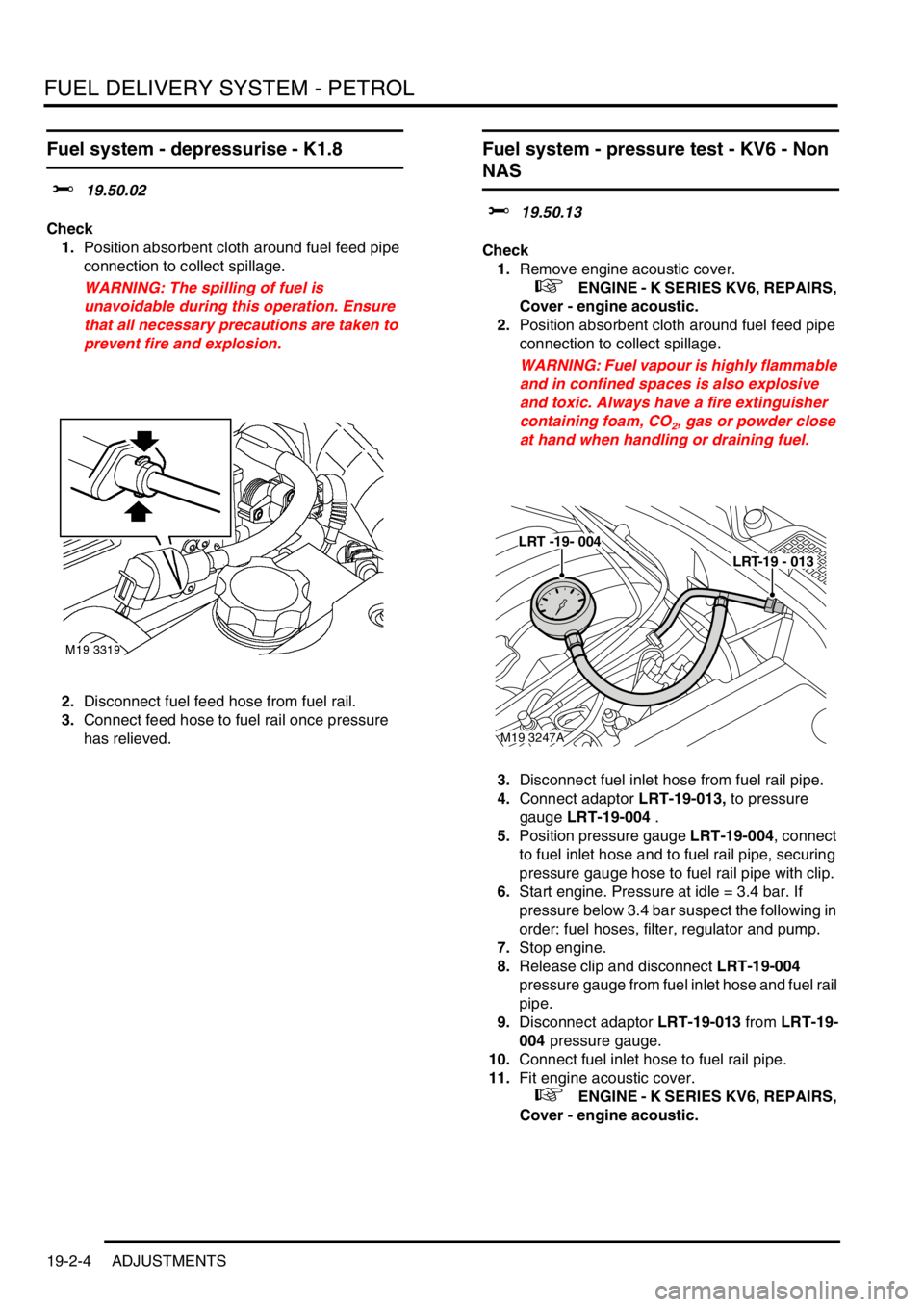

Fuel system - depressurise - K1.8

$% 19.50.02

Check

1.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

2.Disconnect fuel feed hose from fuel rail.

3.Connect feed hose to fuel rail once pressure

has relieved.

Fuel system - pressure test - KV6 - Non

NAS

$% 19.50.13

Check

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3.Disconnect fuel inlet hose from fuel rail pipe.

4.Connect adaptor LRT-19-013, to pressure

gauge LRT-19-004 .

5.Position pressure gauge LRT-19-004, connect

to fuel inlet hose and to fuel rail pipe, securing

pressure gauge hose to fuel rail pipe with clip.

