dimensions LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 748 of 1007

BODY DIMENSIONS

BODY DIMENSIONS 77-1-13

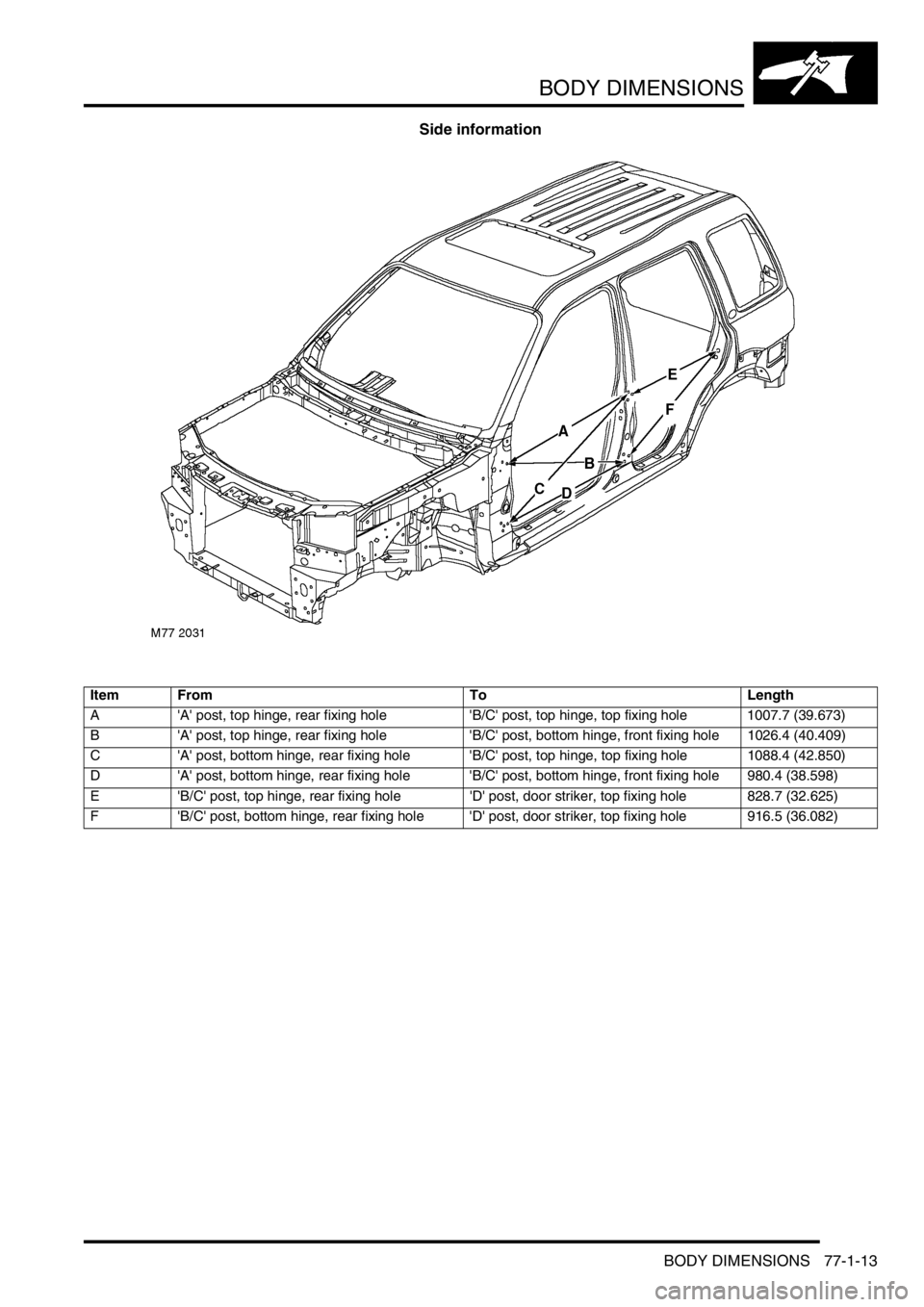

Side information

Item From To Length

A 'A' post, top hinge, rear fixing hole 'B/C' post, top hinge, top fixing hole 1007.7 (39.673)

B 'A' post, top hinge, rear fixing hole 'B/C' post, bottom hinge, front fixing hole 1026.4 (40.409)

C 'A' post, bottom hinge, rear fixing hole 'B/C' post, top hinge, top fixing hole 1088.4 (42.850)

D 'A' post, bottom hinge, rear fixing hole 'B/C' post, bottom hinge, front fixing hole 980.4 (38.598)

E 'B/C' post, top hinge, rear fixing hole 'D' post, door striker, top fixing hole 828.7 (32.625)

F 'B/C' post, bottom hinge, rear fixing hole 'D' post, door striker, top fixing hole 916.5 (36.082)

Page 749 of 1007

BODY DIMENSIONS

77-1-14 BODY DIMENSIONS

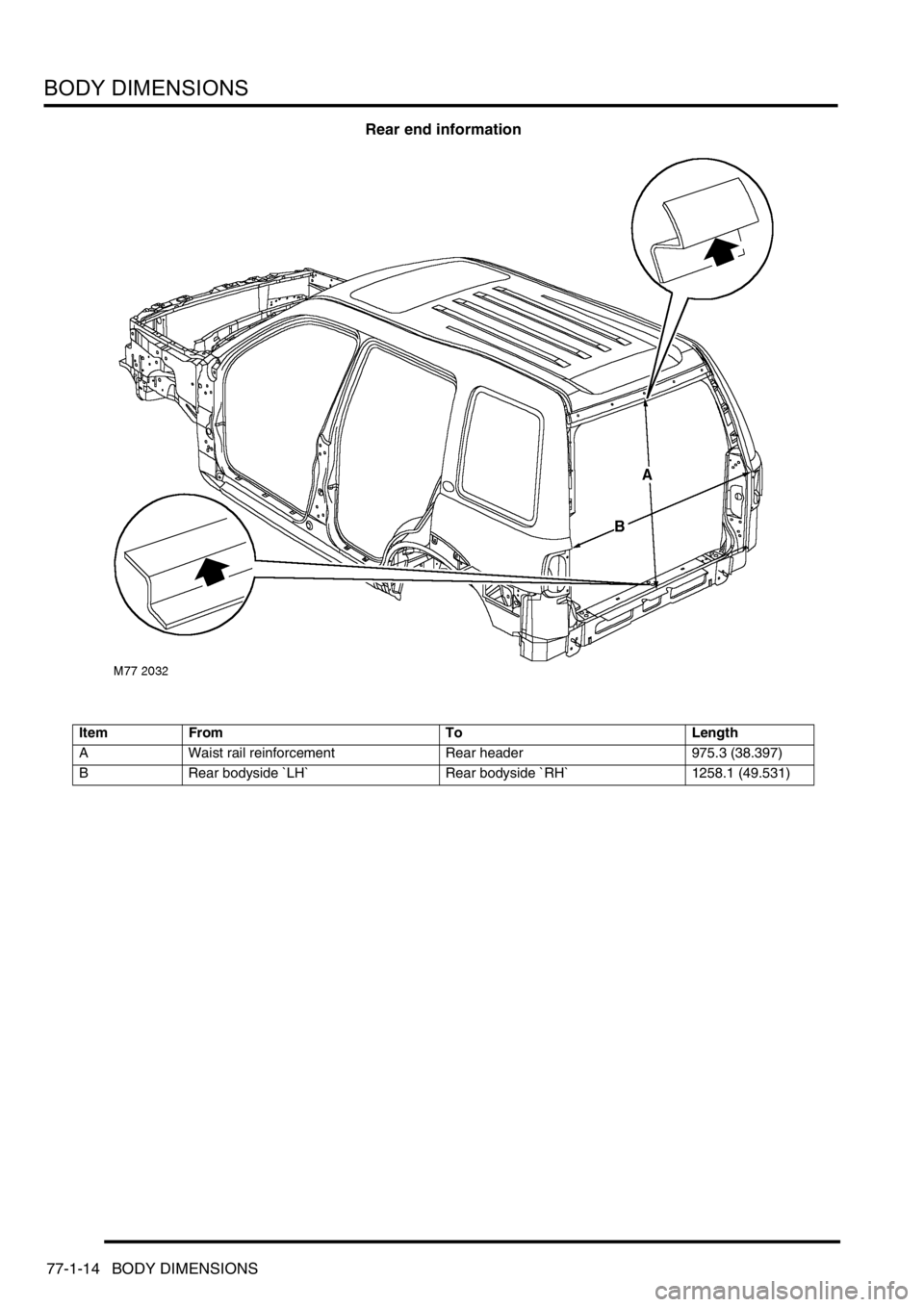

Rear end information

Item From To Length

A Waist rail reinforcement Rear header 975.3 (38.397)