6.Start engine. Pressure at idle = 3.4 bar. If

pressure below 3.4 bar suspect the following in

order: fuel hoses, filter, regulator and pump.

7.Stop engine.

8.Release clip and disconnect LRT-19-004

pressure gauge from fuel inlet hose and fuel rail

pipe.

9.Disconnect adaptor LRT-19-013 from LRT-19-

004 pressure gauge.

10.Connect fuel inlet hose to fuel rail pipe.

11.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

M19 3247A

LRT-19 - 013

LRT -19- 004

Page 326 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-5

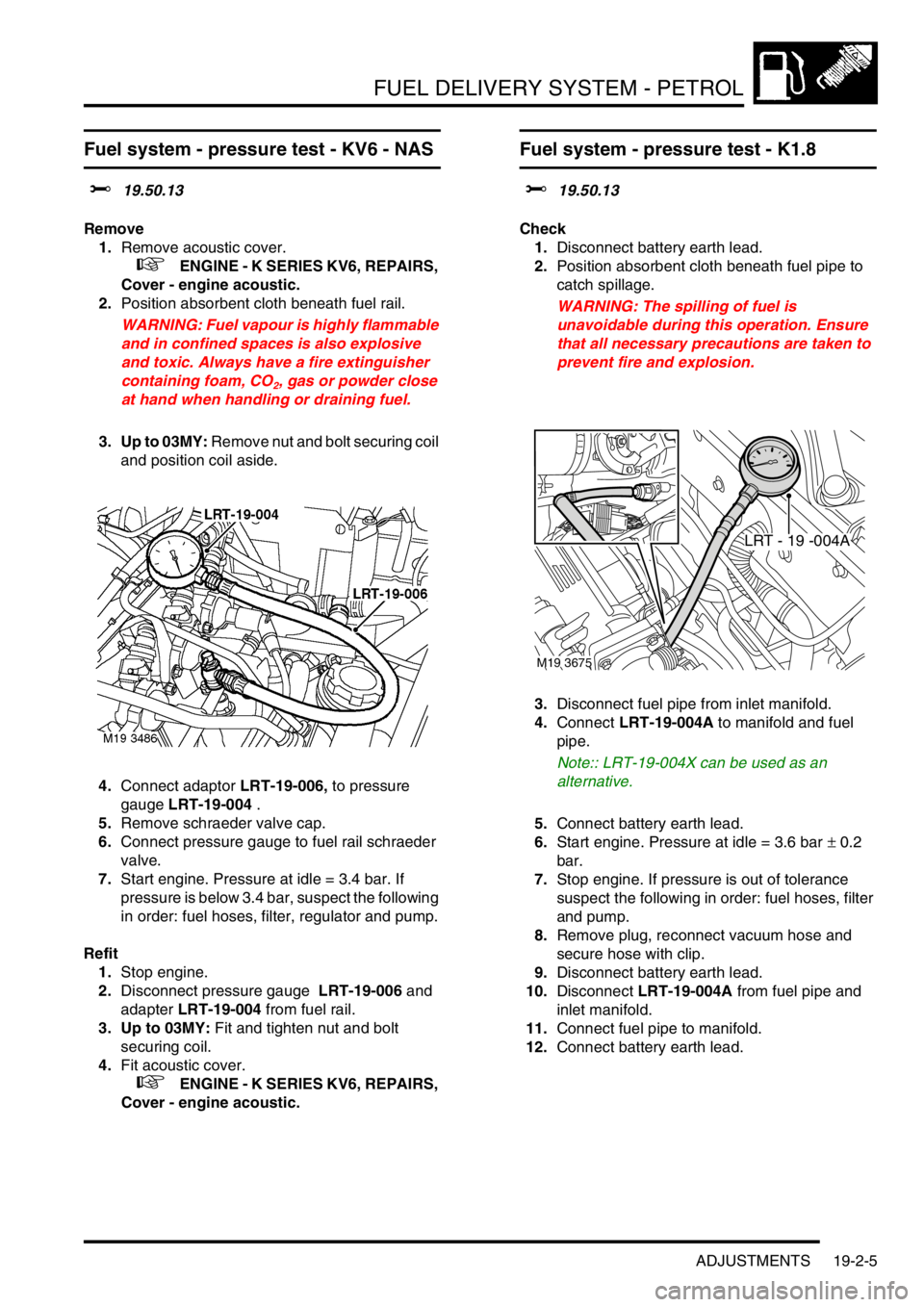

Fuel system - pressure test - KV6 - NAS

$% 19.50.13

Remove

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth beneath fuel rail.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

4.Connect adaptor LRT-19-006, to pressure

gauge LRT-19-004 .