B Rear bodyside `LH` Rear bodyside `RH` 1258.1 (49.531)

Page 750 of 1007

BODY DIMENSIONS

BODY DIMENSIONS 77-1-15

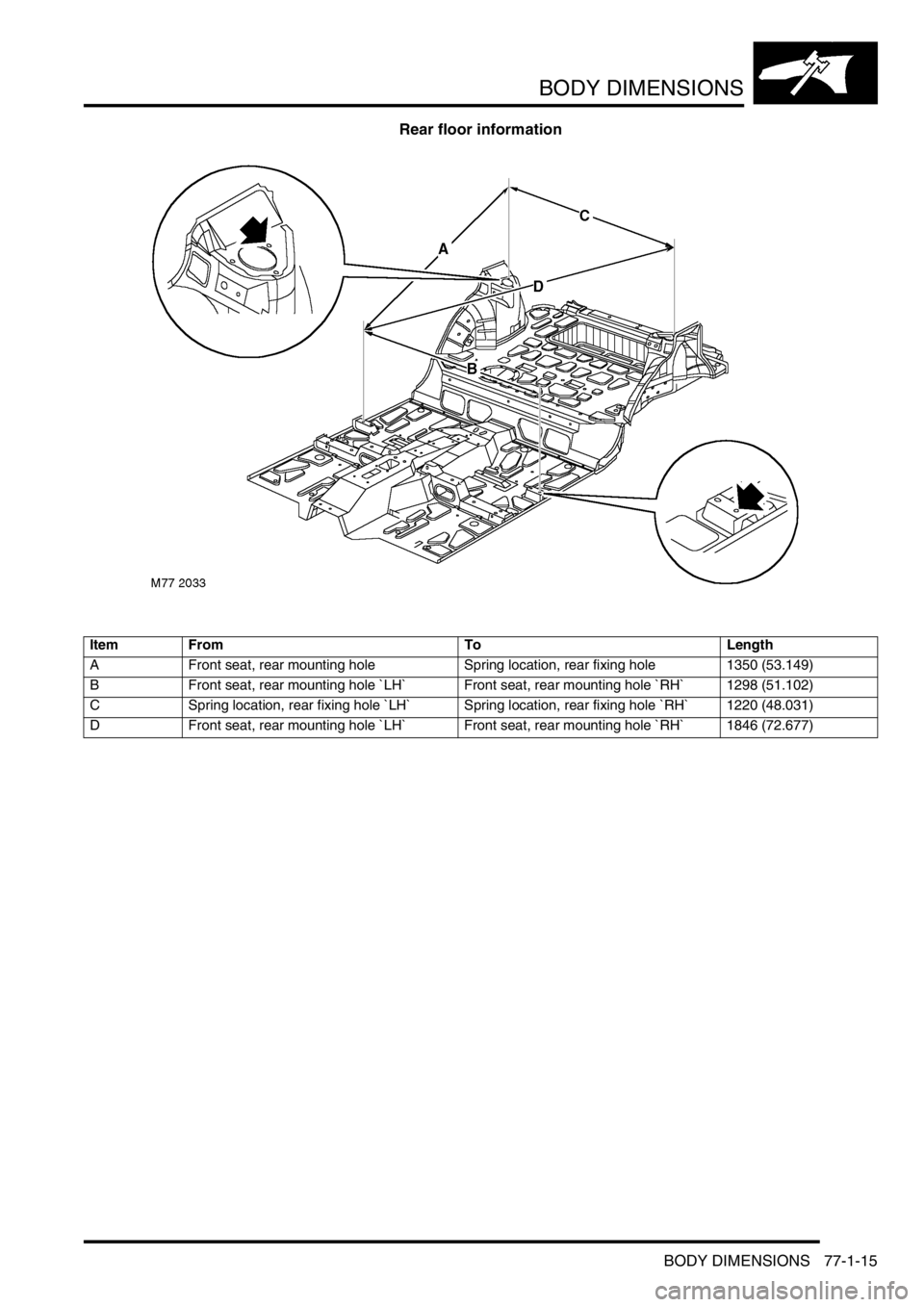

Rear floor information

Item From To Length

A Front seat, rear mounting hole Spring location, rear fixing hole 1350 (53.149)

B Front seat, rear mounting hole `LH` Front seat, rear mounting hole `RH` 1298 (51.102)

C Spring location, rear fixing hole `LH` Spring location, rear fixing hole `RH` 1220 (48.031)

D Front seat, rear mounting hole `LH` Front seat, rear mounting hole `RH` 1846 (72.677)

Page 752 of 1007

BODY DIMENSIONS

BODY GAPS AND PROFILES 77-1-17

BODY GAPS AND PROF ILE S

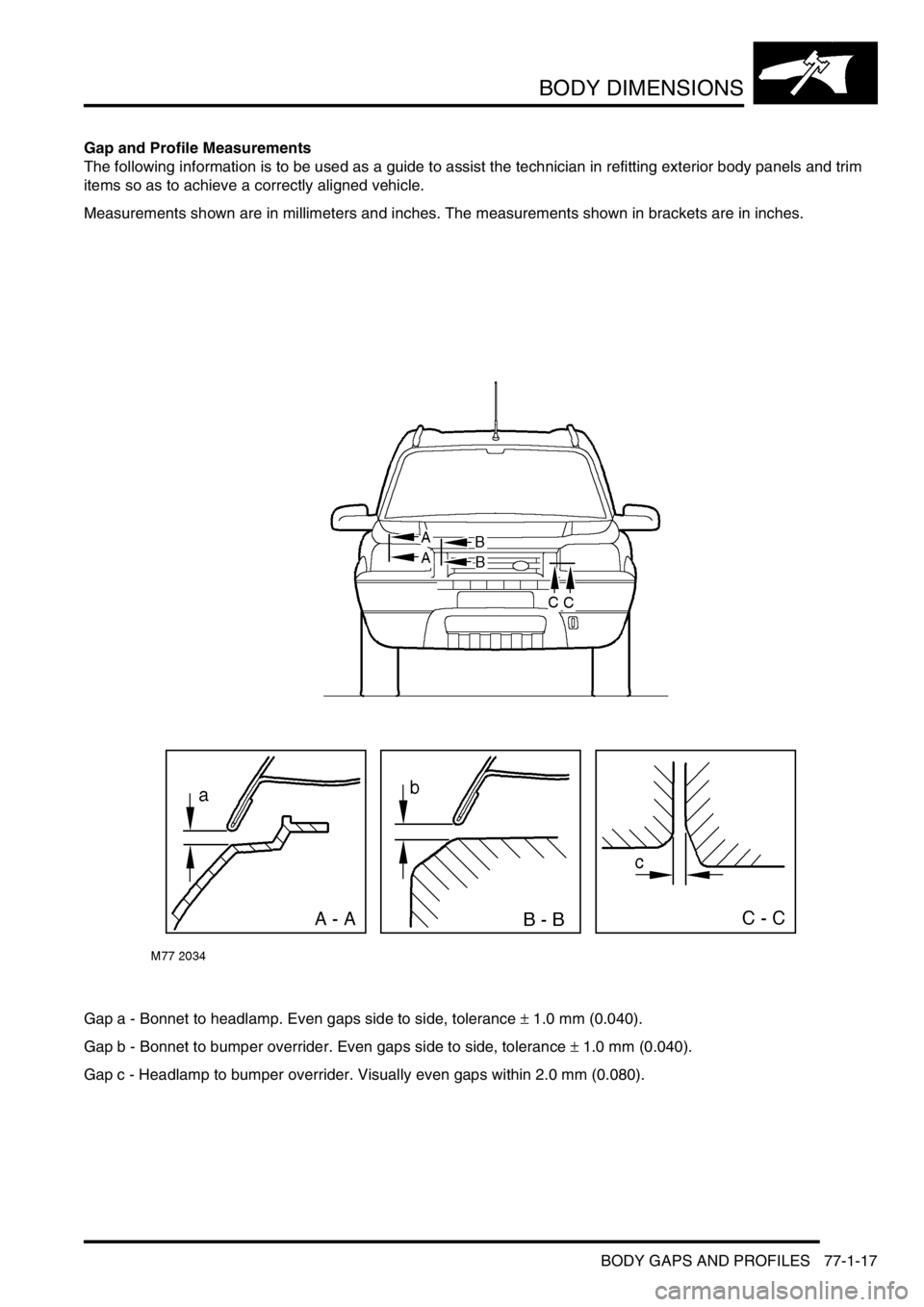

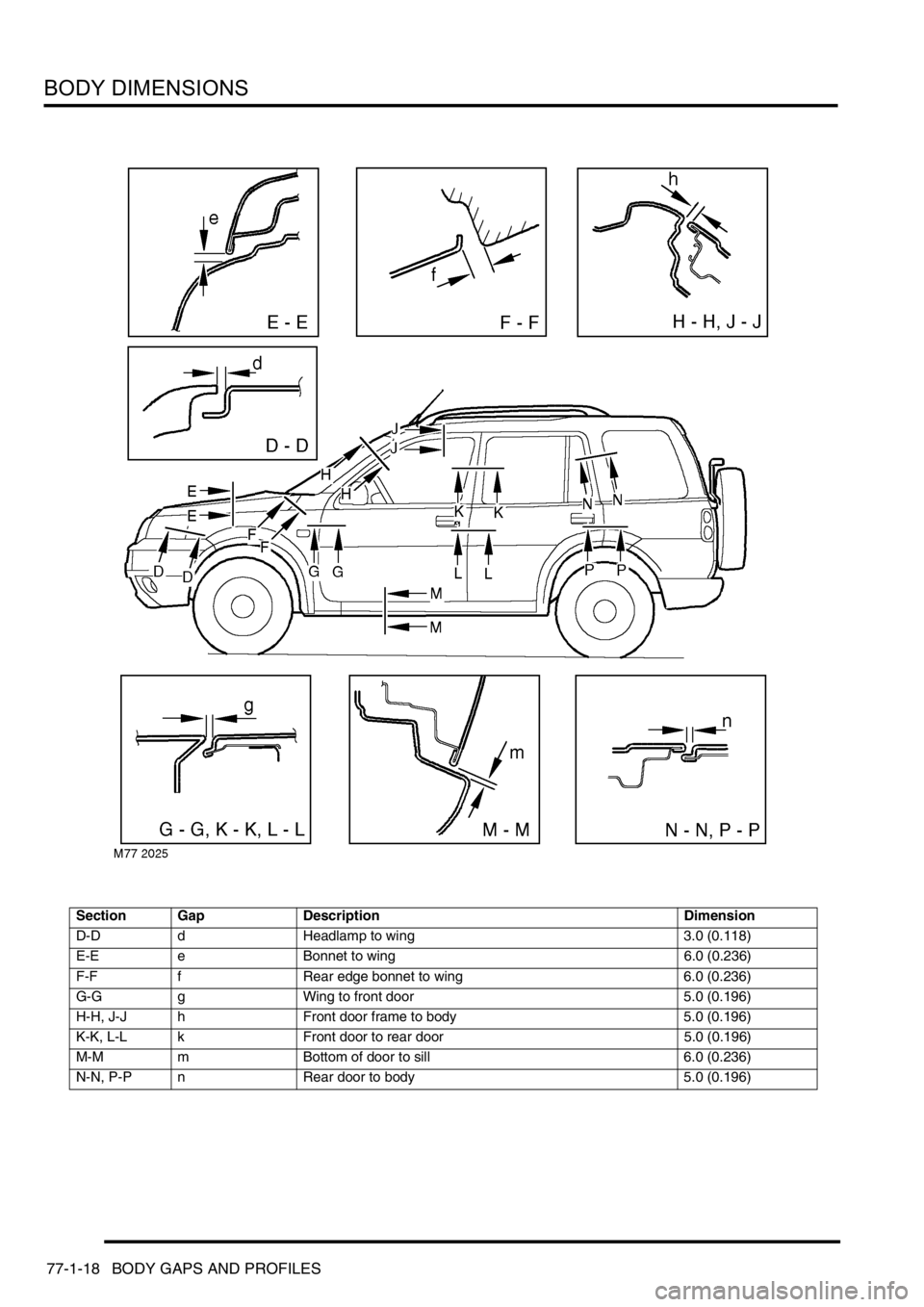

Gap and Profile Measurements

The following information is to be used as a guide to assist the technician in refitting exterior body panels and trim

items so as to achieve a correctly aligned vehicle.