5.Remove schraeder valve cap.

6.Connect pressure gauge to fuel rail schraeder

valve.

7.Start engine. Pressure at idle = 3.4 bar. If

pressure is below 3.4 bar, suspect the following

in order: fuel hoses, filter, regulator and pump.

Refit

1.Stop engine.

2.Disconnect pressure gauge LRT-19-006 and

adapter LRT-19-004 from fuel rail.

3. Up to 03MY: Fit and tighten nut and bolt

securing coil.

4.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Fuel system - pressure test - K1.8

$% 19.50.13

Check

1.Disconnect battery earth lead.

2.Position absorbent cloth beneath fuel pipe to

catch spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Disconnect fuel pipe from inlet manifold.

4.Connect LRT-19-004A to manifold and fuel

pipe.

Note:: LRT-19-004X can be used as an

alternative.

5.Connect battery earth lead.

6.Start engine. Pressure at idle = 3.6 bar ± 0.2

bar.

7.Stop engine. If pressure is out of tolerance

suspect the following in order: fuel hoses, filter

and pump.

8.Remove plug, reconnect vacuum hose and

secure hose with clip.

9.Disconnect battery earth lead.

10.Disconnect LRT-19-004A from fuel pipe and

inlet manifold.

11.Connect fuel pipe to manifold.

12.Connect battery earth lead.