Measurements shown are in millimeters and inches. The measurements shown in brackets are in inches.

Gap a - Bonnet to headlamp. Even gaps side to side, tolerance ± 1.0 mm (0.040).

Gap b - Bonnet to bumper overrider. Even gaps side to side, tolerance ± 1.0 mm (0.040).

Gap c - Headlamp to bumper overrider. Visually even gaps within 2.0 mm (0.080).

Page 753 of 1007

BODY DIMENSIONS

77-1-18 BODY GAPS AND PROFILES

Section Gap Description Dimension

D-D d Headlamp to wing 3.0 (0.118)

E-E e Bonnet to wing 6.0 (0.236)

F-F f Rear edge bonnet to wing 6.0 (0.236)

G-G g Wing to front door 5.0 (0.196)

H-H, J-J h Front door frame to body 5.0 (0.196)

K-K, L-L k Front door to rear door 5.0 (0.196)

M-M m Bottom of door to sill 6.0 (0.236)

N-N, P-P n Rear door to body 5.0 (0.196)

Page 754 of 1007

BODY DIMENSIONS

BODY GAPS AND PROFILES 77-1-19

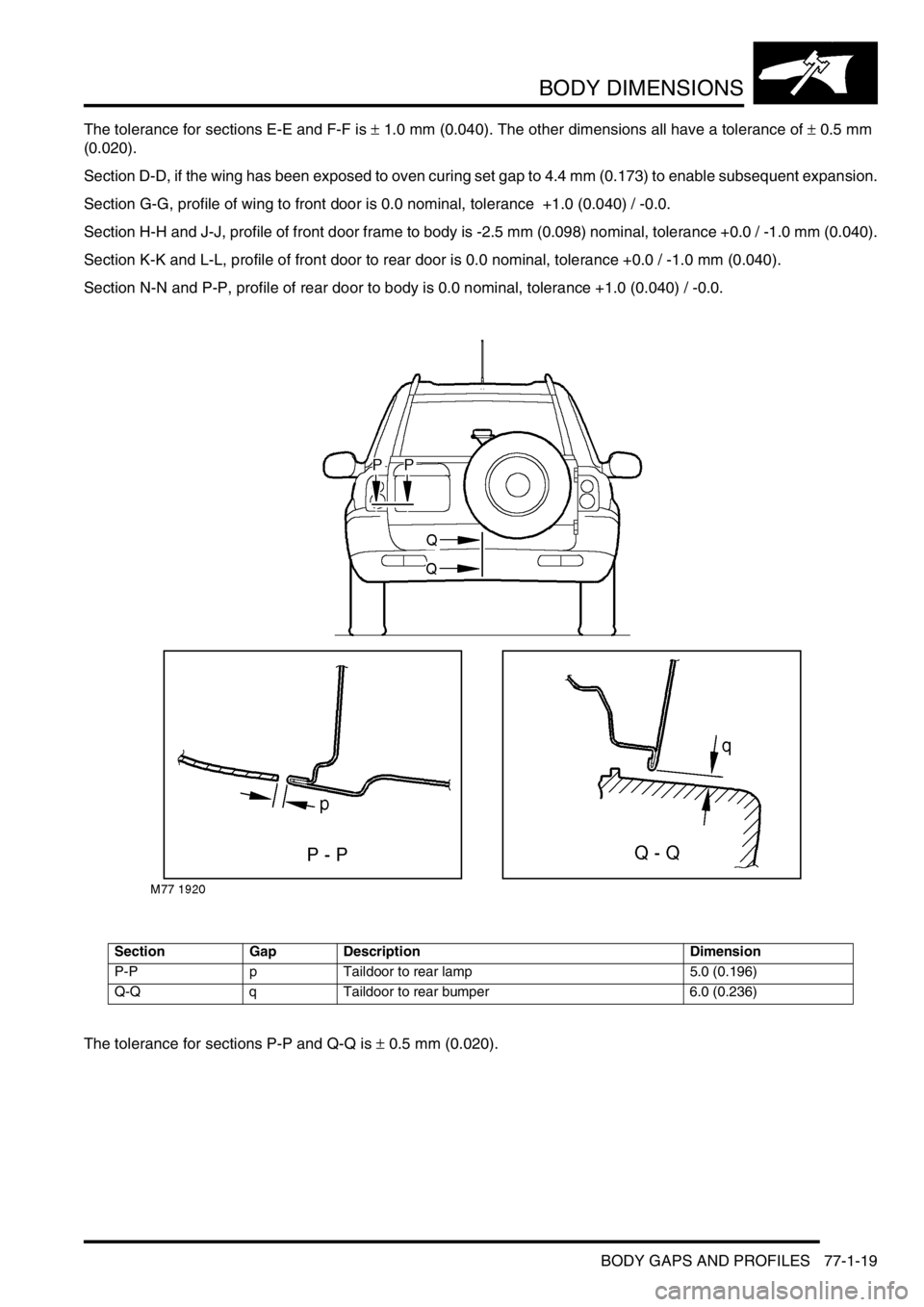

The tolerance for sections E-E and F-F is ± 1.0 mm (0.040). The other dimensions all have a tolerance of ± 0.5 mm

(0.020).

Section D-D, if the wing has been exposed to oven curing set gap to 4.4 mm (0.173) to enable subsequent expansion.

Section G-G, profile of wing to front door is 0.0 nominal, tolerance +1.0 (0.040) / -0.0.

Section H-H and J-J, profile of front door frame to body is -2.5 mm (0.098) nominal, tolerance +0.0 / -1.0 mm (0.040).

Section K-K and L-L, profile of front door to rear door is 0.0 nominal, tolerance +0.0 / -1.0 mm (0.040).

Section N-N and P-P, profile of rear door to body is 0.0 nominal, tolerance +1.0 (0.040) / -0.0.

The tolerance for sections P-P and Q-Q is ± 0.5 mm (0.020).

Section Gap Description Dimension

P-P p Taildoor to rear lamp 5.0 (0.196)

Q-Q q Taildoor to rear bumper 6.0 (0.236)

Page 756 of 1007

PANEL REPAIRS

BODY REPAIRS 77-2-1

PANEL REPAIRS

General

Body shells are of monocoque construction. Front and rear sections of the shell are designed as 'energy absorbing'

zones. This means they are designed to deform progressively when subjected to impact in order to minimise the

likelihood of injury to vehicle occupants.

It is essential that design dimensions and strength are restored in accident rectification. It is important that neither

structural weakness nor excessive local stiffness are introduced into the vehicle during body repair.

Repairs usually involve a combination of operations ranging from straightening procedures to renewal of individual

panels or panel assemblies. The repairer will determine the repair method and this decision will take into account a

balance of economics between labour and material costs and the availability of repair facilities in both equipment and

skills. It may also involve considerations of the vehicles' downtime, replacement vehicle availability and repair turn-

around time.

It is expected that a repairer will select the best and most economic repair method possible, making use of the facilities

available. The instructions given are intended to assist a skilled body repairer by expanding approved procedures for

panel replacement. The objective is to restore the vehicle to a safe running condition by carrying out a repair which is

as close as is feasible to original standard. The results should not advertise to the experienced eye that the vehicle

has been damaged, although the repair might not be identical in all respects to the original factory build. Commercial

bodyshop repair facilities cannot always duplicate methods of construction used during production.

Operations covered in this Manual do not include reference to testing the vehicle after repair. It is essential that work

is inspected and suspension geometry checked after completion. Where necessary a road test of the vehicle should

be carried out, particularly where safety-related items are concerned.

Where major units have been disconnected or removed it is necessary to ensure that fluid levels are checked and

topped up where necessary. It is also necessary to ensure that the repaired vehicle is in a roadworthy condition in

respect of tyre pressures, lights, washer fluid etc.

Body repairs often involve the removal of mechanical and electrical units and associated wiring. Where necessary,

refer to the relevant section of the Workshop Manual for removal and refitting instructions.

Body components

Taking into consideration the differences in body styles, suspension systems and engine and transmission layouts,

the location of the following components as applicable to a particular vehicle is critical:

lFront suspension upper damper mountings.

lFront suspension or sub frame mountings.

lRear suspension upper damper mountings.

lRear suspension mountings or lower pivots.

Additional points which can be used to check alignment and assembly are:

lInner holes in crossmember - side - main floor.

lHoles in front longitudinals.

lHoles in side members.

lHoles in rear longitudinals.

lHoles in rear lower panels or extension rear floor.