LRT - 19 -004A

M19 3675

Page 331 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-10 REPAIRS

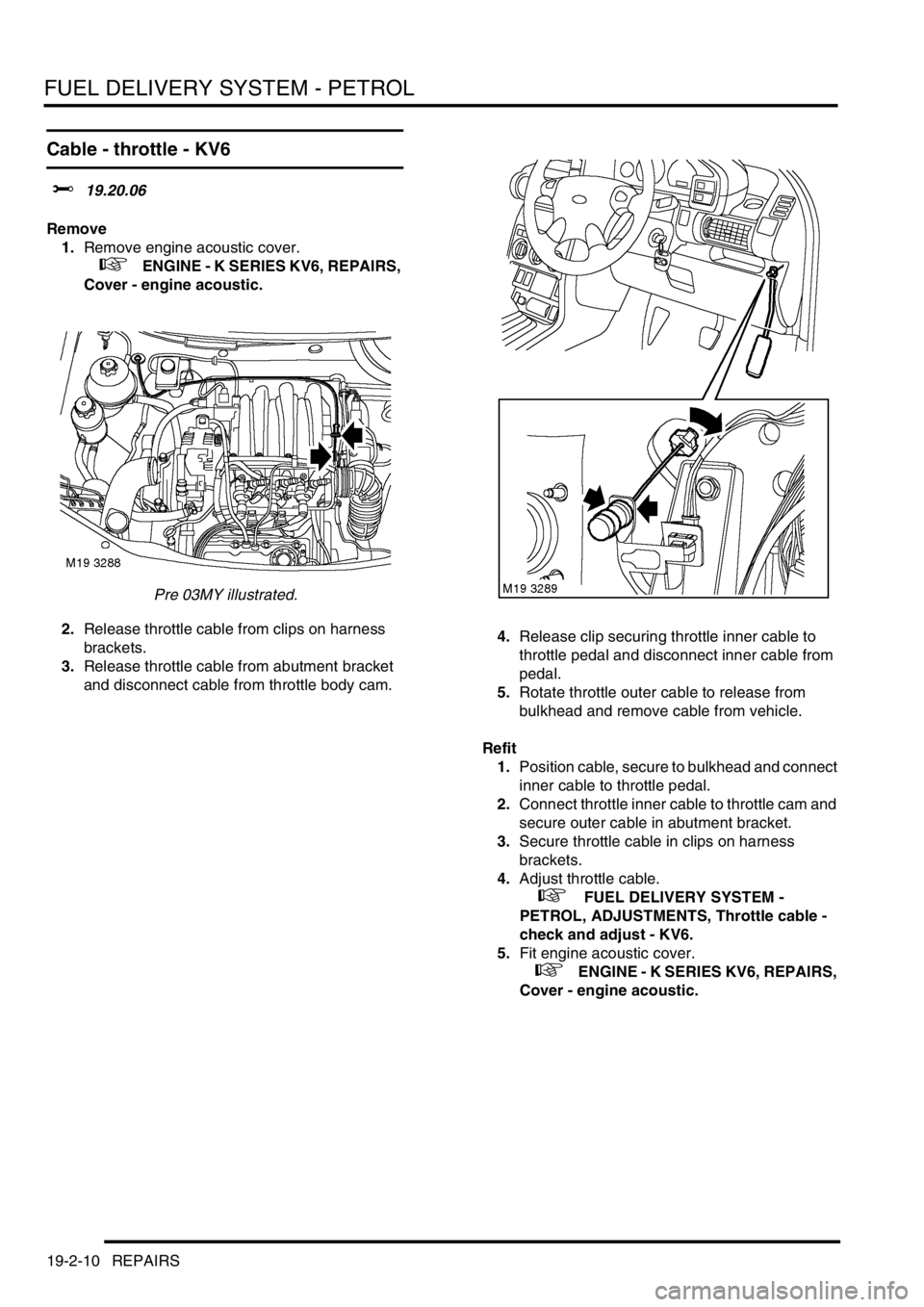

Cable - throttle - KV6

$% 19.20.06

Remove

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Pre 03MY illustrated.

2.Release throttle cable from clips on harness

brackets.

3.Release throttle cable from abutment bracket

and disconnect cable from throttle body cam.4.Release clip securing throttle inner cable to

throttle pedal and disconnect inner cable from

pedal.

5.Rotate throttle outer cable to release from

bulkhead and remove cable from vehicle.

Refit

1.Position cable, secure to bulkhead and connect

inner cable to throttle pedal.

2.Connect throttle inner cable to throttle cam and

secure outer cable in abutment bracket.

3.Secure throttle cable in clips on harness

brackets.

4.Adjust throttle cable.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

5.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 342 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-21

Refit

1.Clean mating faces of IACV and throttle body.

2.Fit new gasket, position IACV to throttle body,

fit and tighten Allen screws to 6 Nm (4.5 lbf.ft).

3.Clean TP sensor and throttle body mating face.

4.Fit TP sensor to throttle spindle. Ensure that

during fitting the machined flat on the throttle

spindle is aligned with the mating portion of the

TP sensor

CAUTION: The throttle position sensor can

be easily damaged during fitting. When

pressing the sensor onto the throttle

spindle, use fingers only, and only apply

pressure to the area shown shaded in the

illustration.

5.Rotate TP sensor in an anti-clockwise direction

to align fixing holes.

CAUTION: Do not rotate throttle position

sensor in a clockwise direction and ensure

that it is not rotated beyond its internal

stops.

6.Fit TP sensor specification plate.

7.Fit new Torx screws and wave washers, tighten

Torx screws to 1.5 Nm _1.0 lbf.ft).

8. Vehicles with cruise control: Position

actuator support bracket to throttle body. Fit

Torx screws and tighten to 9 Nm (7 lbf.ft).

Connect actuator arm to throttle linkage.

9.Clean throttle body and mating face on inlet

manifold chamber.

10.Fit new seal to inlet manifold chamber.

11.Position throttle body to inlet manifold chamber,

fit and tighten Torx screws to 7 Nm ( 5 lbf.ft).

12.Connect multiplugs to TP sensor and IACV.

13. Vehicles with cruise control: Connect cruise

control actuator vacuum hose.

14.Connect primary throttle cable to throttle cam

and abutment bracket.

15.Connect engine breather/vacuum pipes to

throttle body and IACV.16.Adjust throttle cable.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

17.Connect battery earth lead.

18.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

19.Retune using TestBook

M18 0695

Page 361 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-40 REPAIRS

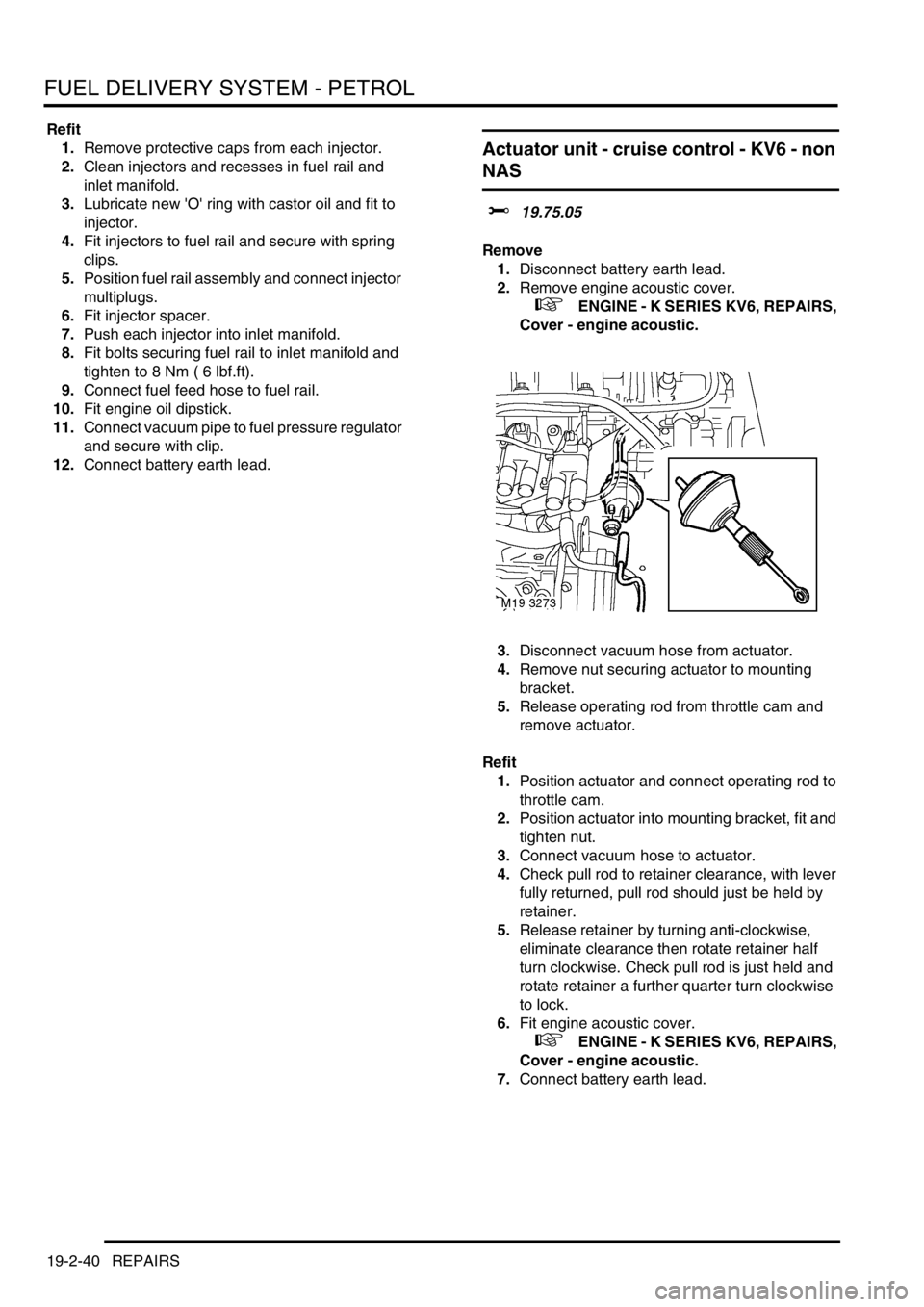

Refit

1.Remove protective caps from each injector.

2.Clean injectors and recesses in fuel rail and

inlet manifold.

3.Lubricate new 'O' ring with castor oil and fit to

injector.

4.Fit injectors to fuel rail and secure with spring

clips.

5.Position fuel rail assembly and connect injector

multiplugs.

6.Fit injector spacer.

7.Push each injector into inlet manifold.

8.Fit bolts securing fuel rail to inlet manifold and

tighten to 8 Nm ( 6 lbf.ft).

9.Connect fuel feed hose to fuel rail.

10.Fit engine oil dipstick.

11.Connect vacuum pipe to fuel pressure regulator

and secure with clip.

12.Connect battery earth lead.

Actuator unit - cruise control - KV6 - non

NAS

$% 19.75.05

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Disconnect vacuum hose from actuator.

4.Remove nut securing actuator to mounting

bracket.

5.Release operating rod from throttle cam and

remove actuator.

Refit

1.Position actuator and connect operating rod to

throttle cam.

2.Position actuator into mounting bracket, fit and

tighten nut.

3.Connect vacuum hose to actuator.

4.Check pull rod to retainer clearance, with lever

fully returned, pull rod should just be held by

retainer.

5.Release retainer by turning anti-clockwise,

eliminate clearance then rotate retainer half

turn clockwise. Check pull rod is just held and

rotate retainer a further quarter turn clockwise

to lock.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.