Apertures for windscreen, backlight, bonnet and doors can be measured and checked using the dimensional

information provided and also by offering up an undamaged component as a gauge.

Straightening

Whenever possible, structural members should be cold straightened under tension. Do not attempt to straighten with

a single pull but rework the damaged area using a series of pulls, releasing tension between each stage and using

the opportunity to check alignment.

Page 757 of 1007

PANEL REPAIRS

77-2-2 BODY REPAIRS

Body jig

Unless damage is limited to cosmetic panels, all repair work to body members must be carried out on a body jig, to

ensure that impact damage has not spread into more remote parts of the structure. Mounting on a jig will also ensure

that the straightening and panel replacement procedures do not cause further distortion.

If original dimensions cannot be satisfactorily restored by these methods, damaged structural members should be

replaced. Damaged areas should be cut away using a high speed saw, NOT an oxy-acetylene torch.

As a rule, body dimensions are symmetrical about the centre line. A good initial check for distortion is therefore to

measure diagonally and to investigate apparent differences in dimensions.

Inspection

Every accident produces individual variations in damage. Each repair is influenced by the extent of the damage and

the facilities and equipment available for its rectification.

Most accident damage can be visually inspected and the approximate extent of damage assessed. Sometimes

deformation will extend beyond the directly damaged area, and the severity of this must be accurately established so

that steps can be taken to restore critical body components to their original dimensions. An initial check can be carried

out by means of drop checks or, preferably, trammels. Gauges are available which will accurately check for body twist.

Where repairs necessitate renewal of a critical body component it is recommended that a body jig is used.

Page 772 of 1007

PANEL REPAIRS

WELDING PROCEDURES 77-2-17

Seat belt anchorages

Seat belt anchorages are safety critical. When making repairs in these areas, it is essential to follow design

specifications. Note that High Strength Low Alloy (HSLA) steel may be used for seat belt anchorages.

Where possible, the original production assembly should be used, complete with its seat belt anchorages, or the cut

line should be so arranged that the original seat belt anchorage is not disturbed.

All welds within 250mm (9.842) of seat belt anchorages must be carefully checked for weld quality, including spacing

of spot welds.

warn : Body parts incorporating seat belt anchorages MUST be renewed completely if damaged beyond repair, as the

welds in these areas are safety critical and cannot be disturbed.

High Strength Steels

Body panels are being increasingly manufactured in high strength steels to meet design requirements for safety and

weight saving. As panels in high strength steels cannot be visually identified by the repairer, and as they can be more

sensitive to excess heat than would be the case with low carbon steels, it is advisable that the following procedure be

observed at all times.

While individual repairs will differ in detail, the following Panel Replacement Procedure has been devised placing

emphasis on ease of repair and the elimination of unnecessary work. Where replacement of a particular panel

involves departure from the Panel Replacement Procedure, a note to that effect is included in the relevant panel

replacement operation.

Straightening

Whenever possible, structural members should be cold straightened under tension. Do not attempt to straighten with

a single pull but rework the damaged area using a series of pulls, releasing tension between each stage and using

the opportunity to check alignment

Body jig

Unless damage is limited to cosmetic panels, all repair work to body members must be carried out on a body jig, to

ensure that impact damage has not spread into more remote parts of the structure. Mounting on a jig will also ensure

that the straightening and panel replacement procedures do not cause further distortion. If original dimensions cannot

be satisfactorily restored by these methods, damaged structural members should be replaced. Damaged areas

should be cut away using a high speed saw, NOT an oxy-acetylene torch. As a rule, body dimensions are

symmetrical about the centre line. A good initial check for distortion is therefore to measure diagonally and to

investigate apparent differences in dimensions.

Inspection

Every accident produces individual variations in damage. Each repair is influenced by the extent of the damage and

the facilities and equipment available for its rectification. Most accident damage can be visually inspected and the

approximate extent of damage assessed. Sometimes deformation will extend beyond the directly damaged area, and

the severity of this must be accurately established so that steps can be taken to restore critical body components to

their original dimensions. An initial check can be carried out by means of drop checks or, preferably, trammels.

Gauges are available which will accurately check for body twist. Where repairs necessitate renewal of a critical body

component it is recommended that a body jig is used.